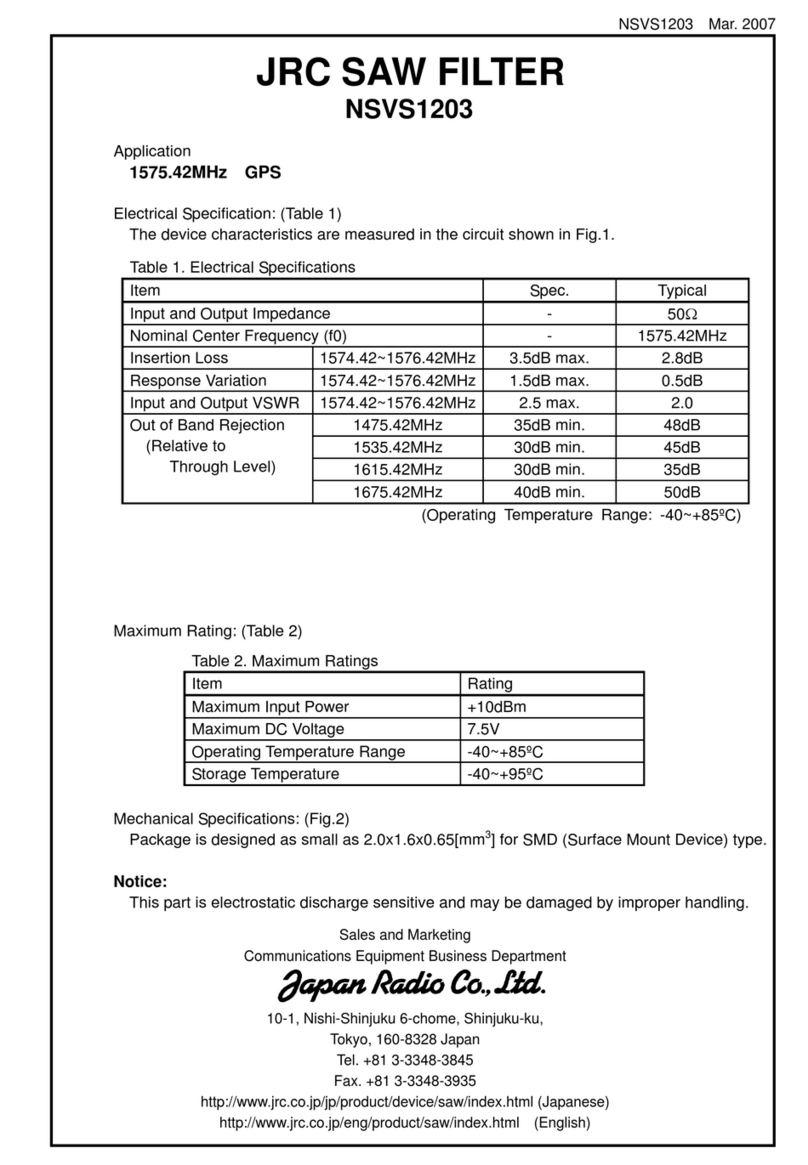

Trojan Technologies Aquafine TrojanUVLogic Series User manual

PLEASE KEEP FOR PERMANENT REFERENCE

Part Number 127 Rev E

7KLV PDQXDO FRYHUV WKH VHUYLFLQJ DQG JHQHUDO PDLQWHQDQFH UHTXLUHPHQWV IRU $TXDILQH 8OWUDYLROHW :DWHU

7UHDWPHQWHTXLSPHQW

DISINFECTION • TOC REDUCTION • OZONE DESTRUCTION • CHLORINE/CHLORAMINE DESTRUCTION

TrojanUVLogic Series

Installation & Operation Manual

It is imperative that those responsible for the installation

of this equipment, as well as operating personnel, read this

manual and carefully follow all instructions and guidelines.

EQUIPMENT OPERATORS AND INSTALLERS MUST COM-

PLY WITH OPERATIONAL SAFETY REQUIREMENTS.

A TROJAN TECHNOLOGIES COMPANY

READ THIS MANUAL

TrojanUVLogic

TM

Revision:E

LastUpdate:07AU21

PlaceSystemLabel

Here.

Ifnolabelhasbeen

placedhere,referto

thelabelonthe

UVEquipment

fordetails.

Forfurtherclarificationoflabelinformation,pleaserefertoChapter2,page23,“SystemVerification

LabelDefinitions”.

Recordsystemsetpointsindicatedbelow:

UVIntensitySetPoint

TheTrojanUVLogic

TM inthismanualmaybecoveredbyoneormoreofthe

followingUnitedStates(US)Patents:

US6,342,188

US6,659,431

US6,564,157

US6,635,613

OTHERPATENTSMAYBEPENDING.

COPYRIGHT©2008byAQUAFINECORPORATION

ALLRIGHTSRESERVED

Volume Table of Contents

Trojan ogicTM Operations and Maintenance

UVL

PREFACE III

GENERAL INFORMATION.....................................................................................................................III

IMPORTANT CONTACTS...................................................................................................................... IV

WARNINGS AND PRECAUTIONS......................................................................................................... V

GENERAL LOCKOUT PROCEDURES ................................................................................................. XI

Lockout and Tag Procedure...............................................................................................................xi

LIST OF ACRONYMS/GLOSSARY...................................................................................................... XII

TROJANUVLOGIC MAINTENANCE REQUIREMENTS

TM .................................................................. XIII

Maintenance Schedule .................................................................................................................... xiv

Maintenance Checklist.....................................................................................................................xvi

Alarm Log........................................................................................................................................ xvii

System Operating Parameters.........................................................................................................xix

Maintenance Log ..............................................................................................................................xx

Lamp Log Table...............................................................................................................................xxi

1 INTRODUCTION TO UV THEORY 1-1

1.1 OVERVIEW OF TROJANUVLOGICTM ............................................................................................1-1

1.2 WHAT IS ULTRAVIOLET LIGHT?..................................................................................................1-1

1.3 DISINFECTION VS. STERILIZATION.............................................................................................1-2

1.4 APPLICATIONS OF UV LIGHT ......................................................................................................1-2

1.5 FACTORS AFFECTING UV DISINFECTION..................................................................................1-2

UV Transmittance:...............................................................................................................................................1-3

Suspended Solids:..............................................................................................................................................1-3

Level of Total Dissolved Solids:..........................................................................................................................1-3

Total Hardness:...................................................................................................................................................1-4

Sleeve Cleanliness:.............................................................................................................................................1-4

Treatment Process:.............................................................................................................................................1-4

Flow Rate:............................................................................................................................................................1-4

2 SYSTEM OVERVIEW 2-1

2.1 SYSTEM COMPONENTS ...............................................................................................................2-1

UV Reactor (UVR)............................................................................................................................................2-1

Control Panel (CP)...........................................................................................................................................2-1

UV Sensor........................................................................................................................................................2-2

Wiping Systems ...............................................................................................................................................2-2

Automatic Mechanical Wiping System (AMWS)....................................................................................................................2-2

Manual Mechanical Wiping System (MMWS)........................................................................................................................2-3

Power Pack.................................................................................................................................................................................2-3

2.2 OPERATIONS OVERVIEW.............................................................................................................2-3

Volume Table of Contents

Trojan ogicTM Operations and Maintenance

UVL

Main Menu Screen........................................................................................................................ 7-18

Active Alarms Screen.................................................................................................................... 7-18

Alarms List Screen Series............................................................................................................. 7-18

Alarm History Screen.................................................................................................................... 7-18

Alarm History Details Screen........................................................................................................ 7-18

Digital Input-Output Screen Series ............................................................................................... 7-19

Operator Access Level Screens..................................................................................................................7-19

Technician Level Access Screens..............................................................................................................7-19

Analog Input-Output Screen Series.............................................................................................. 7-20

Operator Access Level Screens..................................................................................................................7-20

Technician Level Access Screens..............................................................................................................7-20

System Settings Screens.............................................................................................................. 7-21

Operator Access Level Screens..................................................................................................................7-21

Technician Level Access Screens..............................................................................................................7-22

Trend Screens .............................................................................................................................. 7-23

Wiper Screen (AMWS)(For systems with a Wiper)...................................................................... 7-24

Wiper Sequence Timer (AMWS) (For systems with a Wiper)................................................................7-24

Wiper Auto Power Off (For systems with a Wiper)..................................................................................7-24

Analog Menu Screen .................................................................................................................... 7-25

Reactor Hi Temp (Reactor High Temperature) Configure Screen (Optional)............................... 7-25

Login Screen................................................................................................................................. 7-26

7.4 SYSTEM STATUS ALARM LIST..................................................................................................7-27

7.5 ALARM OVERVIEW......................................................................................................................7-27

Minor Alarms................................................................................................................................. 7-27

Major Alarms................................................................................................................................. 7-28

Critical Alarms............................................................................................................................... 7-29

7.6 INPUT AND OUTPUT OVERVIEW ...............................................................................................7-30

Standard Inputs and Outputs........................................................................................................ 7-30

Optional Inputs and Outputs......................................................................................................... 7-30

Additional Inputs and Outputs....................................................................................................... 7-31

7.7 DIGITAL OUTPUT WIRING DIAGRAMS......................................................................................7-31

8 ALARMS AND TROUBLESHOOTING 8-1

8.1 ALARM INDICATORS.....................................................................................................................8-1

8.2 GENERAL TROUBLESHOOTING..................................................................................................8-9

9 INSTALLATION INSTRUCTIONS 9-1

9.1 OVERVIEW .....................................................................................................................................9-1

9.2 SHIPPING CONTENTS...................................................................................................................9-1

9.3 SET-UP............................................................................................................................................9-1

Volume Table of Contents

Trojan ogicTM Operations and Maintenance

UVL

UV Sensor...........................................................................................................................................................7-3

External Interfaces............................................................................................................................................7-3

SCADA Communication (Optional)...............................................................................................................7-3

Alarms.................................................................................................................................................................7-3

Auto Home Position Reset (if Wiper is provided).......................................................................................7-4

Reactor Proximity Switch Input (Rev Counter)...........................................................................................7-4

Alarm Output Relays........................................................................................................................................7-4

7.2 CONTROL PANEL (CP) HARDWARE...........................................................................................7-5

Description...................................................................................................................................... 7-5

Specifications ....................................................................................................................................................7-5

Maintenance.......................................................................................................................................................7-6

Power Pack..................................................................................................................................... 7-6

Description.........................................................................................................................................................7-6

Specifications ....................................................................................................................................................7-6

Electronic Ballasts........................................................................................................................... 7-6

Description.........................................................................................................................................................7-6

Maintenance.......................................................................................................................................................7-0

AM Model –Ballast Removal & Replacement ............................................................................7-0

AS & AL Model –Ballast Removal & Replacement....................................................................7-8

System Controller – The Control Board........................................................................................ 7-10

Description.......................................................................................................................................................7-10

Board Power supply requirements – AM Models....................................................................................7-10

P40 Board Power supply requirements –AS and AL Models................................................................7-10

Board Diagram.................................................................................................................................................7-11

RS232 Com Port......................................................................................................................7-13

Ballast Communication Ports...................................................................................................7-13

Lamp Status (Midflow Models Only) ........................................................................................7-13

Board Fuse...............................................................................................................................7-13

Keypad Connector ...................................................................................................................7-13

VFD Communication Port ........................................................................................................7-13

Battery Replacement......................................................................................................................................7-13

Input / Output Features..................................................................................................................................7-13

Programmable Output Relays..................................................................................................7-13

Digital Output Relays (if Wiper is provided) .............................................................................7-14

Digital Inputs ............................................................................................................................7-14

Analog Inputs...........................................................................................................................7-14

Analog Outputs ........................................................................................................................7-14

Operator Interface......................................................................................................................... 7-15

Operation..........................................................................................................................................................7-15

Specifications ..................................................................................................................................................7-15

Maintenance.....................................................................................................................................................7-16

7.3 CONTROL PANEL (CP) SOFTWARE..........................................................................................7-16

Boot Menu Screen........................................................................................................................ 7-16

Main Display Screen..................................................................................................................... 7-16

UV Sensor..................................................................................................................................... 7-16

Reactor Temp Option (4 – 20 Analog Required): ......................................................................... 7-17

Volume Table of Contents

Trojan ogicTM Operations and Maintenance

UVL

5 MECHANICAL WIPING SYSTEM (OPTIONAL) 5-1

5.1 INTRODUCTION .............................................................................................................................5-1

Description...................................................................................................................................... 5-1

5.2 MANUAL MECHANICAL WIPING SYSTEM (MMWS) (OPTIONAL).............................................5-1

Description...................................................................................................................................... 5-1

Maintenance ................................................................................................................................... 5-1

Manual Wiper Assembly Removal....................................................................................................................5-1

Push Retainer Replacement..............................................................................................................................5-2

Sleeve Wiper Replacement (MMWS)...............................................................................................................5-3

5.3 AUTOMATIC MECHANICAL WIPING SYSTEM (AMWS) (OPTIONAL) ....................................5-5

Description...................................................................................................................................... 5-5

Wiping System Drive...........................................................................................................................................5-5

Wiping System Operation...................................................................................................................................5-5

Specifications.................................................................................................................................. 5-5

Maintenance ................................................................................................................................... 5-5

Gear Motor Removal...........................................................................................................................................5-5

Stop Plate Bushing Replacement......................................................................................................................5-7

Drive Screw Roller Bearing, O-ring & Seal Replacement...............................................................................5-8

Sleeve Wiper Replacement (AMWS)................................................................................................................5-9

Drive Nut Removal /Replacement..................................................................................................................5-12

6UVSENSOR 6-1

6.1 INTRODUCTION .............................................................................................................................6-1

Description...................................................................................................................................... 6-1

Specifications.................................................................................................................................. 6-1

Maintenance ................................................................................................................................... 6-1

UV Sensor Removal and Cleaning................................................................................................................6-1

UV Sensor Replacement .................................................................................................................................6-2

7CONTROLPANEL(CP) 7-1

7.1 OPERATIONAL DETAILS ..............................................................................................................7-1

Controls Philosophy........................................................................................................................ 7-1

Control System Overview ...............................................................................................................................7-1

UV Reactor Control...........................................................................................................................................7-1

Normal Operation Start-up..............................................................................................................................7-1

Normal Operation..............................................................................................................................................7-1

Shutdown............................................................................................................................................................7-2

Lamp Control and Monitoring........................................................................................................................7-2

Wiping System (Optional) ...............................................................................................................................7-2

Volume Table of Contents

Trojan ogicTM Operations and Maintenance

UVL

Control System Overview ............................................................................................................... 2-3

2.3 SYSTEM VERIFICATION LABEL DEFINITIONS...........................................................................2-4

3 START UPAND SHUT DOWN PROCEDURES 3-1

3.1 START UP UV SYSTEM.................................................................................................................3-1

3.2 SHUT DOWN UV SYSTEM.............................................................................................................3-1

4UVREACTOR(UVR) 4-1

4.1 INTRODUCTION .............................................................................................................................4-1

Description...................................................................................................................................... 4-1

Specifications.................................................................................................................................. 4-3

Maintenance ................................................................................................................................... 4-3

4.2 END CAPS ......................................................................................................................................4-3

Description...................................................................................................................................... 4-3

Specifications.................................................................................................................................. 4-3

Maintenance ................................................................................................................................... 4-3

End Cap Removal & Installation....................................................................................................................4-3

For Bolt-On Flange Style End Plates (20+cm Diameter Models)...............................................4-3

For Sanitary Clamp Style (Up to and including 20cm diameter chambers) ...............................4-4

4.3 UV LAMP ASSEMBLY....................................................................................................................4-4

Description...................................................................................................................................... 4-4

Specifications.................................................................................................................................. 4-4

Maintenance ................................................................................................................................... 4-4

Maintenance ................................................................................................................................... 4-5

Lamp Inspection/Replacement......................................................................................................................4-5

Elapsed Time Reset..........................................................................................................................................4-7

Lamp Number Configuration..........................................................................................................................4-7

4.4 QUARTZ SLEEVES ........................................................................................................................4-7

Description...................................................................................................................................... 4-7

Specifications.................................................................................................................................. 4-7

Maintenance ................................................................................................................................... 4-8

Sleeve Replacement.........................................................................................................................................4-8

Sleeve Cleaning...............................................................................................................................................4-11

Sleeve Cleaning Solutions.......................................................................................................4-11

Sleeve Cleaning Procedure .....................................................................................................4-11

Sleeve Holder / Wiper Assembly Removal................................................................................................4-11

Sleeve Bushing Replacement......................................................................................................................4-13

4.5 TEMPERATURE SWITCH ............................................................................................................4-15

Description.................................................................................................................................... 4-15

Specifications................................................................................................................................ 4-15

Volume Table of Contents

Trojan ogicTM Operations and Maintenance

UVL

9.4 AUTOMATIC MECHANICAL WIPING SYSTEM (AMWS) INSTALLATION..................................9-4

9.5 SYSTEM START-UP.......................................................................................................................9-4

Appendices................................................................................................. ..

APPENDIX A........................................................................................................................ WARRANTY

........................................................................................................................ Certificate of Equipment Warranty

APPENDIX B.............................................................................................REPLACEMENT PARTS LIST

APPENDIX C............................................................................................................................LAYOUT DRAWINGS

.................................... LG0001D01 - STD., UVLOGIC SHORT LAMP 40 SERIES (AMWS AND NO WIPING)

.......................................LG0004D01 - STD., UVLOGIC LONG LAMP 50 SERIES (AMWS AND NO WIPING)

............................................................LG0005D01 - STD., UVLOGIC LONG LAMP 30 SERIES (NO WIPING)

....................................................................LG0006D01 - STD., UVLOGIC LONG LAMP 30 SERIES (MMWS)

....................................................................LG0007D01 - STD., UVLOGIC LONG LAMP 30 SERIES (AMWS)

..............................................LG0008D01 - STD., UVLOGIC SHORT/LONG LAMP 20 SERIES (NO WIPING)

.....................................LG0009D01 - STD., UVLOGIC SHORT/LONG LAMP 20 SERIES (NO WIPING) ANSI

......................................................LG0010D01 - STD., UVLOGIC SHORT/LONG LAMP 20 SERIES (MMWS)

........................... LG0011D01 - STD., UVLOGIC SHORT/LONG LAMP 20 SERIES (MMWS) ANSI

..................................................... LG0012D01 - STD., UVLOGIC SHORT/LONG LAMP 20 SERIES, (AMWS)

............................................. LG0013D01 - STD., UVLOGIC SHORT/LONG LAMP 20 SERIES (AMWS) ANSI

.................................................................... LG0014D01 - STD., UVLOGIC MIDFLOW SERIES, (NO WIPING)

.......................................................... LG0015D01 - STD., UVLOGIC MIDFLOW SERIES, (NO WIPING) ANSI

........................................................................... LG0016D01 - STD., UVLOGIC MIDFLOW SERIES, (MMWS)

...................................................................LG0017D01 - STD., UVLOGIC MIDFLOW SERIES, (MMWS)ANSI

APPENDIX D..................................................................................................ELECTRICAL DRAWINGS

..............................................LG0002D01 – STD., UVLOGIC SINGLE LINE DIAGRAM – MIDFLOW MODELS

..........................LG0003D01 – STD., UVLOGIC SINGLE LINE DIAGRAM – SHORT / LONG LAMP MODELS

.............................................................................LG0018D01 – STD., UVLOGIC INTERCONNECT DIAGRAM

APPENDIX E...................................................................................SCADA COUMMICATION MODULE

E.1 P40 MODBUS ACTIONS AT POWER UP...................................................................................................V

E.2 MODBUS COMMANDS...............................................................................................................................VI

E.3 LOGIC/SWIFTSC CCB RECEIVE PROTOCOL (FROM PLANT PLC)....................................................... IX

E.4 LOGIC/SWIFTSC CCB TRANSMIT PROTOCOL (FROM P40 TO PLC)....................................................X

E.5 REVISION HISTORY................................................................................................................................XXII

PREFACE

TrojanUVLogic

TM Operations&Maintenance

i

Preface ....................................................................................................iii

GENERALINFORMATION ................................................................................................................................ III

IMPORTANTCONTACTS..................................................................................................................................IV

WARNINGSANDPRECAUTIONS......................................................................................................................V

GENERALLOCKOUTPROCEDURES ..............................................................................................................XI

LockoutandTagProcedure...........................................................................................................................xi

LISTOFACRONYMS/GLOSSARY...................................................................................................................XII

TROJANUVLOGIC

TM MAINTENANCEREQUIREMENTS................................................................................XIII

MaintenanceSchedule ................................................................................................................................xiv

MaintenanceChecklist.................................................................................................................................xvi

AlarmLog.................................................................................................................................................. xviii

SystemOperatingParameters.....................................................................................................................xix

MaintenanceLog..........................................................................................................................................xx

LampLogTable ..........................................................................................................................................xxi

PREFACE

TrojanUVLogic

TM Operations&Maintenance

ii

PREFACE

TrojanUVLogic

TM Operations&Maintenance

iii

PREFACE

GeneralInformation

Congratulationsonyourpurchaseofthe

TrojanUVLogic

TM

ThisOperationsandMaintenance(O&M)

Manualprovidesinstructionsonhowtooperate

thesystemandcarryoutroutinemaintenance.

Theobjectiveofthismanualistoprovide

simple,clearandcompleteinstructions.Itis

backedbyAquafineCorporationscommitment

tooffersuperiorcustomersupport.Everyeffort

hasbeentakentoensuretheaccuracyand

completenessofinformationinthismanual.

Ifyoudonotunderstandanyofthe

informationorprocedureexplanationsin

thismanual,callyourAquafineService

Providerforassistance.

Donotundertakeoperation,repairsor

servicingofequipmentunlessyouarefamiliar

withtheoperationandservicingoftechnical

equipmentandaretrainedinelectricaland

mechanicalsafety.

Ifyourleveloftraining,skillorcomprehension

ofthemanual’sinstructionscouldpossibly

resultininjuryordamagetotheequipment,

havetheworkdonebyaqualifiedoperatorora

Aquafinerepresentative.Yourcommonsense

andgoodjudgmentarecrucialtothesafeand

successfuloperationandmaintenanceofthe

TrojanUVLogic™.

1. ReadtheWarningsandPrecautions and

GeneralLockoutProcedure inthissection

beforeoperatingorperformingany

maintenanceonthisequipment.

2. Readprocedures thoroughlybeforestarting.

3. Reviewallwarningsandcautionsthat

accompanyanyprocedureandreviewthe

WarningsandPrecautions sectioneachtime

youpreparetoperformmaintenanceonthe

TrojanUVLogic

TM

Threetypesofnoticesareusedinthismanual.

WARNING

CONTAINSINFORMATIONTHATIF

NOTHEEDED,MAYRESULTIN

INJURYTOPERSONNELOR

EQUIPMENTDAMAGE.

CAUTION

TELLSREADERSWHENCAREIS

NEEDEDTOPREVENTEQUIPMENT

DAMAGE.

Note:PROVIDESCOMMENTSWHICHCLARIFY

INFORMATION.

ThissectionoftheO&MManualcontains

ImportantContacts,WarningsandPrecautions,

GeneralLockoutProcedures,andaListof

AcronymsandGlossaryofTerms.

Chapter1providesanintroductionintothe

theoryofultravioletlightdisinfection.

Chapter2 isanoverviewofthe

TrojanUVLogic™ComponentsandOperation

anddescribesregularMaintenance

Procedures.

Chapter3 providesinstructionsforthestartup

andshutdownoftheTrojanUVLogic

TM

Chapters4 7 providesdetailsforthe

operation,maintenanceandspecificationsfor

themajorcomponentsoftheTrojanUVLogic

TM

includingtheUVReactor(UVR),Lampsand

Sleeves,UVSensor(s),ControlPanel,and

optionalManualorAutomaticMechanical

WipingSystems.

Chapter8 providesinformationonAlarmsand

Troubleshooting.

Chapter9 – providesInstallationInstructionsfor

theTrojanUVLogic

TM

PREFACE

TrojanUVLogic

TM Operations&Maintenance

iv

Appendicesincludeavarietyofmaterialsuch

asElectricalDrawings,LayoutDrawingsand

theEquipmentWarranty.

ImportantContacts

AQUAFINECORPORATION

HeadOffice(Canada)

29010AvenuePaine

Valencia,CA91355

TollFree:18004233015

(outsideCA,withinUSA&Canadaonly)

Phone:6612574770

Fax:6612572489

Internet:www.aquafineuv.con

Europe†

AquafineGmbH

Ramskamp7785

D25337Elmshorn

Germany

Phone:+49(4121)5780613

Fax:+49(4121)5780630

†ForprojectsinContinentalEurope

LocalRepresentative

PREFACE

TrojanUVLogic

TM Operations&Maintenance

v

WarningsandPrecautions

Pleasereadwarningsandprecautionsbeforeproceedingwithoperation,maintenanceorrepairofthe

equipment.Alwaysfollowlocalsafetycodesandensuretoolsandpersonalprotectiveequipmentarein

goodconditionandproperlyfittedandtested.

WARNING

WearUVResistantFaceShield!

UNPROTECTEDEXPOSURETOULTRAVIOLETLIGHTCANCAUSESEVERE BURNSTOTHEEYESAND

SKIN. FACESHIELDSHOULDBEWORNASTHEPRIMARYPROTECTIONAGAINSTSUCHEXPOSURE.

NEVERLOOKDIRECTLYATTHEENERGIZEDLAMPSUNLESSYOUAREWEARINGULTRAVIOLET

RESISTANTFACESHIELDORGLASSES(FORSHORTTERMEXPOSURE)

EyeProtectionMustbeWorn!

ASADDEDPROTECTION,ORASAMINIMUMPROTECTIONFORSHORTTERMEXPOSURES,TIGHT

FITTINGGLASSESWITHSIDESHIELDSPROTECTIONWHERESUCHSHIELDSARECONTIGUOUSMUST

BEWORNATALLTIMESWHENTHEREISAPOTENTIALEXPOSURETOULTRAVIOLETLIGHT. GLASSES

SUCHASWRAPAROUNDSTYLEAREMOSTEFFECTIVE.

WearProtectiveGloves!

ALWAYSWEARPROTECTIVEGLOVESWHENWORKINGONEQUIPMENT.

WearSafetyBoots!

ALWAYSWEARPROTECTIVEFOOTWEARWHENWORKINGONEQUIPMENT.

WearEarProtection!

THETROJANUVLOGIC™DOESNOTPRODUCEAHARMFULLEVELOFNOISE,BUTUSERSARE

CAUTIONEDTHATTHEYSHOULDWEARHEARINGPROTECTIONASAPPROPRIATETOPROTECT

AGAINSTOTHERNOISETHATMAYBEPRESENTATAWASTEWATERORWATERTREATMENTPLANT.

PREFACE

TrojanUVLogic

TM Operations&Maintenance

vi

WARNING

ElectricalHazard!

BECAUSEOFTHEPOTENTIALHAZARDFROMTHISPOWERSOURCE,ITISPRUDENTTOUSELOCK

OUTPROCEDURESANDTAGALLSOURCESOFPOWERBEFOREPERFORMINGANYMAINTENANCE,

CLEANINGORREPAIRSONANYPIECEOFEQUIPMENT. THEPOWERSOURCESMAYINCLUDE

ELECTRICALORSTOREDENERGY. REFERTOTHEGENERALLOCKOUTANDTAGPROCEDURESIN

THISMANUAL.

WearHardHat!

WEARANAPPROVEDHARDHATANDOTHERPERSONALPROTECTIVEEQUIPMENTTHATISREQUIRED

ACCORDINGTOCONSTRUCTIONSITE,WASTEWATERORWATERTREATMENTPLANTSAFETY

REGULATIONS.

TripHazard!

STAYALERTANDBEAWAREOFPOTENTIALTRIPHAZARDSBEFOREWORKINGONEQUIPMENT.

HotSurface!

ALLOWELECTRONICBALLASTANDLAMPSTOCOOLBEFOREHANDLING.

ULTRAVIOLETLAMPSBECOMEHOTDURINGOPERATION. HOTLAMPSCANCAUSESERIOUS BURNS.

ALLOWTHELAMPSTOCOOLBEFORESERVICING.

3~THREEPHASEALTERNATINGCURRENT!

~SINGLEPHASEALTERNATINGCURRENT!

PREFACE

TrojanUVLogic

TM Operations&Maintenance

vii

WARNING

|ON(SUPPLY)

OFF(SUPPLY)

PROTECTIVEEARTHTERMINAL!

PINCHHAZARD!

CONSULTYOURTECHNICALMANUALBEFORESERVICING!

PREFACE

TrojanUVLogic

TM Operations&Maintenance

viii

CAUTION

THELAMPSINTHISSYSTEMEMITULTRAVIOLETLIGHT. EXPOSURETOULTRAVIOLETLIGHTCANCAUSE

SERIOUSBURNSTOUNPROTECTEDEYESANDSKIN. NEVERVIEWULTRAVIOLETLIGHTDIRECTLYWITH

THENAKEDEYE. ALWAYSUSETHEPROPERPROTECTIVEEYEWEARORAUVRATEDVIEWPORT.

ALWAYSWEARPROTECTIVECLOTHINGWHENEXPOSEDTOULTRAVIOLETLIGHT. ENSUREALLLAMPS

AREPROPERLYSECUREDWITHINTHEUVRCHAMBERBEFORETURNINGTHESYSTEMON. TURNTHE

SYSTEMOFFBEFORESERVICING.

TOPREVENTELECTRICALSHOCK,TURNTHESYSTEMOFFBEFOREREMOVINGANYOFTHECOVERSON

THEUVRCHAMBEROROPENINGTHECONTROLPANEL.

TOAVOIDPERSONALINJURY,TURNOFFPOWERBEFOREREMOVINGREACTORENDCAP.

ULTRAVIOLETLAMPS,ANDTHESLEEVESTHEYAREHOUSEDIN,ARECONSTRUCTEDOFQUARTZ

TUBING. QUARTZTUBINGISVERYFRAGILEANDEASILYFRACTURED. DONOTSTRIKE,BENDORAPPLY

PRESSURETOTHISMATERIALORITWILLBREAK. BROKENLAMPSORSLEEVESCANCAUSESERIOUS

CUTS.

DISCARDLAMPSANDSLEEVESACCORDINGTOTHEREQUIREMENTSOFYOURJURISDICTION.

ACIDSUSEDFORCLEANINGTHESLEEVESMAYCAUSEBURNS. WEARPROTECTIVECLOTHINGAND

PROTECTIVEEYEWEARWHENUSINGTHESEMATERIALS. AFTERCLEANING,RINSETHESYSTEM

COMPONENTSTHOROUGHLYWITHDISTILLEDWATER. ALWAYSFOLLOWTHESAFETYPRECAUTIONS

RECOMMENDEDBYTHEMANUFACTUREROFTHECLEANINGSOLUTION.

ACIDSUSEDTOCLEANTHESENSORCANCAUSEBURNS. WEARPROTECTIVECLOTHINGANDEYEWEAR

WHENHANDLINGTHESEMATERIALS. AFTERCLEANING,RINSETHESYSTEMCOMPONENTS

THOROUGHLYWITHDISTILLEDWATER. ALWAYSFOLLOWTHESAFETYPRECAUTIONSRECOMMENDEDBY

THEMANUFACTUREROFTHECLEANINGSOLUTION.

THISSYSTEMUSESULTRAVIOLETLIGHTTOREDUCETHECONCENTRATIONOFPATHOGENSTOANON

INFECTIOUSLEVEL. NONOBSERVANCEOFTHEMAINTENANCEINSTRUCTIONSORTHEALARM

MESSAGESWILLDIMINISHTHEEFFECTIVENESSOFTHISSYSTEM. REQUIREDDISINFECTION

EFFECTIVENESSISNOLONGERGUARANTEEDANDTHATTHEREQUIREMENTSOFTHEWATERSUPPLY

REGULATIONSARENOLONGERBEINGMET. AHEALTHRISKEXISTS.

THISSYSTEMISDESIGNEDTOWORKOPTIMALLYUNDERTHEREQUIREMENTSDESCRIBEDBYTHE

CUSTOMER. ANYMODIFICATIONTOTHESEFACTORSMAYREDUCETHEEFFECTIVENESSOFTHE

DISINFECTIONOFTHESYSTEM. THEFACTORSTHATAFFECTOPERATIONMAYBEFOUNDINTHE

INTRODUCTIONTOUV THEORY. SEECHAPTER1.

REMOVETHEENDCAPCOMPLETELY. DONOTALLOWTHEENDCAPTOHANGONTHEWIPERHANDLE

WHILECONDUCTINGWORK.

THESLEEVESMAYBELEFTINTHEWIPERASSEMBLYWHENTHESTOPPLATEISREMOVED;HOWEVER,

IFTHESLEEVESARENOTREMOVED,YOUMUSTENSURETHEYAREPROPERLYSUPPORTEDWHENTHE

STOPPLATEISNOTTHERETOAVOIDDAMAGE.

ITISESSENTIALTHATTHECOMPONENTSOFTHESTOPPLATEASSEMBLYBEPROPERLYINSTALLEDON

TOTHEENDOFTHEDRIVESCREWFORCONSISTENTWIPEROPERATION.

FAILURETODOSOMAYRESULTINIMPROPERWIPEROPERATION.

LONGLAMPSYSTEMS(ALMODELS)HAVETWOSEPARATEWIPERASSEMBLIESMOUNTEDONTOTHE

DRIVESCREW. MAINTAINTHEDISTANCEOF28” CENTERTOCENTERBETWEENTHETWOWIPER

PREFACE

TrojanUVLogic

TM Operations&Maintenance

ix

CAUTION

ASSEMBLIES. THISISTOMAINTAINFULLWIPINGCOVERAGEOFTHESLEEVESANDPREVENTJAMMING

OFTHEWIPERASSEMBLYONTHEOUTLETENDOFTHECHAMBER.

IFYOUHEARORSUSPECTSLEEVEBREAKAGE,DONOTWIPEBYRESETTINGTHEPOWER. YOUWILL

BREAKMORESLEEVESORLAMPS.

INSTALLATIONANDMAINTENANCETOBEPERFORMEDBYQUALIFIEDPERSONNELONLY.

THISSYSTEMISDESIGNEDONLYFORINDOORUSE.

THISSYSTEMCANDISINFECTONLYWATER.

NEVEROPERATETHEUNITWHILEEMPTYORWITHOUTFLOWFORANEXTENDEDPERIOD.

OPERATETHESYSTEMONLYIFTHECHAMBERISCOMPLETELYFILLEDWITHFLOWINGWATER.

INTERMITTENTOPERATIONOFTHESYSTEMREQUIRESTHATAMINIMUMAMOUNTOFWATERFLOWS

THROUGHTHESYSTEMINORDERTOCOOLTHELAMPS.

CONNECTTHISSYSTEMONLYTOACPOWERTHATCONFORMSTOTHEINFORMATIONINTHERATING

PLATEASREGARDSVOLTAGEANDVOLTAGESPECIFICATION.

IFYOURSYSTEMRUNSWITHPULSECOMPRESSION,ABUFFERTANKOROTHERREMEDIALMEASURE

MUSTBEPROVIDED.

THEULTRAVIOLETEMISSIONOFTHESELAMPSDECREASESOVERTIME. THEUV LAMPSINTHISSYSTEM

MUSTBEREPLACEDEVERY9000HOURSOFOPERATIONINORDERTOENSUREPROPEROPERATION,

SEECHAPTER4.

REGULARTESTINGOFSYSTEMPERFORMANCEUSINGSTANDARDIZEDMETHODS(E.G.,WATERSUPPLY

REGULATIONSOFVARIOUSCOUNTRIES)ISRECOMMENDED. WHENINSTALLINGTHE

TROJANUVLOGIC

TMSYSTEM,ALLOWENOUGHROOMFORSAMPLINGPOINTS.

ALLREPAIRSARETOBEDONEBYAQUAFINECORPORATION’SSERVICEORBYQUALIFIEDSPECIALISTS.

DEPRESSURIZE& DRAINTHEUVR.

PRESSUREMUSTBERELIEVEDFROMTHESYSTEMPRIORTOANYMAINTENANCE,TOPREVENTDAMAGE

TOTHEEQUIPMENTORPERSONALINJURY.

TOAVOIDPERSONALINJURY,TURNOFFPOWERBEFOREREMOVINGUVR ENDCAP.

FORCORRECTINSTALLATION,FOLLOWTHEINSTALLATIONINSTRUCTIONSINCHAPTER9. REFERTO

THEAPPROPRIATEELECTRICALDIAGRAMINAPPENDIXD,WHICHSHOWSHOWTOSETUPTHEPROPER

SYSTEMCONNECTIONSBETWEENTHECONTROLPANELANDTHEREACTORCHAMBER.

PREFACE

TrojanUVLogic

TM Operations&Maintenance

x

CAUTION

ATTENTION

OBSERVE PRECAUTIUONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

DEVICES

PREFACE

TrojanUVLogic

TM Operations&Maintenance

xi

GeneralLockoutProcedures

Thefollowinglockoutprocedureistheminimum

requirement.Additionalprecautionsshouldbe

takendependingonsitespecificprotocols.

Alwayscheckwiththeplantmanagerand

seniorelectricianforadditionalprecautions.

WARNING

EYEPROTECTION! WEARUV

RESISTANTFACESHIELDWHEN

LOOKINGATLAMPSORREACTION

CHAMBER.

WARNING

HANDPROTECTION! WEARPROPER

GLOVESANDCLOTHINGWHEN

SERVICINGEQUIPMENT.

WARNING

FOOTPROTECTION! WEARPROPER

FOOTPROTECTIONBEFORE

ENTERINGAWATERTREATMENT

PLANT.

LockoutandTagProcedure

1. Locateandidentifyelectricalsupplyto

equipment.Identifyspecificbreakersor

disconnectsthatservice AquafineCorporation

equipment.Ifyouareunsure,contacttheplant

electricianormaintenancepersonneltolocate

thecorrectelectricalsupply.

WARNING

BEAWARETHATTHEPANELMAYBE

FEDFROMMULTIPLESOURCES!

2. WhilestandingtothesideoftheElectrical

Panel,useyourclosestarmtomovethe

RotaryDisconnectSwitchtotheOFFposition.

3. AttachyourLockandSafetyTagtotheRotary

DisconnectSwitch.Includeyourname,date

andtime,andtheworktobeperformedonthe

tag.

4. ReturntotheControlPanel(CP)andverify

correctpowersourcehasbeenlockedout.

WARNING

THEEQUIPMENTMAYHAVE

STOREDENERGY! ENSURETHAT

ALLPARTSHAVESTOPPED

MOVINGANDANYSTORED

CAPACITANCEHASBEEN

EFFECTIVELYDRAINED.

5. Proceedtotheworkareaandvisuallycheckto

ensurethattheequipmentisOFF.

6. DoublecheckwithaMultimeteratthe

equipmentServiceEntrancetoensurethatthe

systemhasbeendeenergized.

7. Wait fiveminutes oncesystemisturned

OFF,toallowforCapacitiveDischarge.

8. Itisnowsafetoworkonthesystem.

9. Completeallrequiredmaintenance.

AfterServiceWorkIsComplete

10.EnsureCPdoorisclosed.

11.EnsurealloftheequipmentisintheOFF

position.

12.Clearanytoolsordebrisfromworkarea.

13.RemoveallLockoutDevicesandTags.

14.WhilestandingtothesideoftheElectrical

Panel,useyourclosestarmtomovethe

RotaryDisconnectSwitchtotheONposition.

15.Notifytheplantmanagerorsiteelectricianthat

workiscompleteandthatthesystemhas

beenrestarted.

PREFACE

TrojanUVLogic

TM Operations&Maintenance

xii

ListofAcronyms/Glossary

Thisglossarydefinesalistofacronymsthatwill

befoundthroughoutthismanual.

o

C–DegreesCelsius

AC–AlternatingCurrent

_LLongLampLogicModel

AMWSAutomaticMechanicalWipingSystemis

anoptionalcomponentthatprovidesautomated

wipingoftheLampSleevesduringnormal

operation.

ANSI–AmericanNationalStandardsInstitute

_SShortLampLogicModel

BarBarometricPressure

BSP–BritishStandardPipe

CCB–CommunicationControlBoard

cmCentimeter

CPControlPanel

DC–DirectCurrent

DINDeutscheIndustrieNorm(German

EquivalentofANSI)

DNADeoxyribonucleicAcid

EOLEndofLife

GNDGround

GPMUSGallonsperMinute

Hp–Horsepower

Hrs–Hours

in

.

lb–Inchpound

Lb

.

ft–PoundFoot

L/s–Literspersecond

LEDLightEmittingDiode

mA–Milliamps

MAXMaximum

MGDMillionsofGallonsperDay

mg/l–Milligramsperliter

MIN–Minimum

mJ/cm

2Millijoulespersquarecentimeter

MLDMillionsofLitersperDay

mmMillimeters

MMWSManualMechanicalWipingSystemis

anoptionalcomponentthatprovidesthe

operatortheabilitytowipetheLampSleeves

duringnormaloperation.

MPaMegapascals

mW/cm

2Milliwattspersquarecentimeter

N

.

m–Newtonmeter

nm–Nanometers

NPT–NationalPipeThread

O&MOperationsandMaintenance

OH–HydroxylFreeRadicals

phPhase

ppm–PartsperMillion

psi–PoundsperSquareInch

sec–Second

SST–StainlessSteel

TOC–TotalOrganicCarbon

UVUltraviolet

UVRUVReactor

VAC–VoltageAlternatingCurrent

VDC–VoltageDirectCurrent

VFD–VacuumFluorescentDisplay

w–Wire

W/m

2–Wattspermetersquared

Table of contents

Other Trojan Technologies Water Filtration System manuals

Trojan Technologies

Trojan Technologies Aquafine DW Series User manual

Trojan Technologies

Trojan Technologies TrojanUVMax Pro10 User manual

Trojan Technologies

Trojan Technologies Aquafine UVK-2 User manual

Trojan Technologies

Trojan Technologies Trojan UV Max User manual

Trojan Technologies

Trojan Technologies Aquafine CSL Series User manual

Popular Water Filtration System manuals by other brands

Dontek

Dontek PWP2 Ioniser instruction manual

Barco

Barco F40 installation manual

Petsafe

Petsafe DRINKWELL hy-drate PFD17-12901 quick start guide

Richdon Koi

Richdon Koi UltraSieve MIDI instruction manual

MEDENUS

MEDENUS DF 100 Operating and maintenance instructions

Keating Of Chicago

Keating Of Chicago Safe and Easy Filter owner's guide