Trooper ADVANTAGE TR-100 User manual

NEGATIVE PRESSURE UNIT

TM

I.O.M. #08A 9/95 updated 11/13

INSTRUCTION MANUAL • INSTALLATION • OPERATION • MAINTENANCE

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, IN 46142

317-887-0729 fax: 317-881-1277

Service Department fax: 317-885-8683

www.AdvantageEnegineering.com

e-mail: [email protected]

INSTRUCTION MANUAL

TROOPER NEGATIVE PRESSURE

UNITS

TR-100 TR-200 TR-300 TR-350 TR-400 TR-500

COVERING

INSTALLATION

OPERATION

MAINTENANCE

NEGATIVE PRESSURE UNIT

TM

ADVANTAGE ENGINEERING, INC. 525 East Stop 18 Road Greenwood, IN 46142

317-887-0729 fax: 317-881-1277 Service Department fax: 317-885-8683

Page: 4

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

TABLE OF CONTENTS

1 GENERAL 6

1.1 Safety 6

1.2 Introduction 7

2 INSTALLATION 8

2.1 Connecting a power cord 8

2.2 Checking the phase monitor (3Ø units) 9

2.3 Connections to a mold 9

3 OPERATOR INSTRUCTIONS 10

3.1 Startup and adjustments 10

3.2 Gauge reading check 12

3.3 Pressure indicating lights 13

3.4 Shut down and storage 14

4 BASIC FUNCTION AND OPERATION 15

4.1 How an ADVANTAGE TROOPER works 15

4.2 Pressure drop across a mold 16

4.3 Mold leak simulation

(demo and operation check) 17

4.4 Using mold heaters with TROOPER units 18

4.5 Fixing problem leaks (multiple and cavity) 20

4.6 Using ADVANTAGE TROOPER as

a booster pump 21

5 TROUBLESHOOTING 22

5.1 Unit will not start - power light off -

pressure lights off 22

5.2 Unit will not start - power light on -

pressure lights off 22

5.3 Unit shuts on and off -

pressure lights on 22

5.4 Unit shuts on and off

pressure lights off 23

5.5 Low pressure switch check 24

5.6 High pressure switch check 24

5.7 Unit looses vacuum 25

5.8 Excessive air or foam in the return line 25

5.9 No coolant flow: higher mold temperature

on TROOPER line 25

5.10 Unit leaks at pump or motor housing 26

5.11 Hose collapses 26

5.12 Water drains constantly from vent line 26

Page: 5

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

6 APPENDICES 27

6.1 Maintenance procedures 27

6.2 Drain for storage 27

6.3 Specifications and performance data

(all units) 27

6.4 Operating temperature 27

6.5 Capacity 28

6.6 Weight / dimensions / port sizes 28

6.7 Changing voltage 28

6.8 Setting and resetting the overload 30

6.9 Parts failure - common causes 30

6.10 Replacement parts 32

6.11 Parts list - TR-100 33

6.12 Parts list - TR-200 34

6.13 Parts list - TR-300 35

6.14 Parts list - TR-400 36

6.15 Parts list - TR-500 37

6.16 Electronic float switch assembly

on TR-400 and TR-500 38

6.17 TROOPER flow diagram (all models) 39

6.18 TR-340, TR-400, TR-500 electrical

(pictorial) 40

6.19 TR-100, TR-200, TR-300 3Ø electrical

(pictorial) 41

6.20 TR-100, TR-200, TR-300 1Ø electrical

(pictorial) 42

6.21 TR-350, TR-400, TR-500 3Ø AC ladder

diagram 43

6.22 TR-100, TR-200, TR-300 3Ø AC ladder

diagram 44

6.23 TR-100, TR-200, TR-300 1Ø AC ladder

diagram 45

6.24 Boiling point of water at various pressures 46

Page: 6

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

1.0 GENERAL

1.1 SAFETY

A. Failure to follow correct operating instructions may damage the unit.

B. Please read your manual.

C. CAUTION: the following conditions will damage this unit:

a. Running the unit at temperatures higher than 180°F

b. Using synthetic oils as a coolant fluid

c. Running with “drain” pressure less than 5 PSI below the

‘FROM MOLD’ pressure.

d. Reversing pump rotation

D. CAUTION: ‘DRAIN’ gauge must never show less than 5 PSI

pressure while unit is running or pump may be damaged.

(see troubleshooting section for more details).

Page: 7

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

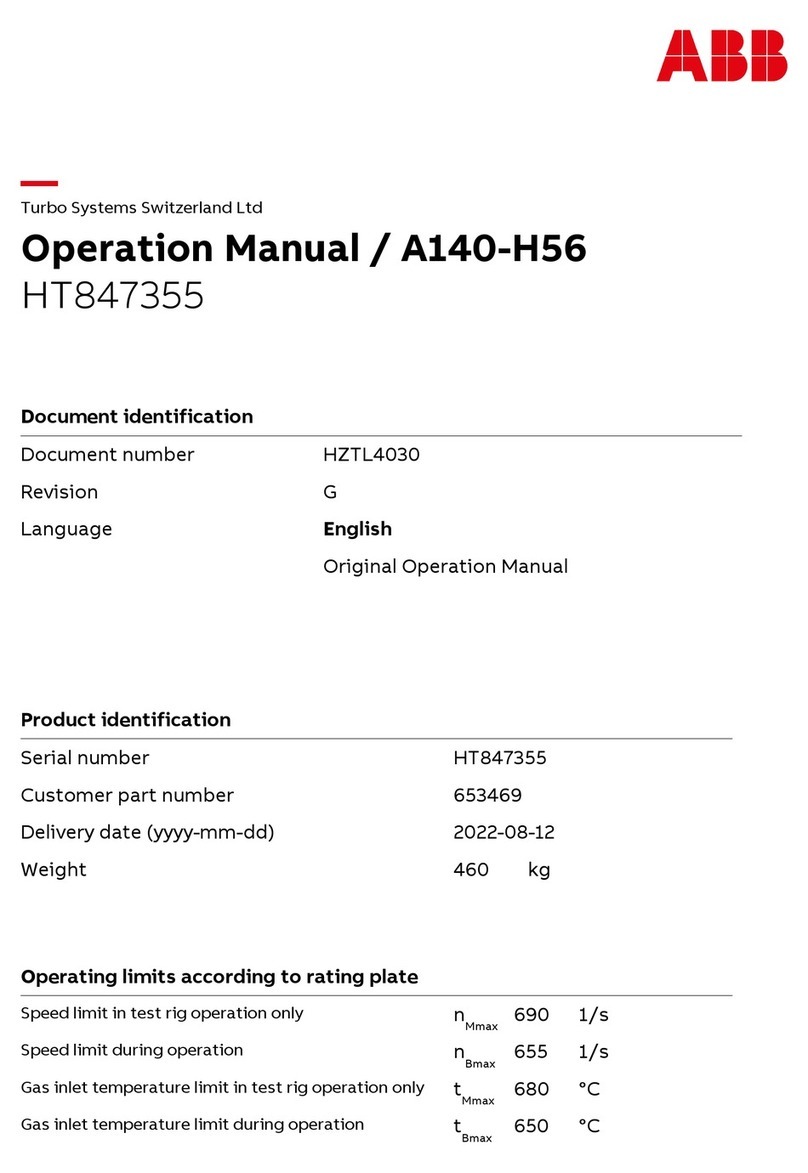

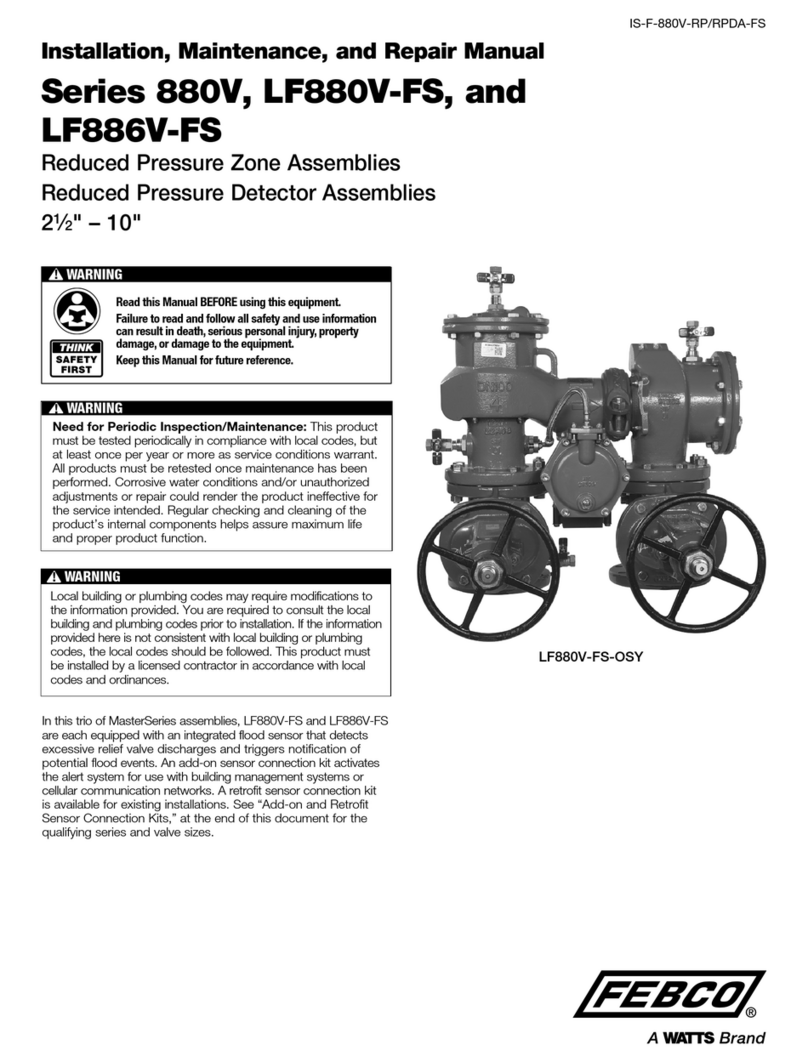

A. The ADVANTAGE TROOPER

negative pressure unit is a fluid

circulating device utilizing a special

pump to create a negative pressure

inside the mold to stop any leak.

B. The above picture will give the reader

an overview of the major components

of the TROOPER system.

A- Gauge panel

B - Electrical panel door

C - Rocker switch and lights

D- Electrical panel

E- Air vent

F- Pump

G - Pump motor

H - Regulator (can’t be seen in

photograph)

1.2 INTRODUCTION

A

BC

D

E

G

H

F

Page: 8

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

2.0 INSTALLATION

2.1 CONNECTING A POWER CORD

A. CAUTION: electrical connections should only be done by qualified

persons who are familiar with proper electrical safety procedures.

B. CHOOSING THE CORRECT WIRE

1. The voltage and phase of the ADVANTAGE TROOPER is

labeled at the power cord mounting hole at the back of the

terminal block.

2. For safety, ALWAYS use a

properly grounded cord.

3. 110/22/ VAC, 1Ø units: use

a standard THREE WIRE

cord, UL approved and rated

for 15 amps.

4. 230/460 VAC, 3Ø units: use

a standard FOUR WIRE

cord, UL approved and rated

for the amperage of the unit

being wired.

4. Electrical code requires

power cords to be rated

for 25% more than the Full

Load Amperage (FLA) of the

unit. FLA for every unit is

recorded on the motor serial

plate.

5. 14 Gauge wire is adequate

for all ADVANTAGE

TROOPER negative pressure

units.

6. The unit may also be wired directly to a fuse box. Always

be sure that the fuses used do not exceed the FLA rating of

the motor.

6. The power cord should be connected to the terminal block

located at the inside rear of the electrical box.

7. Mount the cord with the appropriate strain relief through the

hole provided.

8. Be sure that the ground wire of the power cord is connected

to the same position on the terminal block as the green

Terminal Block

Motor data plate

Page: 9

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

ground wire of the ADVANTAGE TROOPER.

2.2 CHECKING THE PHASE MONITOR (3Ø UNITS ONLY)

A. All three phase ADVANTAGE

TROOPERS units are equipped

with a phase monitor to protect the

pump against damage caused by

phase loss, low voltage and phase

reversal.

B. After connecting the power cord,

leave the electrical box cover open

so that the phase monitor is in view.

C. Plumbing connections are

unnecessary at this point. Be sure

that ADVANTAGE TROOPER power

switch is in the “off” position. Running the unit without fluid will

damage the stator. Connect the power supply, leave the unit “off”.

The indicator LED on the top of the phase monitor should glow.

D. If the indicator LED does not light, turn the power off and disconnect

the power supply. Swap any two (2) of the three (3) input wires at

the terminal block (DO NOT REMOVE THE GROUND).

E. Reconnect the power supply and turn the power on. The LED will

now glow, indicating that the unit is wired to the phase sequence

required for correct motor rotation.

F. NOTE: it may be necessary to slightly lower the adjustment dial

of the phase monitor to prevent nuisance tripping. CAUTION:

lowering the adjustment dial setting more than 10-12 degrees below

the precise setpoint may interfere with the proper operation of the

phase monitor.

G. Turn the power off. tighten down the screws on the electrical box

cover. The ADVANTAGE TROOPER is now protected against

phase reversal, phase loss and low voltage power faults.

2.3 CONNECTIONS TO A MOLD

A. For maximum efficiency and life of the ADVANTAGE TROOPER

unit, use hoses that are the same diameter as the ports to which

they are connected.

B. “Quick Release” fittings that are not vacuum rated, are not

recommended, as they will severely impair the use of the

ADVANTAGE TROOPER as a leak stopper and when using “water

transfer”.

Phase monitor

Page: 10

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

3.0 OPERATING INSTRUCTIONS

3.1 START UP & ADJUSTMENTS

A. A simplified version of the following instruction are silkscreened on

the ADVANTAGE TROOPER cabinet for easy reference.

B. Make all hose connections to the appropriate ports at the back of

the ADVANTAGE TROOPER.

C. Begin with the ‘POWER’ switch in the ‘OFF’ position.

‘FROM MOLD

connection ‘RETURN’

connection

‘SUPPLY’

connection

‘TO MOLD’

connection

C. When using the ADVANTAGE TROOPER as a leak stopper you

will have maximum coolant flow when the “TO MOLD” line is

Page: 11

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

D. STEP 1: Back out regulator screw

(original set-up only).

a. At the top of the

ADVANTAGE TROOPER,

the regulator is on the left

side, connected to the ‘TO

MOLD’ port.

b. Back the regulator screw all

the way out (counter clock-

wise).

c. Then turn the screw in

(clockwise) until you feel it just touch the internal diaphram.

d. In this position, the regulator is off (maximum vacuum) and

is ready for adjustments to a new molding set-up.

E. STEP 2: open ‘DRAIN’ line.

a. The ‘RETURN/DRAIN’ line should always be opened first.

Because the pump is positive-displacement, if it is run

without the return line open, excessive pressure will build

up and possibly rupture the drain line hose or cause internal

pump damage.

b. After waiting a moment for internal pressure to balance, you

can read your system drain pressure in the ‘DRAIN’ gauge

at the front of the ADVANTAGE TROOPER.

F. STEP 3: open the ‘SUPPLY’ line.

G. STEP 4: turn the unit on.

a. The rocker power switch

will light to indicate that

there is power supplied to

the unit.

b. The ADVANTAGE

TROOPER will run now,

even though the mold

lines are closed. All

ADVANTAGE TROOPER

units are equipped with

an internal supply-to-pump

by-pass line to protect the

pump from running dry.

c. The ‘FROM MOLD’ gauge on the front of the unit will show

maximum vacuum, about minus (-)24, which is, 24 inches

of mercury.

Regulator

Rocker power switch

Page: 12

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

H. Step 5: open the ‘FROM MOLD’ line.

a. This will place your mold lines under a vacuum so that

the mold will not pressurize when the ‘TO MOLD’ line is

opened.

I. Step 6: open the ‘TO MOLD’ line.

a. At this point there will be little or no flow through the mold

because the regulator is off.

J. Step 7: adjust the regulator (original set-up only).

a. Watch the mold at the leak point and slowly turn the

regulator screw in (clock-wise) until water begins to leak

out.

b. Now, slowly turn the regulator screw out (counter clock-

wise) until the leak stops and continue an additional

one-half turn.

c. The ADVANTAGE TROOPER is now adjusted for the

maximum coolant flow through the mold. Continuing to back

out the regulator screw will reduce flow until the regulator is

completely shut off.

K. NOTE: (original set-up only): the regulator only needs to be

adjusted once for a particular mold. After initial set-up the unit may

be shut down and restarted without having to readjust the regulator.

3.2 GAUGE READING CHECK

A. NOTE: internal dampeners are used in all ADVANTAGE

‘TO MOLD’ ‘DRAIN’ ‘FROM MOLD’

Page: 13

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

TROOPER gauges to protect them from extreme pressure

oscillations. Gauge readings will lag slightly behind actual line

pressures.

B. ‘TOMOLD’GAUGE: this gauge should show positive pressure. If

this gauge reads negative it means that the entire mold circuit is

under vacuum, you may not have optimum coolant flow.

C. ‘SUPPLY’GAUGE: when the unit is running, this gauge will show

supply pressure to the pump. When the unit is turned off the

reading becomes inaccurate as internal pressures balance.

D. ‘DRAIN’GAUGE: when the unit running, this gauge will show the

return pressure the unit is pumping against. When the unit is turned

off, the reading becomes inaccurate as internal pressures balance.

E. CAUTION: ‘DRAIN’ gauge should never show less than five (5)

PSI below ‘TO MOLD’ pressure while unit is running or pump may

be damaged. (See appendix - ‘Parts Failure - Stator’).

F. Static pressure readings of house system may be obtained by

turning the unit off. Shut off the ‘DRAIN’ and leave the ‘SUPPLY’

open to read the supply pressure. Shut off the ‘SUPPLY’ and leave

the ‘DRAIN’ open to read the drain pressure.

G. ‘FROMMOLD’GAUGE: this gauge should show negative

pressure when the ADVANTAGE TROOPER is running. If you

have no leaks you may open the regulator (clock-wise) as much

as possible without this gauge reading positive pressure, this is the

maximum flow.

H. CAUTION: ‘FROM MOLD’ gauge must always be less pressure

than the ‘DRAIN’ while unit is running or pump may be damaged.

(See appendix - ‘Parts Failure - Stator’).

3.3 PRESSURE INDICATOR LIGHTS

A. These lights warn of pressures outside of acceptable limits. They

‘SUPPLY PRESSURE

TOO LOW’

‘DRAIN PRESSURE

TOO HIGH’

Page: 14

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

are off during normal operation.

B. Pressure switches on all ADVANTAGE TROOPER units are preset

to prevent pump damage and extend the life of the unit. DO NOT

ADJUST OR DISABLE PRESSURE SWITCHES.

C. ‘SUPPLYPRESSURETOOLOW’: this indicator light will come on

when the unit has shut down because the supply pressure is less

than 8 PSI. All ADVANTAGE TROOPER units have a low pressure

shut off switch connected to the supply plumbing to prevent the

pump from being damaged by running dry.

D. ‘DRAINPRESSURETOOHIGH’: this indicator light will come on

when the unit has shut down because the drain pressure is greater

than the pumping capacity of the unit. The high pressure shut off

switch protects the motor from being damage by excessive strain.

E. FOR ADDITIONAL INFORMATION OR PROBLEM SOLVING

REFER TO THE TROUBLESHOOTING GUIDE.

3.4 SHUT DOWN & STORAGE

A. The following instructions are silk-screened on the top of the unit for

easy reference.

B. Step 1: shut off “TO MOLD’ line.

C. Step 2: To purge mold completely, allow air to enter ‘TO MOLD’

hose until all water is out.

D. Step 3: Shut off ‘FROM MOLD’ line.

E. Step 4: Turn off unit.

F. Step 5: Shut off ‘SUPPLY’ line.

G. Step 6: Shut off “DRAIN’ line.

H. Step 7: Drain unit for storage.

I. It is important to drain the unit when no in use for extended periods.

This will prevent sediments and mineral deposits from building up

inside the pump and causing damage.

Page: 15

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

4.0 BASIC FUNCTION AND OPERATION

4.1 HOW AN ADVANTAGE TROOPER WORKS

A. The reason that water leaks out from inside of anything is because

the pressure of the water has overcome the pressure of the air

holding it in. If you had a small hole on the hose for example, and

the pressure of the air pushing in on it was strong enough, it would

keep the water inside the hose. Since it is impossible to increase

the pressure of the atmosphere, an ADVANTAGE TROOPER

decreases the pressure of the water to the point where the air holds

the water in.

B. There are three factors involved in creating or controlling leaks:

incoming water pressure, atmospheric pressure and outgoing

pressure. The available draw or vacuum capability of the pump,

outgoing pressure, remains constant. Atmospheric pressure also

remains constant. Therefore, the control we have for stopping

leaks is the incoming pressure. The pressure regulator inside

the ADVANTAGE TROOPER is used to limit the incoming water

pressure to the leak.

C. When using an ADVANTAGE TROOPER, the water is pulled

through a mold to lower pressure. In all other circulating systems,

the water is pushed through, which increases pressure.

D. Regulating the flow to a mold does not necessarily reduce the

flow when using an ADVANTAGE TROOPER. Because the

ADVANTAGE TROOPER draws a vacuum on the ‘FROM MOLD’

line, the over all pressure drop remains the same or even increases.

This means that in many cases there is no loss of cooling flow and

in some cases it may even be improved.

E. The ADVANTAGE TROOPER unit uses a progressive cavity pump

because it can pump both water and any air that may be drawn in

from a leak. The air is then vented from the system before the water

leaves the unit.

Positive displacement pump

Page: 16

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

4.2 PRESSURE DROP ACROSS A MOLD

A. To prevent coolant from leaking out, the fluid pressure must be zero

PSI or less at the point of the leak. In the “incorrect hook-up” (see

figure), coolant enters the mold near the leak and the incoming

pressure must be adjusted close to zero PSI to prevent leakage into

the damaged area.

-12 PSIG

FROM MOLD

0 PSIG

TO MOLD

-9 PSIG

-3 PSIG

-6 PSIG

LEAK

INCORRECT HOOKUP

Pressure differential of only 12 PSI with no leak, minimum coolant flow.

B. The ADVANTAGE TROOPER in this example can pull a maximum

vacuum of about -12 PSI on the ‘FROM MOLD’ line. This

determines the overall pressure differential on only 12 PSI.

C. The coolant pressure must be zero only at the point of the leak.

Therefore, by having the coolant enter the mold at the point farthest

from the leak, much of the pressure drop can take place before

the leak. This means that a much higher incoming pressure can be

used. In the “correct hook-up” (see figure), the incoming pressure

is +36 psi, which drops as it flows through the mold, becoming zero

psi just before the leak. Since the ADVANTAGE TROOPER in this

example can still pull -12 PSI on the ‘FROM MOLD’ side, there is

now a total pressure differential of 48 PSI. Maximum coolant flow

with no leak. compare this to only 12 PSI in the “incorrect hook-up”

and you will see the importance of flow direction in relation to leak

position.

Page: 17

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

4.3 MOLD LEAK SIMULATION (DEMO & OPERATION CHECK)

A. Begin with the ‘POWER’ switch turned off and the regulator screw

back out.

B. Connect a jumper hose from the ‘TO MOLD’ port to the ‘FROM

MOLD’ port. (Clear hose is ideal for this purpose).

C. Connect ‘SUPPLY’ and ‘DRAIN’ ports as you would to run a mold.

D. Open the ‘DRAIN’ line first.

E. Then open the ‘SUPPLY’ line.

F. Turn the power on.

G. With a jumper hose between the ‘TO MOLD’ and ‘FROM MOLD’

ports, the suction of the pump may draw some fluid through the

regulator even through it is closed. Pinch the jumper hose closed.

The ‘FROM MOLD’ gauge should show a vacuum of more that 24

inches of mercury.

H. Be sure the regulator screw is backed out. If you wish, you may

now disconnect the jumper hose from the ‘TO MOLD’ port and only

a tiny amount of water will drip out. If you place your finger over the

open end of the jumper hose you will feel the suction of the pump.

+36 PSIG

TO MOLD

-12 PSIG

FROM MOLD

+24 PSIG

0 PSIG

+12 PSIG

LEAK

CORRECT HOOKUP

Pressure differential of 48 PSI with no leak, maximum coolant flow.

Page: 18

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

I. Reconnect your jumper hose.

J. To simulate a mold leak, cut about half way through the diameter of

the jumper hose. Notice that no water leaks from the hose.

K. Open the regulator (turn screw clockwise) until water begins to leak

from the cut in the jumper hose. The farther you open the regulator,

the more water will leak from the hose. Slowly close the regulator

(turn screw counter clock-wise) until the leak stops. The farther you

close the regulator, the more air will be drawn in. (If you are using

a clear jumper hose, you will be able to see the amount of air being

sucked in at the leak.)

L. When adjusting an ADVANTAGE TROOPER to a mold the

regulator should not be closed more than is necessary to stop the

leak. This procedure will maximize the pressure differential across

the mold and provide the maximum coolant flow in the mold.

M. CONCLUSION:

a. You have thoroughly checked the operation of the

ADVANTAGE TROOPER negative pressure unit.

Following and understanding the procedure outlined ‘how

an ADVANTAGE TROOPER works’ will help in the future

when dealing with negative pressure cooling.

b. Remember that a mold is much more complex than the

simple jumper hose used in the ‘Mold Leak Simulation’. Yet

in general, the same procedure should be followed.

c. RECAP: start with the regulator adjusting turned out, for

maximum vacuum, then turn it in (clockwise) until you

notice a leak, then back the screw out one-half turn more.

Each time you make an adjustment, pause for a few

seconds to allow the system come to equilibrium before

making another turn.

4.4 USING MOLD HEATERS WITH TROOPER UNITS

A. Temperatures higher than 180° will damage pump. See appendices:

“Parts failure - stator” and “Boiling Points of Water”.

B. Preventing boiling: water boils at 212°F (100°C) at sea level. The

term “sea level” means air pressure at seal level which is 14.7 PSI

(1 bar). At higher altitudes (lower pressure) water boils at lower

temperatures. The TROOPER unit is a negative pressure system,

in essence creating an artificial higher altitude. When using the

TROOPER as a leak stopper, the absolute pressure of the water

may be as low a 3 PSI, which will cause water to boil at slightly

Page: 19

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

above 180°F (82°C). For comparative temperatures and pressure,

see Appendix “Boiling points of water”.

C. For proper operation with a mold heater, it is essential to make all

connections as shown in this diagram.

D. Mold heaters are pressurized by their open supply line, the drain

remains closed except for cooling. Therefore, the incoming supply

pressure becomes the minimum pressure of the system. In this

situation, if the system pressure exceeds the back-pressure

pumping capabilities of the unit, then the supply pressure must be

reduced.

E. As shown in the diagram, the purpose of the external regulator on

the mold heater supply line is to control the total pressure in the

system. The flow control valve allows a constant relief of pressure

downstream of the regulator even when the mold heater does not

need cooling or the drain is shut off.

F. Start up procedure - mold heater with TROOPER

1. Set the TROOPER regulator to maximum vacuum (screw

backed out).

2. Adjust the mold heater regulator as high as possible without

over loading the TROOPER.

3. Fully open the flow control by-pass valve.

4. Open the supply and drain valves on the mold heater.

5. Open the ‘DRAIN’ line on the TROOPER. ALWAYS OPEN

THE‘DRAIN’LINEBEFORETHE‘SUPPLY’ONTHE

TROOPER.

6. Open the ‘SUPPLY’ line on the TROOPER.

7. Turn power on to TROOPER.

8. Turn power on to mold heater. If necessary, increase

pressure delivered by mold heater supply regulator until

there is sufficient pressure to start the mold heater.

9. Adjust the TROOPER regulator for minimum vacuum

required to stop the mold leak. Do not over adjust.

10. Slowly close the flow control by-pass for the minimum

amount that allows the TROOPER to run continuously.

Never leave the flow control completely closed.

Page: 20

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277 Service Fax: 317-885-8683

web site: www.AdvantageEngineering.com

TROOPER : Negative Pressure System

4.5 FIXING PROBLEM LEAKS (MULTIPLE AND CAVITY)

A. MULTIPLE LEAKS ON A SINGLE MOLD CIRCUIT

1. If there are two or more leaks on one moldcircuit and they

are grouped toward one end, they should be treated as a

single large leak.

2. However, if they are distributed almost evenly throughout

the circuit, then the flow cannot be maximized for flow

in one direction or another. See section 4.1 - How a

TROOPER works.

B. LEAKS INTO MOLD CAVITY

1. In a few cases, if the leak is directly into the cavity or core,

the draw of the part when the mold opens or upon ejection

CONNECTIONS FOR ADVANTAGE TROOPER UNIT

USED WITH MOLD HEATER

DO NOT RUN UNIT WITH WATER OVER 180°F

NOTES:

A. When supply pressure is greater than 45 PSI, use regulator valve,

as noted. It must be set so that coolant pressure, downstream of

regulator, is greater than system back pressure at the return line.

B. The purpose of the sight glass is to check for air in the return line. If

the leak is very large, the logic seal unit may not be able to expel all

the air. If this is the case an extra air vent should be placed at the

return port of the ADVANTAGE TROOPER as air returned to the

mold heater could cause pump cavitation and, possibly, damage the

heaters.

This manual suits for next models

5

Table of contents

Popular Industrial Equipment manuals by other brands

PCB Piezotronics

PCB Piezotronics 1203-13A Installation and operating manual

ABB

ABB HT613306 Operation manual

Allied Systems

Allied Systems LONG REACH CCHA Installation maintenance and service manual

Timco Tools

Timco Tools 22T Operation instructions

ABB

ABB HT609429 Operation manual

Siemens

Siemens SINUMERIK 840D sl Programming manual