Trox EM-LON Specification sheet

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)

The art of handling air

Operating and Installation Manual

EASYLAB Expansion module

EM-LON

LonWorks interface for EASYLAB

TCU3 controllers and TAM adapter modules

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)2

1 General information __________________ 3

Other applicable documentation ________ 3

Symbols used in this manual ____________ 3

2 Safety and correct use ________________ 4

General information regarding safety ______ 4

General safety measures ______________ 4

Correct use ________________________ 4

Incorrect use ________________________ 4

Residual risks ______________________ 4

3 Product description __________________ 5

Product overview and technical data ______ 5

Functional description ________________ 6

4 Transport, storage and packaging ________ 6

5 LonWorks network variables ____________ 8

6 Installation __________________________ 10

7 Wiring ____________________________ 12

Making connections __________________ 12

Recommended bus cables ____________ 12

8 Commissioning ______________________ 13

9 Maintenance ________________________ 13

Contents

TROX GmbH

Heinrich-Trox-Platz

D-47504 Neukirchen-Vluyn

Phone +49(0)28 45 20 20

Fax +49(0)28 45 20 22 65

www.troxtechnik.com Subject to change / All rights reserved © TROX GmbH

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013) 3

Danger!

Designates danger to life and limb due to

electrical voltage.

Warning!

Designates danger to life and limb.

Important!

Designates danger that can cause minor

personal injury or damage to property.

Symbols used in this manual

This manual describes the EM-LON expansion

module that supplements EASYLAB TCU3

controllers and TAM adapter modules with a

LonWorks-FTT-10A interface.

To ensure complete functioning of the expansion

module it is essential to read this operating and

installation manual before starting any work, and

to comply with it.The manual must be given to the

facilities manager when handing over the system.

The facilities manager must include the manual with

the system documentation.

The manufacturer does not accept any liability

for any malfunction or damage resulting from

non-compliance with these instructions or non-

compliance with relevant statutory regulations.

Other applicable documentation

In addition to this manual, the following documents

apply:

• Control Systems catalogue

– EASYLAB EM-LON expansion module

– EASYLAB TCU3 controller

• Project-specific wiring documents

1 General information

General information regarding safety

Only skilled qualified personnel are allowed to

perform the described work on the expansion

module. Only skilled qualified electricians are

allowed to work on the electrical system.

For all work performed on EASYLAB components,

the following regulations and guidelines must be

complied with.This applies in particular to the

following German country specific regulations or as

appropriate in the country where the installation is

taking place:

• Equipment and Product Safety Laws (GPSG)

• Industrial Health and Safety Regulations

(BetrSichV)

• Accident Prevention Regulations (BGV A1,

BGV A3)

General safety measures

• Large temperature differences

Condensation can damage the electronics

beyond repair. If the expansion module has been

kept in an unheated area, wait at least two hours

before switching on the supply voltage for

commissioning.

• Electrostatic charge

Electrostatic charge can damage the electronics.

For this reason, first touch an equipotentially

bonded metal surface, e.g. a water pipe, for

electrical earthing before you remove the unit

from its protective wrapping. Avoid skin contact

with any components or printed circuits on the

expansion module or the main PCB.

• Installing the PCB

Tighten the mounting screws and distance pieces

only hand-tight to avoid damage to the PCB or to

the fixing points in the casing.

• Foreign matter and liquids

If liquid gets onto the PCB or inside the

expansion module, let the expansion module

completely dry before commissioning. Remove

foreign matter, if any.

If the device emits a smell or smoke, have it

checked by the manufacturer.

4 EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)

2 Safety and correct use

Correct use

The EM-LON expansion module provides a

LonWorks interface for EASYLAB base

components.

• Use the expansion module only for an EASYLAB

TCU3 controller or a TAM adapter module.

• Use the expansion module only within the

ranges given in the technical data.

• When used on a room controller or adapter

module with active room management function

(RMF) the expansion module provides data for

the entire room.

• When used on a fume cupboard controller, room

controller or adapter module the expansion

module provides access to the data of the

controller.

• Observe the technical data of the expansion

module.

Incorrect use

Do not use the expansion module outdoors, in wet

areas, or in potentially explosive atmospheres.

Residual risks

Failure of the LonWorks interface does not affect

the control function of the volume flow controller but

does affect data exchange with the central BMS.

Additional safety measures are required for

safety-relevant applications.

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013) 5

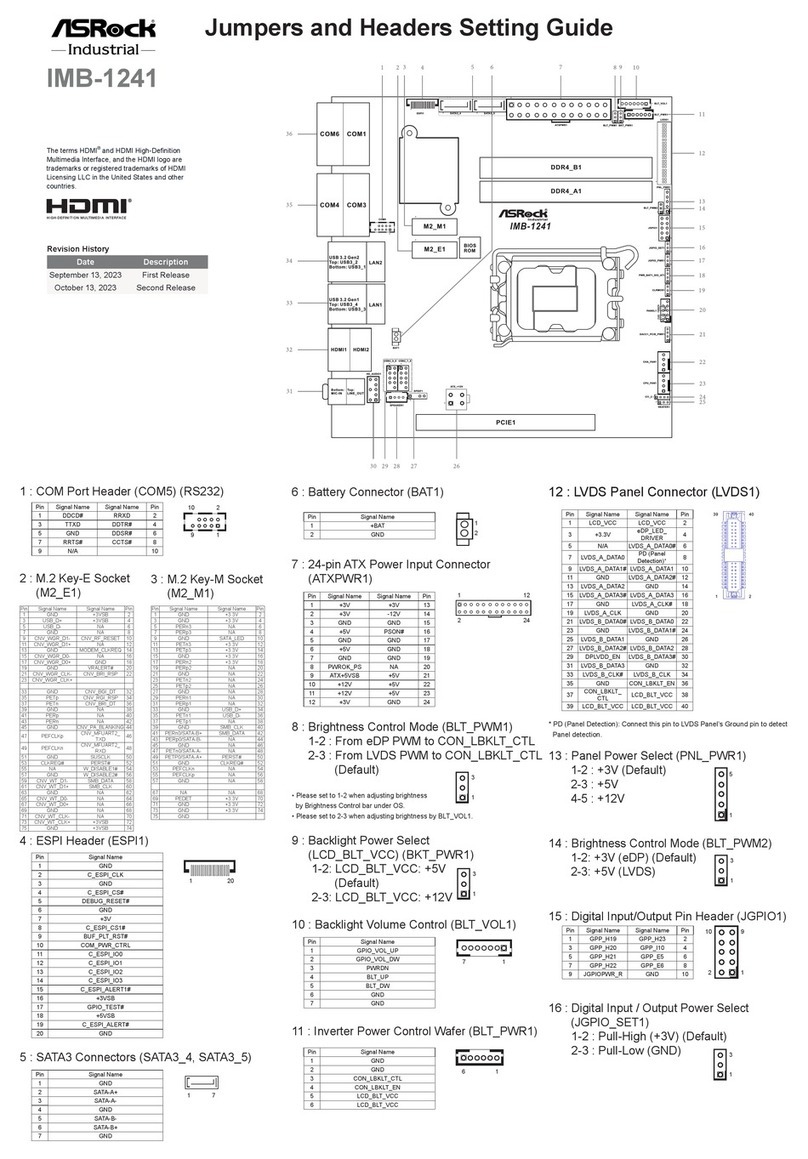

Product overview

Product overview and technical data

Service pin push button

Service pin push button indicator light

Indicator lights for LonWorks communication

TX: Sending data

RX: Receiving data

Terminals for LON FTT-10A network

Plug base for connection with the EASYLAB

main PCB

3 Product description

LON B

LON A

SH

SH

LON A

LON B

Technical data

Supply voltage 5 V DC from the TCU3 controller or TAM adapter module

Communication LonWorks transceiver FTT-10A (Free Topology, Twisted Pair)

Acceptable temperature range for storage: -10°C to +70 °C

for operation: 0°C to +50 °C

Permissible humidity for storage and

operation <90 % non-condensing

Protection level IP 20

Dimensions B × H × T 65 × 15 × 90 mm

Connection to LonWorks network 6 terminals for cable cross sections of 0.12 – 1.5 mm² (LON A, LON B

and shielding, two of each)

Operation and display Service pin push button and three indicator lights

6 EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)

3 Product description

4 Transport, storage and packaging

Delivery check

Check delivered items immediately after arrival for

transport damage and completeness. In case of any

damage or an incomplete shipment, inform the

shipping company and your TROX contact person

immediately.

A complete shipment includes:

• PCB

• 20-pin header

• Fixing material (4 distance pieces and 4 screws)

• Operating and installation manual

Transport on site

• If possible, take the expansion module in the

transport packaging up to the installation location.

• Do not remove the protective wrapping until just

before installation.

Storage

If you need to store the expansion module

temporarily, make sure that the following conditions

apply:

• Leave the unit in its packaging and do not expose

it to the effects of weather.

Store the unit in a dry place and away from direct

sunlight.

• Temperature: –10°C to +70°C

Maximum humidity: 90% (non-condensing)

Packaging

Properly dispose of packaging material.

Functional description

The EM-LON expansion module supplements the

EASYLAB base components (TCU3 controller or

TAM adapter module) with a LonWorks interface for

the purpose of linking rooms or individual volume

flow controllers to the central BMS.

The PCB contains terminals for the LonWorks

network and a service pin push button with indicator

light.The PCB can be fitted to the TCU3 or TAM

main PCB using a header.

To simplify diagnosis during commissioning the

expansion module is equipped with two additional

indicator lights that indicate data traffic on the

LonWorks interface.

Standard network variables are used for the

communication within the LonWorks infrastructure.

These variables ensure unambiguous data

exchange between the nodes. For commissioning, it

is necessary to link the network variables between

the nodes (binding). Project software is used to link

the outputs of a node to the inputs of other nodes.

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013) 7

5 LonWorks network variables

Name of variable Data type

FH

RR

TAM

RR RMF

TAM RMF

Meaning

nviManOverride

SNVT_hvac_overid

x¹ x x

Operating mode default setting for controller or room

nviMode

SNVT_state

x¹ x x

Operating mode default setting for controller or room

nviOccCmd

SNVT_occupancy

x¹ x x

Operating mode default setting for controller or room

nviManOP_Disable

SNVT_switch

x¹ x x

Enabling/disabling manual control

nviVolOffset_T

SNVT_switch

x x

Signalling of flow rate setpoint change for temp. control

nviVolOffset_P

SNVT_switch

x x

Signalling of flow rate setpoint change for diff. pressure control

nviPressSetSel

SNVT_switch

x x

Switching between differential pressure setpoint values 1 and 2

nvoManOverride

SNVT_hvac_overid

x x x

Current operating mode for a single controller

nvoManOverride_R

SNVT_hvac_overid

x x

Current operating mode for the room

nvoMode

SNVT_state

x x x

Current operating mode for a single controller

nvoMode_R

SNVT_state

x x

Current operating mode for the room

nvoOccCmd

SNVT_occupancy

x x x

Current operating mode for a single controller

nvoOccCmd_R

SNVT_occupancy

x x

Current operating mode for the room

nvoVolflowSet

SNVT_flow

x x x

Volume flow rate setpoint value for the controller

nvoVolflowAct

SNVT_flow

x x x

Volume flow rate actual value for the controller

nvoVolTotalExh

SNVT_flow

x x x x x

Total extract air for the room

nvoVolTotalSup

SNVT_flow

x x x x x

Total supply air for the room

nvoPressSet

SNVT_press_p

x x

Differential pressure setpoint value for the room

nvoPressAct

SNVT_press_p

x x

Differential pressure actual value for the room

nvoLocalAlarm

SNVT_switch

x x x x x

Single controller alarm

nvoSummaryAlarm

SNVT_switch

x x

Consolidated alarm for the room

nvoPressAlarm

SNVT_switch

x x

Differential pressure alarm

nvoVelocitySet

SNVT_speed_mil

x

Face velocity actual value

nvoVelocityAct

SNVT_Count

x

Face velocity setpoint value

nvoSwitchPos

SNVT_switch

x

Sash position (stage 1,2,3)

nvoWireSensorPos

SNVT_switch

x

Sash position (sash opening %)

nvoDampPos

SNVT_switch

x x x

Damper blade position of single controller

nvoDampPosMax_FH

SNVT_switch

x x x x x

Evaluated damper blade position for fume cupboards – max

nvoDampPosMin_FH

SNVT_switch

x x x x x

Evaluated damper blade position for fume cupboards – min

nvoDampPosMax_RE

SNVT_switch

x x x x x

Evaluated damper blade position, extract air – max

nvoDampPosMin_RE

SNVT_switch

x x x x x

Evaluated damper blade position, extract air – min

nvoDampPosMax_TE

SNVT_switch

x x x x x

Evaluated damper blade position, total extract air – max

nvoDampPosMin_TE

SNVT_switch

x x x x x

Evaluated damper blade position, total extract air – min

nvoDampPosMax_RS

SNVT_switch

x x x x x

Evaluated damper blade position, supply air – max

nvoDampPosMin_RS

SNVT_switch

x x x x x

Evaluated damper blade position, supply air – min

FH: Fume cupboard controller

RR: Room controller for supply air or extract air

TAM: Adapter module

RR RMF: Room controller with active room management function

TAM RMF: Adapter module with active room management function

¹ only for individually selected operating mode (stand-alone operation)

Overview of data points for EM-LON LonWorks interface, firmware version 1.0

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)8

5 LonWorks network variables

Name of variable Data type

FH

RR

TAM

RR RMF

TAM RMF

Meaning

nviSunblinder SNVT_switch x x Control input signal for sun protection/blinds

nviVolflowExh SNVT_flow

xxxxx

Connection of an extract air flow

nviVolflowSuph SNVT_flow

xxxxx

Connection of a supply air flow

nvoSystemDevices SNVT_count

xxxxx

Number of EASYLAB controllers

nvoStateDIO SNVT_state

xxxxx

State of the digital inputs and outputs (TCU3)

Overview of additional data points for EM-LON LonWorks interface firmware version 2.0,

and TCU firmware version 3.0

Name of variable Data type

FH

RR

TAM

RR RMF

TAM RMF

Meaning

nviSC_LockHP SNVT_switch

x

Automatic sash device

Close and lock sash - HighPrio

nvoSC_LockHP SNVT_switch x Automatic sash device

Feedback, sash has been locked - HighPrio

nviSC_SetPos SNVT_switch x Automatic sash device

Default setting from central BMS: Close sash

nvoSC_GetPos SNVT_switch x Automatic sash device

Position status

nvoSC_Alarm SNVT_switch x Automatic sash device

Alarm

Overview of additional data points for EM-LON LonWorks interface firmware version 2.0,

and TCU firmware version 4.0

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013) 9

5 LonWorks network variables

nviManOP_Disable

nviManOverride

nviMode

nviOccCmd

nviPressSetSel

nviVolOffset_P

nvi

nviSunblinder

nviVolflowExh

nviVolflowSup

nviSC_LockHP

nviSC_SetPos

VolOffset_T

nvoDampPos

nvoDampPosMax_FH

nvoDampPosMax_RE

nvoDampPosMax_RS

nvoDampPosMax_TE

nvoDampPosMin_FH

nvoDampPosMin_RE

nvoDampPosMin_RS

nvoDampPosMin_TE

nvoLocalAlarm

nvoManOverride

nvoMode

nvoOccCmd

nvoManOverride_R

nvoMode_R

nvoOccCmd_R

nvoPressAct

nvoPressAlarm

nvoPressSet

nvoSummaryAlarm

nvoSwitchPos

nvoVelocityAct

nvoVelocitySet

nvoVolflowAct

nvoVolflowSet

nvoVolTotalExh

nvoVolTotalSup

nvoWireSensorPos

nvoSystemDevices

nvoStateDIO

nvoSC_LockHP

nvoSC_GetPos

nvoSC_Alarm

Virtual functions

Variables of firmware versions 1.0 and 2.0

The variables marked ‘X’ are available for

firmware version 2.0 and higher.

X

X

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)10

6 Installation

For installation, wiring, and commissioning

observe the recognised technical regulations,

especially safety and accident prevention

regulations.

For any wiring work follow the national and

local regulations and guidelines for electrical

installation.

Installation

The expansion module is to be fitted into the casing

of a TCU3 controller or TAM adapter module.

Step 1

Screw the four distance pieces into the

corresponding openings in the TCU3 or TAM

main PCB and tighten them (hand-tight only).

Step 2

Take the pin header and push it from below

through the EM-LON PCB just far enough such

that the pins protrude slightly on the upper side.

Danger!

Danger of electric shock! Do not touch any

live components! Electrical equipment

carries a dangerous electrical voltage

during operation.

• Only skilled qualified electricians are

allowed to work on the electrical system.

• Switch off the power supply before

working on any electrical equipment.

Important!

Danger of injury from the metal pins of the

pin header.

Wear electrician gloves for protection.

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013) 11

6 Installation

Step 3

Take the EM-LON PCB with the upside up and

position it on the TCU3 or TAM main PCB such that

the pin header is exactly above the corresponding

plug-in base, and the holes for the distance pieces

are above the distance pieces. Then press the PCB

onto the distance pieces.

• In case the positions do not exactly line up,

check whether the pin header is still correctly

positioned.Repeat step 2.

• If the pins have been pushed too far through the

PCB (step 2), the electrical connection may not

work properly. Repeat step 2.

Step 4

Fix the PCB using the four fixing screws .Tighten

the screws only hand-tight.

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)12

For installation, wiring, and commissioning

observe the recognised technical regulations,

especially safety and accident prevention

regulations.

For any wiring work follow the national and

local regulations and guidelines for electrical

installation.

Danger!

Danger of electric shock! Do not touch any

live components! Electrical equipment

carries a dangerous electrical voltage

during operation.

• Only skilled qualified electricians are

allowed to work on the electrical system.

• Switch off the power supply before

working on any electrical equipment.

Making connections

The EM-LON PCB has terminals for two bus cables

of a LonWorks network. Depending on the network

topology, controllers at the end of a chain may be

connected to one bus, controllers at other positions

in the chain may be connected to two buses.

Strip the insulation from at least two wires of the bus

cable, insert the bare wires into the terminals and

tighten the screws.

• Fix the bus cable to the casing using the wire

clamping bracket.

• Connect the shield of shielded cables to the

SH terminals.Within a chain (channel) connect

the shield only at one point with the earth.

Earthing the shield at every controller will

lead to interferential voltages.

• To avoid reflections at the end of a chain

(channel) use a terminator.

Recommended bus cables

Bus cables to TIA 568A, category 5

• Belden 8471 or 85102

• Cables to DOCSIS specification level IV

• JY(St)Y 2×2×0.8 (use only twisted pair for

LON-A and LON-B)

Bus

LON-B

LON-A

SH (shield)

7 Wiring

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013) 13

8 Commissioning

9 Maintenance

Commissioning

Commissioning the LonWorks interface requires

detailed technical knowledge and special software,

e.g. Echelon LonMaker.The installation should only

be carried out by qualified experts.

1.Commissioning

Press the service pin push button and download

the software for the EASYLAB LonWorks node.

The software for the EM-LON expansion module

is available for download on our website.

2.Binding

Create the logical bindings for the network

variables to be transferred by the EM-LON

expansion module. As an alternative, use

polling.

3.Configuration

If necessary, adjust the configuration for

nciMaxSendTime or nciConfig_Occ.

Maintenance

The EM-LON expansion module is

maintenance-free.

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)14

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013) 15

EM-LON Operating Manual / Leaflet no. M375EV4 (3/2013)16

Other manuals for EM-LON

1

Table of contents

Other Trox Computer Hardware manuals

Popular Computer Hardware manuals by other brands

GigaDevice Semiconductor

GigaDevice Semiconductor GD32130F-START user guide

ADLINK Technology

ADLINK Technology cPCI-9116 user guide

ESD

ESD CPCI-DP-2S Hardware manual

Texas Instruments

Texas Instruments HVL038 manual

ADLINK Technology

ADLINK Technology NuDAQ DAQ-2500 Series user guide

Vtron

Vtron Digicom Ark5000 user manual