Trox RM-O-3-D Specification sheet

Operating and

installation Manual

Smoke Detector

TypeRM-O-3-D

For controlling fire and smoke protection dampers

General building inspectorate approval

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015)

Z-78.6-125

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015)2

Subject to changes / All rights reserved © TROX GmbH

Contents

TROX UK

Caxton Way,

Thetford, Norfolk, IP24 3SQ

Tel:+44(0)1842754545

Fax:+44(0)1842763051

E-Mail: service@troxuk.co.uk

www.troxuk.co.uk

1 General Information 3

Co-Applicable Documents 3

Explanation of the symbols of this manual 3

Explanation of the symbols on the smoke

detector RM-O-3-DD 3

2 Safety and Intended Use 4

General information on safety

Standards and guidelines

Repair and spare parts

Notes on environmental protection

Intended use

Prohibited use

Residual dangers

3 Product Description 5

Function description 5

Description RM-O-3-E 5

Operating status displays 6

4 Technical Data 7

5 Transport, Storage

and Packaging 7

Checking the delivery

Transportation on site

Storage

Packaging

6 Installation 8

Installation in fire damper FK-EU 8

Installation in air duct or V-part 9

7 Electrical Installation 10

230 V AC supply voltage 10

24 V DC supply voltage 10

Connection of fire / smoke damper 10

Connection of fan 10

Connection of contamination indicator 10

Connection of external reset button 10

8 Fuction Test/Commissioning 11

9 Maintenance 12

Maintenance 12

Inspection 12

Repair 12

10 Cleaning 12

Dismantling smoke detector head 12

Mounting smoke detector head

4

4

4

4

4

4

4

7

7

7

7

12

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015) 3

1 General Information

This operating manual describes the smoke

extraction device in the variants:

• RM-O-3-D for24V DCSupply Voltage

• RM-O-3-D for230 V ACSupply Voltage

In order to ensure the complete function of the

smoke extraction device RM-O-3-D, it is

necessary to read the instructions supplied with

the device before any use and to observe the

instructions contained therein. When the system

is handed over, the operating instructions must

be handed over to the plant operator. The system

operator must attach the operating instructions to

the system documentation.

Malfunctions or damage caused by non-

observance of this manual or by non-compliance

with legal provisions do not give rise to liability

claims against the manufacturer.

These operating instructions are intended for

planners, installers and operators of ventilation

systems into which the smoke extraction device

is to be integrated. Furthermore, the operating

instructions are directed to persons performing

the following tasks:

• Transport and storage

• Installation

• Electrical installation

• Commissioning

• Maintenance

• Cleaning

Co-Applicable Documents

In addition to these operating instructions, the

general building inspectorate approval

Z-78.6-125 must be observed.

Explanation of the symbols of

this manual

Danger!

Marking a risk to life and limb by electrical

voltage.

Note

Identification of important notes or

information.

Explanation of the symbols on the

smoke detector RM-O-3-D

Danger!

Electric shock when opening the housing

cover due to live parts.

• The housing cover may only be opened

by qualified electricians.

• Switch off the power supply before

working on the electrical equipment.

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015)

4

2 Safety and Intended Use

General safety information

Only qualified personnel may carry out the work

described on the smoke extraction device. Only

electricians may work on the electrical

components.

For installation, electrical connection and

maintenance, sufficient space must be provided for

unimpeded operation at the smoke extraction

device.

Standards and guidelines

During all work on the smoke extraction device

u.a. to observe the following regulations and

guidelines:

• Geräte- und Produktsicherheitsgesetz

• Ordinance on Industrial Safety

• Building regulations

• Accident Prevention Regulations (BGV A1, BGV A3)

• Maintenance standards DIN 31051 and

EN 13306

• All other relevant standards and regulations for fire

protection

Repair and replacement parts

The smoke detector RM-O-3-D is a safety

component specially developed for fire protection

in ventilation systems. To maintain the function,

only original TROX replacement parts may be

used for repair.

Notes on environmental protection

To protect the environment, please pay attention

to the following points:

• The packaging of the smoke detector must be

disposed of in an environmentally sound manner.

• The smoke detector must be properly disposed of

by an authorized body after it has been taken out of

service.

• Electronic components must be disposed of in

accordance with national electronic scrap

regulations.

Intended Use

The smoke detector RM-O-3-D is used to control

and trigger fire or smoke dampers to prevent the

transmission of fire and smoke through the air

duct.

In addition, the smoke extraction device can be

used to shut down the fan of the ventilation

system.

The fire or smoke damper must be equipped with

an electric spring return actuator or a holding

magnet or a solenoid valve.

The operation of the smoke extraction device is

only permitted under consideration of the general

and special provisions of the general building

inspectorate approval Z-78.3-125. In addition,

the installation instructions and the technical data

of these operating and assembly instructions

must be observed.

Illegal use

The smoke detector must not be used under the

following conditions:

• Use in ventilation systems of commercial

kitchens (general kitchen exhaust air)

• Use inEx-Zones.

• Outdoor use without adequate protection

against weather conditions.

• Use in ventilation systems where the function

is hindered by heavy soiling, extreme humidity

or chemical contamination

• Use in installation situations in which an

inspection, maintenance or functional test

when installed is not possible.

Changes to the smoke detector and the use of

spare parts that are not approved by TROX are

not permitted.

Residual risks

TROX smoke detectors are subject to strict quality

controls during manufacture. In addition, a

functional test is carried out before delivery.

Damage during transport or installation may impair

the function. The proper function of the smoke

detection device must be checked during

commissioning and ensured in the course of

further operation by recurring maintenance

measures.

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015) 5

3 Product Description

Function Description

In order to prevent the spread of smoke in buildings

through the ventilation and air conditioning

systems, it is important to detect the smoke at an

early stage.

The smoke detector RM-O-3-D is used to control

and trigger fire and smoke dampers. It works

according to the scattered-light principle and

detects the smoke independently of temperature,

so that fire dampers close even before the

triggering temperature has been reached.

In addition, can be caused by the

Rauchauslöseein-direction switching off the fan.

The closing of the fire or smoke protection

damper occurs in the case of smoke detection by

interrupting the supply voltage.

The smoke detector can be used for fire or smoke

dampers with the following triggering devices:

• Electric spring return actuator (normally

CLOSED)

• Pneumatic drive (pressureless CLOSED)

• Holding magnet

①Casing

②LED redalarm position

③LEDyellowcontamination indicator

④LED green system monitoring

⑤Button Test/Reset

⑥Smoke detector head (Order No. M536HC7)

⑦Base

⑧Slot for 24 V DC board

⑨Connection terminals 230 V AC

⑩24 V DC PCB VWM (Order No. M516EJ4)

⑤

④

③

②

①

⑦

⑥

⑨

⑧

⑩

Description RM-O-3-D

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015)

6

3 Product Description

Operational states

LED display operating condition Damper position

Fire / smoke

protection damper

red yellow green

alarm relay signal relay

Ready for operation

Supply voltage OK

3412

Supply voltage is missing

3412

Supply voltage OK

Electronics defective

Smoke detector is missing

–

Alarm triggering immediately -

3412

Contamination 1)

70 % .... 90%

3412

Contamination 1)

> 90%

–

Alarm triggering immediately -

3412

Test/Reset

–

inspection –

3412

Smoke detection 2)

– Alarm triggering immediately -

3412

LED on

LED off

LED blinking

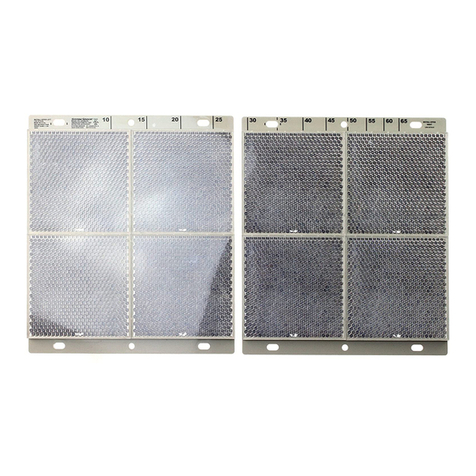

1) Contamination indicator

up to 70% – Normal range

> 70 % ... 90% – Warning

> 90% – Alarm

2)The alarm position triggered by smoke (event or

maintenance) can only be canceled by pressing the

push button after the smoke detector is smoke free

again.

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015) 7

4 Technical Data

RM-O-3-D

EMC immunity to EN 61000-6-1,

EN 61000-6-2,

EN 61000-6-3,

EN 61000-6-4

Supply voltage 230 V AC + 10 / – 15 %

50/60 Hz

oder

24 V DC ± 6 %

Power consumption 3 VA

Fuse T 100 L 250 V

Protection IP 42

Ambient temperature 0 °C … + 60 °C

Permissible air

speed

1 m/s ... 20 m/s

Permissible

humidity

≤95%RH,non-

condensing

Warning increased

contamination

> 70 %

System monitoring • > 90 % contamination

• Smoke detector is

missing

• Data not transmitting

Alarm relay

contact (trip,

contamination)

250 V 2 A

24 V DC 100 W

Mass 0,7 kg

5 Transport, Storage

and Packaging

Check the delivery

Check delivery immediately after delivery for

transport damage and completeness. In the case

of transport damage or incomplete delivery,

inform the freight forwarder and the supplier

immediately.

Complete delivery includes:

• Smoke detector RM-O-3-D

• Operating and installation manual

Transporting on the construction site

If necessary, transport the smoke detector to the

point of installation in the shipping container.

Storage

For interim storage observe the following points:

• Remove the foil from the shipping box.

• Protect the smoke detector from dust and dirt.

• Protect from moisture and direct sunlight.

• Do not expose the smoke detector (also

packed) directly to the weather.

• Do not store the smoke detector below - 40 ° C

and above 50 ° C.

Packaging

Dispose of packaging material properly

after unpacking.

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015)

8

6 Installation

Installation in fire damper FK-EU

The smoke extractor RM-O-3-D can be installed

in the inspection opening of fire dampers of the

FK-EU series. When doing so, observe the

installation location, see illustration on the right.

When using the FK-EU as overflow flap, in

accordance with the building inspectorate

approval Z-6.50-2031: install the smoke detector

RM-O-3-D in the upper inspection opening of the

fire damper.

Assembly sequence::

1. Place adapter ③ on inspection cover ② and

screw it to the housing of the fire damper with

self-tapping screws ((inspection cover serves

for centering).

2. Unscrew and remove inspection cover.

3. Insert the smoke detector RM-O-3-D ① into

the inspection opening and secure it to the

adapter with knurled nuts ⑤.

4. Connect the fire damper electrically to the

smoke detector, see "Electrical installation"

on page 10.

Note:

Older fire dampers of the FK-K90 and FK-EU

series may have a metal inspection cover.

In this case, the inspection cover can be

disassembled and the smoke extraction device

with the washers and wing nuts without adapters

mounted directly on the fire damper.

①Smoke detectorRM-O-3-D

②Inspection cover BSK (plastic)

③Adapter RM-O-3-D, order no.

Galvanized: A00000043410

Stainless steel: A00000043411

④ Tapping screws (4 pieces)

⑤ Knurled nuts (3 pieces)

①

③

④②

⑤

Installation in FK-EU

H 200 – 320 H 200 – 800

Installation location depending on the

height H

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015) 9

6 Einbau

Installation in Air Duct

The smoke extractor RM-O-3-D is installed in

the following procedure:

Note

For proper function, it must be ensured

that the smoke detector head is

constantly traversed by air. This results

in the following recommendations:

• Minimum distance of 1.5 × H between

smoke extraction device and bends,

controllers, etc.

• Install the smoke detector in the upper

third of the air duct (not in the corner

area).

• Install the smoke detector in the

direction of the air in front of the fire

or smoke damper.

1. Determine installation location and

attach sticker ①.

2. Make a hole for the smoke detector head of

the smoke detector.

3. Pre-drill holes for tapping screws.

4. Insert the smoke detector RM-O-3-D ②

into the hole 3 Secure the self-tapping

screws ③.

5. Connect the fire damper electrically to the

smoke detector, see "Electrical installation"

on page 10.

①Sticker

②Smoke detector RM-O-3-D

③Sheet metal screw 3 pieces, by others

Installation in Air Duct

① ② ③

Rauchauslöseeinrichtung

Auslösung / relase

Verschmutzung / pollution

Betrieb / operation

Test / Reset

Typ RM-O-3-D

A

A

Ø100

Ø140

Ø180

Ø160

~ 40~ 95

Ø7

23

Ø13

Dimensions

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015)10

7 Electrical Installation

L1 1 2 3 4 1 2NL1 N PE PE

L1 L2 L3

– + S1 S2 S3 S4 S5 S6

5–250 V

AC / DC

N(–) L(+)

PE N L

230 V AC

①

② ③

⑤

④

⑥

⑦N L

230 V AC Supply Voltage

Danger!

Electric shock when touching live parts.

Electrical equipment is under dangerous

electrical voltage.

• Only electricians may work on the

electrical components.

• Switch off the power supply before

working on the electrical equipment.

When connecting, observe the VDE guidelines

and local power supply company regulations!

The state regulations, in accordance with the

"Directive on fire protection requirements for piping

systems" in the currently valid version, must be

observed.

Supply voltage 230 V AC

Terminal strip L1, terminal L1 / N / PE

Connection is made on the basis of the adjacent

connection example.

Install the strain relief of the connection cable on

site.

Supply voltage 24 V DC

Terminal strip L4, terminal + / -

Connection is made using the connection

example on page 11.

The connection with 24 V DC may only be made

via the optionally available connection board

VWM (Order No. M516EJ4), as this causes

tripping in the event of impermissible voltage

fluctuations. Install the strain relief of the

connection cable on site.

Connection of fire / smoke damper

Terminal strip L2, terminal 3/4

In the range of permissible switching capacity

(see page 7) several fire or smoke dampers can

be connected in parallel.

Connection fan

Terminal strip L2, terminal 3/4

In the range of the permissible switching

capacity (see page 7), the fan can also be

switched off via the smoke release device. For

higher switching power, auxiliary relays must be

used.

Connection contamination indicator

Terminal strip L2, terminal 1 - 2

In the range of the permissible switching

capacity (see page 7), relays or indicator lights

can be switched or the forwarding to the fire

alarm technology implemented.

Connection of external reset button

Terminal strip L3, terminal 1 - 2

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015) 11

7 Electrical Installation 8 Functional Test/

Commissioning

A functional test shall be carried out before

commissioning, thereafter annually and after

modifications, e.g. Repair.

Without Smoke

Press the "Reset / Test" button on the smoke

extraction device or in the control panel (optional).

The circuit to the located on the fire or smoke-

protection shutter release device is interrupted;

the fire or smoke damper closes.

After relieving the button, fire and smoke

protection flaps with spring return drive or

pneumatic drive automatically move to the OPEN

position.

Note

Fire dampers with magnetic release

devices can only be opened manually on

site.

With Smoke

Spray the test gas through an opening in the

immediate vicinity of the smoke extraction device

into the air line (on-site testing). If the threshold

value (fire characteristic smoke) is exceeded, the

circuit for the extinguishing device located in the

fire or smoke damper is interrupted; the fire or

smoke damper closes.

To open - after the smoke detector is again smoke

free - press the "Test / Reset" button on the smoke

triggering device.

After relieving the button, fire and smoke

protection flaps with spring return drive or

pneumatic drive automatically move to the OPEN

position.

Note

Fire dampers with magnetic release

devices can only be opened manually on

site.

All operating, warning and alarm functions are

described on page 4.

24 V DC Supply Voltage

L1 1 2 3 4 1 2NL1 N PE PE

L1 L2 L3

– + S1 S2 S3 S4 S5 S6

5–250 V

AC / DC

+ – + –

24 V DC

L4

N(–) L(+)

– +

①

② ③

⑤

④

⑥

⑦

①Smoke detectorRM-O-3-D

②External contamination indicator

(by others)

③External button "Test / Reset"

④Triggering device fire / smoke

protection damper

⑤Damper position display CLOSED

⑥Damper position display OPEN

⑦Further tripping device or fan

Operating Instructions RM-O-3-D / Publication no. M375DD8 (08/2015)

12

9 Maintenance

Danger!

Electric shock when touching live parts.

Electrical equipment is under dangerous

electrical voltage.

• For cleaning, the housing must not be

opened.

• Do not use any liquids near the smoke

detector.

If it is dirty> 70% (yellow LED lit), the smoke

detector head should be cleaned.

• Cleaning the smoke detector by blowing it out

with oil and water-free compressed air.

If this measure is unsuccessful, the smoke

detector head must be replaced (Order No.

M536HC7).

• Removing contaminants on the strainer screens

for the air inlets.

Dismantling Smoke Detector Head

• Dismantle smoke extraction device ① from the

air duct.

• Turn smoke detector head ② counterclockwise

until the smoke detector head disengages.

• Remove smoke detector head from socket ③.

Mounting Smoke Detector Head

• Place smoke detector head ② on base ③.

• Turn the smoke detection head on the base until the

smoke detection head engages in the base.

• Turn the smoke detector head clockwise until the

smoke detector head clicks into place.

Note

After installation of the smoke detection

head, a functional test must be carried out.

①

②

③

Danger!

Electric shock when touching live parts.

Electrical equipment is under dangerous

electrical voltage.

• Only electricians may work on the

electrical components.

• Switch off the power supply before

working on the electrical equipment

Regular care and maintenance ensures the

operational readiness, operational safety and

service life of the smoke extraction device.

Maintenance is carried out in accordance with EN

13306 in conjunction with DIN 31051.

The maintenance is the responsibility of the

operator of the plant. The operator is responsible

for setting up a maintenance plan with the

definition of maintenance objectives and

functional safety with its maintenance

management.

Maintenance

The smoke detector RM-O-3-D and the drive-up

aid are maintenance-free with regard to wear.

Inspection

Before the first commissioning and after changes,

the smoke extraction device must be inspected.

Thereafter, the functional reliability of the smoke

evacuation device is to be checked at least once a

year. In addition, the state or building regulations

must be observed.

The test of each smoke extraction device must be

documented and evaluated. In the event of

deviations from the nominal condition, suitable

repair measures must be taken.

Repair

For safety reasons, repair work that influences the

fire protection may only be carried out by qualified

personnel or by the manufacturer. For repair only

original spare parts may be used. After a repair, a

functional test must be carried out, see "Function

test / commissioning" on page 11..

10 Cleaning

Table of contents

Other Trox Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

Vermont Castings

Vermont Castings Signature VC3624GS Assembly and owner's manual

Kidde

Kidde P4010ACSAQ-WF user guide

Innogy

Innogy WSD-2.0 manual

Honeywell

Honeywell 5800COMBO Installation and setup guide

FireAngel

FireAngel Thermoptek ST-622 user manual

Resolution Products

Resolution Products RE612 CryptiX quick start guide