Trox TVZ User manual

TROX UK Limited

Caxton Way

Thetford

Norfolk, IP24 3SQ

UK

Phone: +44 (0) 1842 754545

Email: [email protected]

https://www.troxuk.co.uk

Standalone

Electric Heater

Units

Type TVZ

General information

About this manual

This operating and installation manual enables

operating or service personnel to correctly install the

standalone electric heater unit and to use it safely and

efficiently.

This operating and installation manual is intended for

use by fitting and installation companies, in-house

technicians, technical staff, properly trained persons,

and qualified electricians or air conditioning

technicians.

It is essential that these individuals read and fully

understand this manual before starting any work. The

basic prerequisite for safe working is to comply with the

safety notes and all instructions in this manual.

The local regulations for health and safety at work and

the general safety regulations for the area of

application of the ventilation unit also apply.

This manual must be given to the system owner when

handing over the system. The system owner must

include the manual with the system documentation. The

manual must be kept in a place that is accessible at all

times.

Illustrations in this manual are mainly for information and

may differ from the actual design.

Other applicable documentation

TROX TVZ technical documentation

Project specific documents (if any)

TROX Technical Service

To ensure that your request is processed as quickly as

possible, please keep the following information ready:

Product name

TROX order number

Delivery date

Brief description of the fault

Online www.troxuk.co.uk

Phone +44 (0) 1842 754545

Design changes reserved. All rights reserved. TROX UK Ltd (05/2018)

Standalone Electric Heater Units Type TVZ 1

Table of contents

1 Unit Overview …………………………………………………. 3

2 Safety ……………………...……………………………………. 4

2.1 Safety notes ………...……………………………………. 4

2.2 Correct use ………….……………………………………. 4

2.3 Safety signs ………...……………………………………. 4

2.4 Electric shock hazard ………...…………………………. 5

2.5 Risks caused by an unsuitable installation location …. 5

2.6 Qualified staff ……...……………………………………. 5

2.7 Personal protective equipment ………………………. 6

3 Transport and storage ………..……………………………. 6

4 Installation ………...…………………..………………………. 7

4.1 General installation information ……………….………. 7

4.2 Installing the standalone heater unit …………………. 7

4.3 Connecting pressure switch ……..………….…………. 8

4.4 Making electrical connections …………………………. 8

5 Initial commissioning ………...………………….…………. 9

5.1 Unit inspection ………...…………………….….………. 9

5.2 Initial start up ………...……………………….…………. 9

5.3 Post start up checks ………...………………….………. 10

5.4 Control Strategy ………...……………...………………. 10

5.5 Troubleshooting ………...………………………………. 10

6 Maintenance ………...………………………....……….……. 11

6.1 Maintenance ………...…………………………….……. 11

6.2 Commissioning report/Maintenance report …….……. 12

7 Replacement parts list ………...……………………………. 13

2Standalone Electric Heater Units Type TVZ

Important notes

1 Unit overview

Heater element terminal enclosure side

This enclosure houses the heater element electrical

connections, and the high temperature cut out.

Controls enclosure side

This enclosure houses the controls supplied with the

unit, such as:

- Fuses

- Site mains connection terminals

- Earth stud

- Thyristor

- Pressure switch

- Transformer

- Safety relay (or contactor)

Functional description

TROX standalone electric heaters are fitted to the

supply air ductwork as and where indicated on the

Record Drawings usually in conjunction with a TROX

TVZ VAV unit.

VAV terminal boxes control primary air to provide a

variable air supply to the occupied zones of the

building. For a more detailed description of the terminal

boxes refer to TROX TECHNIK literature.

The standalone electric heaters unit are complete with

controls including thyristor, fuses and safety interlocks.

A low differential air pressure switch is fitted. This

switch will de-energize the heating element if the

airflow reduces below the minimum required to operate

the heater safely (by removing the heat from the

element)

An automatic reset high temperature cut out (HTCO) is

fitted and set to 40ºC. The HTCO will de-energize the

heating element if the air temperature inside the duct is

too hot to operate the heater safely.

The heater is manufactured to British Standards /

Codes and fully factory tested.

The integral air heater has elements designed for black

heat operation consisting of nickel chrome wire in a

stainless steel tube filled with magnesium oxide

insulation. The heater elements are wired into the

control enclosure where the earth stud and fuse(s) are

supplied.

Control Strategy

Control of the heater is step-less control by thyristor

responding to an external 0-10Vdc control signal.

The control strategy for the heater must allow a

minimum of 10 minutes run on time to allow the heater

element to safely cool at the end of the heating cycle.

During this time the minimum heating cycle volume

must be maintained in the duct for at least 10 minutes

after the heater control signal is switched off.

Never remove the airflow whilst the heater battery is

running as this will result in excessive ambient

temperature inside the heater duct and may trip the

high temperature cut outs.

If the HTCO trips due to an error or fault, although it

will reset when the unit has cooled down, it is

recommended that the cause of the error or fault is

investigated and rectified, and that the HTCO is

replaced before the heater is put back into service.

Standalone Electric Heater Units Type TVZ 3

2

Safety

2.1 Safety notes

Symbols are used in this manual to alert readers to

areas of potential hazard. Signal words express the

degree of the hazard.

Comply with all safety instructions and proceed carefully

to avoid accidents, injuries and damage to property.

2.2 Correct use

Standalone electric heater units are used (in

conjunction with TVZ units) or the air conditioning of

internal spaces such as offices.

Ventilation

Heating

The unit is designed for internal installation behind false

ceilings or freely suspended from the structural soffit

(exposed). The unit has to be properly installed by

competent, qualified operatives.

Correct use also involves complying with all the

information provided in this manual.

Any use that goes beyond the correct use or any

different use of the unit is regarded as incorrect use.

Incorrect use

2.3 Safety signs

The following symbols and signs are found on the unit.

They apply to the very location where they are found.

Electrical voltage

Hazardous electrical voltage is present in the unit. Only

skilled qualified electricians are allowed to work on

parts of the unit marked with this symbol. Such work

must be carried out only by skilled qualified

electricians.

Standalone Electric Heater Units Type TVZ

DANGER!

Imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING!

CAUTION!

Potentially hazardous situation which, if not

avoided, may result in death or serious injury.

Potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Danger due to incorrect use!

Incorrect use of the unit can lead to dangerous

situations.

Incorrect use includes:

Any use that is not described in this

operating manual

Operation that does not comply with the

technical data

Modifying of the unit by others, tampering

with the unit

Use, installation, operation, maintenance

or repair other than described in this

manual

Having work carried out by unqualified

individuals

Use of non-genuine replacement parts or

accessories, whose quality and function

are not equivalent to those of the original

parts

Operation in rooms with explosive gases

or gas mixtures

Operation in rooms where the supply or

extract air contains particles that are

conductive, aggressive, corrosive,

combustible or hazardous to health

Operation in rooms where the humidity is

permanently high (> 90 %)

Operation outdoors

Use for enforced ventilation

Operation without air filters

WARNING!

Safety

4

Safety

Controls access panel

Only skilled qualified electricians are allowed to open the

controls access panel. Ensure that the electrical supply

is isolated and verify that no voltage is present on any

mains circuit before you open the cover to access the

terminal connections.

Heating element terminal enclosure access panel

Only skilled qualified electricians are allowed to open the

heating element terminal enclosure access panel.

Ensure that the electrical supply is isolated and verify

that no voltage is present on any mains circuit before

you open the cover to access the terminal connections.

2.4 Electric shock hazard

2.5 Risks caused by an unsuitable

installation location

2.6 Qualified staff

Qualification

The work described in this manual has to be carried

out by individuals with the qualification, training,

knowledge and experience described below:

Facility manager

Facility managers are trained individuals who under-

stand any potential hazards related to the work under

consideration, and who recognize and avoid any risks

involved. Facility managers must not carry out any jobs

beyond regular operation unless explicitly stated in this

manual and unless the system owner has specifically

agreed to them. Training to a facility manager is pro-

vided by the HVAC contractor when the system is

handed over.

A facility manager's tasks include cleaning the unit,

performing functional tests and regular checks, and

carrying out maintenance and adjustment work.

HVAC technician

HVAC technicians are individuals who have sufficient

professional or technical training in the field they are

working in to enable them to carry out their assigned

duties at the level of responsibility allocated to them

and in compliance with the relevant guidelines, safety

regulations and instructions. HVAC technicians are

individuals who have in-depth knowledge and skills

related to HVAC systems; they are also responsible for

the professional completion of the work under

consideration.

HVAC technicians are individuals who have sufficient

professional or technical training, knowledge and

actual experience to enable them to work on HVAC

systems, understand any potential hazards related to

the work under consideration, and recognize and avoid

any risks involved.

Standalone Electric Heater Units Type TVZ 5

Danger of death due to electric current!

Danger of electric shock! Do not touch any live

components! Damaged insulation or parts are a life

threatening hazard.

Only a skilled qualified electrician must work

on the electrical systems.

If the insulation is damaged, disconnect the

power supply immediately and have the

insulation repaired.

Isolate the power supply and verify no voltage

is present using an approved voltage indicator

before carrying out maintenance or cleaning.

Ensure that live parts do not come into

contact with moisture.

DANGER!

WARNING!

Risks caused by an unsuitable installation lo-

cation!

Installing the unit in an unsuitable location can

lead to dangerous situations.

The unit should preferably be installed in a

thermally insulated, low-leakage building.

Frost free and dry installation location.

Install the unit in a manor to protect the unit

from being tampered with by unauthorized

individuals.

The unit must remain accessible for

maintenance and cleaning.

Network administrator

Network administrators design, install, configure and

maintain the IT infrastructure in companies or

organizations.

Skilled qualified electrician

Skilled qualified electricians are individuals who have

sufficient professional or technical training, knowledge,

experience and qualifications to relevant local wiring

regulations to enable them to work on electrical systems,

understand any potential hazards related to the work

under consideration, and recognize and avoid any risks

involved.

Any work has to be carried out by individuals who can

be expected to carry out their assigned duties reliably.

Individuals whose reaction time is delayed due to

alcohol, drugs or other medication must not carry out

any work.

2.7 Personal protective equipment

Personal protective equipment is equipment that

protects the user against health or safety risks at work.

Personal protective equipment must be worn for various

types of work; the protective equipment required is

listed in this manual together with the description of each

type of work.

Description of personal protective equipment:

Industrial safety helmet

Industrial safety helmets protect the head from falling

objects, suspended loads, and the effects of striking the

head against stationary objects.

Protective gloves

Protective gloves protect hands from friction, abrasions,

punctures, deep cuts, and direct contact with hot

surfaces.

Safety shoes

Safety shoes protect the feet from crushing, falling parts

and prevent slipping on a slippery floor.

3 Transport and storage

Checking delivered goods

Check delivered items immediately after arrival for

transport damage and completeness.

If there is any visible damage, proceed as follows:

Either do not accept the delivered items, or

accept them with reservations.

Note down the damage on the shipping

documents or on the shipping company's

delivery note.

Immediately file a complaint with the shipping

company and vendor.

Transport

Hazardous electrical voltage that is present in the

ventilation unit. Only skilled qualified electricians are

allowed to work on parts of the ventilation unit marked

with this symbol. Such work must be carried out only

by skilled qualified electricians or the technical service.

If possible, take the unit in its transport pack-

aging up to the installation location.

Use only lifting and transport gear designed for

the required load.

Always secure the load against tipping and

falling.

Do not move bulky items just by yourself. Get

help to prevent injuries and damage.

Standalone Electric Heater Units Type TVZ

Transport and storage

6

File a complaint as soon as you detect any damage.

Claims for compensation can be filed only within the

complaint period.

Danger of injury from sharp edges, sharp corners

and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

Be careful when carrying out any work.

Wear protective gloves, safety shoes and a

hard hat.

CAUTION!

Installation

Storage

Please note:

Store the unit only in its original packaging

Protect the unit from the effects of weather

Protect the unit from humidity, dust and

contamination

Storage temperature: -10 °C to 50 °C.

Relative humidity: 95 % max., no condensation

Packaging

Properly dispose of packaging material.

4 Installation

4.1 General installation information

Before installation

Before you install the unit, take suitable precautions to

protect openings from contamination during installation.

If this is not possible, at least cover the unit or take other

precautions to protect it from contamination. In this case

you have to ensure that the unit cannot be started.

Ensure that all components are clean before you install

them. If necessary, clean them thoroughly. If you have to

interrupt the installation procedure, protect all openings

from the ingress of dust or moisture.

Installation information

Install the ventilation unit preferably in a thermally

insulated, low-leakage building.

Frost free and dry installation location.

Installation and connections to be performed by

others; fixing, connection and sealing material to

be provided by others

Install the unit only on structural elements that can

carry the load of the unit.

Use only certified fixing systems.

The unit and controls must remain completely

accessible for maintenance.

Installation

The unit is to be duct mounted.

Ensure the weight of the unit and accessories are

correctly matched to the supports (if any).

Suspension components for installing the unit are not

included in the supply package, but (if required) have to

be selected by others and fit for the project specific

installation.

4.2 Installing the standalone heater unit

Personnel:

HVAC technician

Remove all packaging from the inlet and outlet

connections. Only remove packaging just before

connecting the adjacent ductwork.

Before connecting ductwork check for any debris and

remove if necessary.

The unit can be installed in the false ceiling or the false

floor of the building using the mounting support points

on the unit casing. When using other supporting

methods please refer to our Technical Department for

approval.

All duct connections should be well sealed against air

leakage.

Adequate access must be provided to the controls

enclosure on the side of the box.

Ensure adjacent duct work has suitable size access

panel or similar arrangement for cleaning and

maintenance of the heater element and HTCO probe.

Allow minimum of 200mm clearance for the removal of

the controls enclosure lid and heater enclosure lid.

Ensure the unit is installed with the

correct orientation, according to the

TOP DIRECTION label on the side.

Ensure the unit is

installed with the correct

direction of airflow, as

indicated by the label on

the base of the unit.

Standalone Electric Heater Units Type TVZ 7

4.3 Connecting pressure switch

Personnel:

HVAC technician

Protective equipment:

Industrial safety helmet

Safety shoes

Protective gloves

The pressure switch is intended to connect into the flow

grid connecting tubes on a VAV Flow grid.

Cut the VAV flow grid tubes and insert 'T' pieces

to join the tubes together again.

Then connect 4.2mm internal diameter tube to the

'T' pieces and the other end to the pressure

switch. Use reducers if the VAV flow grid pipes

are not the correct size.

Make sure that the positive pressure flow grid

tube is connected to the positive pressure

connection of the pressure switch and the

negative pressure flow grid tube is connected to

the negative pressure connection of the pressure

switch.

Secure the pipes when installed to ensure it is not

possible for the pipes to become “kinked”.

Always observe the minimum bending radii of the

tubing used, typically 60mm.

4.4 Making electrical connections

Notes on the electrical installation

Any cables must be designed for the supply voltage for

which they will be used. The length and cross section

as well as any contact resistance may increase voltage

losses. The power rating of each unit must also be

considered. A skilled qualified electrician has to select

the correct cable types and sizes. This job must only

be carried out by specialist electrical companies.

Electrical connection must comply with any

applicable regulations and follow the code of

good practice.

The connection data can be found on the wiring

diagrams.

Protect any connections from physical damage.

Secure cables entering the electrical enclosures

with suitable cable glands.

If any maintenance jobs have to be carried out,

the unit first has to be de-energised and safely

isolated (all phases). No voltage must be

present.

Personnel:

Skilled qualified electrician

Standalone Electric Heater Units Type TVZ

Installation

8

Danger of injury from sharp edges, sharp corners

and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

Be careful when carrying out any work.

Wear protective gloves, safety shoes and a

hard hat.

CAUTION!

Negative pressure connection

Positive pressure connection

DANGER!

It is not recommended to leave one side of the

differential pressure switch open to atmospheric

pressure and rely on the downstream external static

pressure to operate the switch because this does

not “prove” airflow is sufficient.

DANGER!

Electric shock hazard! Electrical equipment

carries a dangerous electrical voltage!

Only skilled qualified electricians are

allowed to work on the electrical system

and to connect the unit to the mains.

Isolate the unit from the mains (all phases)

and secure the unit against inadvertently

being energized on again.

Verify that no voltage is present using an

approved voltage indicator.

Carry out assembly or connection jobs only

as long as no voltage is present.

Installation

Take off the controls enclosure lid; to do so, loosen and

remove the M5 pozi screws from the front of the

enclosure, then remove the lid.

Connect the unit according to the wiring diagram.

Refer to TROX wiring diagram within controls

enclosure on each unit (as shown above).

Use sheathed cable, ensuring the cable is suitably

secured and supported (e.g. cable gland). A

Ø20mm hole is provided for mains electrical entry

to the controls enclosure.

The unit voltage rating will be specified on the

rating label inside the controls enclosure, either:

230Vac, 1ph, 50-60Hz

or

400Vac, 3ph, 50-60Hz

Making electrical connections professionally:

Check and ensure that the actual supply voltage

is as indicated by the unit rating label fixed inside

the controls enclosure.

Ensure that the unit has been correctly earthed.

Check that the controls enclosure lid is installed

and securely fastened.

The unit and controls must remain completely

accessible for maintenance.

Communications, network and BMS wiring

should be separated from power, controls and

signal wiring.

If the units have been stored for more than 3

months, all electrical terminals should be

checked and insulation resistance checks must

be carried out.

Check the insulation resistance of the heating

elements is greater than 1MΩ.

All wiring must comply with local wiring

regulations. The factory made internal wiring

complies with BS 7671: IET Wiring Regulations

5 Initial commissioning

Personnel:

Skilled qualified electrician

5.1 Unit inspection

Before initial commissioning:

Remove protective film, if any.

Ensure that the unit is clean, and clean if

necessary.

Check and ensure that the actual supply voltage

is in accordance with the unit electrical rating

label.

Ensure that the unit has been correctly earthed.

5.2 Initial start up

Standalone Electric Heater Units Type TVZ 9

Danger of electric shock! Do not touch any live

components! Electrical equipment carries a

dangerous electrical voltage.

Only skilled qualified electricians are allowed

to work on the electrical system.

Isolate the power supply before working on

any electrical equipment.

DANGER!

The unit must not be energised until all initial

commissioning checks have been completed

satisfactorily.

Rectification works to correct incomplete

initial commissioning checks should be

carried out by skilled, qualified operatives.

CAUTION!

Once all unit inspection checks have been

completed and any issues identified are

rectified, the unit must have the minimum airflow

flowing before it can be energized.

CAUTION!

Pressure switch set-up procedure

With the air volume at the Minimum heating

volume (as shown above), switch on the power

supply.

Using a No.7 slotted screwdriver, set up the

pressure switch by turning the screw CW until the

heater safety relay (or contactor) is de-energized.

Slowly turn the screw back CCW until the heater

Relay or Contactor energizes again.

5.3 Post start up checks

Check the thyristor is working. There should be an LED

indication to show the output power according to:

For 1-phase heaters,

CONTROL & LOAD LEDs indicate as follows:

Green LED - Control input (0-10Vdc)

0 V, flashing 0.5s ON, 0.5s OFF

>0 V, fully ON

Yellow LED - Load ON

For 3-phase heaters,

Red LED flashes depending on the power output.

OFF = load OFF

ON = load ON

Flashing = partially ON (proportional to control signal)

5.4 Control Strategy

The control strategy for the heater must allow a

minimum of 10 minutes run on time to allow the heater

element to safely cool at the end of the heating cycle.

During this time the minimum heating cycle volume

must be maintained in the duct for at least 10 minutes

after the heater control signal is switched off.

5.5 Troubleshooting

If for any reason the thyristor does not start the heating

cycle, check the following:

Check the 0-10Vdc control signal is being

applied correctly to the thyristor.

Check that the airflow is greater than the

minimum airflow specified for the unit, and that

the airflow is sufficient to operate the pressure

switch.

Check that the HTCO (inside the heater terminal

enclosure) is set at 40C and has not tripped. The

correct setting is shown below:

Check the unit fuses have not ruptured.

Standalone Electric Heater Units Type TVZ

Commissioning

10

CAUTION!

If the HTCO trips due to an error or fault, although it

will reset when the unit has cooled down, it is

recommended that the cause of the error or fault is

investigated and rectified, and that the HTCO is

replaced before the heater is put back into service.

CAUTION!

Never switch off the unit whilst the heater

battery is running as this will result in excessive

ambient temperature inside the heater duct and

may trip the high temperature cut outs.

Maintenance

6 Maintenance

6.1 Maintenance

The units are virtually maintenance free with no moving

parts and no lubrication required.

During initial operation of the system it is recommended

that a three month inspection period is used increasing

to a six/twelve months after eighteen months use.

Any components removed from the unit during

inspection and maintenance should be stored away

securely, at low level.

Ensure all components are re-installed in the correct

orientation and to the same unit with fixings securely

tightened.

Standalone Electric Heater Units Type TVZ 11

CAUTION!

Danger of injury from sharp edges, sharp

corners and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

Be careful when carrying out any work.

Wear protective gloves, safety shoes and a

hard hat.

DANGER!

Electric shock hazard! Electrical equipment

carries a dangerous electrical voltage!

Only skilled qualified electricians are

allowed to work on the electrical system

and to connect the unit to the mains.

Isolate the unit from the mains (all phases)

and secure the unit against inadvertently

being energized again.

Verify that no voltage is present using an

approved voltage indicator.

Carry out assembly or connection jobs only

as long as no voltage is present.

The heating elements inside the duct can

reach temperatures exceeding 300ºC. Do not

touch the elements.

If maintenance of the elements is required,

allow a minimum of 10 minutes cooling time

to allow the elements to cool down to a safe

temperature.

WARNING!

6.2 Commissioning report/Maintenance report

Maintenance measures

1) initial inspection period. After 12 month running period, inspection interval could increase to 6 month cycle

depending on reported findings

Standalone Electric Heater Units Type TVZ

Maintenance

12

Building: Floor: Unit:

Commissioning: ☐Maintenance: ☐Date:

Item to be checked Measures Interval [months] Done

3612 Yes No

Checking heater element(s) Remove dust and perform

insulation resistance test

between terminal and stainless

sheath.

X1) X☐☐

Checking high temperature cut

out operates

Adjust set point to ambient

temperature to check heater de-

energizes and reset to 40ºC

X☐☐

Checking the pressure switch

operates

Checking that the minimum

airflow is present, and when

not present the heater de-

energizes.

X☐☐

Comment:

Next

maintenance

scheduled for:

Signature:

(Technician)

Company:

(Stamp)

7 Replacement parts list

Standalone Electric Heater Units Type TVZ

Replacement Parts

13

Name Replacement part no.

Heating elements Refer to TROX

High temperature cut out 113898T

Pressure switch 008894T

Transformer 117210T

Relay 088313T

Contactor (3-phase only) 088388T

Thyristor (1-phase) – Carlo Gavazzi 123230T

Thyristor (3-phase) 088408T

Thyristor (1-phase) – Obsolete Imtec EC3/1 088316T

Thyristor (1-phase) – Obsolete Imtec EC6/1 088317T

You can identify order-specific components of the unit either by a code on the component itself or by

the reference number detailed on the label or TROX technical schedule.

Ordering replacement parts

Table of contents

Popular Electric Heater manuals by other brands

Valor Fires

Valor Fires 824 Blenheim Longlite Installer and owner guide

CONVECTAIR

CONVECTAIR CALYPSO 7825 Installation & operating instruction

Harvia

Harvia HH6 Instructions for installation and use

ThermoTec

ThermoTec AeroFlow MINI 650 user manual

Duraflame

Duraflame 5HM7000-B335 owner's manual

Harvia

Harvia BC45 Instructions for installation and use

Bromic Heating

Bromic Heating Tungsten 2000W Installation, instruction and service manual

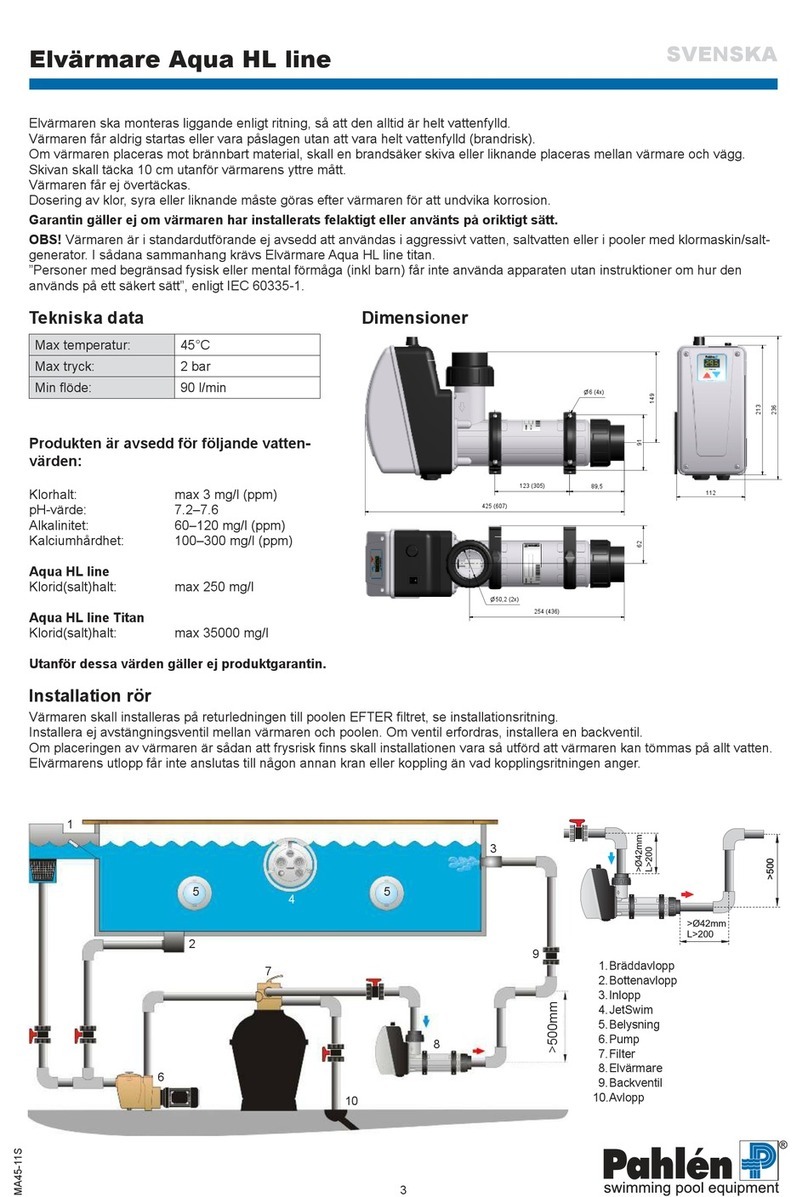

Pahlen

Pahlen Aqua HL manual

Black & Decker

Black & Decker BHOF04 instruction manual

Teesa

Teesa TSA8029 owner's manual

Twin-Star International

Twin-Star International Duraflame 18II332FGL-L operating instructions

KING

KING KBP series user manual