Trumpf TruTool TPC 165 User manual

Table of contents

1 Safety 4

1.1 General safety information 4

1.2 Specific safety information for Panel Cutter

TPC 165

5

2 Description 7

2.1 Intended use 7

2.2 Technical data 9

2.3 Icons 9

2.4 Noise and vibration information 10

3 Setting work 12

3.1 Changing/tensioning the tool 13

4 Operation 15

4.1 Working with the Panel Cutter 15

Checking the tool 16

Working procedure 16

Overload protective device on the motor 18

4.2 Main machine position 18

4.3 Table markings 19

4.4 Plunging depth 20

4.5 Guide rails 20

Working with the guide rail 20

4.6 Cutting along scribed line 21

4.7 Slide rails and wearing plate 22

Replacing the slide rails 23

Replacing the wearing plate 23

Replacing the front wearing plate 23

4.8 Exhaust system 23

4.9 Electronic signal display 24

5 Maintenance and repairs 26

5.1 Maintenance 26

Set screw - Adjusting the ratchet 27

5.2 Repairs 28

Replacing carbon brushes 28

2Table of contents E848EN_00

1. Safety

1.1 General safety information

■Read all safety warnings and all instructions including those

in the brochure also supplied.

■Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

■Save all warnings and instructions for future reference.

Electrical voltage! Risk of fatal injury due to electric shock!

ØRemove the plug from the plug socket before undertaking

any maintenance work on the machine.

ØCheck the plug, cable and machine for damage each time

before using the machine.

ØKeep the machine dry and do not operate it in damp rooms.

ØConnect the fault current (FI) circuit breaker with a maxi-

mum breaking current of 30 mA when using the electric tool

outside.

ØOnly use original TRUMPF accessories.

ØIf the connection cable has to be replaced, this may only be

done by the manufacturer or an authorized dealer to avoid

safety hazards.

Damage to the machine due to improper handling.

ØWear safety glasses, hearing protection, breathing protec-

tion, protective gloves and working shoes when working.

ØConnect the plug only when the machine is switched off.

Pull the power plug after use.

ØDo not carry the machine by the cable.

ØHave maintenance carried out by specialists.

Note

If the power cable is to be replaced, it should be procured from

the manufacturer or an authorized dealer to avoid safety haz-

ards.

4Safety E848EN_00

DANGER

WARNING

1.2 Specific safety information for Panel

Cutter TPC 165

Electrical voltage! Risk of fatal injury due to electric shock!

ØHold the machine with both hands on the insulated handle

during machining.

ØAlways keep the power cable behind the device and do not

pull it over sharp edges.

ØDo not perform any work that may cause the machine to

come into contact with hidden power lines or its own cable.

Contact with a live conductor can cause metallic machine

parts to become live and can lead to an electric shock.

Risk of injury to hands.

ØDo not reach into the processing line with your hands.

ØDo not reach into the saw chain with your hands.

ØDo not reach under the workpiece. The saw chain and the

blade are unguarded when they are in the swivelled out sta-

tus.

ØNever hold the workpiece in your hands or over your leg

during machining.

Health risks especially damage to muscles and joints due

to strong vibrations during operation.

ØCarry out machining at normal feed power.

E848EN_00 Specific safety information for Panel Cutter TPC 165 5

DANGER

WARNING

WARNING

Risk of injury due to improper handling!

ØMake sure the machine is always in a stable position when

operating it in order to absorb any possible kickback forces.

ØAlways operate the machine away from your body.

ØDo not carry out overhead work on the machine.

ØThe machine may only be operated with a protective cover.

ØIf the saw falls down, check that the saw chain and saw

blade move freely afterwards. The protective cover and

other parts must not be touched.

ØBefore putting the machine down, ensure that the blade is

folded in.

ØIf the saw should get stuck in the material, release the

switch and do not move the saw in the material until the

saw chain stops. When restarting, center the saw blade in

the kerf and make sure that the teeth of the saw chain are

no longer stuck.

ØBlades of the predecessor models (e. g. TP 150-0 and

TPC 150-2) as well as damaged blades must not be used.

ØFollow the instructions for lubrication, chain tensioning and

changing accessories. An improperly tensioned or lubricated

chain can break.

ØKeep the handles clean and free of oil and grease. Greasy,

oily handles are slippery and will lead to loss of control.

Risk of injury through defective brake!

ØCheck the brake before every use. The brake must stop

movement of the chain within 2 s. If there is a defect, inform

TRUMPF Service.

ØDo not clamp the switch for the saw chain and swivel lever

for the blade.

ØIf the saw falls down, check the brake for perfect operation

afterwards.

6Specific safety information for Panel Cutter TPC 165 E848EN_00

WARNING

WARNING

2. Description

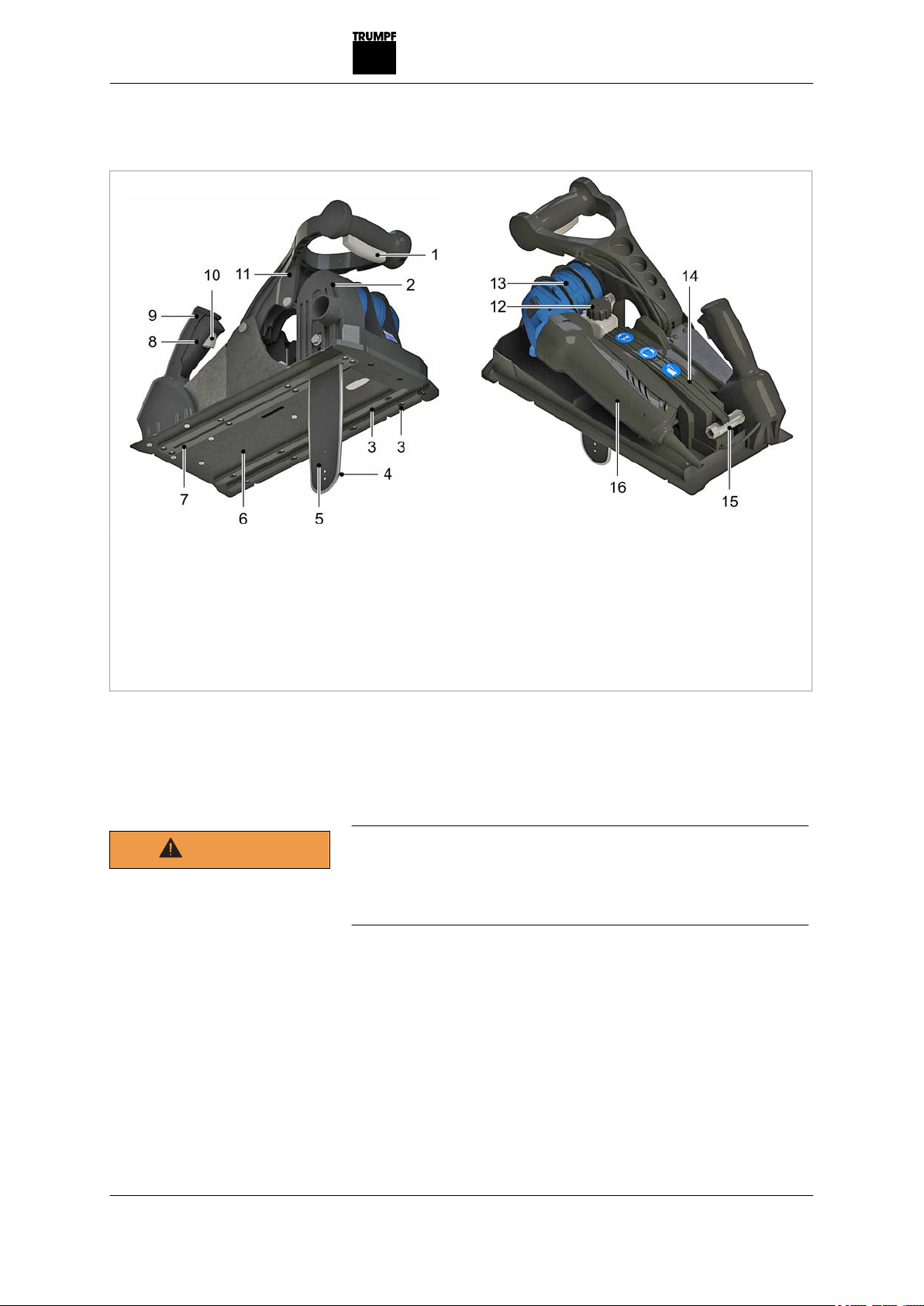

1 Swivel lever, blade

2Protective cover and suction

connection piece, vacuum

cleaner

3 Slide rails

4 Saw chain

5 Blade

6 Support table

7 Wearing plate

8Switch, saw chain

9 Adjustable grip

10 Release button

11 Lever handle, blade

12 Oil tank cover

13 Gearbox

14 Cover

15 Combination wrench

16 Motor

TruTool TPC 165 Fig. 67302

2.1 Intended use

Danger of injury and health hazard!

ØOnly use the machine for the work and materials described

under "Intended use".

ØDo not cut materials containing asbestos.

The TRUMPF Panel Cutter TPC 165 is an electrically operated

hand-held device:

■For commercial use in industry and trade.

■For efficiently cutting panels with metal outer shells and poly-

urethane or polyisocyanurate rigid foam insulation (roof and

wall panels).

■For easy piercing in panels for producing cornered cutouts.

E848EN_00 Description 7

WARNING

■For cutting along a scribed line.

■For cutting with a guide rail.

8Intended use E848EN_00

2.2 Technical data

Other countries USA

Values

Voltage 230 V 120 V 110 V 120 V

Frequency 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

Working speed 4 m/min 4 m/min 4 m/min 9.8 ft/min

Nominal power consumption 1400 W 1400 W 1400 W 1400 W

Idle stroke rate n02300/min 2300/min 2300/min 2300/min

Cutting track width 4 mm 4 mm 4 mm 4 mm

Weight 9.6 kg 9.6 kg 9.6 kg 21.2 lbs

Safety class

II / II / II / II /

Technical data Tab. 1

Other countries USA

Permissible material thicknesses

Individual material thickness for

steel up to 400 N/mm2

0.9 mm 0.9 mm

(0.035 in)

With insulation made of polyur-

ethane foam (PUR) and polyisocya-

nurate foam (PIR)

165 mm 165 mm (6.4 in)

Permissible material thicknesses Tab. 2

Other countries USA

Minimum cutouts

Blade 165 340 x 340 mm 340 x 340 mm

(13.5 x 13.5 in)

Minimum cutouts Tab. 3

2.3 Icons

Note

The following symbols are important for reading and understand-

ing the operator's manual. The correct interpretation of the sym-

bols will help you operate the machine better and safer.

Icon Name Meaning

Read operator's manual Read the operator's manual and safety information in

their entirety before starting up the machine. Closely

follow the instructions given.

Wear safety glasses. Chips could fly out of the tool.

E848EN_00 Technical data 9

Icon Name Meaning

Wear gloves. Chips could fly out of the tool.

Wear hearing protection. Noise emission value can be exceeded.

Danger of injury due to rotating

saw.

Do not reach into the saw chain with your hands.

Safety class II Indicates a doubly insulated tool.

Alternating current Type or property of current

V Volt Voltage

A Ampere Current, current input

Hz Hertz Frequency (oscillations per second)

W Watt Power, power input

mm Millimeters Dimensions e.g.: material thickness, chamfer length

in Inch Dimensions e.g.: material thickness, chamfer length

noIdle speed Revolution speed without load

.../min Revolutions/strokes per minute Revolution speed, stroke rate per minute

Tab. 4

2.4 Noise and vibration information

Noise emission value may be exceeded.

ØWear hearing protection.

The vibration emission value can be exceeded!

ØSelect the right tools and exchange them in time in the

event of wear.

ØHave maintenance carried out by trained specialized techni-

cians.

ØDefine additional safety measures for protecting the operator

from the effect of vibrations (e. g. keep hands warm, organi-

zation of working procedures, machining at normal feed

force).

ØDepending on the operating conditions and state of the elec-

tric tool, the actual load might be higher or lower than the

specified measured value.

Health risks especially damage to muscles and joints due

to strong vibrations during operation.

ØCarry out machining at normal feed power.

10 Noise and vibration information E848EN_00

WARNING

WARNING

WARNING

Notes

■The specified vibration emission value was measured in

accordance with a standardized testing procedure and can

be used to compare one electric tool with another.

■The specified vibration emission value can also be applied

for a provisional estimate of the vibration load.

■Times during which either the machine is switched off or run-

ning but not actually in use can considerably reduce the

vibration load during the entire working period.

Designation of measured value Unit Value according to

EN 60745

Vibration emission value ah (vector

sum of three directions)

m/s25.1

Uncertainty K for vibration emission

value

m/s21.5

A-class acoustic pressure level LPA

typically

dB (A) 89

A-class acoustic power level LWA

typically

dB (A) 100

Uncertainty K for noise emission

value

dB 3

Tab. 5

E848EN_00 Noise and vibration information 11

3. Setting work

Risk of fatal injury due to electric shock!

ØRemove the plug from the plug socket before changing the

tool or undertaking any maintenance work on the machine.

Damage to property!

Wear and destruction of the saw chain and blade, tool

failure.

ØDo not tension the saw chain too tautly (see "Fig. 67306",

pg. 14).

ØWhen inserting the saw chain, always pay attention to the

tooth direction.

ØDo not operate the saw chain without lubricant (see "Tab.

8", pg. 26).

ØAvoid collisions during work. Do not cut into nails, screws,

etc.

Damage to property due to the wrong tools being used!

Reduction in service life of the tools.

ØDepending on the application, use the right tools according

to the following table.

Panel thickness (outer plate + foam insula-

tion)

Saw chain 165 with

blade 165

max. 165 mm

Tab. 6

Both the saw chains as well as the blades are meant for pro-

cessing panels with outer plates up to a tensile strength of

400 N/mm² and a thickness up to 0.9 mm. A panel thickness up

to 165 mm with foam insulation can be processed.

The machine is suitable for cutting panels with the insulation

materials polyurethane foam (PUR) and polyisocyanurate foam

(PIR).

Note

If the structure of the panels to be processed vary from the

above-described version (thicker outer plates or higher tensile

strength, other insulation materials), it is to be expected that the

service life of the saw chain and blade will be reduced. Also,

penetrating into the material with the blade might be more diffi-

cult, or might not be possible at all.

12 Setting work E848EN_00

DANGER

NOTICE

NOTICE

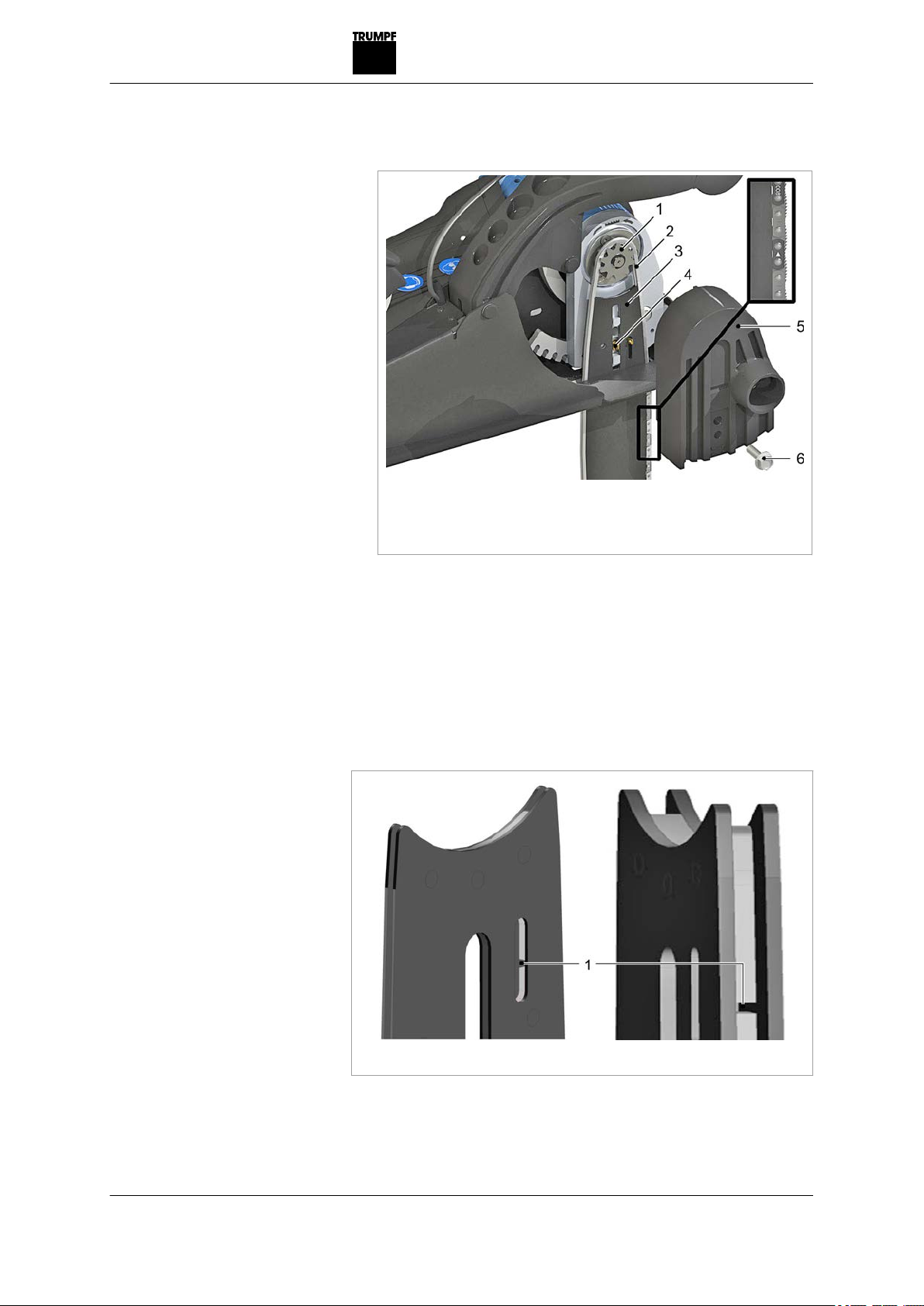

3.1 Changing/tensioning the tool

1 Chain wheel

2Saw chain

3 Blade

4 Chain tightener

5Protective cover

6 Hexagon-head screws

Fig. 67303

1. Loosen the hexagon-head screw (6) using a combination

wrench (in the cover) and remove.

2. Take off the protective cover (5).

3. Shift the blade (3) by turning the chain tensioner (4) toward

the chain wheel (1).

4. Lift the saw chain (2) with the blade (3) out of the chain

wheel (1).

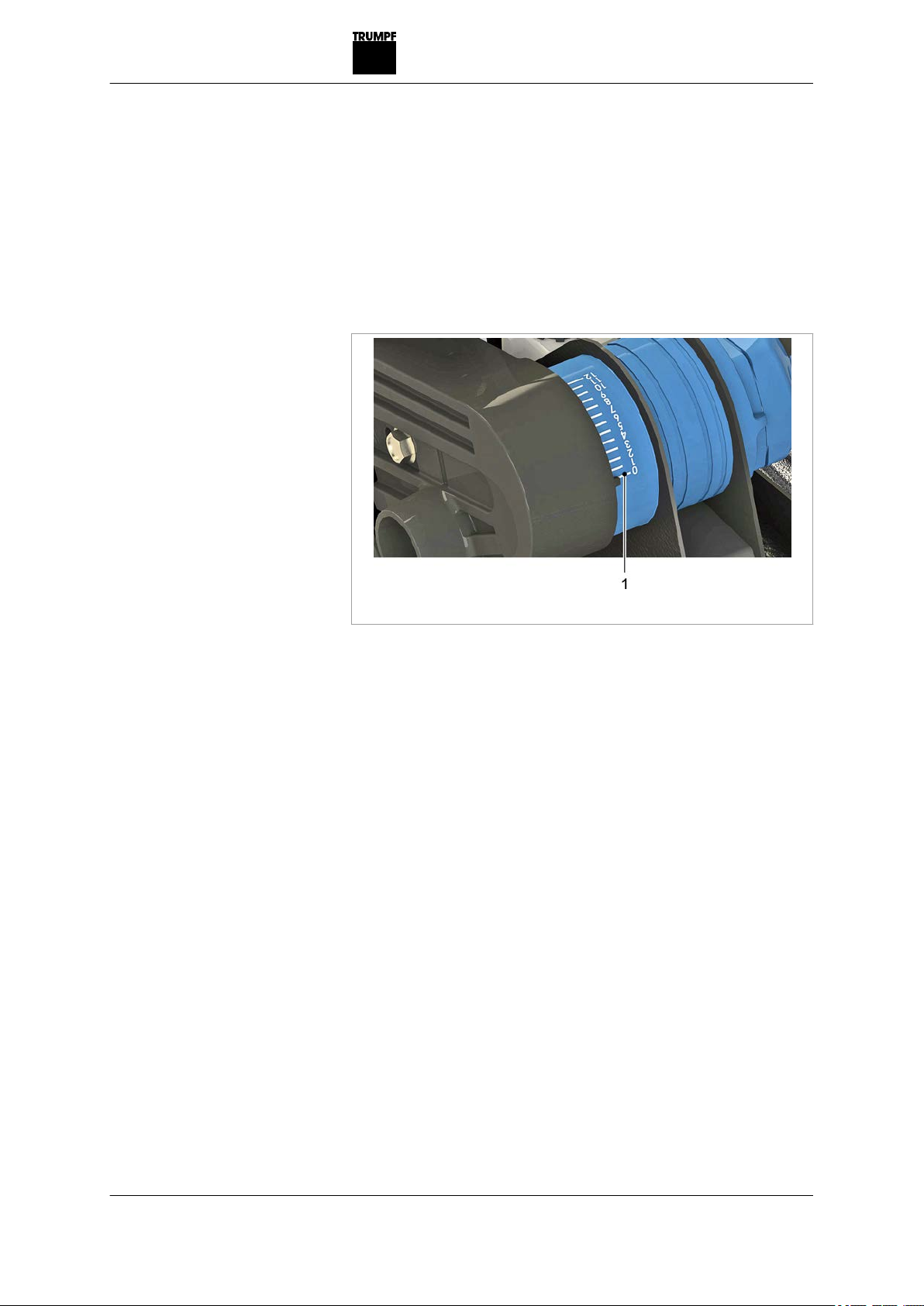

1 Oil channel

Fig. 31844

E848EN_00 Setting work 13

Removing the saw chain

Checking the oil channel

Damage to property.

A clogged oil channel can lead to increased wear or to the

saw chain breaking.

ØClean the oil channel regularly.

5. Check the oil channel. It must not be dirty.

6. Insert a new saw chain in the blade and chain wheel. While

doing so, pay attention to the running direction (arrow) of the

saw chain.

Correct chain tension Fig. 67306

7. Shift the blade by turning the chain tensioner. Tension the

saw chain until it can be lifted approx. 3 mm (dimension, see

Fig. 67306) from the blade by hand (measuring point is mid-

dle of blade).

8. Stick on the protective cover.

9. Screw the protective firmly in place using the hexagon-head

screws (6).

10. Loosen the hexagon-head screw (6) using a combination

wrench (in the cover) with one turn.

11. Shift the blade by turning the chain tensioner.

12. Tension the saw chain until it can be lifted approx. 3 mm

(dimension, see Fig. 67306) from the blade by hand (meas-

uring point is middle of blade).

13. Screw the protective cover firmly in place.

14 Setting work E848EN_00

NOTICE

Inserting the saw chain

Tensioning the saw chain

4. Operation

4.1 Working with the Panel Cutter

Damage to property due to excessively high line voltage!

This could result in motor damage due to overload.

ØCheck the line voltage. The power supply voltage must cor-

respond to the information on the nameplate of the machine.

Risk of injury due to improper handling!

ØMake sure the machine is always in a stable position when

operating it.

ØNever touch the tool while the machine is running.

ØAlways operate the machine away from your body.

ØDo not carry out overhead work on the machine.

ØThe machine may only be operated with the protective

cover.

Work is performed with two-hand operation for all machine posi-

tions.

2-hand control device Fig. 67304

When operating the machine ensure that the machine is held

with both hands in such a way that both hands are kept away

from the processing point.

E848EN_00 Operation 15

CAUTION

WARNING

2-hand control device

Checking the tool

Damage to property caused by blunt tools!

Machine overload.

ØCheck tools every hour for wear. Sharp saw blades have

good cutting performance and prevent damage to the

device. Change the saw chain in due time.

ØCheck whether both tools, the saw chain and the blade, are

correctly mounted.

Working procedure

Damage to property!

Wear and destruction of the saw chain and blade, tool

failure.

ØDo not tension the saw chain too tautly (see "Fig. 67306",

pg. 14).

ØWhen inserting the saw chain, always pay attention to the

tooth direction.

ØDo not operate the saw chain without lubricant (see "Tab.

8", pg. 26).

ØAvoid collisions during work. Do not cut into nails, screws,

etc.

16 Working with the Panel Cutter E848EN_00

NOTICE

NOTICE

1 Motor

2 Switch

3 Guide rail

4 Release button

5Saw chain

6 Panel

Fig. 67305

1. Fill the oil tank with punching and nibbling oil.

2. Press the release button (4)(see "Fig. 67305", pg. 17) and

then press the switch (2).

Motor (1) switches on, saw chain (5) runs.

3. Keep the switch (2) pressed for approx. 2 minutes until both

oil hoses have filled with oil.

4. Pierce into the material from above.

The machine is equipped with an electronic start-up current

limiter. Therefore, make sure that the machine is only guided

toward the workpiece when it is switched on and has

reached its full speed.

When piercing into the full panel, the panel can kick back

when the running tool comes into contact with it.

Notes

■A new chain will elongate and must be retensioned after

approx. 15 - 20 cut meters.

■If the saw chain jams during cutting, immediately switch

off the motor (see "Fig. 67305", pg. 17) (2), retract the

machine and restart.

5. Cut the material.

When cutting, the chain tension (section 3.2) and the oil level

(oil level indicator below the angular gear) must be checked

regularly.

E848EN_00 Working with the Panel Cutter 17

Putting integrated

lubrication device into

operation when used for

first time

Working with the Panel

Cutter

Checking the chain tension

and oil level

Tip

During cutting, the saw chain is constantly lubricated with the

fully automatic lubricating device. The lubricating oil is usu-

ally sufficient for a cutting length of approx. 150 m.

6. Release the switch (2) (see "Fig. 67305", pg. 17).

The saw chain (5) will stop within 2 seconds and the motor

shuts off.

7. Swing in the blade.

The blade is in its parking position and is thereby protected

from contamination and damage.

8. Have the machine lie level with the table on the panel (6) or

guide rail (3).

Overload protective device on the motor

Notes

■The appliance may switch off prematurely when affected by

electromagnetic interference. The appliance will resume oper-

ation when the faults have been cleared.

■If the motor temperature is too high, the motor limits the

input power. The red indicator light (LED) on the motor lights

up.

1. Allow the machine to run in idle until it has cooled down.

2. Operate the machine normally after it has cooled down.

4.2 Main machine position

In the main machine position, the machine lies with the support

table flat on the material and the blade is aligned vertically

downward. Cutting in the main machine position generates a ver-

tical cut.

18 Main machine position E848EN_00

Switching off the Panel

Cutter

Main machine position Fig. 67307

4.3 Table markings

The three markings on the side of the table indicate the front

and rear sides of the blades in the main machine position and

the blade insertion positions. If the chain tension slackens, the

actual cutting edge deviates from the marked position.

1 Blade insertion position in the

support table

2 Rear side of the blade

3 Front side of the blade

4 Cut marking, front

5 Marking for straight cut

Markings on the support table Fig. 67308

E848EN_00 Table markings 19

For a straight cut, make sure that the marking (4) lies at the cut

each time.

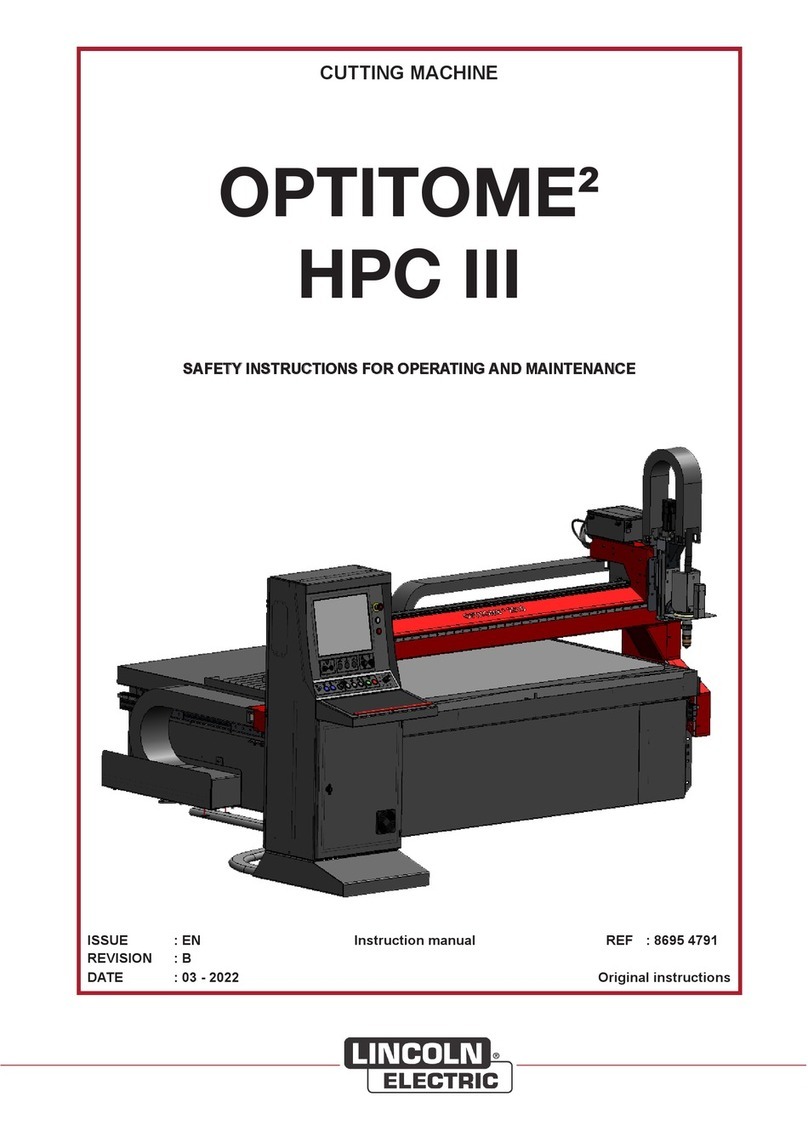

4.4 Plunging depth

The scale on the gear housing indicates the plunging depth of

the blade in stages 0 - 12.

1 Scale on the gear housing

Fig. 67464

4.5 Guide rails

Using the guide rail allows:

■a clean, straight cut.

■better machine guidance.

■easy processing of roof panels (trapezoidal shape).

■protection of the panel surfaces. Scratch-free panel process-

ing is possible.

Working with the guide rail

The guide rail (4), together with the guide notch (3) in the

machine table, guarantees straight machine guidance.

20 Plunging depth E848EN_00

Using the guide rail

(options)

Table of contents

Other Trumpf Cutter manuals

Popular Cutter manuals by other brands

Craftsman

Craftsman CompuCarve 133.217540 Operator's manual

Koike

Koike IK-72T Operation manual

Lincoln Electric

Lincoln Electric OPTITOME2 HPC III instruction manual

Alpha tools

Alpha tools A-FS 1800 UG Original operating instructions

Ironton

Ironton 30091 owner's manual

Weber mt

Weber mt SM 57-2 Operating and maintenance manual

G&J Hall

G&J Hall POWERBOR PB32 instruction manual

Dexter Laundry

Dexter Laundry 956657 Assembly, Use, Maintenance Manual

Borkey

Borkey 919 REXA 5 operating manual

ARCBRO

ARCBRO Spark Series Operator's manual

Ingersoll-Rand

Ingersoll-Rand 326 Operation and maintenance manual

Koike

Koike PICLE1-II Operation manual