True blue power TS6 Technical Document

Revision

A

•

A

ugust 24, 2023

1 Manual Number 9019857• Revision A, August 24, 2023

FOREWORD

This manual provides information intended for use by people who, in accordance with current

regulatory requirements, are qualified to install this equipment. If further information is required,

please contact:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Customer Service Dept.

9400 E. 34th St. N.

Wichita, KS 67226 USA

Phone 316-630-0101

Fax 316-630-0723

www.truebluepowerusa.com

www.mcico.com

We welcome your comments concerning this manual. Although every effort has been made to

keep it free of errors, some may occur. When reporting a specific problem, please describe it

briefly and include the manual part number, the paragraph/figure/table number, and the page

number. Send your comments to:

True Blue Power

c/o Mid-Continent Instrument Co., Inc.

Attn: Technical Publications

9400 E. 34

th

St. N.

Wichita, KS 67226 USA

Phone 316-630-0101

Fax 316-630-0723

© Copyright 2023

Mid-Continent Instrument Co., Inc.

Download the current

version of this

installation manual

using your

smartphone or tablet.

2 Manual Number 9019857• Revision A, August 24, 2023

TABLE OF CONTENTS

SECTION 1GENERAL DESCRIPTION 4

1.1 INTRODUCTION 4

1.2 PHYSCIAL ATTRIBUTES 4

1.3 UNIT ARCHITECTURE 4

1.4 TECHNICAL SPECIFICATIONS 5

1.5 IMPORTANT SAFETY INFORAMTION 7

SECTION 2PRE-INSTALLATION CONSIDERATIONS 9

2.1 COOLING 9

2.2 EQUIPMENT LOCATION 9

2.3 ROUTING OF CABLES 9

2.4 LIMITATIONS 9

2.5 MODIFICATION 10

SECTION 3INSTALLATION 11

3.1 GENERAL 11

3.2 PRE-INSTALLATION INSPECTION 11

3.3 PARTS 11

3.4 INSTALLATION 11

SECTION 4OPERATION 16

4.1 DESCRIPTION 16

4.2 THERORY OF OPERATION 16

4.3 BATTERY PERFORMANCE AND CAPACITY 18

4.4 MAINTENANCE 18

SECTION 5CONFORMANCE 19

5.1 DISPATCH VERIFICATION AND IN-FLIGHT MONITORING 19

5.2 ROUTINE MAINTENANCE 19

5.3 COMPONENT MAINTENANCE 19

5.4 STORAGE INFORMATION 20

5.5 END OF LIFE 20

5.6 DISPOSAL 20

5.7 ENVIRONMENTAL QUALIFICATION STATEMENT 21

3 Manual Number 9019857• Revision A, August 24, 2023

REVISION HISTORY

Rev Date Detail Approved

A

8/24/2023 Initial Release CAS

4 Manual Number 9019857• Revision A, August 24, 2023

SECTION 1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The True Blue Power TS6 Emergency Battery Power Supply part number 6430006 is designed to

supply DC power for emergency equipment after aircraft power failure occurs. During normal

aircraft operation, the TS6 Emergency Battery Power Supply (EBPS) will utilize the aircraft’s power

to recharge or maintain existing charge at full capacity. The TS6 is a sophisticated power system

that utilizes NiMH cell technology which provides improvements in performance, safety, life, and

weight when compared to traditional or competing backup systems. Consideration given to key

electrical and mechanical design principles yield compliance with regulatory standards and meet or

exceed industry expectations. The TS6 is a complete EBPS that provides significant value and

benefit to an aircraft designer, owner, and operator.

The TS6 requires professional use and maintenance to deliver maximum performance and value

as designed. This manual contains information related to the specifications, installation, operation,

storage, scheduled maintenance, and other related topics associated with the proper care and use

of this product.

1.2 PHYSCIAL ATTRIBUTES

The TS6 consists of a rugged metal chassis with a DB9 style connector for electrical interface, and

a permanently installed rechargeable battery. The unit is designed to be mounted with four 6-32

screws to the aircraft structure.

1.3 UNIT ARCHITECTURE

The unit has four primary functional features:

Power pass through

Internal cell charging.

Cell state of charge gauging

Consistent standby output voltage

The unit passes through normal 28V power, while maintaining internal power storage with internal

battery charge and discharge control. The unit input provides a regulated 24V output in the event

of loss of input power. Additional functions include analog state-of-charge, 80% capacity dispatch

test, and discharge shutdown. All battery management functions are handled internally, including

protection against safety considerations such as short circuit, over temperature, under voltage, and

over voltage conditions.

5 Manual Number 9019857• Revision A, August 24, 2023

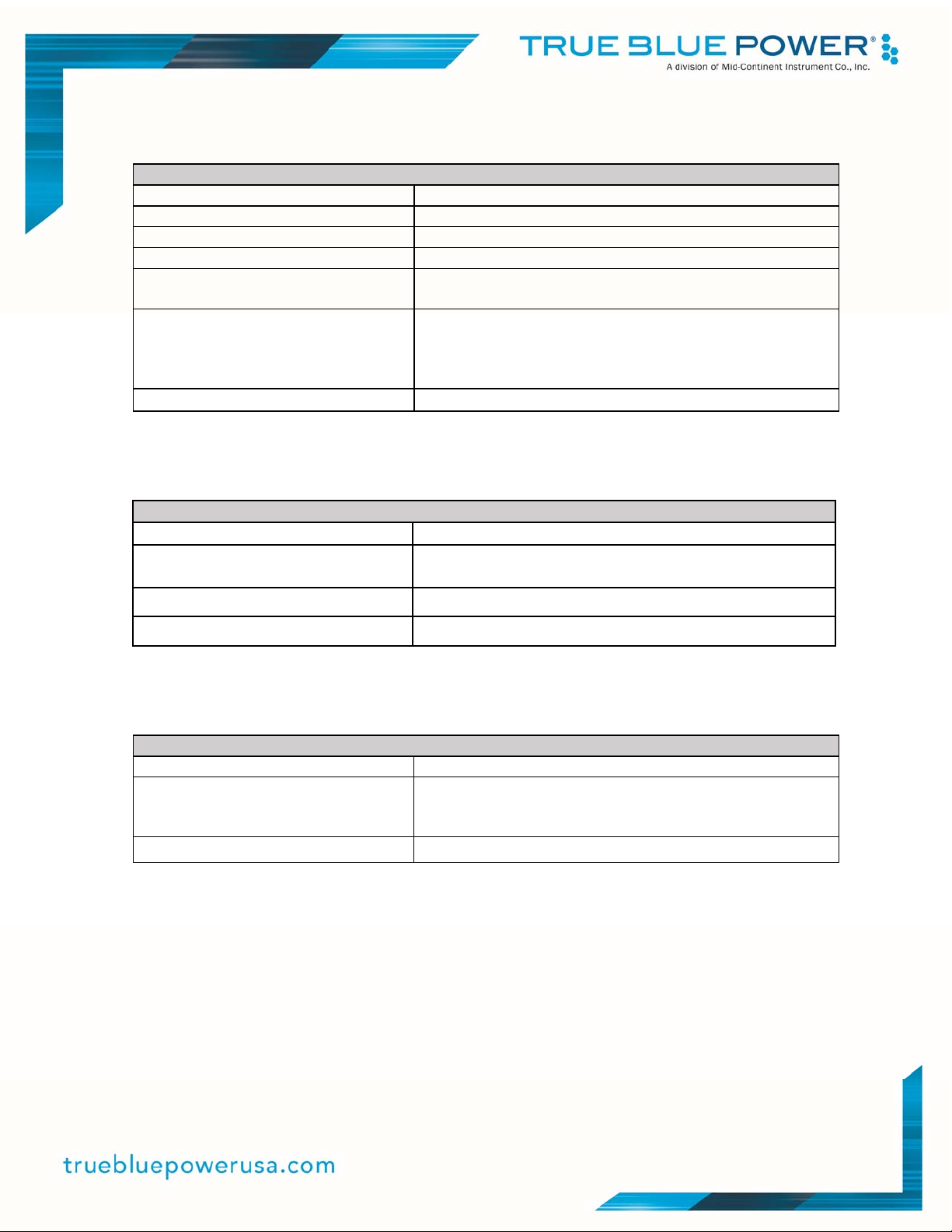

1.4 TECHNICAL SPECIFICATIONS, 6430006

Electrical Attributes

Power Input: 24.5 to 32 VDC; 0.5

A

peak

Nominal Power Output 0.25

A

@ 24 VDC Nominal

Max Current Output: 0.25

A

Battery Capacity: 6 Wh

Charge Time @ 28 VDC: ~2 hours for fast charge, majority of capacity

~2.5 hours to complete charge

Discharge Time:

At 50⁰C (122⁰F)

At 23⁰C (73⁰F)

A

t -8⁰C (18⁰F)

60 minutes @ 0.25A

60 minutes @ 0.25A

60 minutes @ 0.25

A

Maintenance: Perform capacity check every 1 year

Table 1.1

Electrical Functions

Table 1.2

Physical Characteristics

Qualifications

Certification: FAA TSO-C173a

Performance Qualification: DO-293A Minimum Operational Performance

Standards for Rechargeable Nickel-Metal Hydride

(NiMH) Batteries and Battery Systems

Environmental Qualification: RTCA DO-160G

Table 1.3

Qualification Standards

Physical Attributes

Weight:0.5 pounds

Dimensions: (see Figure 1.1)

(without connector)

2.75 x 3.00 x 0.94 inches (LxWxH)

Mating Connector: 8017287

Mounting: (see Figure 1.1) #6 Screws (4)

6 Manual Number 9019857• Revision A, August 24, 2023

Figure 1.1

Outline Drawing

7 Manual Number 9019857• Revision A, August 24, 2023

1.5 IMPORTANT SAFETY INFORAMTION

Read this safety information BEFORE maintaining or servicing the battery.

Symbol Definition

This section describes the precautions necessary for safe operations. The following safety

symbols have been placed throughout the guide.

Warnings identify conditions or practices that could result in personal injury.

Cautions identify conditions or practices that could result in damage to the equipment.

Handling Precautions

Though the TS6 has short circuit protection, caution should always be used when working

with battery powered products. It is recommended to wear safety glasses, fire retardant

smocks, and use insulated tools when servicing the EBPS.

Do not disassemble or modify the battery.

The battery contains an alkaline electrolyte. This electrolyte may result in the loss of

eyesight if it comes into contact with an eye. In such cases, do not rub the eye, but

immediately wash the eye with clean water and then consult a doctor.

Remove metal items such as rings, bracelets, and watches when working with

batteries. A battery could produce a short circuit current that could harm a person.

• Ensure that the TS6 service area is properly ventilated and egress paths are

unobstructed.

• Specialized breathing filters are not required under normal use.

• Always use insulated tools.

• Never smoke or allow a spark or flame near the TS6.

Additional Precautions

The following design and operation factors are required for safe use.

• It is not acceptable to combine or use any battery cells or modules other than those

approved by True Blue Power.

CAUTION

W

ARNING

CAUTION

W

ARNING

8 Manual Number 9019857• Revision A, August 24, 2023

• Always use appropriate Electrostatic Discharge (ESD) protection while working with the

TS6.

There are no limitations in storing or using this TS6 in the vicinity of other battery

chemistries. The TS6 does not emit or absorb any gas during storage, transportation or

during normal operating conditions.

Connector terminals must be covered with non-conductive protective devices to avoid

any possibility of shorting during handling, shipping, or storage.

Shipping

Shipping complies with domestic and international shipping regulations.

9 Manual Number 9019857• Revision A, August 24, 2023

SECTION 2 PRE-INSTALLATION CONSIDERATIONS

2.1 COOLING

No internal or external cooling of the unit is required. The unit is designed to operate over a wide

temperature range and includes internal thermal monitoring and protection circuits. See Section 4

for more details.

2.2 EQUIPMENT LOCATION

The TS6 EBPS is designed to mount in a pressurized and temperature-controlled environment.

Although not required, optimum performance and life can be achieved by mounting the TS6 in a

temperature-controlled section of the aircraft that does not require operation below -8°C. The unit

is designed to withstand high levels of condensing humidity. However, installation locations where

the unit could be subject to standing or direct water exposure should be avoided. The unit has no

limitations regarding mounting orientation.

The unit should not be installed in compartments where lines, tanks or equipment containing fuel,

oil or other flammable fluids are present. Installation near potential sources of ignition should be

avoided.

2.3 ROUTING OF CABLES

Avoid sharp bends in cabling and be cautious of routing near aircraft control cables. Also avoid

proximity and contact with aircraft structures, avionics equipment, or other obstructions that could

chafe wires during flight and cause undesirable effects. Cables should not run adjacent to heaters,

engine exhausts, or other heat sources. The signal cable bundle wires are recommended to be no

smaller than 22 gauge.

2.4 LIMITATIONS

The conditions and tests for TSO approval of this article are minimum performance standards.

Those installing this article, on or in a specific type or class of aircraft, must determine that the

aircraft installation conditions are within the TSO standards. TSO articles must receive additional

installation approval prior to being operated on each aircraft. This article meets the minimum

requirements of technical standard order (TSO) C173a. Installation of this article requires separate

approval. The article may be installed only according to 14 CFR Part 43 or the applicable

airworthiness requirements.

See Section 4.3 for Performance Specifications and potential limitations and ratings under various

environmental and application installations. Also see Section 2.2 for limitations associated with

equipment installation location.

10 Manual Number 9019857• Revision A, August 24, 2023

2.5 MODIFICATION

This product has a nameplate that identifies the manufacturer, part number, description,

certification(s) and technical specifications of the unit. It also includes the “MOD” or modification

number representing notable changes in the hardware design of the unit.

Modification (MOD) 0 is the initial release of the product and is identified on the nameplate by the

lack of marking on the MOD numbers 1 through 9 (i.e. 1-9 are visible). All subsequent

modifications are identified on the nameplate by the marking/blacking out of that particular MOD

number (i.e. for MOD 1, the number 1 is not visible and 2-9 are visible - see Figure 2.1 for

examples). MODs do not have to be sequentially inclusive and may be applied independent of

each other.

For additional details regarding specific changes associated with each MOD status refer to the

product published Service Bulletins at www.truebluepowerusa.com.

Figure 2.1

Nameplate and MOD Status Example

MOD 0

MOD 1

MOD 1

& MOD 2

11 Manual Number 9019857• Revision A, August 24, 2023

SECTION 3 INSTALLATION

3.1 GENERAL

This section contains mounting, electrical connections and other information required for

installation. These instructions represent a typical installation and are not specific to any aircraft.

3.2 PRE-INSTALLATION INSPECTION

Unpacking: Carefully remove the TS6 battery from the shipping container. The shipping container

and packing are designed specifically for the transit of NiMH batteries and approved by

international transportation agencies. These materials should be retained for use should the unit

require future shipment.

Inspect for Damage: Inspect the shipping container and unit for any signs of damage sustained in

transit. If necessary, return the unit to the factory using the original shipping container and packing

materials. File any claim for damages with the carrier.

3.3 PARTS

Included Parts

A. TS6 Emergency Battery Power Supply MCIA P/N 6430006-1

B. Installation and Operation Manual MCIA P/N 9019857

C. Connector Kit MCIA P/N 8017287

Installer Supplied Parts

A. Wires

B. Appropriate hold-down hardware

3.4 INSTALLATION

The connector pins of the TS6 are always active and energized.

DO NOT SHORT CONNECTOR PINS AT ANY TIME!

Caution should be applied when handling and connecting to the unit.

Harness Preparation

Prepare aircraft wiring with mating connectors in accordance with the proper Wire Size and

Type (Table 3.1), Unit Locations (Figure 3.1) and Pin Identification Diagram (Table 3.2).

Recommended external connections to the aircraft can be seen in Figure 3.3.

W

ARNING

12 Manual Number 9019857• Revision A, August 24, 2023

Use of PTFE, ETFE, TFE, Teflon or Tefzel insulated wire is recommended for aircraft use.

Recommended wire sizes and types are identified in Table 3.1 below.

Table 3.1

Wire Size and Type

Figure 3.1

Unit Locations

Wire Size and Type

Wire Gauge Wire Type Connecto

r

Pins

18-22

A

WG Stranded Coppe

r

9-pin 1-9

13 Manual Number 9019857• Revision A, August 24, 2023

Figure 3.2

EBPS Connector

TS6 Connector (9-pin)

Pin Function

1 Reserved

2 Reserved

3 Ground

4 State of Charge

5 Dispatch

6 Shutdown

7 Power Output

8 Power Input

9 Ground

Table 3.2

Connector Pinout

Securing the Unit

The TS6 is designed to be secured in the aircraft using four (4) #6 screws (or equivalent)

as shown in Figure 1.1.

14 Manual Number 9019857• Revision A, August 24, 2023

Installation and Wiring

TS6

Ground

1

2

3

4

5

6

7

8

9

Ground

PowerInput

PowerOutput

Shutdown

StateofCharge

MD23‐()

19

*

*

1

Aircraft28VPower

* Device pins are installation-specific

Figure 3.3

MD23 FLEX Wiring Example

15 Manual Number 9019857• Revision A, August 24, 2023

* Device pins are installation-specific

Figure 3.4

Generic Equipment Wiring Example

16 Manual Number 9019857• Revision A, August 24, 2023

SECTION 4 OPERATION

4.1 DESCRIPTION

The True Blue Power TS6 Emergency Battery Power Supply (EBPS) is designed to supply DC

power for an MD23 when aircraft power failure occurs. It utilizes rechargeable NiMH chemistry to

provide output power. During normal aircraft operation, the TS6 EBPS will utilize the aircraft’s

primary power bus to recharge or maintain existing charge at full capacity. The TS6 will pass the

28V input voltage through to the output via an internal diode.

4.2 THEORY OF OPERATION

The TS6 Emergency Battery Power Supply system provides a minimum voltage output of 24V at a

maximum current output of 0.25A. The units are designed to receive 24.5-32V input and to

seamlessly switch to backup battery power if the input voltage drops below 24V. The unit includes

two power return (GND) pins for installation convenience with only one being required for

operation. Refer to Section 3.4.3 for external connection to aircraft system.

28V bus present

If the 28V bus is present, the unit will pass it through to the output and maintain or charge

the backup batteries. When charging, the additional load on the aircraft system is

approximately 0.25A during fast mode and 0.15A during trickle charge, falling under 0.1A

when the cells are fully charged.

28V bus dropout

If the 28V bus drops out or is below 24V, the unit will continue to supply power through a

diode circuit from the internal battery supporting a 24V output level. The unit constantly

monitors a variety of internal conditions and applies protections by automatically

disconnecting the EBPS from the charging source if any of the design thresholds are

exceeded. These includes over-voltage and over-temperature.

Discharge

The TS6 provides an internally regulated 24V discharge whenever it is active. When input

voltage drops below 24V, the output will be maintained at 24V. This unit is automatically

activated when power is applied, and automatically will provide power to its connected load

until exhaustion of the internal storage cells, or until the SHUTDOWN pin is momentarily

connected to GND. Input power must be applied to re-enable the discharge output. Short

circuit protection is provided internally as a 0.5A PTC self-resetting fuse on the output.

17 Manual Number 9019857• Revision A, August 24, 2023

State of Charge (PIN 4)

The State of Charge signal represents an estimated SOC for the internal cells with 0-10V

representing 0-100% SOC respectively. This signal is active when aircraft power is

available making the unit active, and while the unit is still active following a loss of input.

Dispatch (PIN 5)

The Dispatch signal asserts GND when the SOC is above 80%. This signal is open when

SOC is below 80%. Dispatch is intended to drive a lamp/LED or discrete input to another

system to indicate that the battery is charged. Figure 3.4 shows how a momentary switch

and lamp can be wired for a manual test. This signal is active when aircraft power is

available making the unit active, and while the unit is still active following a loss of input.

Shutdown (PIN 6)

To preserve the state-of-charge, extend the life of the unit, and maintain immediate

usefulness for its next mission the unit should be deactivated after loss of power when its

use is not further required. This is done by momentarily grounding the Shutdown pin.

Software and Complex Hardware

No software or complex hardware is incorporated in the design of this product.

18 Manual Number 9019857• Revision A, August 24, 2023

4.3 BATTERY PERFORMANCE AND CAPACITY

In comparing the benefits of Nickel-Metal Hydride (NiMH) cell technology with Nickel Cadmium

(NiCad) cell technology, it is clear that NiMH is a superior choice.

NiMH cell technology offers significant advantages over NiCad. NiCad batteries suffer from a

memory effect, which reduces their capacity. On the other hand, modern NiMH batteries show little

to no memory effect, allowing for more flexible charging and discharging patterns without

negatively impacting their overall capacity. In our testing and qualification process we have not

seen any memory effect in our NiMH packs.

NiMH batteries possess a higher energy density compared to NiCad batteries. This means they

can store more energy in a given space, making them suitable for applications where weight and

size are crucial factors. Additionally, they have a much lower self-discharge rate than NiCad

batteries. This means they can retain their stored energy for longer periods without requiring

frequent recharging. NiMH batteries are better suited for applications that demand extended

periods of standby or intermittent use. NiMH batteries also tend to have a much longer cycle life as

compared to NiCad.

Unlike NiCad batteries, NiMH batteries do not contain toxic cadmium, making them more

environmentally friendly and safer for disposal. NiMH batteries are considered a more sustainable

choice due to their reduced environmental impact.

NiMH cell technology presents a superior alternative to NiCad. With its environmental friendliness,

higher energy density, reduced memory effect, lower self-discharge rate, and enhanced safety,

NiMH batteries offer a compelling choice for various applications and provide an overall improved

user experience.

For specific capacity and EBPS discharge time, refer to Section 1.4.

Note that this battery does not contain an internal heater. Capacity will not be available for

charging or discharging at temperatures below -8°C.

4.4 MAINTENANCE

Because the cells are designed to maintain their charge-holding capability over time, True Blue

Power is recommending a two-year maintenance cycle. The two-year check includes a full charge,

discharge, and recharge while evaluating the discharge time against minimum requirements.

Additionally, at any time when the capacity of the unit is in question or after being utilized in an in-

flight emergency situation, True Blue Power recommends conducting this procedure.

19 Manual Number 9019857• Revision A, August 24, 2023

SECTION 5 CONFORMANCE

5.1 DISPATCH VERIFICATION AND IN-FLIGHT MONITORING

The TS6 serves to provide power to an MD23 or other critical equipment upon loss of aircraft

power. Typical installation will include monitoring through the MD23 application-specific user

interface. For general installation without MD23, see the appropriate aircraft flight manual.

5.2 ROUTINE MAINTENANCE

The TS6 requires scheduled maintenance based on calendar life of the EBPS. Maintenance as

described in this section shall be conducted every 24 months from date of original aircraft delivery

or subsequent new battery installation. The EBPS battery shall be recharged every 6 months if it is

uninstalled.

The connector pins of the TS6 should always be treated as if it were active and energized.

Visual Inspection

A. Remove the unit from the aircraft. Visually inspect the exterior of the EBPS

casing for signs of damage or wear. Verify that no damage has occurred which

would prevent the EBPS from functioning. If any wear is apparent which has not

compromised the case, inspect the EBPS area of the aircraft for any signs of

improper installation.

B. Visually inspect the connector. Verify that it isn’t loose and there are no signs of

damage, wear, or corrosion.

C. If any of the above conditions are present, the unit must be evaluated and tested

for repair or replacement by an authorized repair facility.

Charging and Capacity Check

A. To charge the battery, apply 28V to PIN 8 and GND to PIN 9. Charging will

occur automatically, continuing until the input current drops below 0.1A.

B. Discharge the battery by connecting a 0.25A load (96 ohms) between PIN 7 and

PIN 9, and disconnecting input power. The unit should supply power (24V) on

the output for at least 60 minutes.

Return to Service

A. Recharge the unit with 28V supply until input current drops below 0.1A. This

should take roughly 2 hours for a full charge.

5.3 COMPONENT MAINTENANCE

The cells, electronics, and other components that comprise the TS6 Emergency Battery Power

Supply are not field-serviceable items. Please contact the manufacturer for service.

W

ARNING

Table of contents

Other True blue power Power Supply manuals