Drain cleaner

2

exchanged or the hydraulic lever in the tractor must be put in the other position. The

hydraulic motors on the reel and the side arm are connected in such a way, that the hose

will stay tight on the reel during both coiling and uncoiling. The coiling and uncoiling speed

can be adjusted with the speed control valve next to the valve block.

Water plumbing

Pump

The COMET APS 145 water pump has a capacity of 132 l/min and a maximum pressure of

50 bar. This is an ample reciprocating diaphragm pump driven by the drive shaft of the

tractor. This pump is not sensitive for polluted water. The pump is constructed in such a

manner that all the parts that are liable to wear can be easily replaced. The maximum

number of revolutions of the pump is 550 rev/min., but may never be under 300 rev/min.

When using a drive shaft with 1000 or 750 revolutions you can keep the engine speed of

the tractor lower. This will save fuel and give less noise. Because the pump is ample, you

will be able to work with a lower engine speed.

Pressure regulating

The water pressure can be regulated with the turning knob on top of the pressure

regulator. With a lever on the pressure regulator the pump can be relieved, for example

while you are placing the guide arm in front of the drainpipe.

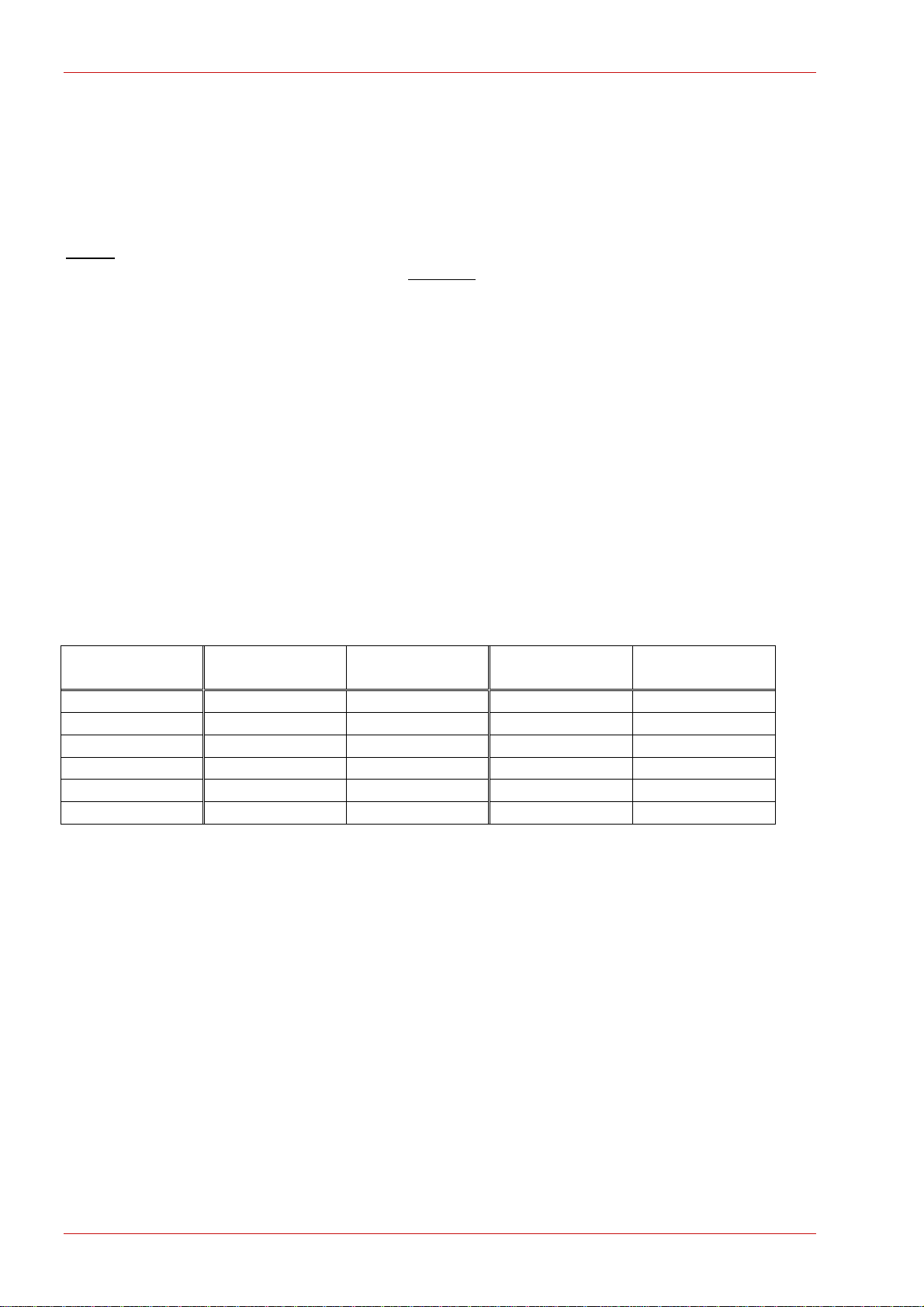

The optimum working pressure is 30 to 35 bar. With a higher pressure the PE hose will be

overloaded and will have a shorter life. Because of the friction in the hose a higher

pressure will hardly bring more delivery.

A lower pressure will not bring enough water to the nozzle, which leads to bad cleaning.

pressure

pressure

pressure

20 bar 6.0 bar 49,4 5 bar 47,4

25 bar 8.5 bar 56,1 7,4 bar 53,3

30 bar 10 bar 61,6 8,5 bar 58,8

35 bar 12.5 bar 67,4 11,3 bar 63,2

40 bar 14.5 bar 71,4 12,9 bar 68,6

45 bar 16.5 bar 75,7 14,8 bar 72,5

The return water of the pressure regulator will be connected to the upper side of the guide

arm. The hose is lubricated with this water in the inserting arm. During withdrawal the hose

is cleaned again.

Filters

The suction filter is 10 m long and has a ditch filter at the end. In front of the pump you find

the main filter.