Trojan Timbers FLOOR ART User manual

INSTALLATION GUIDE

www.trojantimbers.com.au

FLOOR ART

Engineered Timber Flooring - By Trojan Timbers

www.trojantimbers.com.au

For further information or assistance, contact your retailer or Trojan Timbers directly.

Thank you for choosing Trojan FLOOR ART Engineered Timber Flooring.This document contains useful instructions on the installation of

Trojan FLOOR ART. Correct installation will ensure your oor performs at its peak now and into the future.

INSTALLATION GUIDE

1

GETTING STARTED

Store the boards in a cool, shaded and protected dry place. Do not open the packets until the day of installation to avoid moisture pickup.

Check each board carefully prior to installation. Never install any damaged oor and conduct inspections as you work.

Should any obvious mistakes or damages be found when opening the packages, all claims should be raised immediately before

installation.

Timber is a natural product with natural variations of colour, grains and

characteristics. These variations are not considered a defect.

Always work out of several different bundles alternatively for installation. Mix and match between packs to create a beautiful colour

spread across your oor.

Timber is a living material, which swells if moisture or humidity increases and shrinks if moisture of humidity decreases. If the climate

and humidity of the room where your timber is laid is left too high or too low for an extended period of time, this can lead to irreversible

deformation of your oor. This can particularly occur if, e.g. in winter, the humidity in a heated room falls below 45%. If you are heating

your room, you should install an air humidier to prevent damage to your oor. The same may be necessary in an air conditioned room.

2

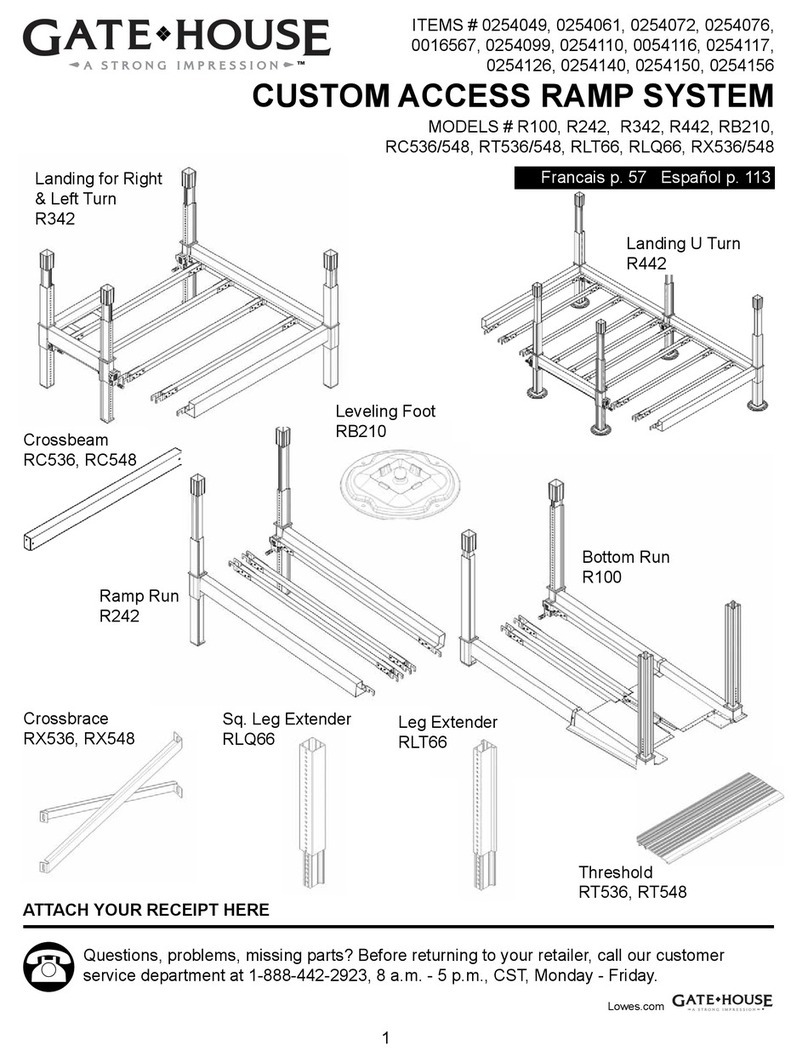

SUBFLOOR PREPARATION

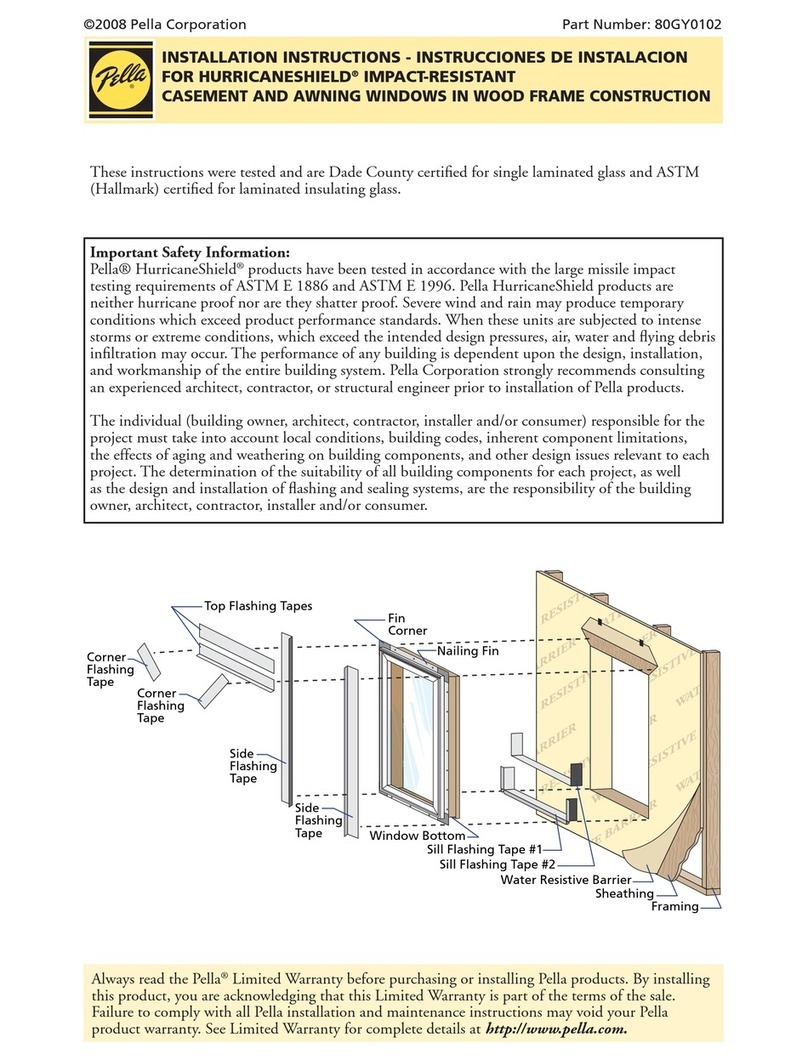

Before installation, remove all debris or dust and clean the oor. Trojan FLOOR ART can be

installed on concrete, particle board or timber suboors, providing the suboor is at, level,

smooth and dry. Ensure the suboor is free of any cracks. Irregularities in the suboor should not

exceed 3mm every 1 metre in all directions. Ensure that the suboor is thoroughly cleaned to

avoid mould growth.

In case there is a need to level the concrete suboor, a cement based oor-ller should be used.

Timber and particle board suboors must be structurally sound. If a particle board suboor is

used, ensure the edges are sanded prior to installation.

Trojan FLOOR ART is not

structural and therefore, it will

reect the condition of the

suboor. Ensure your suboor

is structurally sound and at,

smooth, level and dry.

NOTE:

Should the Relative Humidity (RH) of the environment be above 95%, no ooring should be installed.

Installation in these conditions will void all warranties.

3

UNDERLAY

Age resistant polyethylene membrane plastic sheets (0.2mm thickness) for vapour barrier are recommended and necessary for the

oating-system installation. Joining between the plastic sheets should have sufcient overlap and/or sufcient tight joins to avoid

leakage of vapour from underneath. Recommended overlap should be at least 20cm.

It is important that a suitable underlay with a moisture barrier is utilised. Both Trojan Silent Walk and Trojan IQ Underlays are suitable to

be used in the oating installation of Trojan FLOOR ART.

Please note: Silent Walk and Trojan IQ are not designed to completely seal the suboor or as a solution to rising damp. In such circumstances,

the suboor should be sealed prior to installation of underlay and FLOOR ART.

Silent Walk is an industry standard, acoustic, loose-laid underlay that

does not require expensive gluing or preparation. This underlay is

designed with a PVC moisture barrier to help protect the oor.

TROJAN SILENT WALK TROJAN IQ

4

INSTALLATION

When installing Trojan FLOOR ART, an allowance of at least 10-15mm on each edge should be provided to accommodate expansions,

including at a doorway, heating tube outlet, connect with tiles and any xed items in the area where the oor is laid. Use spacing-wedges

during the installation to assist in maintaining the expansion gaps.

Note: Larger rooms, such as halls, assembly rooms, dance oors, will need a bigger allowance for expansion join.

We recommend an expansion join in the middle of the room. If the oor is installed without this expansion join, all warranties will

be void.

The formula to calculate the expansion across the width of the installed oor is 2mm expansion for every 1 metre of oor width.

Always begin installation by facing the groove-side of the oorboard towards the wall. To join the oorboards together, a 30-40cm

wooden block should be used as a brace against the tongue side to knock the boards together. Do not use force during the joining. Never

hit the oor-board directly with the hammer. This is to avoid either the tongue or nished edges from being damaged.

Lay the ooring lengthwise against the longest wall of the room, starting from the corner furthest from the entrance. This will enhance

the beauty of the room and will enable proper workspace practice (by not walking on the newly laid oor).

DIRECT STICK INSTALLATION:

For installation by direct gluing to the suboor or Direct Stick, please adhere to the glue manufacturer’s instructions. Only use acrylic

based glue.

FLOATING INSTALLATION:

When installing using the oating-system, always apply glue to the upper parts of the groove. This includes the groove at the head joint

(short end) of the plank. Always distribute the glue in a continuous line – never apply the glue in a broken line. Any excess glue that is

squeezed to the surface should be immediately wiped off with a damp cloth.

When laying the next row of oorboards, begin with pieces of planks left from the previous row or using start pieces included in the packs.

Ensure a minimum of 50cm distance between one head-joint and the other of the next row.

When laying the oor through several adjoining rooms, expansion joints must also be provided at every door’s passages. When laying

the oor in a corridor, lay the boards lengthwise along the corridor. Floor-boards forming the last row should be installed with a special

crow-bar designed for this purpose.

Once the oor has been laid, remove all spacing wedges and ll all visible joints with a silicon-free sealant or with an insert prole(s)

designed for this. Install skirting boards by screwing them to the adjacent wall. Never screw skirting boards directly to the oor boards.

www.trojantimbers.com.au

For further information or assistance, contact your retailer or Trojan Timbers directly.

3

UNDERLAY

If you require noise reduction properties, Trojan IQ is suitable for your

oating installation. Trojan IQ is a premium acoustic underlay that

reduces foot trafc noise and sound transmission. Where superior

acoustic performance is required, we recommend the use of Trojan IQ.

INSTALLATION GUIDE

Table of contents