Contents

01 Safety . . . . . . . . . . . . . . . . . . 5

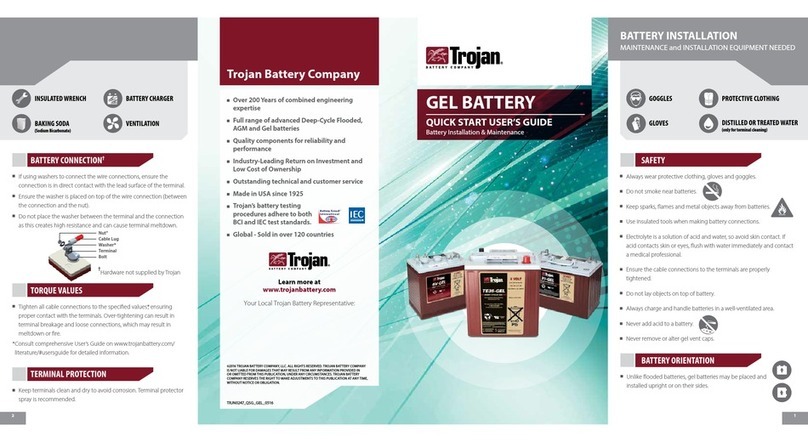

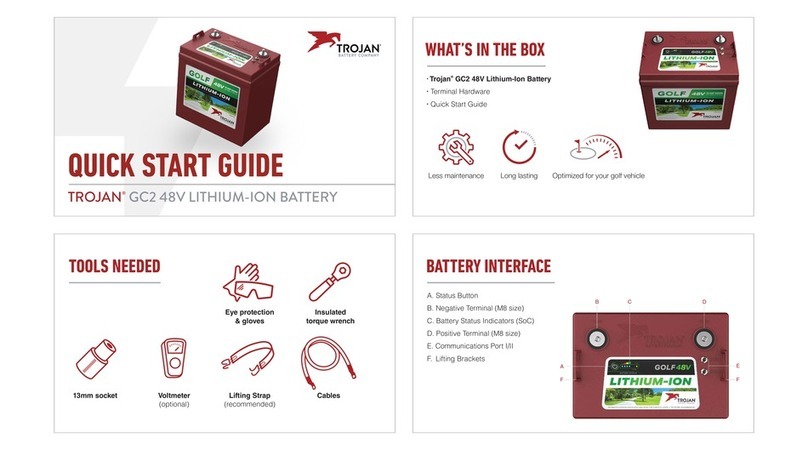

02 Equipment Needed. . . . . . . . . . . . 5

03 Battery Installation . . . . . . . . . . . 6

3.1Battery Connections . . . . . . . . . . . . . 6

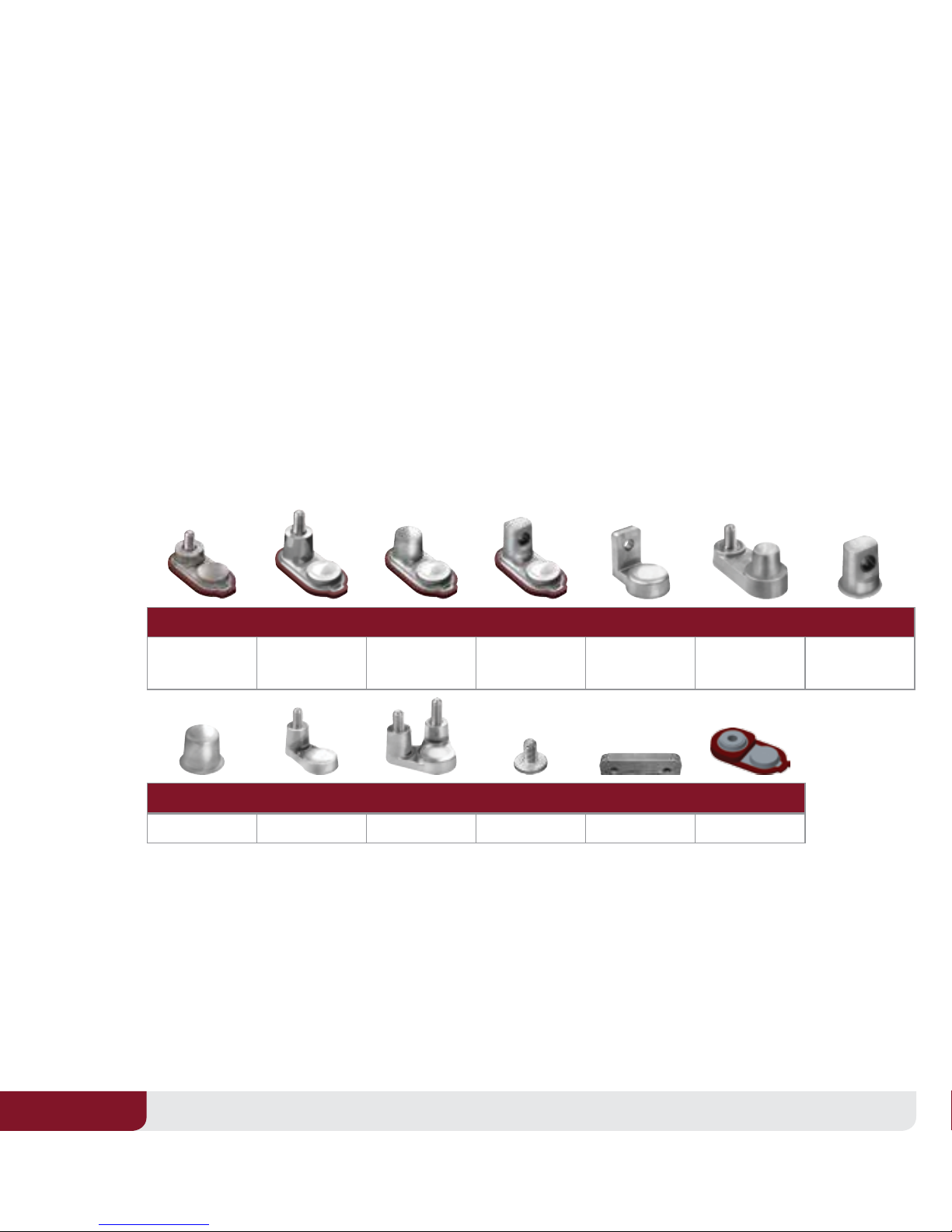

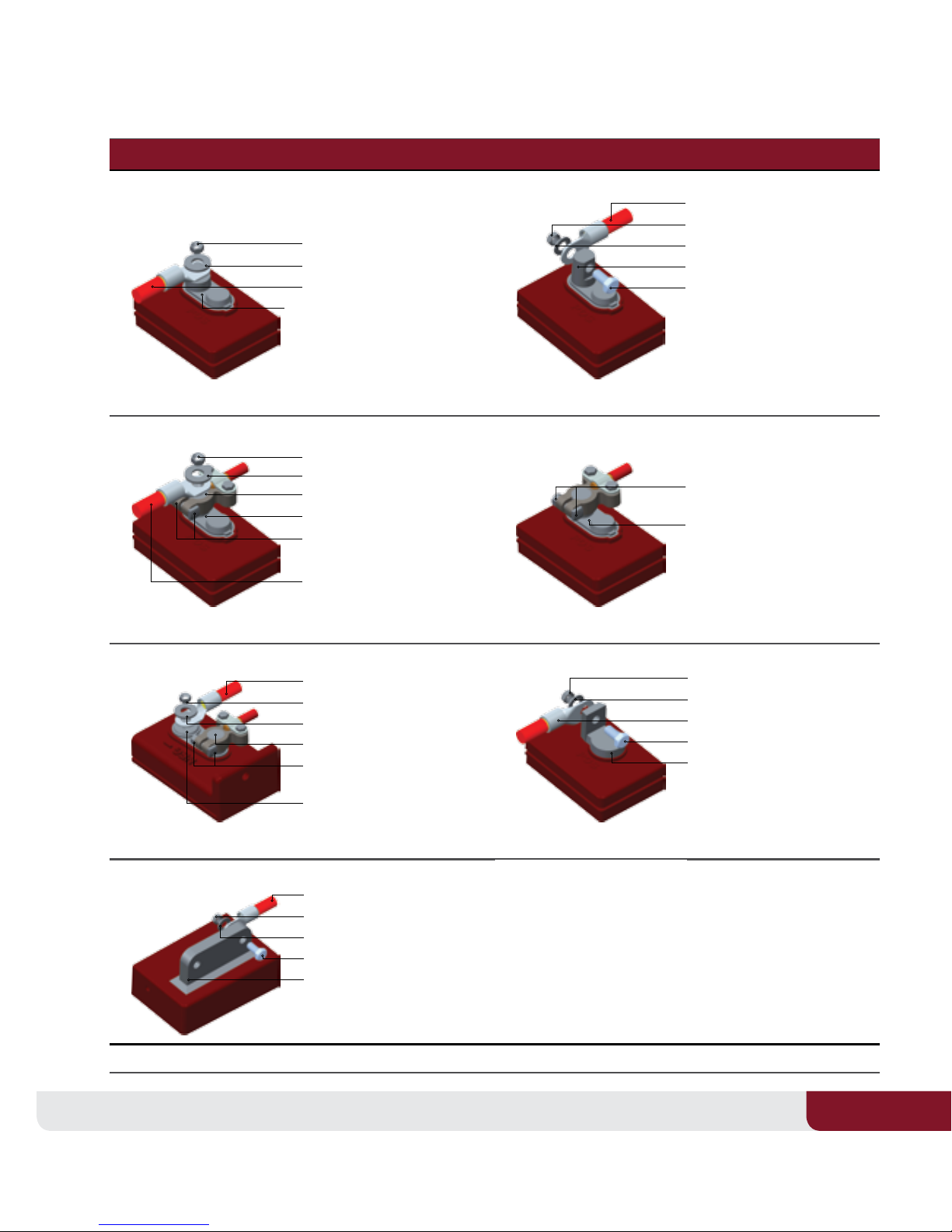

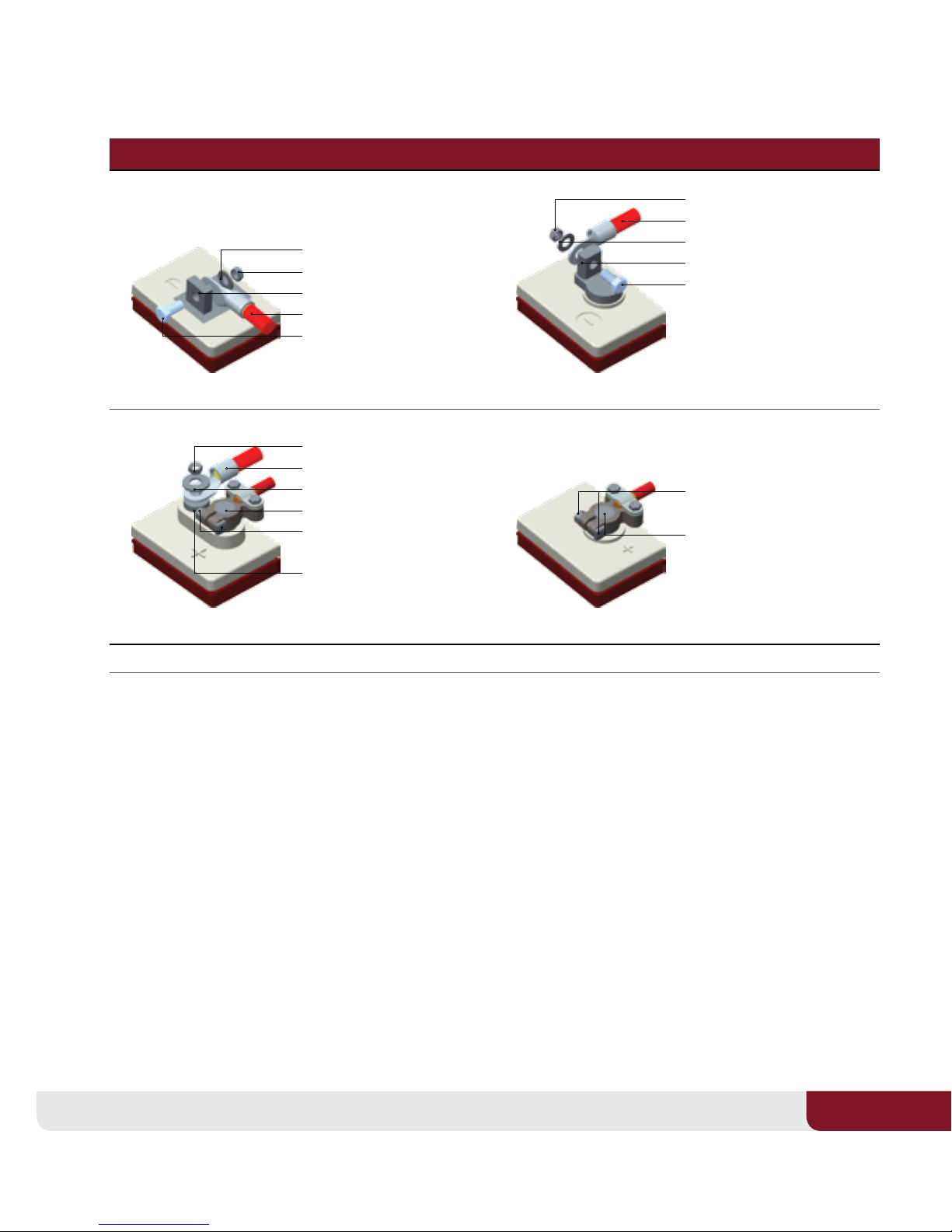

3.2Terminal Types . . . . . . . . . . . . . . . 6

3.4Cable Size . . . . . . . . . . . . . . . . .10

3.5Torque Values . . . . . . . . . . . . . . . .11

3.6Terminal Protection . . . . . . . . . . . . .12

3.7Connecting Batteries to Increase System Power . . .12

3.8Ventilation . . . . . . . . . . . . . . . . .13

3.9Battery Orientation. . . . . . . . . . . . . .13

3.10Battery Environment . . . . . . . . . . . .13

3.11Temperature. . . . . . . . . . . . . . . .13

04 Preventative Maintenance . . . . . . . . 14

4.1Inspection . . . . . . . . . . . . . . . . .14

4.2Watering . . . . . . . . . . . . . . . . .14

4.3Cleaning. . . . . . . . . . . . . . . . . .16

4.4Charging & Equalizing. . . . . . . . . . . . .16

4.4.1Boost Charging . . . . . . . . . . . . . .16

4.4.2Charging . . . . . . . . . . . . . . . .18

4.4.3Equalizing . . . . . . . . . . . . . . . .22

05 Storage . . . . . . . . . . . . . . . . . 24

5.1Storage in Hot Environments . . . . . . . . . .24

5.2Storage in Cold Environments . . . . . . . . .24

06 How to Maximize the Performance of your

Trojan Battery . . . . . . . . . . . . . . 24

07 What to Expect from your Trojan Battery . 25

08 Trouble-Shooting. . . . . . . . . . . . . 26

8.1Preparation for Testing . . . . . . . . . . . .26

8.2On-Charge Voltage Testing . . . . . . . . . . .26

8.3Specic Gravity . . . . . . . . . . . . . . .27

8.4Open Circuit Voltage Testing . . . . . . . . . .27

8.5Discharge Testing . . . . . . . . . . . . . .28

09 Battery Recycling . . . . . . . . . . . . 29

10 Battery Acronyms . . . . . . . . . . . . 30