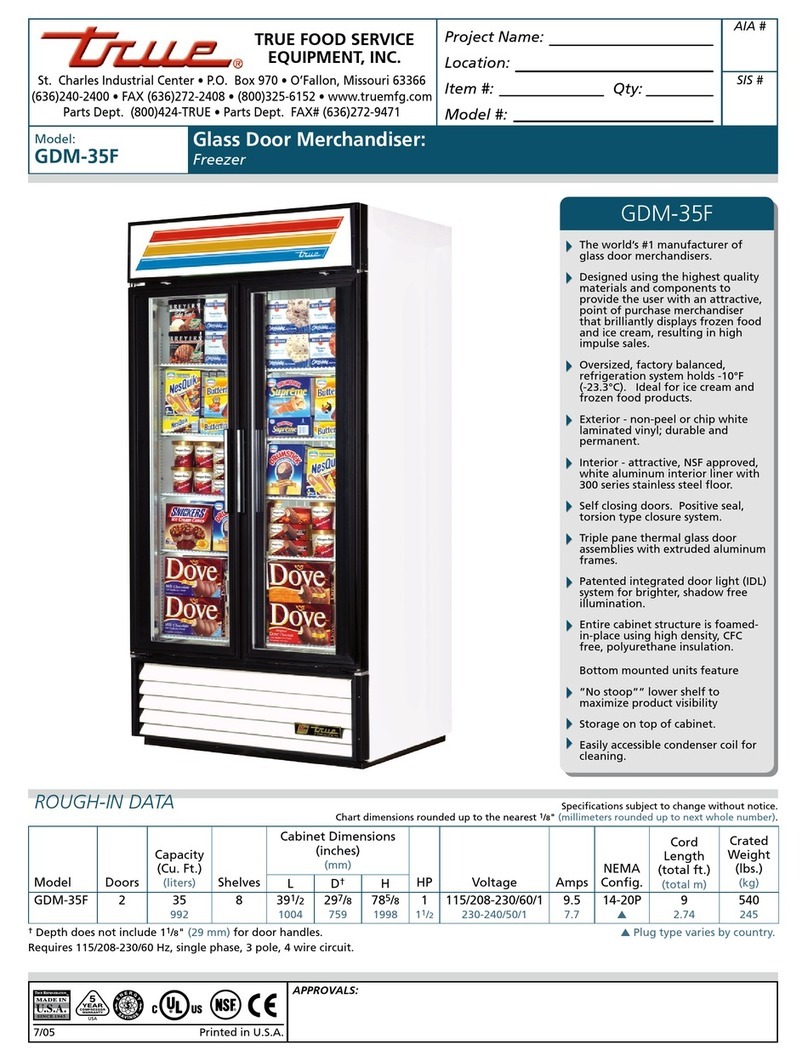

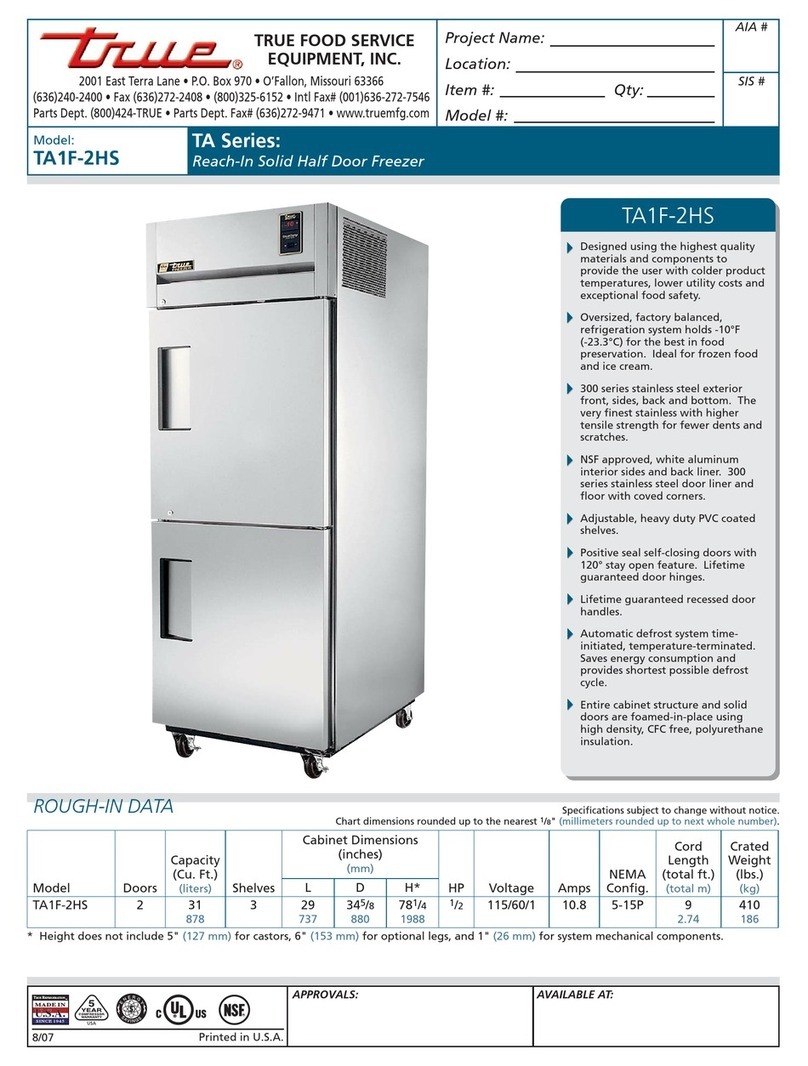

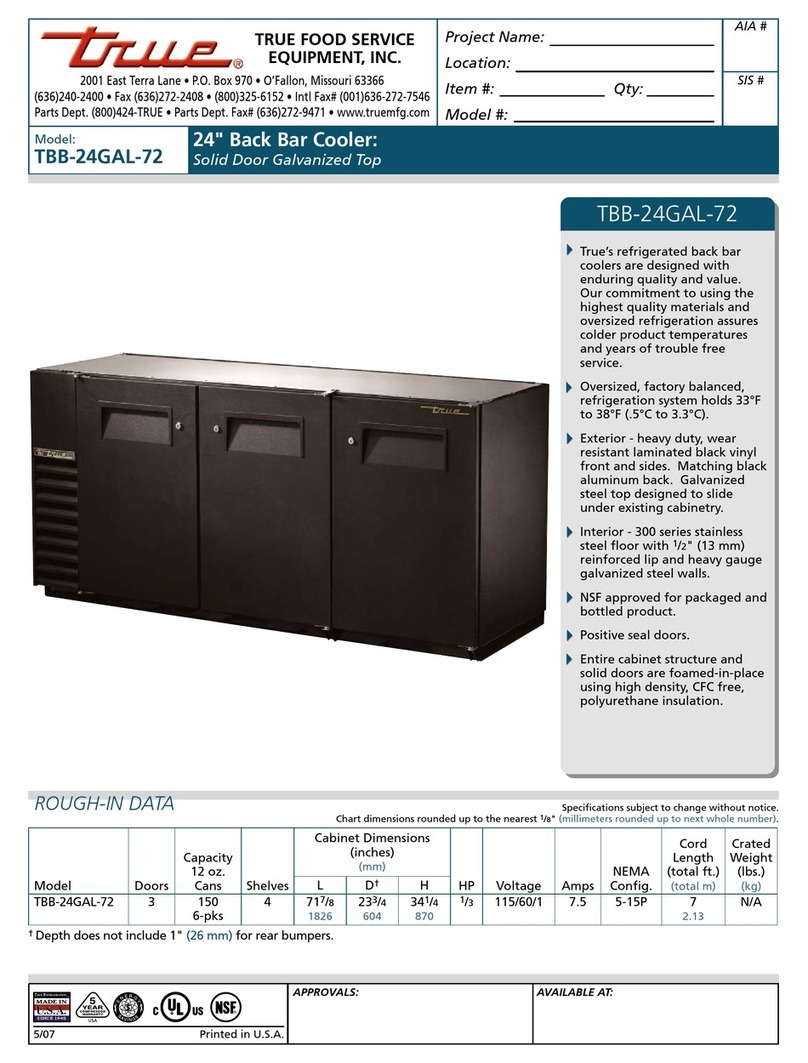

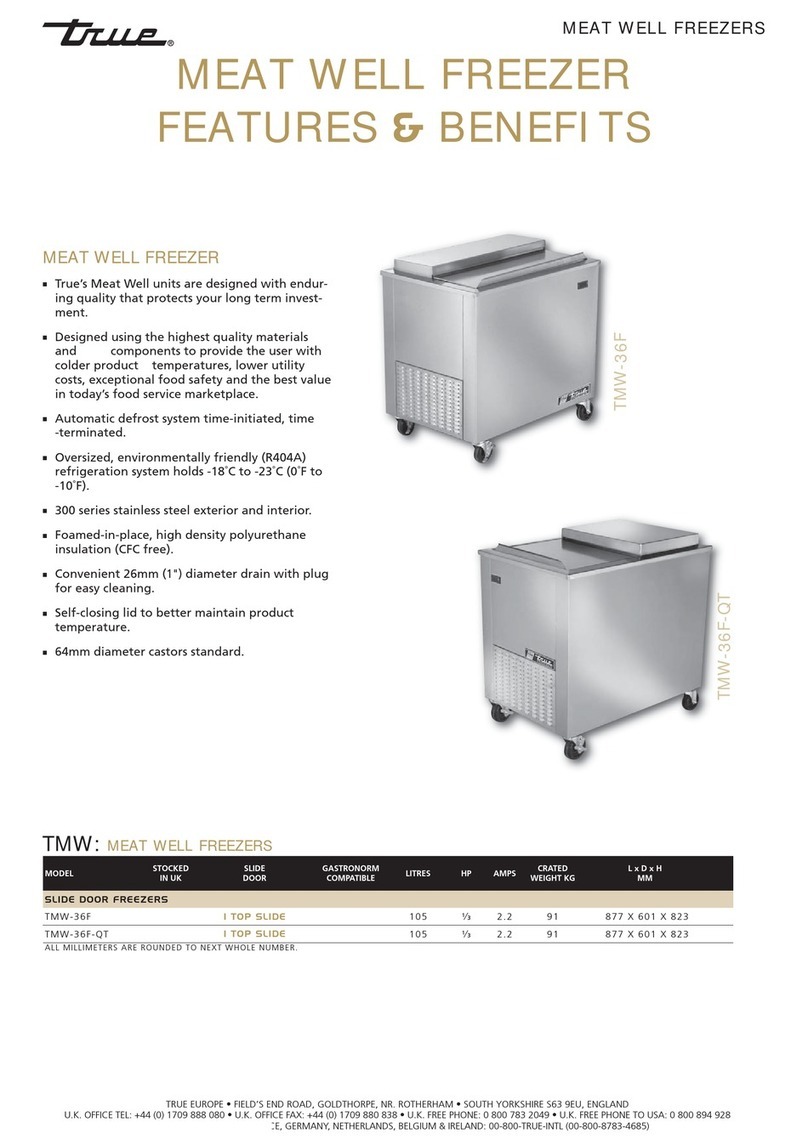

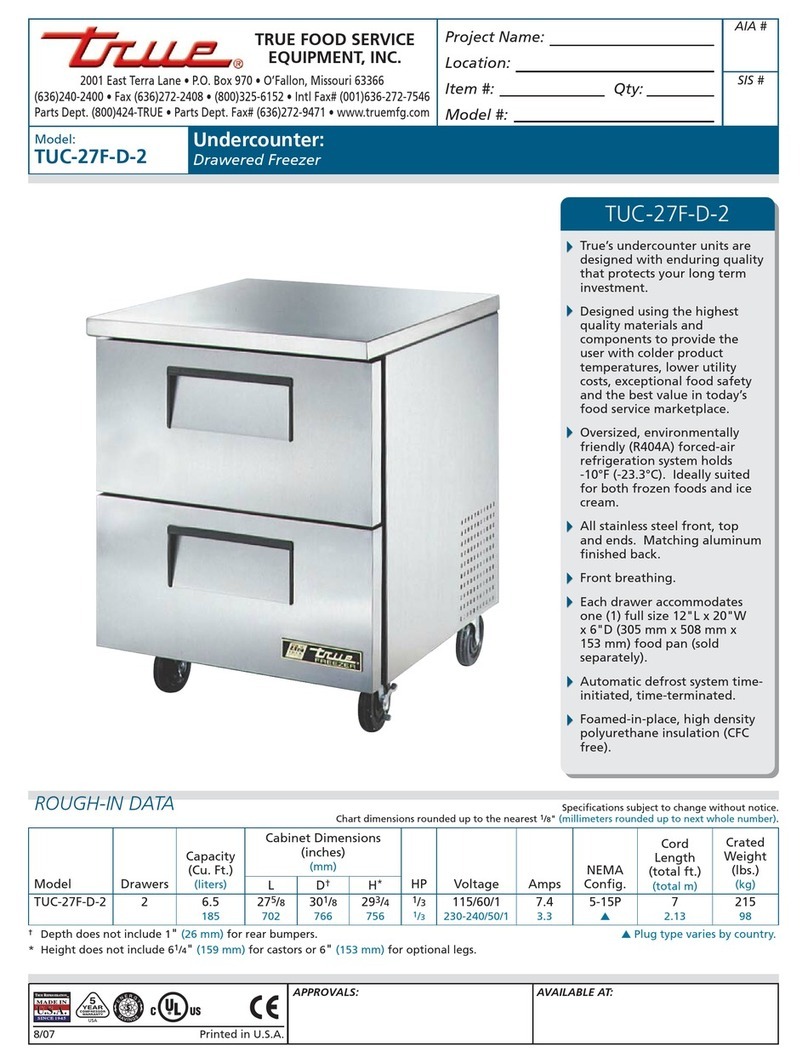

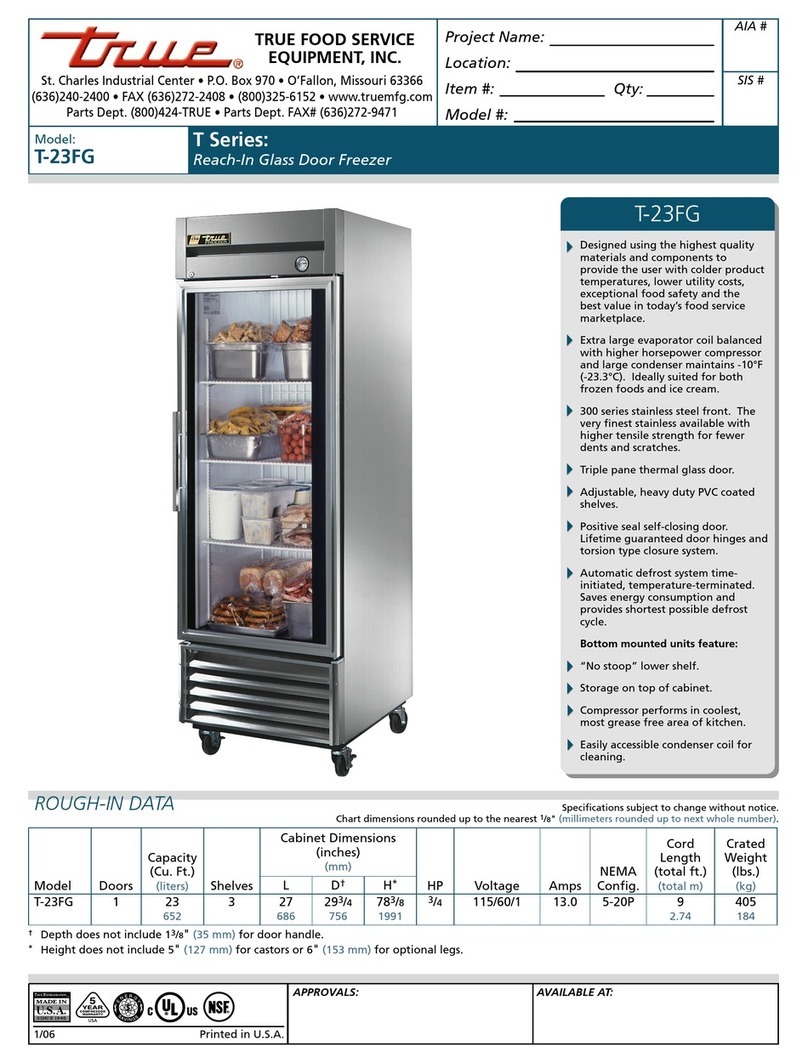

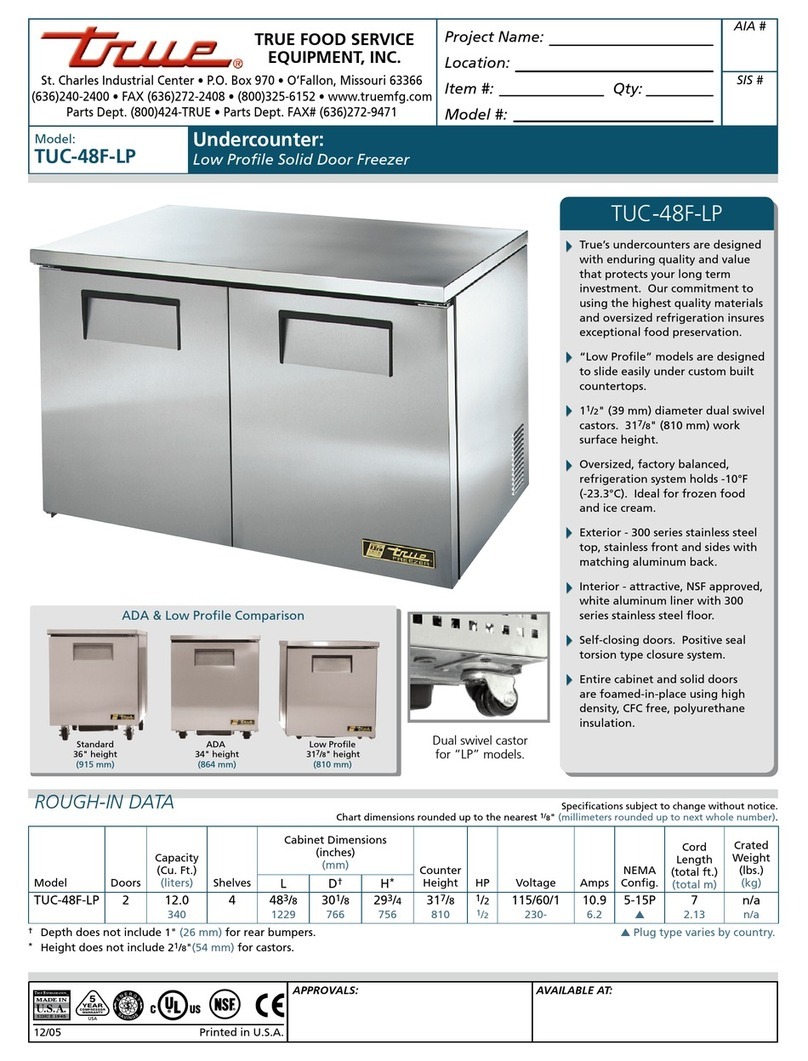

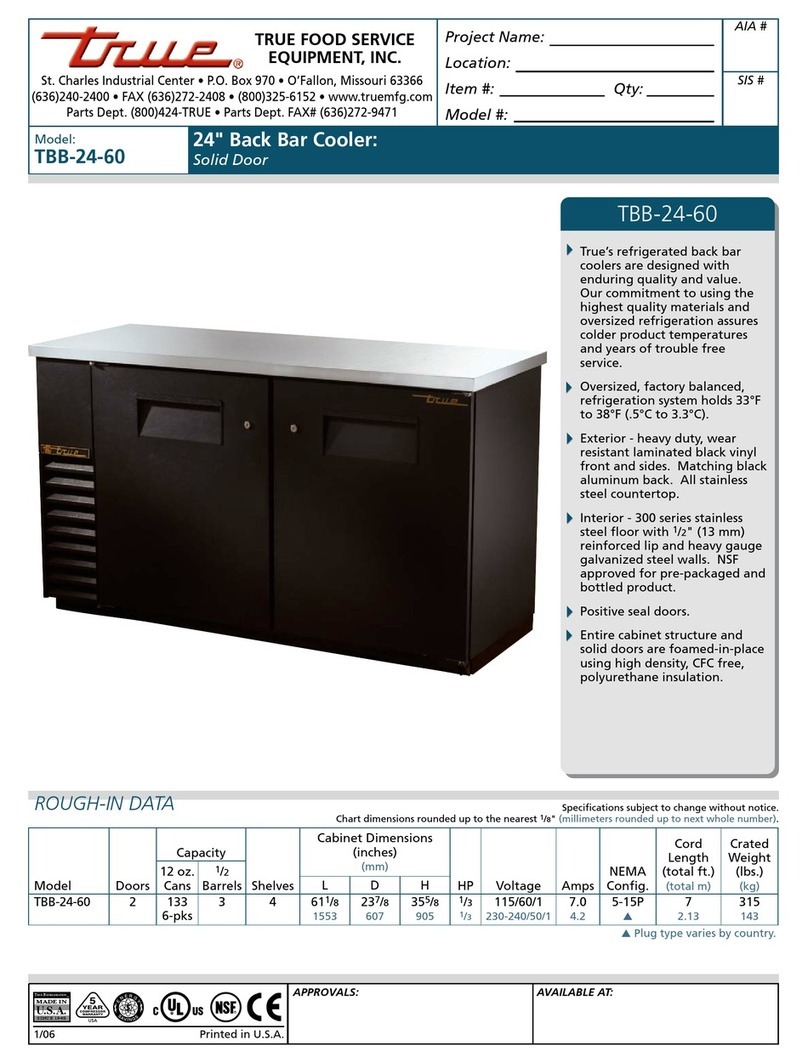

STANDARD FEATURES

Model:

TRUE FOOD SERVICE EQUIPMENT

2001 East Terra Lane • O’Fallon, Missouri 63366 • (636)240-2400 • Fax (636)272-2408 • (800)325-6152 • Intl. Fax# (001)636-272-7546 • www.truemfg.com

METRIC DIMENSIONS ROUNDED UP TO THE

NEAREST WHOLE MILLIMETER

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

PLAN VIEW

KCL

TWT-48F

Worktop:

Solid Door Freezer

Model Elevation Right Plan 3D Back

TWT-48F TFPY02E TFPY02S TFPY02P TFPY023

DESIGN

• True’s commitment to using the highest

quality materials and oversized refrigeration

systems provides the user with colder product

temperatures, lower utility costs, exceptional

food safety and the best value in today’s food

service marketplace.

REFRIGERATION SYSTEM

• Factory engineered, self-contained, capillary

tube system using environmentally friendly

(CFC free) R404A refrigerant.

• Oversized, factory balanced refrigeration system

with guided airow to provide uniform product

temperature.

• Extra large evaporator coil balanced with higher

horsepower compressor and large condenser;

maintains -10°F (-23.3°C). Ideal for both frozen

foods and ice cream.

• Sealed, cast iron, self-lubricating evaporator

fan motor(s) and larger fan blades give True

worktop units a more ecient, low velocity,

high volume airow design. This unique design

ensures faster temperature recovery and

shorter run times in the busiest of food service

environments.

• Condensing unit access in back of cabinet, slides

out for easy maintenance.

• Automatic defrost system time-initiated, time-

terminated.

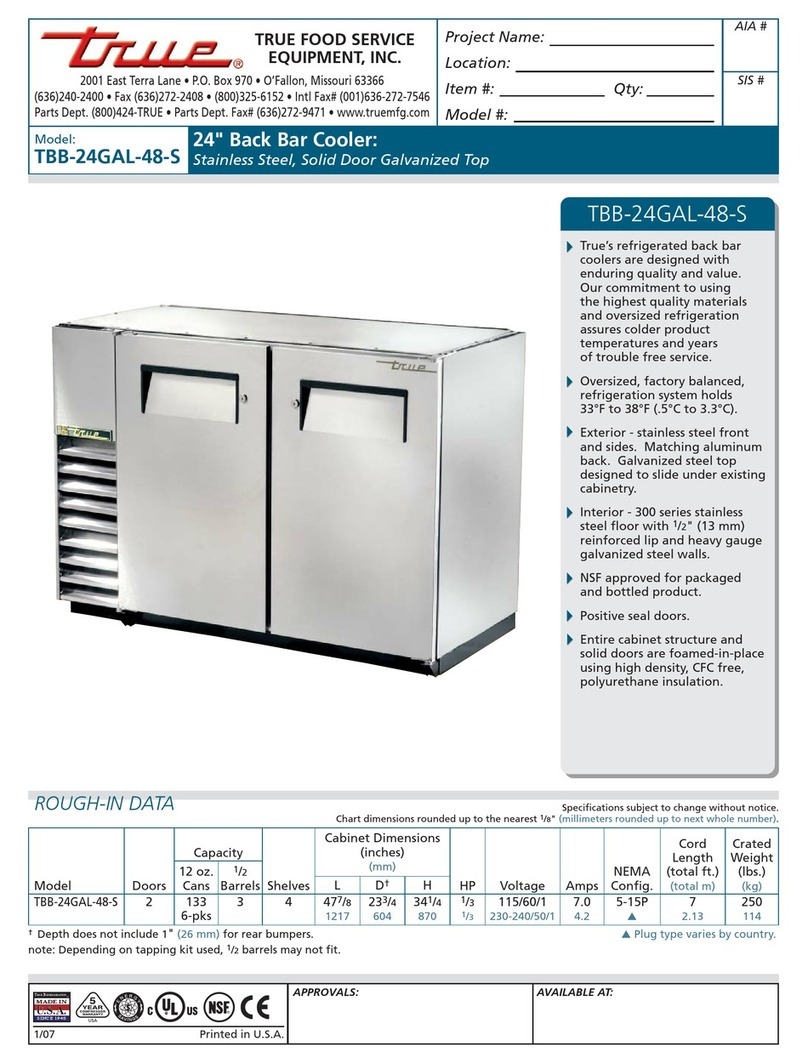

CABINET CONSTRUCTION

• Exterior - stainless steel front, top and ends.

Matching aluminum nished back. Top and

backsplash are one piece formed construction.

Bacteria and food particles cannot be trapped

underneath as with other two-piece worktop

units.

• Interior - attractive, NSF approved, white

aluminum liner. Stainless steel oor with coved

corners.

• Insulation - entire cabinet structure and solid

doors are foamed-in-place using Ecomate. A

high density, polyurethane insulation that has

zero ozone depletion potential (ODP) and zero

global warming potential (GWP).

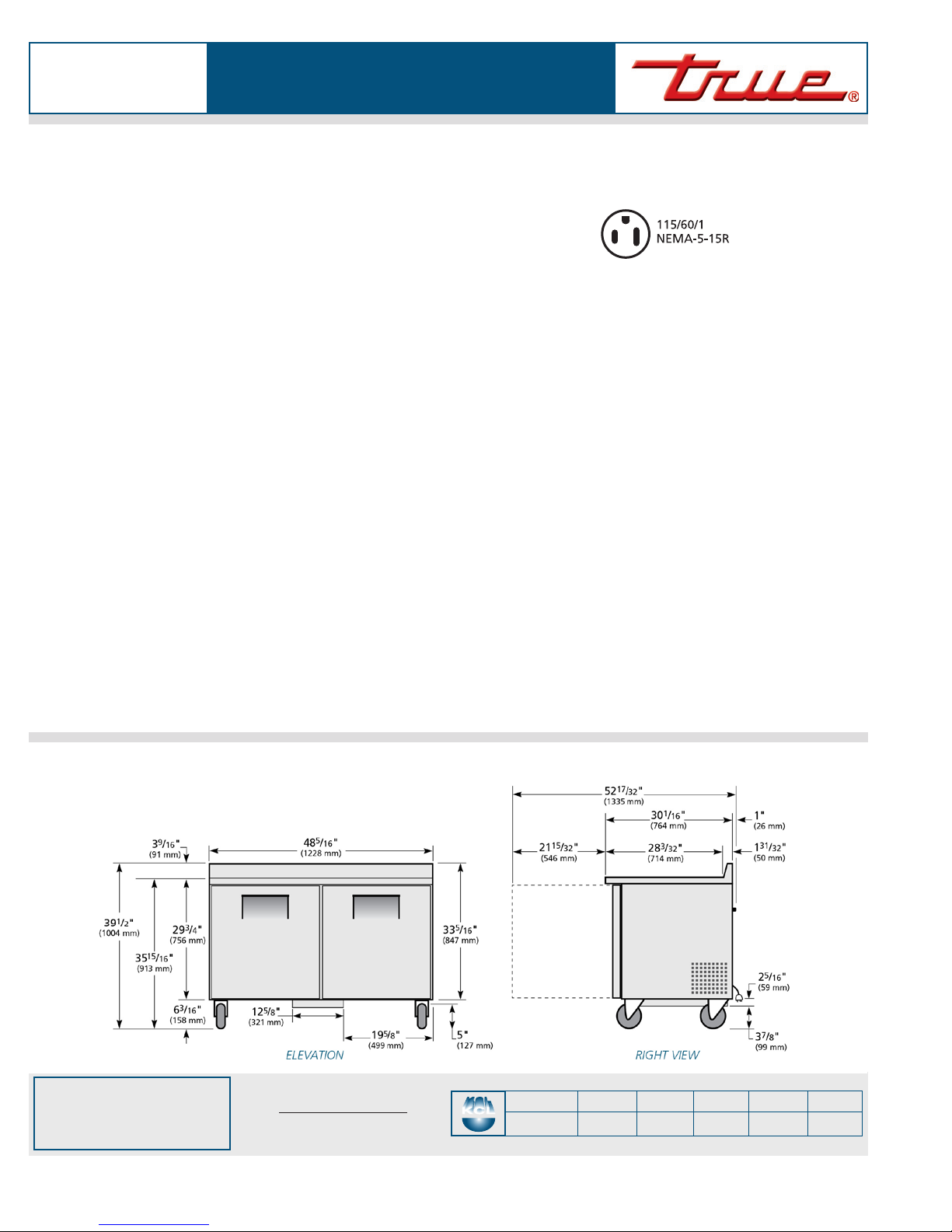

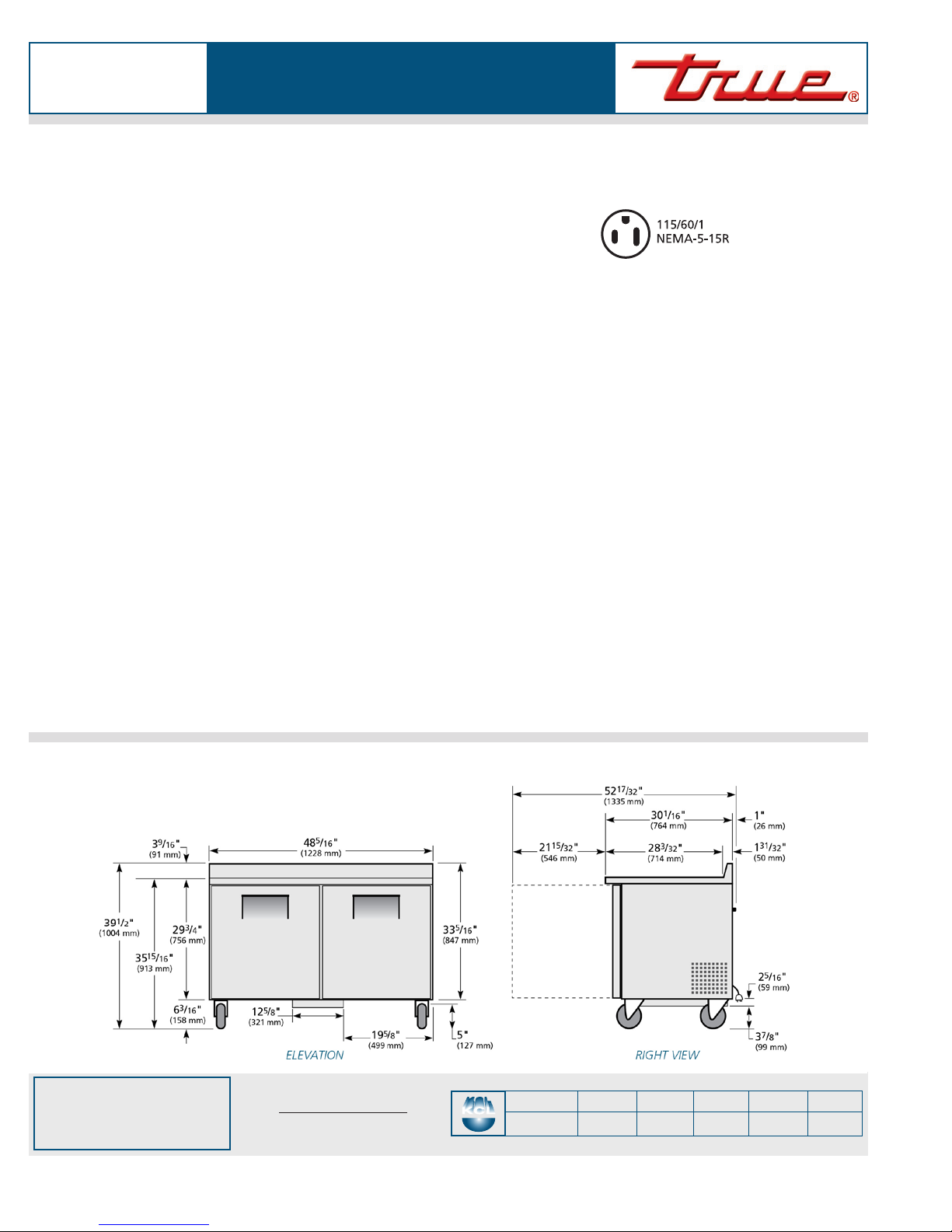

• 5" (127 mm) diameter stem castors - locks

provided on front set. 36" (915 mm) work

surface height.

DOORS

• Each door tted with 12" (305 mm) long

recessed handle that is foamed-in-place with

a sheet metal interlock to ensure permanent

attachment.

• Positive seal self-closing door(s) with 90°stay

open feature. Door(s) swing within cabinet

dimensions.

• Magnetic door gasket(s) of one piece

construction, removable without tools for ease

of cleaning.

SHELVING

• Four (4) adjustable, heavy duty PVC coated wire

shelves 21 ⁄"L x 16"D (548 mm x 407 mm).

Four (4) chrome plated shelf clips included per

shelf.

• Shelf support pilasters made of same material as

cabinet interior; shelves are adjustable on ½" (13

mm) increments.

MODEL FEATURES

• Evaporator is epoxy coated to eliminate the

potential of corrosion.

• NSF-7 compliant for open food product.

ELECTRICAL

• Unit completely pre-wired at factory and ready

for nal connection to a 115/60/1 phase, 15 amp

dedicated outlet. Cord and plug set included.

OPTIONAL FEATURES/ACCESSORIES

Upcharge and lead times may apply.

❑230 - 240V / 50 Hz.

❑6" (153 mm) standard legs.

❑6" (153 mm) seismic/anged legs.

❑2 ½" (64 mm) diameter castors.

❑Single overshelf.

❑Double overshelf.

❑28 ¼" (718 mm) deep, ½" (13 mm) thick, white

polyethylene cutting board. Requires “L”

brackets.

❑28 ¼" (718 mm) deep, ½" (13 mm) thick,

composite cutting board. Requires “L” brackets.

❑Additional shelves.

❑Heavy duty, 16 gauge tops.

❑Exterior rectangular digital temperature display

(factory installed).

❑ADA compliant models with 34" (864 mm) work

surface height.

❑Remote cabinets (condensing unit supplied

by others; system comes standard with 404A

expansion valve and requires R404A refrigerant).

Consult factory technical service department for

BTU information. All remote units must be hard

wired during installation.

WARRANTY

Three year warranty on all parts

and laborand an additional 2

year warranty on compressor.

(U.S.A. only)