Trufrost IC-200 User manual

USER MANUAL

Ice Machine: IC-200, IC-300

IC-455, IC-900

Flake Ice Machines: IF-200, IF-500

IF-1000

2/ 11

Content

I. The Installation of Ice Machine

1.Unpacking Note

2.Environmental Requirements

3.Water supply installation

4.Power Supply Requirements

II. The Use of Ice Machine

1.Checking before Operation

2.Familiarize with the Operation Panel

3.Operating process

4.Other Special Stop Conditions

III. Maintenance and Common Faults

1.Maintenance

2.Common Faults and Removal

3.Conditions Not Covered By Warranty

IV. Attachment

1.List of Attachments

V. Annex

1.Error Codes

2.Circuit Diagrams

Note: We reserve the rights to amend any part of the content in this manual without prior notifications.

Ice Machine Installation and Maintenance Instructions

3

3

3

3

4

4

5

6

7

7

8

8

9

9

8

3/ 11

Modular Type Ice Machine Installation and

Maintenance Instructions

I. Ice Machine Installation

1.Unpacking Note

Check the machine model before unpacking.

Check whether the outer package is intact before unpacking.

Check whether the machine is in good condition, or whether the accessories are

complete after unpacking.

2.Environmental Requirements

Indoor use only. Running the machine below freezing point is strictly prohibited.

Environment temperature: Maximum temperature < 43°C,

minimum temperature > 3°C.

Peripheral spacing: Proper spacing must be observed.(spacing can be reduced

accordingly with water cooling machine).Please refer to the table below:

Machine level placement:Level the machine in place. (It can be adjusted through the

adjustable foot at the bottom of the machine.)

3.Water Supply Installation

The water used for the ice making must be in accordance with the standards of local

drinking water.

The water used for the ice making may be connected to a filtration device first.

(Depending on the local water quality)

It is forbidden to connect the ice machine with hot water.

Please refer to the water inlet and drain pipe layout as following:

Machine

Spacing in cm

Side

15

Back

20

Front

30

Water

Temperature

(°C )

Ice Making

Water

Pressure

(Mpa)

Cooling

Water

Pressure

(Mpa)

Inlet Pipe

Diameter

(mm)

Drain Pipe Diameter (mm)

>0.6

>0.13

>0.59

>9.5(3/8”)

>15.8(5/8”)

<32

<0.55

<1.17

Drop per meter>3cm

Ice Machine Installation and Maintenance Instructions

The installation of drain pipe must observe the following principles

(Please refer to the diagram below):

1. Any point in the middle of drain pipe shall not be higher than the outfall.

2. Any point in the middle of drain pipe shall not be higher than outlet.

4/ 11

Installation Diagram (for reference only):

Air-Cooling Machine

Water-Cooling Machine

Note:

(a)The inlet and outlet of cooling water are only

applicable to the water cooling machine.

(b) The outer filter is optional.

External Power Supply

External Water Supply

Filter

Discharge into sewer

Cooling Water Inlet

Cooling Water Outlet

Ice Machine Installation and Maintenance Instructions

External Power Supply

External Water Supply

Discharge into sewer

Note:

(a) The outer filter is optional.

Drain Pipe Installation Attention

The drain pipe

mustn't be like this.

Drain Pipe Installation Attention

The drain pipe

mustn't be like this.

Drain Pipe Installation Attention

5/ 11

4.PowerSupplyRequirements

The voltage, frequency and capacity of power supply provided is consistent with

that marked on the machine nameplate.

The earth terminal of the power supply, socket or plug must be connected to

the external grounding steadily!

The power supply wire provided etc. shall all be in accordance with the standards of

the local country or region.

The power supply voltage fluctuation shall not exceed ±10% of the rated voltage.

II. The Use of Ice Machine

1. Checking Before Operation

Whether all the temporary fixed tapes in the ice machine has been removed!

Whether all the accessories or other items in the ice machine has been taken out!

Whether the ice machine is appropriately leveled!

Whether all the water pipes are correctly connected!

Whether the plug is connected to the power supply steadily!

Whether the machine grounding is connected to external grounding steadily!

To confirm that the power supply's voltage frequency and others are consistent with

the machine nameplate!

To confirm that the environment temperature and water temperature is with the

scope mentioned!

6/ 11

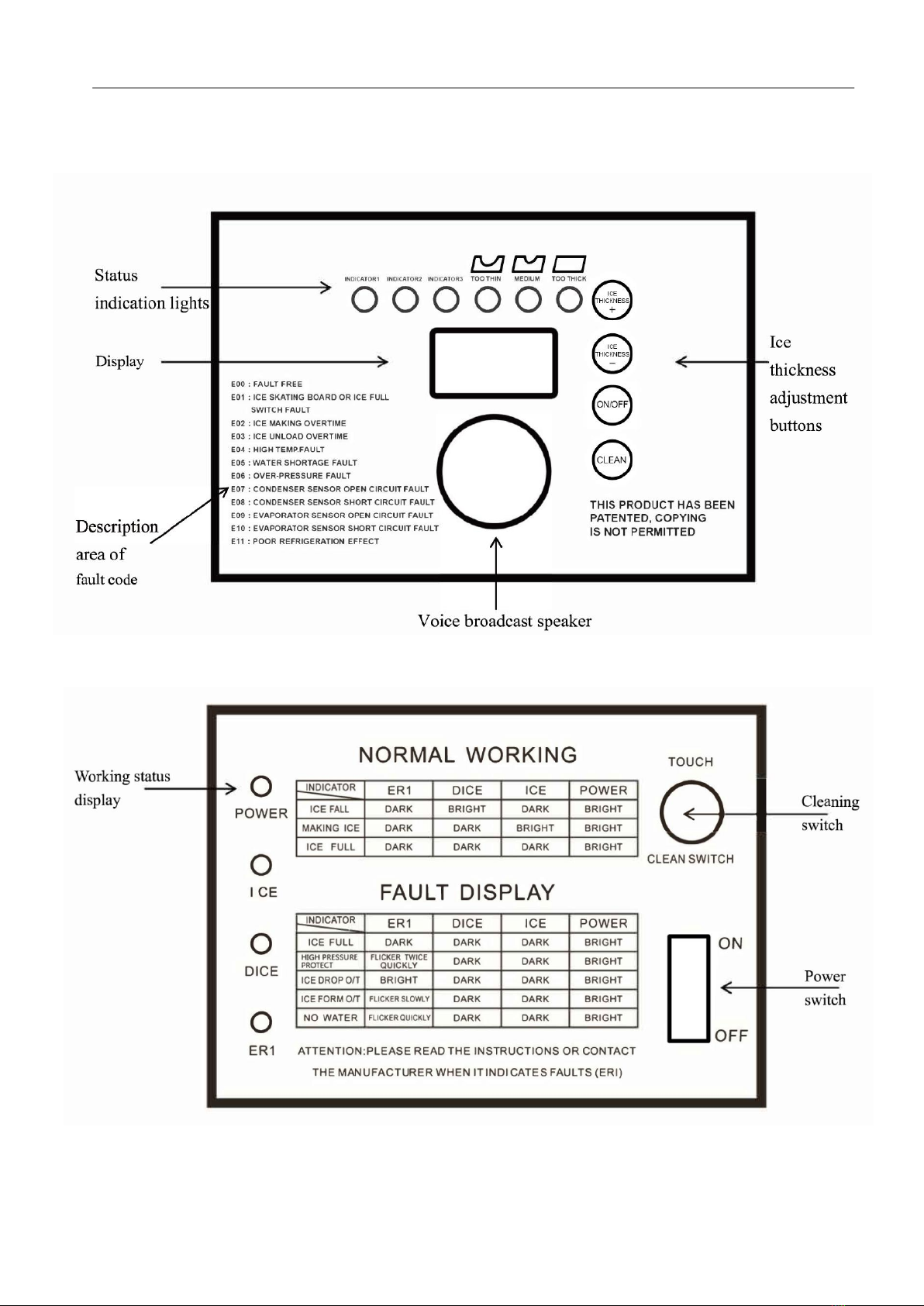

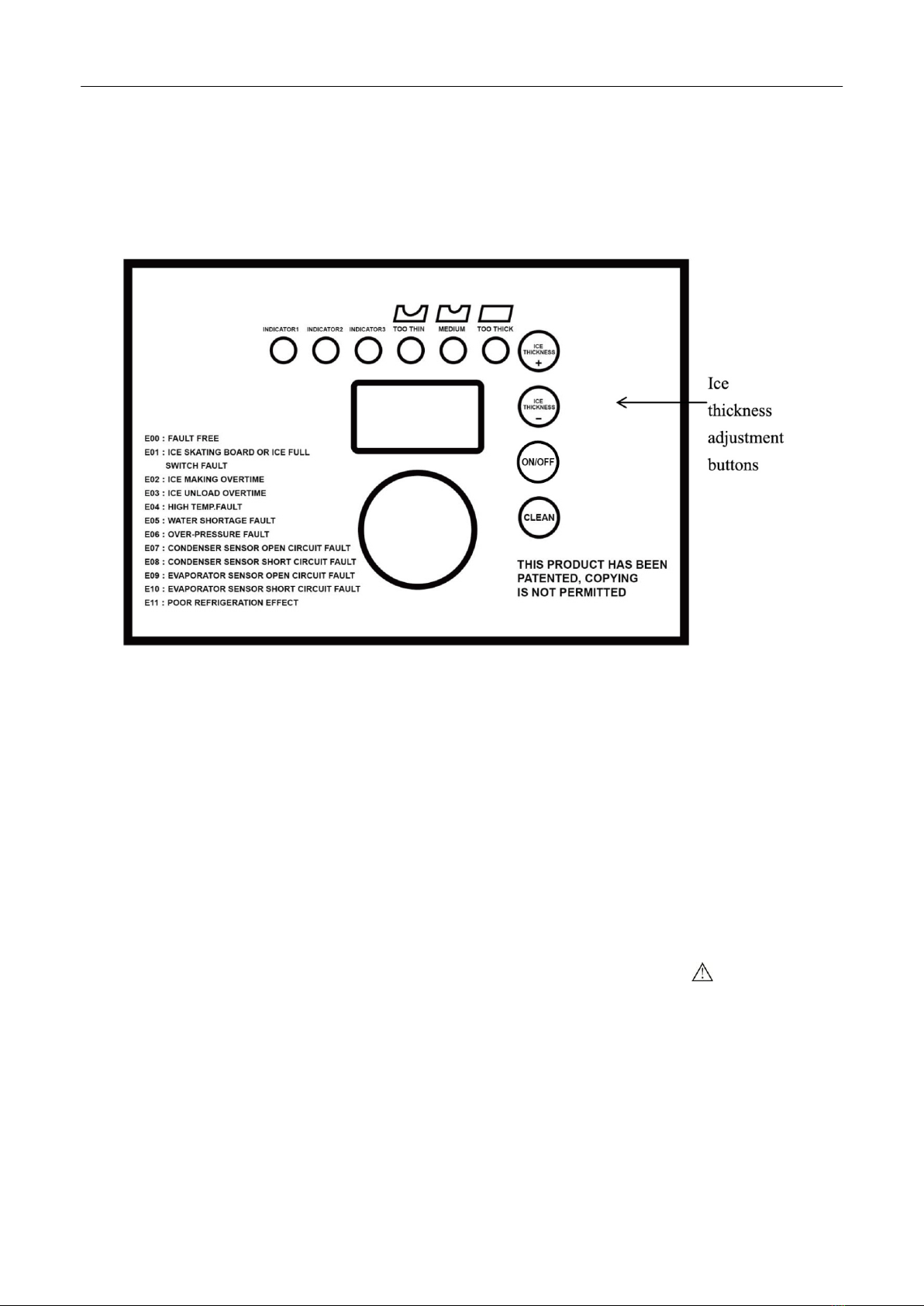

2. Familiarize with the Operation Panel

With voice panel:

Without voice panel:

Ice Machine Installation and Maintenance Instructions

7/ 11

3. Operating Process

Start up: Clicking the button (switch) on the panel after connected to the power

and water supply correctly, the machine will on. During the whole operating

process, it will work automatically.(Note: Please turn off the power supply in case

of thunderstorm or long time not in use.)

Pre-cooling: After power on, the water inlet valve will turn on automatically, the

evaporator pre-cools for 30 seconds before the water pump starts up, meanwhile the

compressor starts, the water pump stops running, the water inlet valve continues to

take in water till the specified level (that is to say water floating ball switch stops

water inlet).

Ice making: After pre-cooling for 30 seconds, the water pump starts up, continuous

water flows smoothly and ice comes into being gradually in ice try of the

evaporator.

Ice falling: After reaching the stipulated ice making time, the water pump shuts

down, the defrost valve powers on and open, and hot air enters into the evaporator,

at the same time the drain valve closes after 30 seconds. The water inlet valve open,

the whole sheet of ice will slide from the evaporator into the storage refrigerator

after defrosting for 1~2minutes. During the process of ice falling, hands should

be away from the storage refrigerator to avoid being hit by it !

Shutdown: When the machine runs, clicking the button(switch) on the panel and

the machine stops working.

Automatic Stop When Ice is Full: In the running, with the accumulation of ice in

the ice bin, it will reach to a certain height and block other ice fall down .Eventually

the full of ice result in sliding board cannot be rebounded and reset. After machine

detected it for a few time (30 seconds or so) and confirmed ice bin is full of ice , the

machine will stop working automatically. Until removed full of ice ,the sliding

board will be rebounded and reset again ,then machine will work automatically

again.

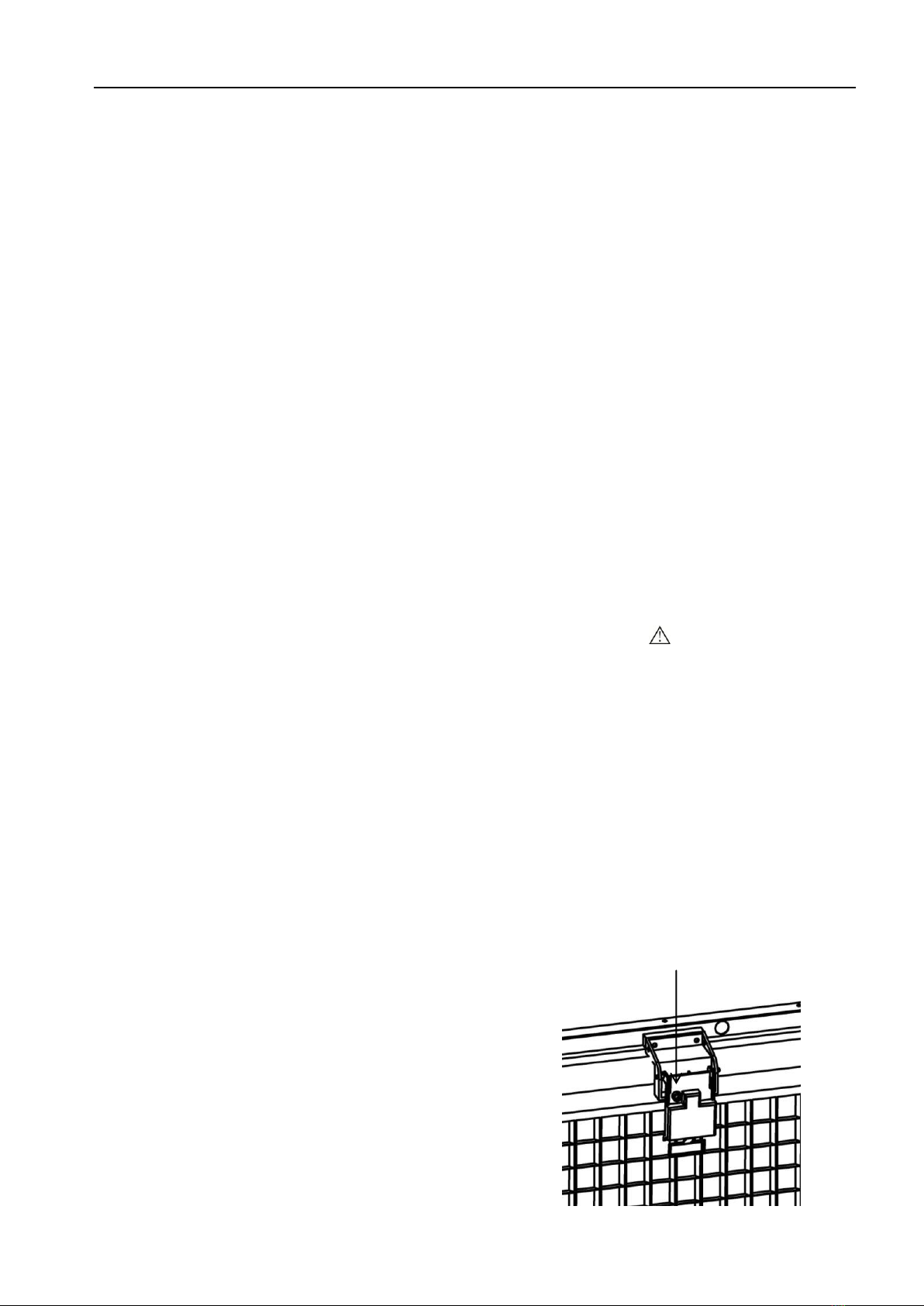

Ice thickness adjustment: There are two methods to adjust the ice thickness.

Please choose one according to the machine.

Method I, In the process of ice making,

the adjusting screw on the ice thickness

detector can be rotated left or right according to

the actual condition and the attached adjustment

instruction labeling if the ice thickness isn't

satisfactory, and tightens the screw after the

adjustment is completed.

Note: The adjustment shall be limited to

a circle each time.

Ice Machine Installation and Maintenance Instructions

Ice Thickness Adjusting Screw

8/ 11

Method II, In ice making process, if you are not satisfied with ice thickness please

adjust it through clicking the button on the touch panel (increase ice thickness + , reduce

ice thickness -)

Note: ice making time will extend or shorten one minute for every click.

4. Other Special Stop Conditions

There is no ice falling in three times consecutive cycles, this series of

machine stops automatically.

Environmental temperatures exceeds the prescribed temperature, this series of

machine stops automatically.

No condensed water in water cooling machine, this series of machine stops

automatically.

III. Maintenance and Common Faults

1. Maintenance:

Before maintenance and repair, the power must be cut off!

Maintenance and repair shall be handled by qualified professionals only.

Please read this manual in detail before maintenance and repair.

The manufacturer isn't responsible for the consequences of poor water quality

and wrong operation.

Clear the dust on the surface of machine regularly.

Clean the filter net (only applicable to air cooling machine)regularly, As

shown by picture:

Ice Machine Installation and Maintenance Instructions

9/ 11

Clean the cooling fin regularly at least at every 6 months. Please use the soft

brush to work in up-and-down lightly. Don’t swipe left-and-right for fear of

damaging the cooling fin and influencing the heat dissipation effect.

2.Common Faults and Removal:

3.Conditions Not Covered By Warranty:

The following conditions are not with the scope of ice machine warranty:

A. Normal maintenance, adjustment and cleaning.

B. Modify ice machine without authorization or use the non-original parts without prior

written permission from manufacturer.

C. Damage incurred due to improper installation, power supply, water supply and drainage,

etc.

Fault Phenomenon

The possible causes of

troubleshooting

Check and eliminate

Ice Machine not

starting up

No power supply

Power switch, power wire

Automatic stop after

starting the ice machine

for 3 minutes

High pressure protection

High ambient temperature,

dirty condenser , high voltage

switch, air cooled motor

Ice machine can only

make ice once

whenever it starts

Ice full

Ice sliding board

Ice cannot fall

Ice machine is dirty, the

ambient temperature is low

Clean, ambient temperature up

to requirement.

Ice is too thin or

incomplete

Tank water level is too low,

inlet valve doesn’t work,

water pressure is not

enough 、waterway is not

smooth

Check water level, water inlet

valve, water pressure and

pipeline

Ice making is too slow

Condenser is dirty, high

ambient temperature and poor

ventilation

Clean the filter and condenser,

keep specific spacing around the

machine

Ice Machine Installation and Maintenance Instructions

Take out all the filter nets along the

direction of arrow on both sides, and put

back the net into the ventilation window

after dusting by soft brush.

10 / 11

D. Additional labor fee due to holidays, overtime, etc., travel expenses during the travel

and reimbursement, etc. The extra expenses caused by inconvenience of maintenance.

E. Damage parts caused by misuse, abuse or negligence.

F. Damage or malfunction incurred caused by failure to follow the installation cleaning or

maintenance of the ice machine in the manual.

G. Other external damages not mentioned above.

IV. Attachment

Please refer to the attached list in detail.

V. Annex

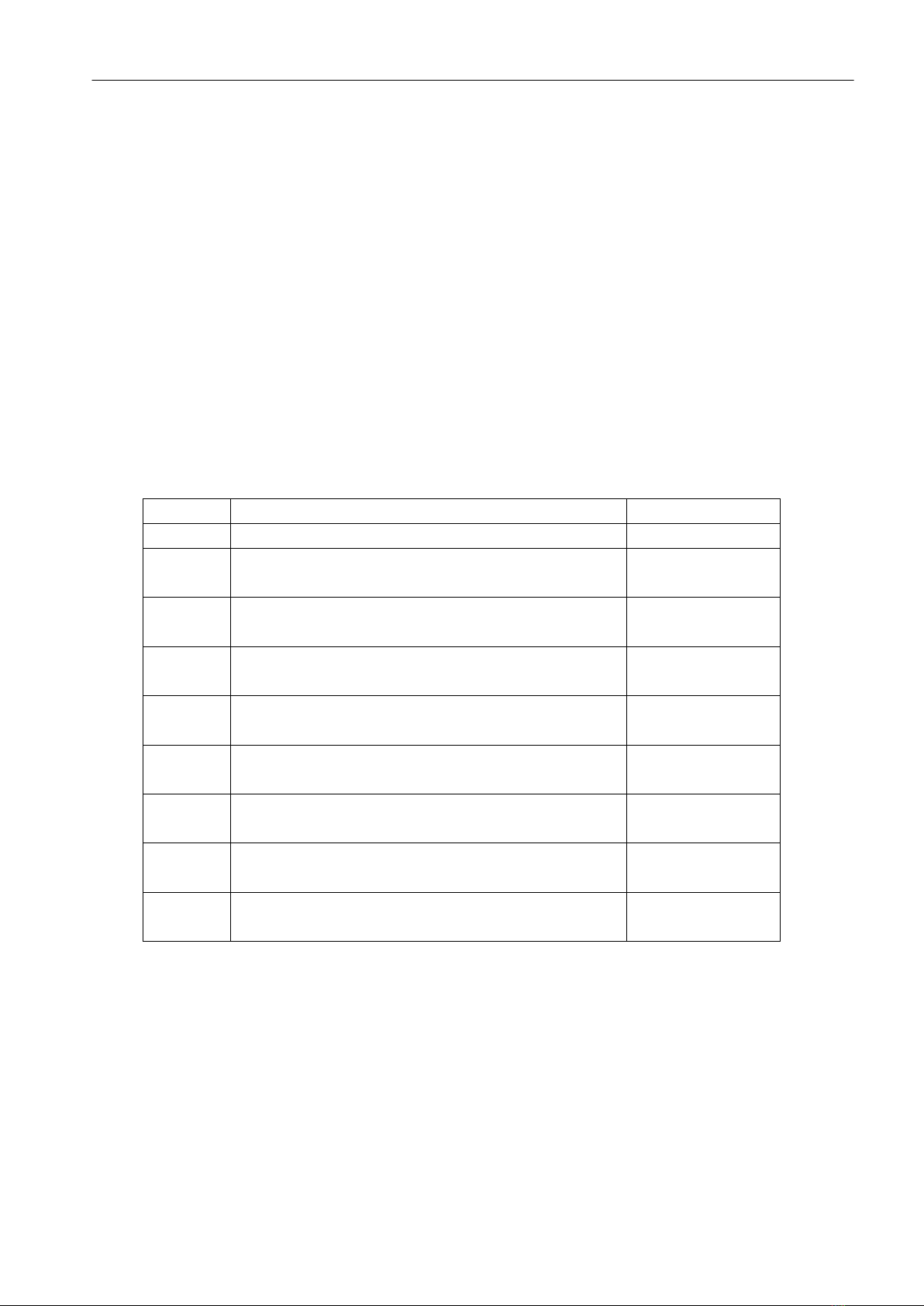

1. Error Codes:

Code

Annotation

Machine Action

E00

No fault

Operating

E01

Ice sliding board fault

Protection

Shutdown

E02

Overtime ice making fault

Protection

Shutdown

E03

Overtime ice-shedding fault

Protection

shutdown

E04

High temperature fault (voice announcement

pressure beyond limit)

Protection

shutdown

E05

Water shortage fault

Protection

shutdown

E06

Excess of pressure limit fault

Protection

shutdown

E07

Condensation sensor open circuit fault, display

once every 5 seconds

Non stop

E08

Condensation sensor short circuit fault, display

once every 5 seconds

Non stop

2.Circuit Diagrams

Please refer to the machine body in detail.

Ice Machine Installation and Maintenance Instructions

TRUFROST COOLING PRIVATE LIMITED

509, 5th Floor, Emaar Palm Springs Plaza, Golf Course Road,

Sector 54, Gurugram- 122011, India

T. +91-124-2570524 info@trufrost.com

www.trufrost.com

This manual suits for next models

6

Table of contents

Other Trufrost Ice Maker manuals