TRISCO R-456 User manual

TRISCO TECHNOLOGY CORP.

8F, No.45, Fu Hsing South Road Sec. 2,

Taipei 106, Taiwan, R.O.

Tel: 886-2-2703 7031 Fax: 886-2-2325 4076

Http//www.trisco.com

E-mail: [email protected]m

2010 Trisco Technology Corp. All rights reserved.Ver.1.0

P/N: 244.144 (A)

R-456

6-Function Analyz r

Us r’s Manual

ENGINE ANALYZER INSTRUCTION MANUAL

An engine analyzer is an indispensable companionshio to an automechanic, regardless if he is a

“Sunday machanic” or a professional.

Warning : To avoid body injuries and damages to the tester, use extreme care when working under the

hood. Do not touch any moving parts or hot surfaces of the engine.

If you will take a few moments to read through the following informations and get yourself familiar with

your new tester, we are sure you can enjoy many years of its service and through its use, the engine

efficiency of your car will be increased highly.

Note : For all the following tests, unless otherwise stated, the engine should be at normal operating

temperature and running at idle speed.

TACHOMETER FUNCTION

Although the Tachometer will give out only RPM readings, judicious use of this function will provide much

more :

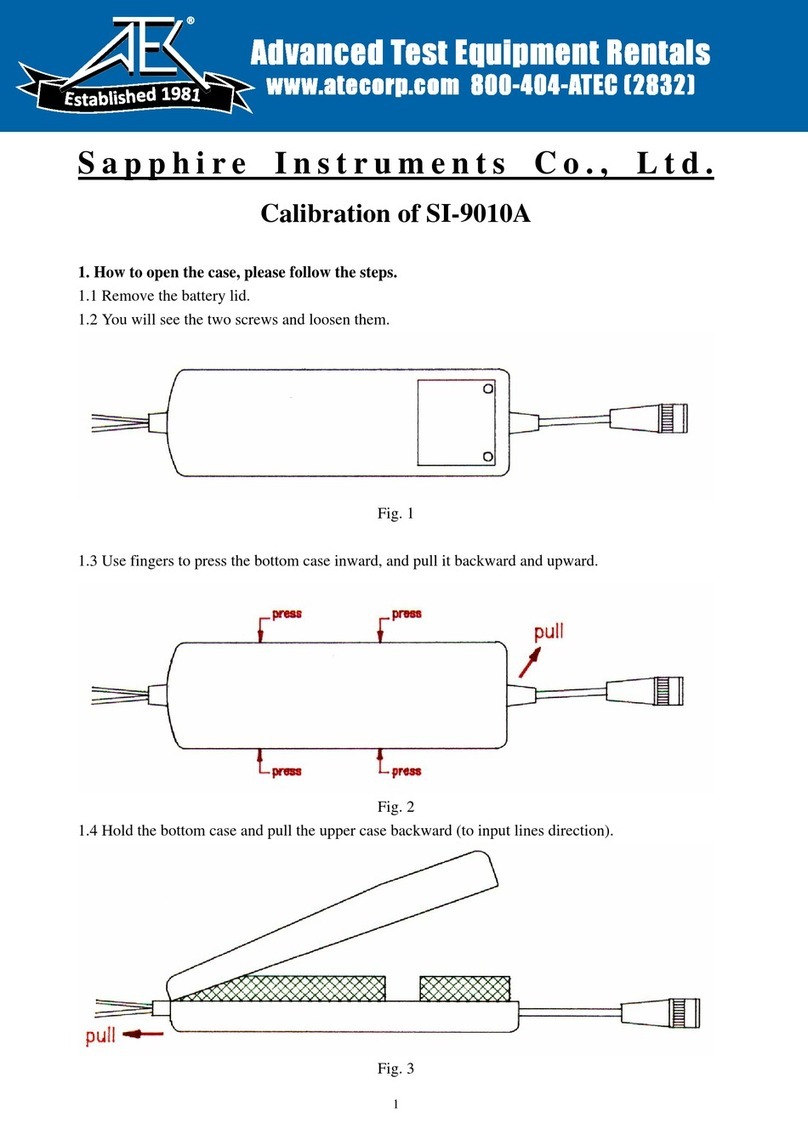

1. onnecting the analyzer:

a. Model equipped with an inductive pick-up (see fig. 1)

b. Model only with two test leads. (see fig. 2)

● onnect Black clip to (-) post of the battery or any part of the engine which is relied to (-) of the

battery.

● onnect red (green) clip to (-) post of the ignition coil.

● Move the ylinder switch selection to the correct position in accordance with the number of

your car cylinder.

2. Zero adjustment :

Before each use verify your analyzer reads “0”, if not, proceed as following:

● Hold the instrument in normal use position, adjust the screw in front of the meter until it reads “0”

on tach scale.

IDLE ADJUSTMENT:

1. Set the analyzer at LO-TA H.

2. Turn the Idle MIXTURE screw in until the engine begins to fall off, turn the screw out until the engine

again begins to fall off, then adjust the screw between these two points to get the highest RPM

without any missing or rolling.

3. Turn the IDLE screw to get the RPM reading according to manufacturer’s specifications.

- 1 -

OHM FUNCTION

TESTING THE ONTINUITY OF A IR UIT:

1. onnect the black and red clips together, turn the “Ohm adjust” knob until the pointer is at “0”

2. onnect the suspect component to the red and black clips.

● If the reading is very low, the continuity exists.

● If the reading is very high, the component is opened.

TESTING THE DIODE : (see fig. 7)

1. onnect the clips to the diode ends and note the value.

2. Reverse the connections at the diode ends and note the value.

● The two noted values should be considerably different, one is very high and one is very low, if not

the diode is defective.

ADJUSTING THE DWELL ANGLE: (see fig. 4)

Note: On the Delco type distributor, the dwell angle can be adjusted from the outside while the engine is

running. Simply lift the window protecting the Allen screw and use an Allen wrench to adjust the

dwell angle to manufacturer’s specifications.

1. Bring the engine temperature to normal working temperature, stop the engine.

2. Remove the distributor cap and rotor. Ground the high voltage cable from the ignition coil.

3. Loosen the locking screw of the points.

4. rank the engine while turning the adjusting screw until the proper dwell angle is obtained.

Note: The meter needle may oscillate at cranking speed, use the average reading for measurement.

5. Reassemble the distributor and recheck the dwell at idle speed.

- 6 -

TESTING THE STARTER IR UIT:

1. Remove the High voltage cable from the ignition coil and ground it.

2. Move the function switch to Lo-Volt.

3. onnect the black clip to the (-) post.

Note : If the clip is connect to the cable clamp, make sure that the contact is clean and tied before

proceeding to next step.

4. onnect the red clip to the housing of the starter motor. Make sure that a good electrical contact is

made.

5. rank the engine while watching the meter. If it reads 2 volt or more, the starter motor is poorly

grounded, repair as necessary.

6. onnect the red clip to (+) post.

Note: see step. 3

7. onnect black clip to the isolated terminal of the starter motor.

8. rank the engine, if meter reads 2V or more, check for loose or dirty connections.

AMMETER FUNCTION

TESTING THE HARGING URRENT : (see fig. 6)

1. Disconnect the (-) cable from the battery.

2. Disconnect the wire from the output terminal of the alternator (BAT) and connect the external shunt

between this terminal and the wire just removed.

3. Reconnect the battery cable, crank the engine several times without starting it to partially discharge

the battery.

4. Start the engine, increase the RPM to about 2000 RPM.

Note the reading of the meter.

If it is within 10 AMP of the value specified by the manufacturer. The charging current is OK.

If it is too low proceed to next step to determine if the regulator or the alternator is defective.

5. Refer to steps 2a, b, c of the “testing the charging system” to jump the field terminal of the alternator.

6. Start engine and increase the RPM to 2000 RPM. If the current now is within the value specified, the

regulator is defective; if it is still too low, then the alternator is defective.

POINTS FUNCTION

TESTING THE POINTS RESISTAN E:

1. onnect the black clip to a good electrical ground on the engine. onnect the red clip to the (-)

terminal of the ignition coil.

2. Turn ignition key on; bump the engine until the points are closed.

3 . The pointer of the meter should stay in the OK area, if not the points need to be replaced.

- 5 -

● onnect read clip to battery positive (+) post, black clip to negative (-) post.

● lip the inductive pick up to any of the spark plug cable, preferably as close as possible of the

spark plug without touching any hot metal part.

NOTE:

If the needle does not move or gives an unstable reading when testing engine RPM, proceed as follow:

1. heck that the jaws of inductive pickup is fully closed and with the right aide facing the spark plug.

2. heck that the contact surfaces of the upper and lower ferrite cores are clean without dirt or grease.

Use a volatile detergent to clean the contact surfaces if necessary.

3. If the needle still fluctuates, slowly move the inductive pickup along the cable towards distributor cap

and observe reading.

4. If needle fluctuation persists, try another spark plug cable. But it is normal for the needle to fluctuate

slightly at low engine speed.

Note:

Now you are ready to read the RPM of the engine regardless of the number of cylinders.

TEST THE AIR/FUEL MIXTURE:

1. Remove the air filter assembly.

2. Using a flat piece of metal, slowly block off the air intake of the carburetor while watching the RPM:

● If the RPM does not change until the intake is almost completely blocked off, the air/fuel mixture is

correct.

● If the RPM increases, the mixture is too lean; if the RPM decreases, the mixture is too rich,

readjust the idle mixture screw accordingly.

TEST THE ONDITION OF THE AIR FILTER:

1. Remove the air filter while watching the RPM, if the RPM varies, the filter is dirty and needs to be

cleaned or replaced.

TEST THE ENTRIFUGAL ADVAN E:

1. Loosen the distributor holdown bolt enough so the distributor can be rotated left and right.

2. Rotate the distributor to get a maximum RPM reading.

3. Increase the RPM to 1000 RPM, again rotate the distributor while watching the RPM; if the RPM can

be increased by 100 or more, the centrifugal advance is faulty, repair or replace as necessary.

TEST THE POSITIVE RANK ASE VALVE (P V) :

1. Remove the P V hose and close off the valve with a finger. Note the RPM, if it drops 50 RPM or

more, the valve is working correctly. If it does not or drops less than 50 RPM, the P V valve is

plugged or inoperative, repair or replace as necessary.

- 2 -

DWELL METER FUNCTION

onnecting the analyzer : (see fig. 3)

1. Model equipped with an inductive pick-up:

● The black clip remained connected to the negative (-) terminal of the battery or the part of the

engine relied to the (-) post.

● Move the red clip to the negative (-) terminal of the ignition coil.

Note: The Tachometer still functions while the analyzer is connected as above there might be some slight

oscillations of the pointer at very low RPM reading.

2. Model with only two test leads:

The connections remain identical as in the Tachometer function.

DEFINITION OF DWELL ANGLE:

The dwell angle is the time the points close, allowing the current to go into the ignition coil and build up

energy before the spark.

If the dwell angle is too low, the point gap is too large, resulting in poor acceleration or missing at high

speed. If the dwell angle is too large, the point gap is too low, resulting in rapid deterioration of the points.

TESTING DISTRIBUTOR AM WEAR:

1. Note the dwell angle at idle speed.

2. Increase the RPM to about 2000 RPM, while observing the dwell angle, if the dwell angle varies more

than the amount specified by the manufacturer, usually 3, the cam is worn out or the distributor shaft

is bent, repair or replace as necessary.

ADJUSTING THE DWELL ANGLE : (see fig. 4)

Note: On the Delco type distributor, the dwell angle can be adjusted from the outside while the engine is

running. Simply lift the window protecting the Allen screw and use an Allen wrench to adjust the

dwell angle to manufacturer’s specifications.

1. Bring the engine temperature to normal working temperature, stop the engine.

2. Remove the distributor cap and rotor. Ground the high voltage cable from the ignition coil.

3. Loosen the locking screw of the points.

4. rank the engine while turning the adjusting screw until the proper dwell angle is obtained.

Note: The meter needle may oscillate at cranking speed, use the average reading for measurement.

5. Reassemble the distributor and recheck the dwell at idle speed.

- 3 -

VOLTMETER FUNCTION

TESTING BATTERY LEAKAGE:

1. onnect the black clip to negative (-) post of the battery.

2. Move function switch to Lo-Volt scale.

3. lip a metal nail to the red clip and touch various spots on the battery while watching the meter, if it

registers any reading, the battery is leaking and need to be cleaned with backing soda and water.

TESTING BATTERY AT HEAVY LOAD:

1. Follow the first two steps of testing battery at light load.

2. Remove the high voltage cable from the ignition coil and ground it.

3. rank the engine for 15 seconds and note the voltage. If the reading is less than 9.5 on 12 volts

system or 5.7 on 6 volts system check the starter circuit, if it is OK, recharge the battery and retest. If

the reading is low, replace the battery.

TESTING THE HARGING SYSTEM: (see fig. 5)

1. onnect the meter as in Testing battery at light load.

2. Gradually increase the RPM while watching the meter:

● If the pointer climbs steadily to between 13.5 and 15.5 or to the value specified by the

manufacturer, the charging system-regulator, alternator is OK.

● If the voltage is above the specified value or oscillates erratically, the regulator is defective.

● If the voltage is below the specified value, the regulator or alternator might be defective, proceed

as follow:

a. Disconnect the (-) cable from the battery.

b. Remove the wire from the field terminal of the alternator, do not let it touch the ground.

c. Use a jumper wire, connect the Field terminal of the alternator to its output (BAT) terminal.

Refer to the owner’s manual for more specific information.

d. Reconnect the (-) battery cable, start the engine and slowly increase the RPM while watching

the meter.

● If the voltage is now above 13.5V, the regulator is defective. aution: perform this test as

quickly as possible and do not exceed 17V.

● If the voltage is still low, the alternator is defective.

- 4 -

Popular Measuring Instrument manuals by other brands

TSI Instruments

TSI Instruments DUSTTRAK 8533 Assembly, operation and service manual

Rhopoint

Rhopoint ID operating instructions

BROWIN

BROWIN Biogrod 071905 Operation manual

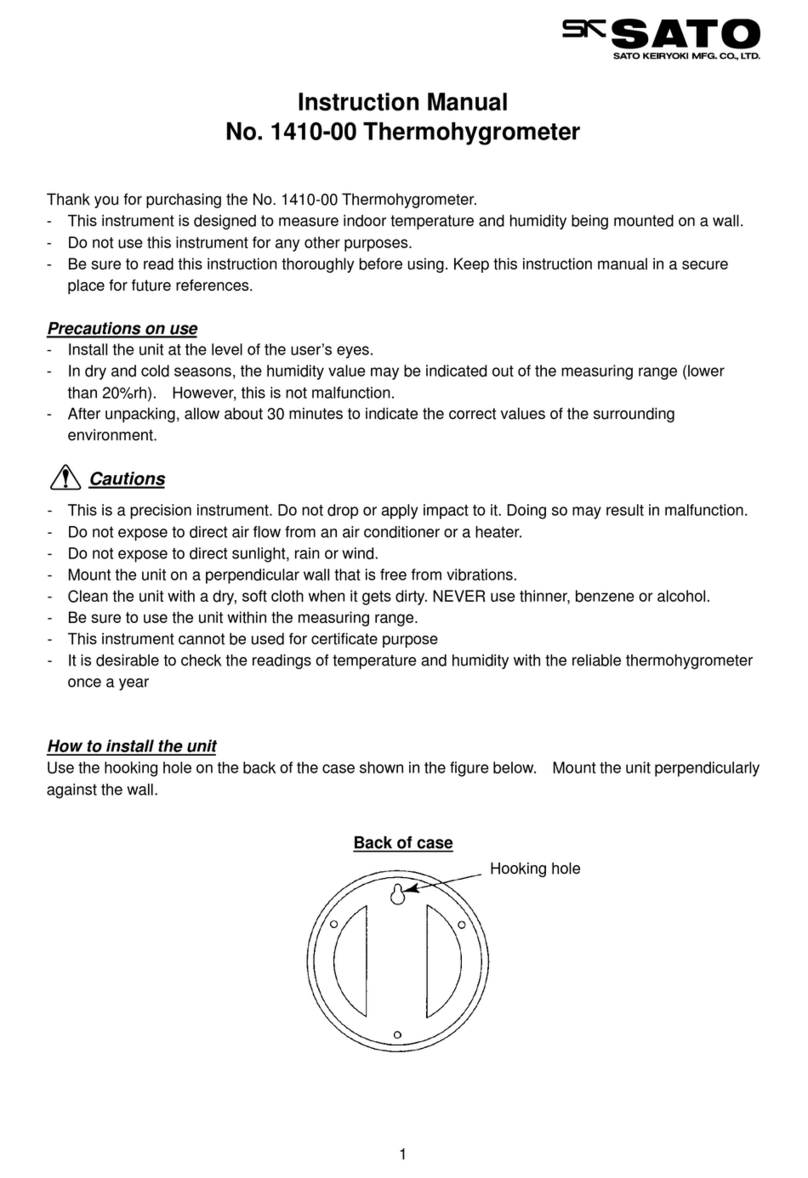

SATO KEIRYOKI

SATO KEIRYOKI 1410-00 instruction manual

LAUMAS

LAUMAS LCB installation instructions

Leviton

Leviton 2R208-21 installation manual