Truckweight SMART SCALE Installation instructions

SMART SCALE

INSTALLATION & OPERATING MANUAL

Handheld - In Cab Display ICD V_1.49

Display power cable connects to truck power 8-30 volt

2

Table of Contents

Page

1.0 Introduction. 3

2.0 Home Screen (Main Axle Screen). 4

3.0 MENU Screen. 5

4.0 Keypad Screen. 5

5.0 Truck Set-Up. 6

6.0 Sensor Screen. 8

7.0 Calibration Screen. 9

8.0 Zeroing. 10

9.0 Drop and Hook. 11

10.0 WIFI set up. 12

11.0 Steps to update firmware in Display. 14

12.0 Serial Data RS232 weight data to tracking devices. 15

3

1.0. Introduction:

The Display is designed for both In Cab mounting and Handheld operation is a touch screen

with RF range of about 1000 feet line of site.

Display works with weight sensors for all suspension types; air, spring, walking beam, Chalmers,

Tuff Track, etc…

Note, when first powering unit on, wait 30 seconds for sensors to synchronize, before pressing

any buttons.

The Display can be powered by Truck power and/or internal Lithium-Ion re-chargeable battery

(optional).

Battery life is 5 hours when fully charged continuous use. WIFI turned off. WIFI is only used if

the firmware is being upgraded, then turned off after upgrade is loaded.

The display can be set up for any truck and trailer configuration with a truck that can hook up to

three trailers connected to one truck. The system can drop and hook between an unlimited

number of trailers.

Top Line(s) are equipment ID. Each sensor will have a unique ID and will have the axle position,

Front Axle, Drive Axle, Trailer, for example. You can have a truck and four trailers connected to

a truck.

Hook, is used to drop and hook different trailers.

4

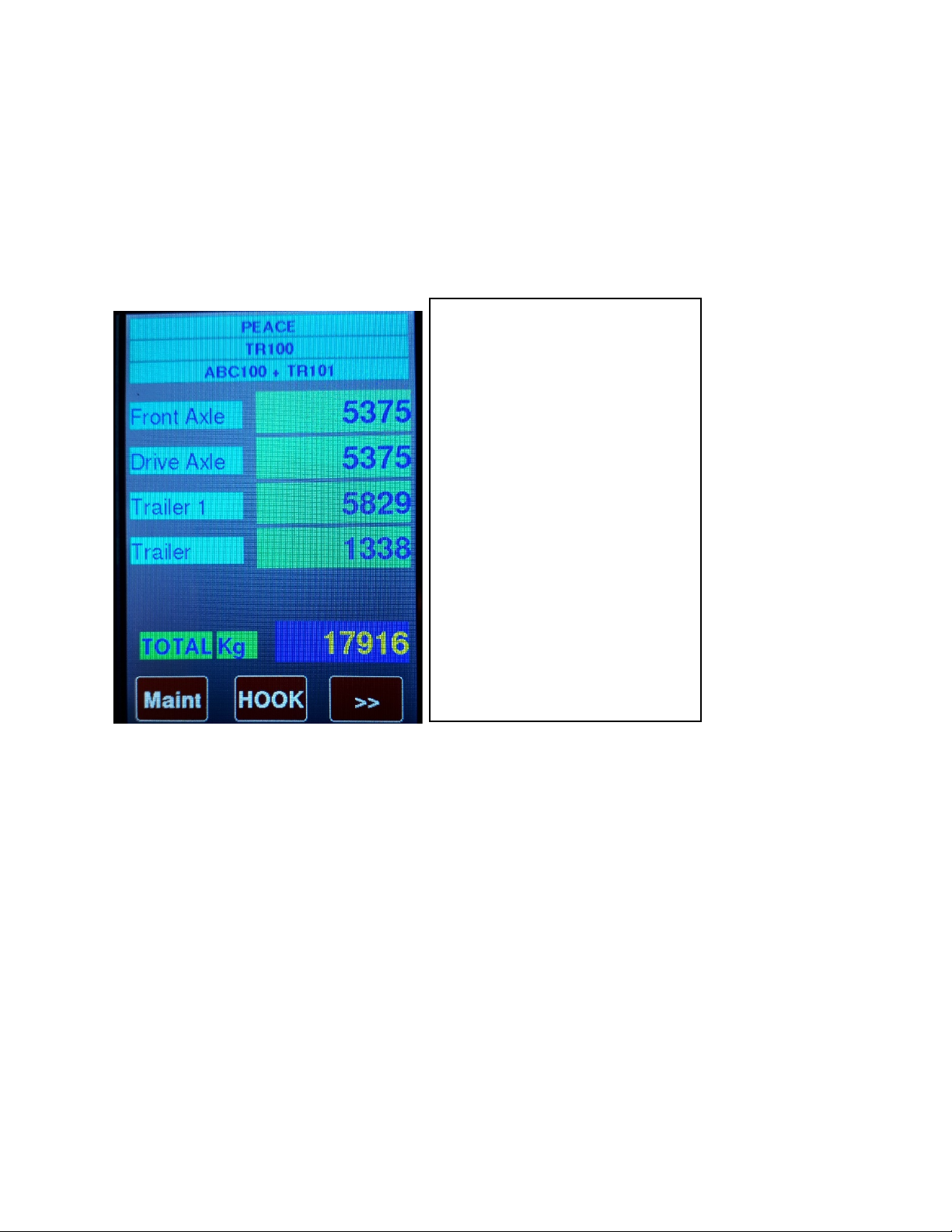

2.0 Home Screen - MAIN SCREEN AXLE WEIGHTS:

r

Once sensors are configured, press right arrows to display the pressure readings for each

sensor that appears on the Axle Screen (Home Screen). These reading will be recorded for

Empty Truck and Loaded Truck, after which, will entered into the Calibration screen for each

sensor.

First screen to show up after

Power up screen.

Showing axle weights and Total

Weight.

Maint Button (Maintenance)

Press to get Menu

Password: 11258

HOOK Button

Press to Hook or Drop equipment.

>> Button

Press to view pressures for

Calibration

5

3.0 MENU. – Maintenance Screen:

4.0. Keypad:

MAINTENANCE MENU. Password: 11258

To get in this menu you need to first enter Password.

CALIBRATION permits user to calibrate each Sensor.

TRUCK SETUP must first be used to setup

Name of the Truck and other configurations.

WIFI setup is only used when firmware is

Required to be upgraded.

RESTART SYSTEM by touching or tapping

The unit will be rebooted immediately.

This needs to be done of sensors are changed

6

5.0. Truck Setup:

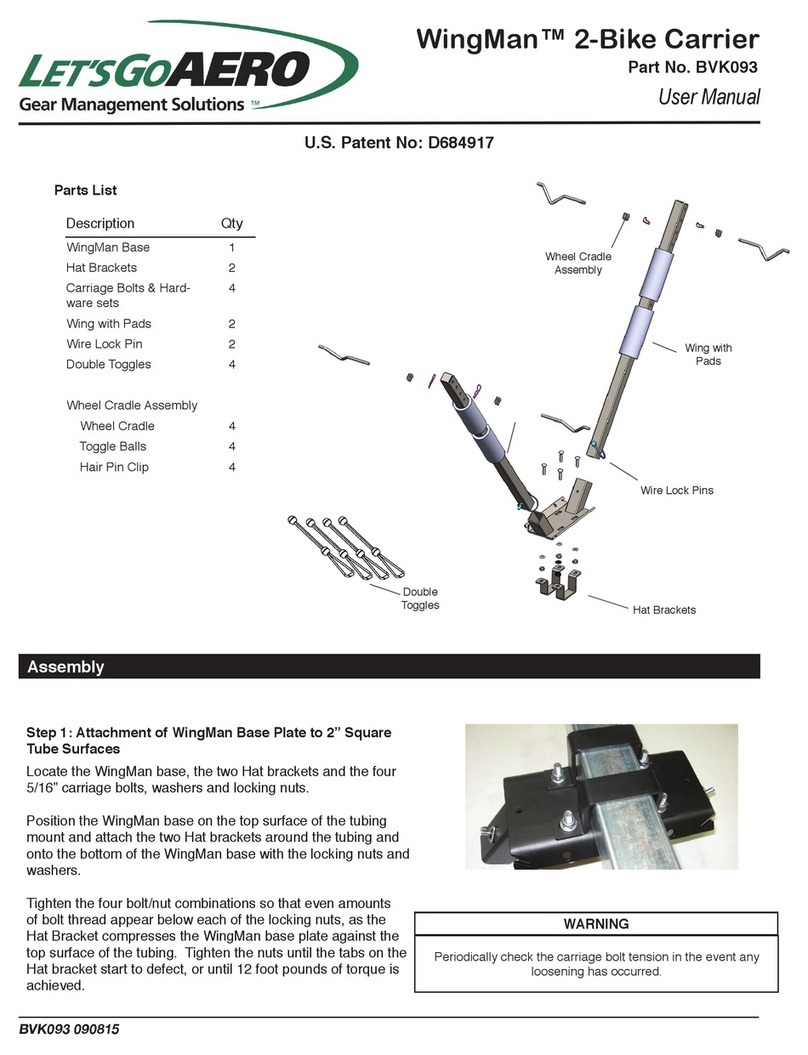

5.1 Truck Setup

KEYPAD

First screen is the numerical numbers.

To change it to Letters, press the A/1 button.

Press again for more letters.

Pressing the A/a button will shift the letters

To lower case.

Pressing the OK button will close this screen

With your text showing up in the other screen.

Or if it is a Password: 11258, will allow you to

enter MAINTENANCE mode.

The << button is not functional. Future use.

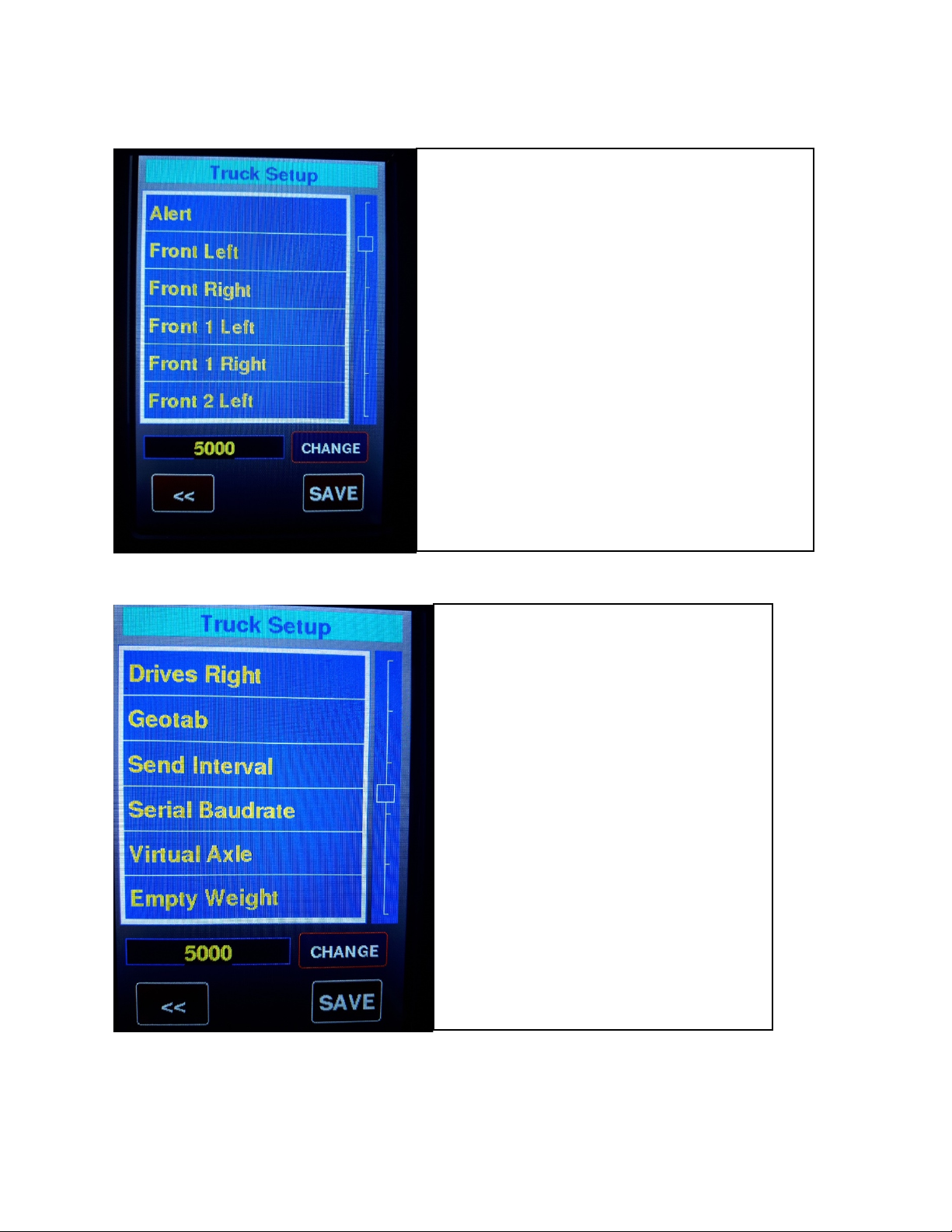

Truck setup (Configuration)

Selecting each item will show value just below

The list, use the Scroll on the right side to see

More items. Password: 11258

Truck Id is name of Truck this unit is installed on

Scale is either Imperial or Metric.

Min Lbs is the minimum increment it will show

In Main screen. Same with Min Kg (Metric).

Max Load is the limit but not used in this version.

Alert is either on or off, not used in this version.

To change any selection press the CHANGE

Button. And press the SAVE button to save it.

7

5.2 Truck Setup continued.

5.3 Truck Setup continued.

Truck setup (Continue)

Front Left or Right will show serial number

Of sensor attached to the Front Axle, Left or

Right is not important only the total of both.

The same for Front1, Front2, Drives.

These serial numbers are automatically picked

Up by the system but can be entered manually.

When powering up it may take up to 30 secondss

Or 1 minute for older sensors for all truck sensors

To be received. It is always better to enter them

Manually to prevent one sensor from being

Missed or was missing at power up.

Truck setup (Continue)

Geotab is a Communication to a host server,

But is not functional in this version.

Send Interval is also part of it and not functional.

Serial Baudrate is used by Geotab and Serial

Port and is not functional with this version.

Virtual Axle is used when it is required for one

Of the Front Axle. Select this and press CHANGE

to choose which Axle you want this to be

active, select NO Virtual if you are not using it.

Empty Weight and Full Weight is used to make

The virtual axle proportional to Drive Axles.

8

5.4. Truck Setup Continued.

6.0 Sensor Screen Setup.

Truck setup (Continue)

Note, if your trailer is always the hooked

to the same truck, you can use the same

Equipment ID used for the truck is Truck

Set-up. If you use the same equipment

ID for the truck and trailer, the trailer will

appear on the axle screen without the

need to Hook.

9

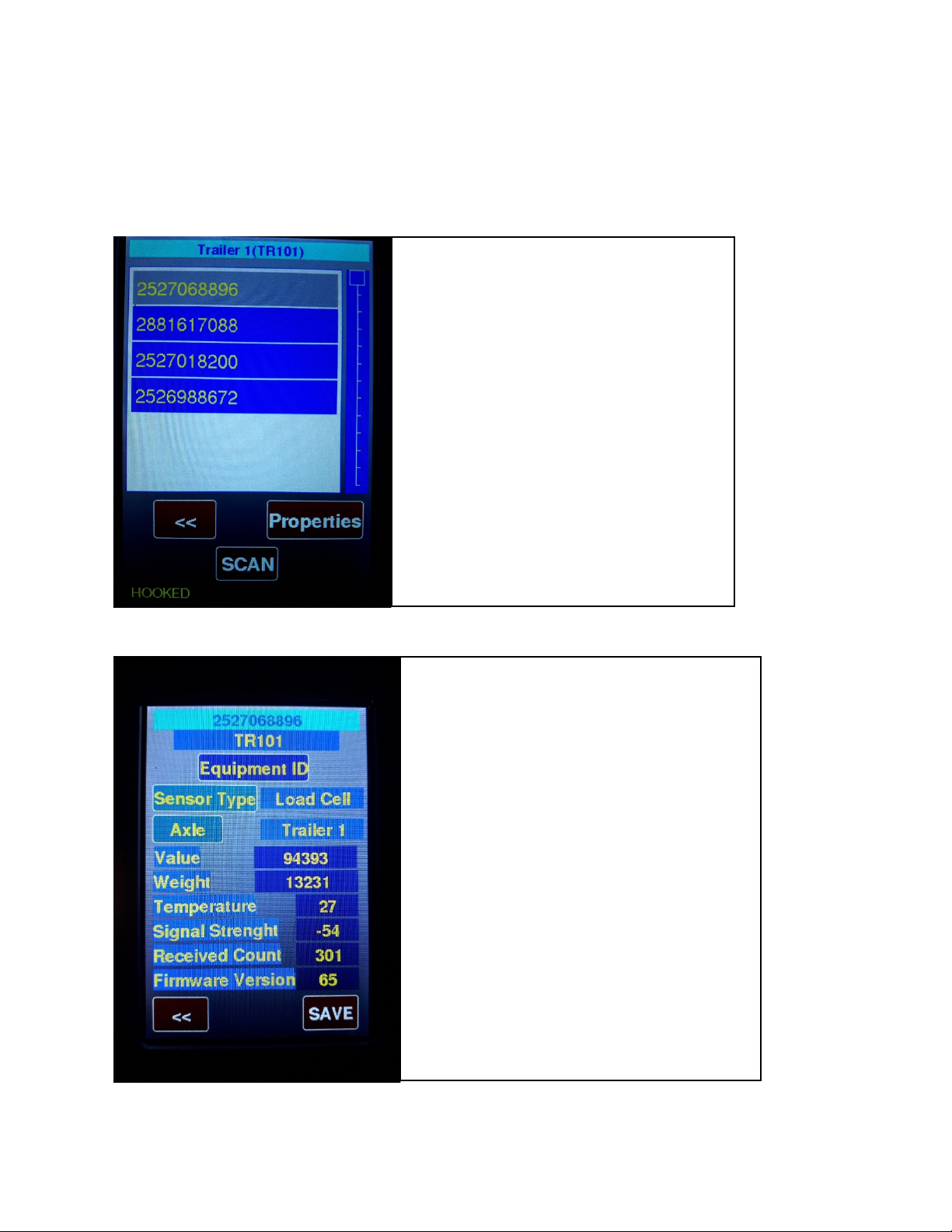

Note, sensors usually come configured, whereby, Equipment ID, axle position (front axle,

Drives, Trailer, Lift, Jeep, Stinger, etc…), and sensor type (air, load cell, etc.. are pre-set before

shipping. Each sensor’s configuration can be changed, if required.

6.1 Sensors

6.2 Sensors continued.

7.0 Calibration: Password: 11258.

SENSOR list screen.

Select which sensor you wish to see or change

Properties of sensor, changing selection will

Show Equipment it belongs to and Axle.

Press Properties Button will go into next

Screen below.

SENSOR Properties screen.

Press Sensor Type button to change sensor type.

Press Axle to change axle and select from list.

Value shows last value received from sensor.

Weight shows last weight received.

Temperature show sensor internal temp in

Centigrade.

Signal Strength shows sensor range value.

Received Count shows the packets received.

Press Save to send changes to sensor.

10

7.1 First record the axle group weights from the inground scale and the Pressure Values by

pressing the >> arrow to display the pressures. Record them Empty and Loaded

7.2 Select a sensor.

7.2 Enter Calibration Values.

Calibration selection screen.

Pressing the Serial number selection will

Cause you to go into calibration of this

Sensor. Pressing the << button will return you

To Maintenance screen.

Press >> to

enter

Press << to

return

11

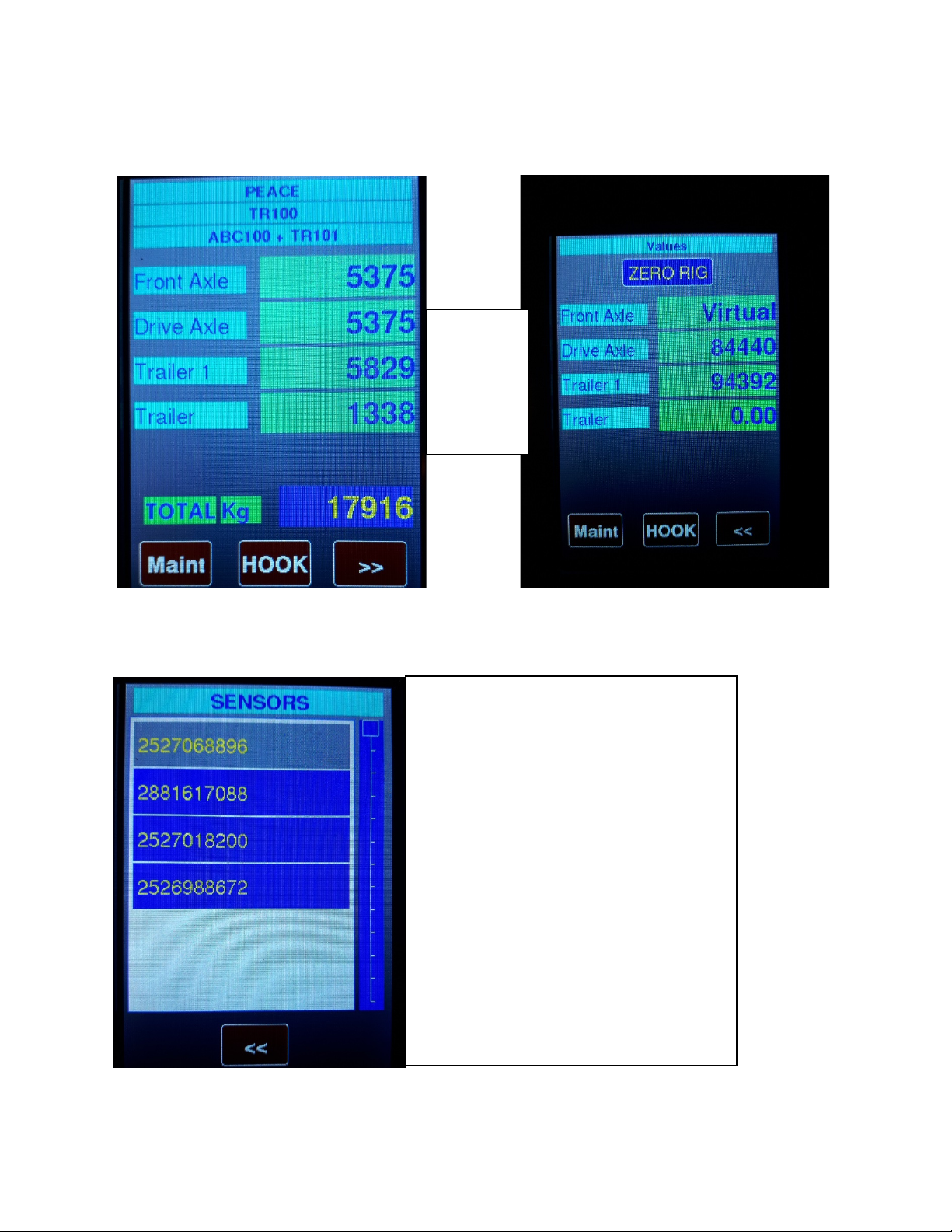

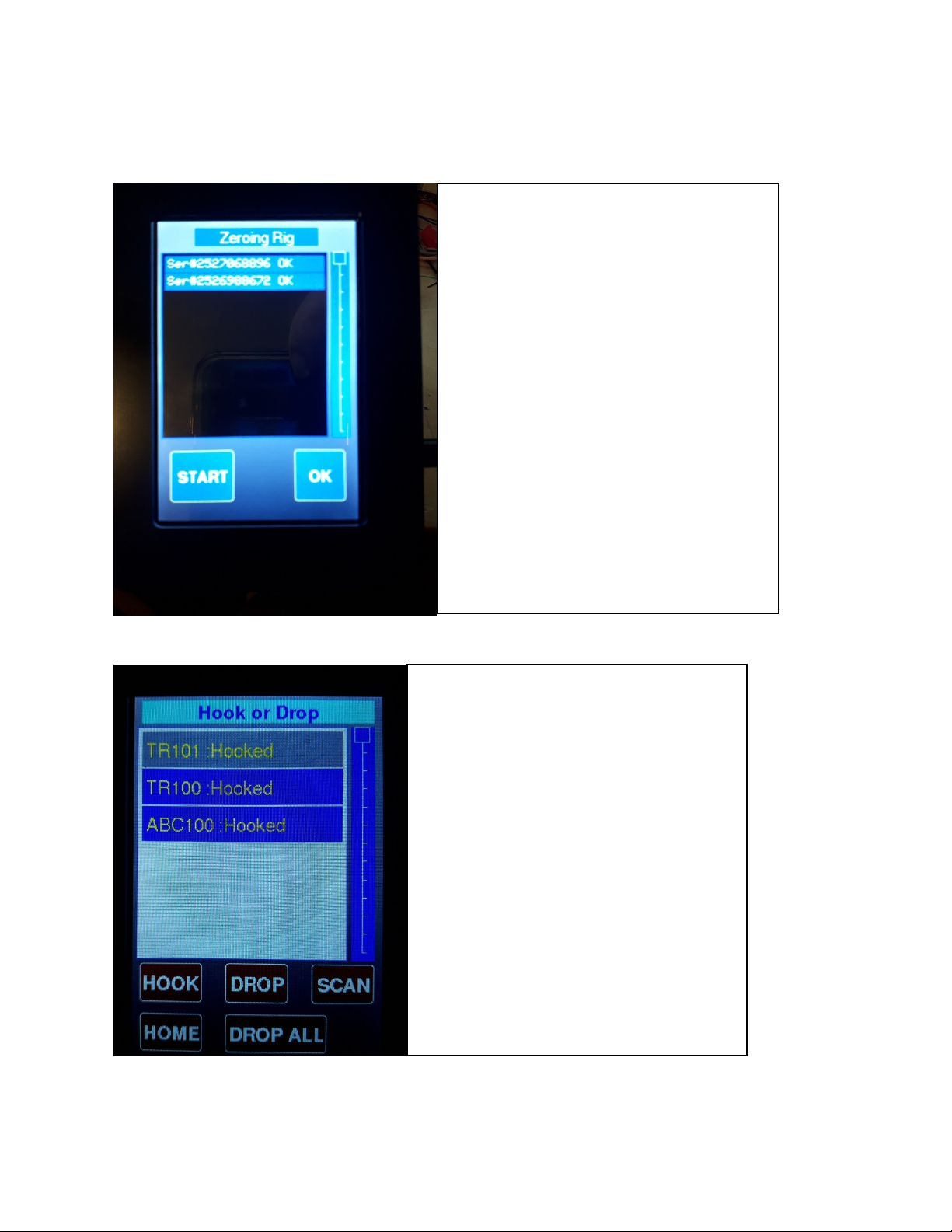

8.0 Zeroing:

8.1 Press >> from Home Screen to enter the zeroing screen. Zeroing is only used with to on

spring or walking beam spring suspensions. Zeroing does not have an effect on air sensors.

First line is the Serial # of the sensor.

2nd line is Equipment name this sensor belongs

To. 3rd line is Axle this sensor is on.

Live is the actual value or pressure from the Sensor.

Press EMPTY VALUE button to change. If the

Live value will show empty value id equipment

Is empty, and you can enter this value.

The Empty weight is the weight you want for

This value. Do the same for Full vehicle weight.

Pressing the SAVE button will send these values

To the sensor if OK you will see message at

Bottom of screen.

Values and Pressures Screen

ZERO RIG

Press to zero weights when

Equipment is empty.

Maint Button (Maintenance)

Press to get Menu

HOOK Button

Press to Hook or Drop equipment.

<< Button

Press to return to Axle Screen

12

8.2 Zeroing continued.

Press the left arrows to return to the Axle Screen (home screen).

9.0. Drop and Hook.

Make sure equipment is empty and

Equipment is stable.

Press START button to proceed.

OK Button will disappear and

Zeroing will commence.

All non AIR sensors will be zeroed.

Screen will show Serial numbers

zeroed. Note: you will get messages

if errors happen. If you try and zero

within 30 sec to 1 minute after

power up you may get errors due

to high traffic during Power up.

This screen will show which Equipment is

Hooked or not, Item in Grey is the selected

Item, you can drop this equipment by

Pressing DROP button, this will show up

The equipment Name only.

You can hook the selected item by first

Selecting by tapping the name in the list

Then press HOOK button.

If the equipment is not listed press the SCAN

Button, this will send a message to all sensors

To report within 10 seconds, sometimes if

13

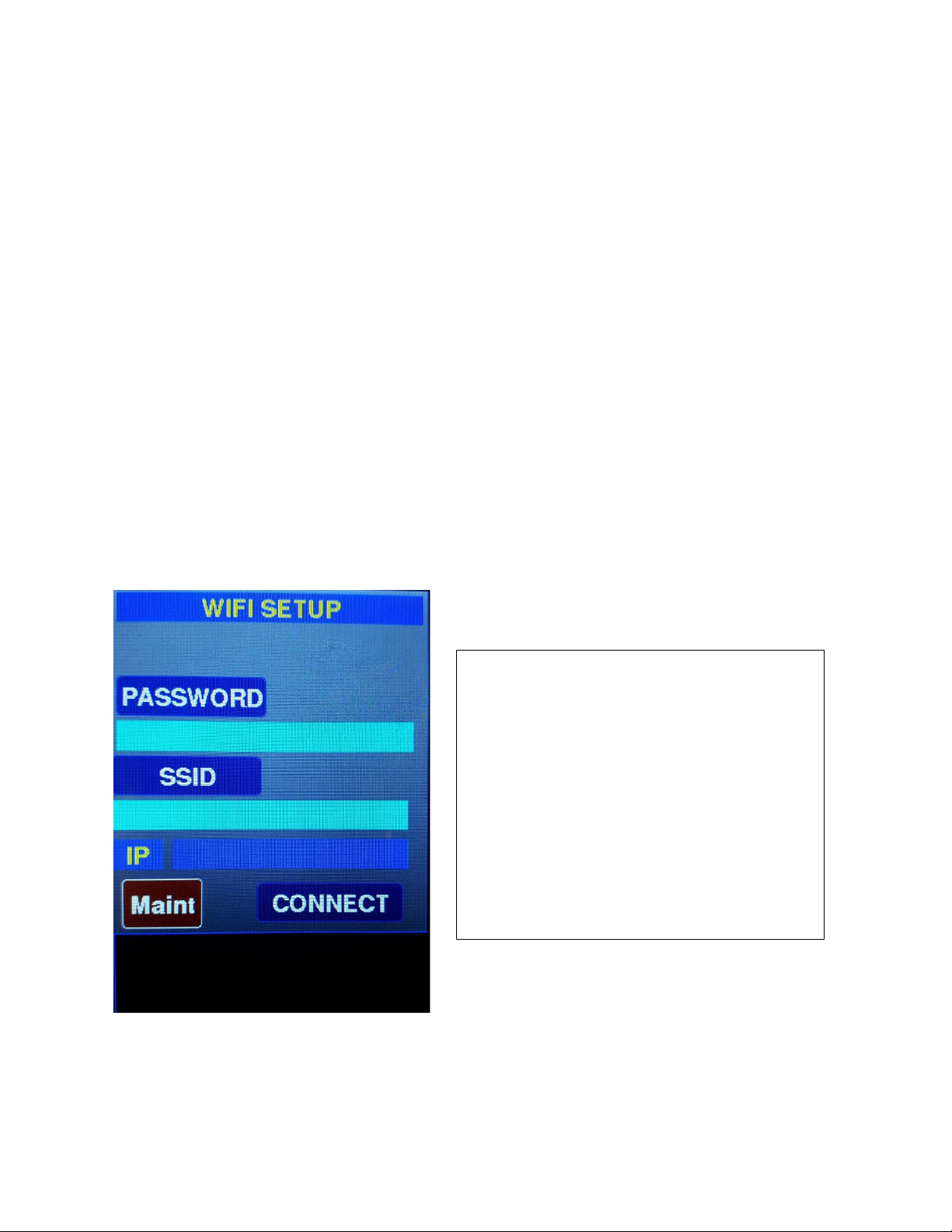

10.0. WIFI Set up:

This is used for downloading new firmware for this device. You must know the SSID of any nearby router and

Password. Enter these by Pressing PASSWORD and SSID

Buttons. Press Connect when done. These settings will be saved for future. Activations. The IP will show up in the

IP box or an error message if not. You May need to wait a few seconds before it

Shows up. Once you have the IP address you can use Any BROWSER on your computer or phone

Or tablet to download new firmware version Provided by TruckWeight Inc.

Shown below is the browser screen, Enter the IP obtained in the Address bar

(top line) in your browser and press ENTER

Or click.

Enter UserName -> tw

Enter Password-> 11258

And press login button.

Press Choose file and a list of your files will be

listed, you need to navigate to where your

File is located (.bin file) and select it. Then press

Update on your browser it will show progress

100% but that does not mean it is completed.

You now need to look at your Handheld screen at

the bottom you will see

Message saying Uploading. After less than a

minute your Handheld will restart with new

version.

14

E GAM A HADHELD

Things you need before programming:

1) Wi-Fi either from Phone(hotspot) or home Wi-Fi. Need to know your Wi-Fi ID and

Password, make sure it does not have any special symbols like @. If it has, we suggest

changing the ID and Password to a simple format.

Example: SSID – Truckweight Password – 12345678

2) Ask Truckweight to send the latest Program for Handheld to your email. (Example Version

1.43). After receiving the email save it to your device through which you are

programming.

Example: If I am using my iPhone. I got my latest version in my email.

a) Click on the file

b) On the top right, you will have send option with an up arrow, click on it. You

will get two options, Save to Account or Share File Via., Click on Share File

Via.

c) Now you will get different options to share, scroll to Save to Files and click

on It.

d) Choose just on My iPhone option and at the top right corner, you will have

the Save option and click on it.

If you are using Android or a computer, you will have a direct option to save in a known

location.

Program the Handheld:

1) Open Maintenance in the Handheld (password is 11258), go to Wi-Fi setup.

2) In Wi-Fi Setup click on SSID and enter your Wi-Fi name without any mistakes.

3) Next, click on the Password option and enter your Wi-Fi password and click Connect.

4) The HH will generate an IP address (Ex-192.168.188.1) at the bottom of the Handheld.

5) Open a web browser (Ex-Google Chrome or Safari). Type the IP address generated in HH

to the search / URL bar without www or .com and click enter/go.

6) This will open a Truckweight page, type ID – tw (lower case) and Password – 11258 and

click enter.

7) It will open a page to choose a file on the top left. Click choose file and choose the file you

saved in your device that came from our email and click on update. (Click Only once)

8) If you click update twice then the Handheld restarts and you need to start the process

again.

9) It will show the update percentage at the bottom (it goes to 100 immediately for

displaying but internally it takes 1-2 min. After few minutes the Handheld restarts itself

and will be programmed to the latest version.

10) If the Handheld was not programmed to the latest version, then you have to repeat from

step 1.

15

Connecting to tracking devices. Serial RS232 data format.

There are two settings, STANDARD and GEOTAB. Select STANDARD in Truck Setup

for all modems when Geotab is off. To Select GeoTab, only, in Truck Setup set to

ON. If it's OFF then it's in Standard output.

There are two ways to send serial data. Manually and Automatic. To manually

send data you must use the Print Button which will send

FLWC format to the Serial Port in either in Standard mode or GEOTAB. For

Automatic Select Interval time in seconds in Truck Setup.

You can also change Baud rate in the Truck Setup, default setting is 115200.

SDS is automatic data sent during a set time interval, and SDM is manually sent

data when print button is pressed.

FLWCV MAJOR.MINOR SDS/SDM*EQUIPMENT ID|VIRTUAL

SERIAL,AXLE,WEIGHT,1|SERIAL#,AXLE,PRESSURE,TEMPERATURE,WEIGHT,1|

repeat for all Serial # then last one will have tow bars ||followed by Total

Weight of all axles followed by CR LF.

Sample Data output

FLWCV 3.20

SDM*TRUCK02|999999,1,0,0,0,1|*PEACE|684759540,5,35.1,29.2,2003,1||2000

FLWCV 3.20

SDS*TRUCK02|999999,1,0,0,0,1|*PEACE|684759540,5,35.1,29.2,2003,1||2000

Axle Group and Temperature ID.

16

* "Front Axle",//1

* "Front Axle1",//2

* "Front Axle2",//3

* "Drive Axle",//4

* "Trailer",//5

* "Trailer 1",//6

* "Trailer 2",//7

* "Trailer 3",//8

* "Lift Axle",//9

* "Lift Axle 1",//10

* "Lift Axle 2",//11

* "Dolly",//12

* "Jeep",//13

* "Stinger",//14

* "Front Fork Arms",//15

* "Bucket Loader",//16

* "Fork Lift",//17

* “TEMP1”,//18

* “TEMP2”,//19

* “TEMP3”,//20

* “TEMP4”,//21

Up to 30 temperature sensors on any truck and or trailer. * “TEMP30”,//47

Table of contents

Popular Automobile Accessories manuals by other brands

etrailer

etrailer E-LEVEL product manual

Silvercrest

Silvercrest SCHW A1 Operation and safety notes

Shurco

Shurco truXedo Lo Profile owner's manual

Tripp Lite

Tripp Lite U280-CQ01 owner's manual

Silvercrest

Silvercrest SFA 40 A2 operating instructions

Horn Tools

Horn Tools HSW9900ISDMDY PA Mounting instructions