Truxta QUADro Q300G Installation and operation manual

MACHINE MODELS

QUADro

Q300G & Q450G

SERIAL Numbers from Q181018

OPERATOR MANUAL & PARTS LIST

Op Manual - Part No 800/17000

Declaration of Conformity .............................................................3

Warning, Symbols & Decals …………………………...……….…..……..4-5

General Safety / Health & Safety ...............................................6 -7

Machine Specification ………...........................................................8

Operating Instructions; - Petrol .................................................... 9

(Pre-Start Checks, Start and Stop Procedures)

Service & Maintenance - Petrol ..............................................10-12

Service - Pump Control Settings & Adjustment …….…...…….…..13

Parts List & Assembly

QUADRO Top Frame Parts List ……..……..…….….…………..14– 15

QUADRO Front Assembly Parts List ……..….……...…………..16– 17

QUADRO Rear Assembly Parts List ...…………….…..……….…18—19

Attachments Parts List

Flat Bed - Log Poles - Greedy-Boards - Skip Handle ……….......20-21

Warranty Registration ..................................................................23

TABLE OF CONTENTS

Page 2

Page 3

DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

We , Tufftruk Ltd, Sheen, nr. Buxton, Derbyshire, SK17 0EU, GB, hereby certify that if the

product described within this certificate is bought from an authorised Tufftruk dealer within the

EEC, it conforms to the following EEC directives: 2006/42/CE (This directive replaces directive

98/37/EC), Electromagnetic Compatibility Directive 2004/108/CE (as amended by 89/336/EEC,

92/31/EEC & 93/68 EEC).

The Waste Electrical and Electronic Equipment (WEEE) 2002/96/CE, the low voltage directive

2006/95/CE, BS EN ISO 12100-1:2003 Safety of machinery and associated harmonised standards,

where applicable.

Noise emissions conform to directive 2000/14/EC Annex VI, for machines under article 12 the

notified body is AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 0XU, GB.

Noise Technical Files are held at the Tufftruk Head Office address stated above.

Declare that the following equipment conforms to the Directive: -

2000/14/EC (as amended) of the European Parliament and of the council on the approximation

of the laws of the Member States relating to the

Noise Emission in the Environment by

Equipment for Use Outdoors.

Equipment Category: Pedestrian Power Barrow

Product Name: TRUXTA

Model: Q 300G / Q450G

Serial No:

The technical documentation is held by: TUFFTRUK Ltd Address above

The conformity assessment procedure followed was in according with annex VI of the Directive.

Notified Body: AV Technology Ltd SK9 3RW

Measured Sound Power Level: 94 dB (LWA)

Guaranteed Sound Power Level: 96 dB (LWA)

A copy of this certificate has been submitted to the European Commission and to EU Member State,

United Kingdom

Place

of Declaration Date Signed By Position in Company

Tufftruk Ltd 01/09/2017 Ronald Blackhurst Managing Director

Name and address of manufacturer or Authorised representative: Tufftruk Ltd SK17 0EU

NOISE LIMITS

ALWAYS READ THE

MANUAL

WEAR APPROPRIATE PPE

WARNING SYMBOLS & DECALS

Page 4

SKIP RETAINER

CATCH

CRUSH ZONE

WARNING DIRECTION OF TRAVEL

PAYLOAD

LIFTING POINTS

UN-LADEN

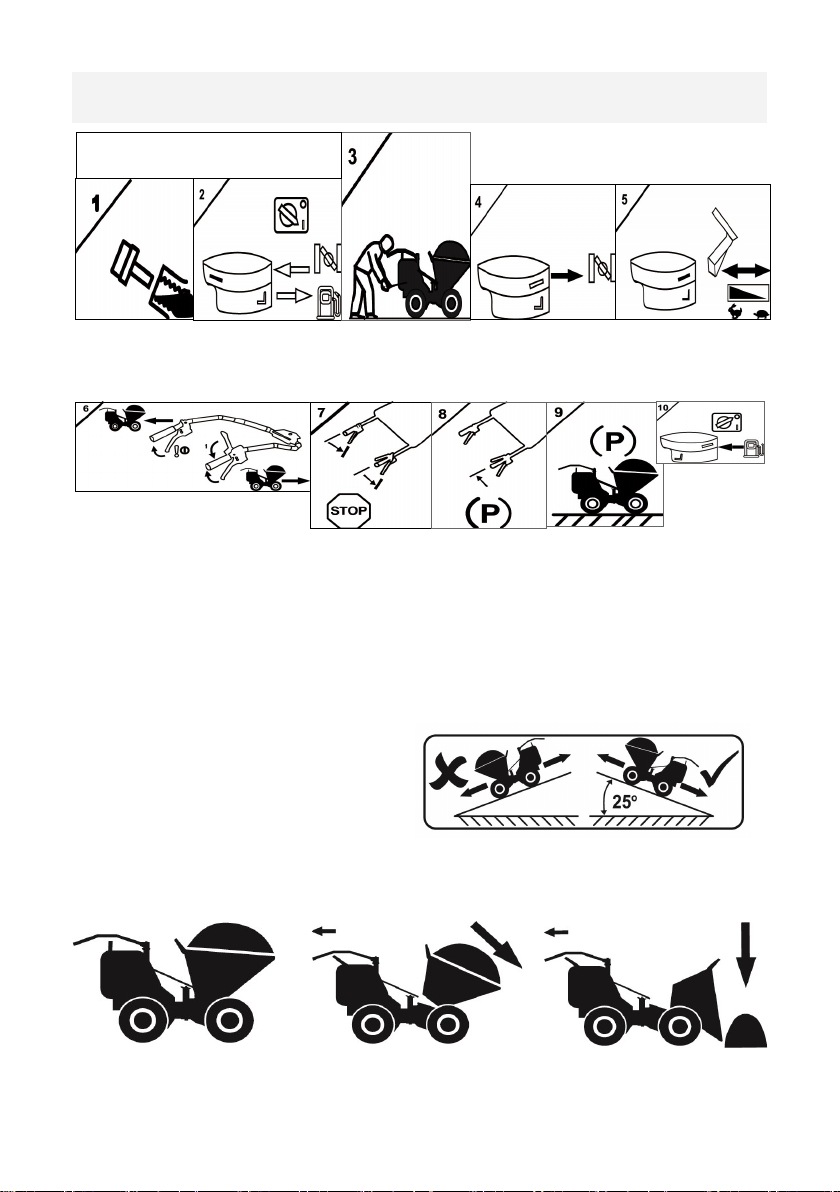

1. Always check oil level before starting.

2. Choke controls starting.

3. Pull to start

TO MOVE TRUXTA

6/7. Press yellow dead-man handle on right handle down for any movement.

Right handle lower lever for forward motion . Left handle lower lever for reverse motion.

8. TO STOP / PARK

Release dead-man handle to stop.

Release lower forward / reverse levers

9. Ideally park on flat surface.

10. Engine OFF switch & close fuel tap when transporting to prevent

carburettor flooding.

ON INCLINES

Do not use TRUXTA on inclines / ramps above 25°

Do Not travel forwards down inclines.

When Tipping always position on a flat Use skip tip handle to release the skip. The skip has a 2-stage tip

action to fully empty

Stage 1 Stage 2

OPERATOR INSTRUTIONS

4. Adjust choke controls when engine is running.

5. Engine rpm control lever

Page 5

OPERATOR INSTRUCTIONS

WARNING SYMBOLS & DECALS

Page 6

For your own personal protection and for the safety of those around you, please read and

ensure you fully understand the following safety information.

It is the responsibility of the operator to ensure that he/she fully understands how to operate

this equipment safely.

• This equipment is heavy and must not be lifted single-handedly, GET HELP and use suitable lifting equipment.

• Cordon off the work area and keep members of the public and unauthorized personnel at a safe distance.

• Personal Protective Equipment (PPE) must be worn by the operator when ever this equipment is being used (see

Health & Safety).

• Make sure you know how to safely switch this machine OFF before you switch it ON in case you get into difficulty.

• Always switch OFF the engine before transporting, moving it around the site or servicing it.

• During use the enginebecomes very hot; allow the engine to cool before touchingit. Never leave the engine running

and unattended.

• Never remove or tamper with any guardsfitted, they are there for your protection.

• Always check guardsfor condition andSecurity, if any is damaged or missing, DO NOT USE THE TRUXTA until

the guard has been replaced or repaired.

• Do not operate the machine when you are ill, feeling tired, or when under the influence of alcohol or drugs.

• Do not stand the machine on end with the engine running.

• Do not use the TRUXTA to transport people.

• Do not release the brake suddenly when travelling forward at speed with a heavy load as themachine may topple

forward.

• (Brake off). Close the throttle if necessaryso that engine braking controls the speed.

Always ensure that when moving downwards on a hill, the machine is travelling in reverse.

• Before refuelling, switch off the engine and allowit to cool.

When refuelling, DO NOT smoke or allow naked flames in the area.

• Spilt fuelmust be made safe immediately, by usingsand. If fuel is spilt on your clothes, change them.

• Store petrol/diesel in an approved, purpose made container away from heat and ignition sources.

• If fuel is spilt when re-fuelling the tank, wipe off the excess and wait 2minutes before re-starting.

• Always travelin a straight line.When travelling across a graduated slope, always travel in a forward direction,

maximum gradient 6 degrees (10%) when travelling across with a TRUXTA.

GENERAL SAFETY

Page 7

VIBRATION

Some vibration from the operation is transmitted through the handle to the operator’s

hands.

DO NOT exceed the maximum usage times. (See Technical Data section)

PPE (Personal Protective Equipment).

Suitable PPE must be worn when using this equipment i.e. Safety Goggles, Gloves, Ear

Defenders, Dust Mask and Steel Toe capped.

Footwear. Wear clothing suitable for the work you are doing. Tie back long hair and

remove any jewellery which may catch in the equipment’s moving parts.

Petrol Machines.

Do not ingest fuel or inhale fuel vapours and avoid contact with your skin. Wash fuel

splashes immediately. If you get fuel in your eyes,

Irrigate with copious amounts of water and seek medical attention as soon as possible.

Exhaust Fumes

Do not operate the TRUXTA indoors or in a confined space, make sure the work area

is adequately ventilated.

HEALTH AND SAFETY

Safe Disposal.

Instructions for the protection of the environment.

The machine contains valuable materials.

Take the discarded apparatus and accessories to the relevant recycling

facilities.

ENVIRONMENT

Page 8

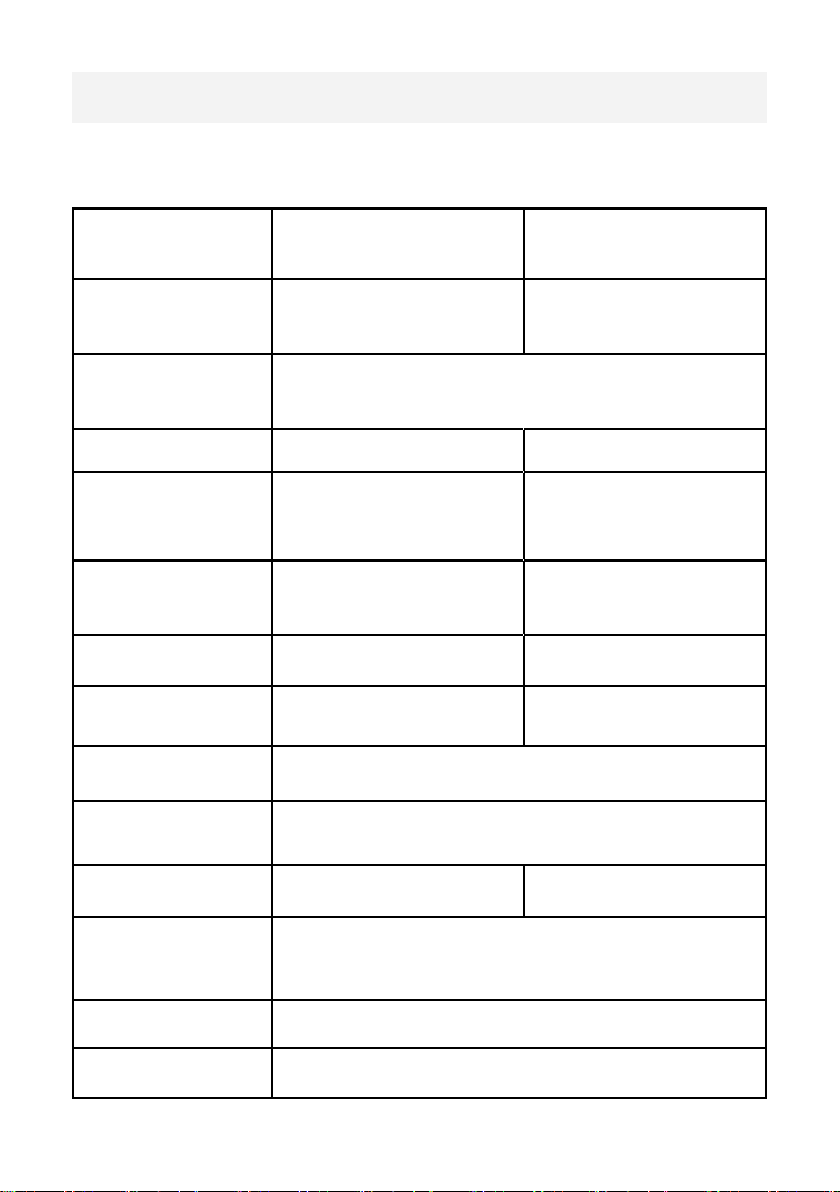

SPECIFICATION

Model QUADRO

Q300G

QUADRO

Q450G

Engine/Motor/

Power kW/hp

HONDA GX 160

3.6 / 4.8

HONDA GX 200

4.1 / 5 .5

Fuel Type Unleaded

Petrol 4 stroke

Fuel Capacity 3.1 litres/ 0.682 gal 3.1 litres/ 0.682 gal

Width x Length x

Height

730mm x 1640mm x 976mm

29 Inch x 65 Inch x 38 Inch

850mm x 1640mm x 976mm

34 Inch x 65 Inch x 38 Inch

Max Payload

300 kg

660 lbs

7ft 3/ 0.2m3

450 kg

990 lbs

10.6ft3/ 0.3m3

Unladen Weight 137kg

302lbs

147kg

324 lbs

Working Gradient

See general safety notes 25° 25°

Drive & Controls Hydrostatic System

Brake System Dynamic braking with

100% fail-safe emergency stop/park brake

Standard

Fitment Tyres

Flotation with option for

turf tyres

Flotation with option for

turf tyres

Travel Speed

Forward

Reverse

Forward 0—4 mph/ 6.44 kph

Reverse 0—2 mph/ 3.22 kph

Noise Level (db) < 96

Hand Arm

Vibration 2.5 m/s²

Page 9

OPERATING THE TRUXTA

1. Start the engine by putting the throttle to the run position and turning the

ignition on. (use choke if cold)

2. Grip the dead man lever and hold it down.

3. Use the forward and reverse levers to control direction of travel and speed.

4. Never press both levers at once or whilst the dead man is released as this will

cause unnecessary strain on the operation cables

EMPTYING THE SKIP

1. Stop the machine by releasing the Drive Lever followed by releasing the dead

man Brake Lever.

2. Once the machine has become stationary, pull the Skip Release Lever and the

Skip will tip forwards disposing of its contents.

3. When the Skip is empty, push back to its original position. The Skip will lock

into place automatically.

4. Do not use the skip as a levelling blade as this could result in damage to the

tipping under carriage.

PRE START UP INSPECTION

The following pre-start-up inspection must be performed before the start of each work

session or after every four hours of use, whichever is first.

Please refer to the service section for detailed guidance.

If any fault is discovered, the TRUXTA must not be used until the fault is rectified.

1. Thoroughly inspect the TRUXTA for signs of damage.

2. Check components are present and secure.

3. Check fluid lines, hoses filler openings, drain plugs and any other areas for

signs of leakage.

Fix any leaks before operating.

4. Check the engine oil and fuel levels and top up as necessary.

5. Check the tyre pressures and top up as necessary.

PETROL - OPERATING INSTRUCTIONS

If it is necessary to travel down a slope of more than 5° when fully laden, ensure that the

machine is turned round and reverse down the slope.

Page 10

OPERATING THE PETROL TRUXTA

Start the engine by putting the throttle to the run position and turning the igni-

tion on. (use choke if cold)

Grip the dead man lever and hold it down.

Use the forward and reverse levers to control direction of travel and speed.

Never press both levers at once or whilst the dead man is released as this will cause

unnecessary damage to the machine.

Release the dead man to stop.

SERVICE & MAINTENANCE - PETROL

Page 11

Hydrostatic Oil

Top up if oil is below minimum level when machine is cold. If there are any

signs of leakage, stop using the machine and contact your local dealer or

Tufftruk Ltd. Refill with motor oil —20W50.

Machine Cleaning

Clean the machine after it has been used to prevent the collection of hardened

debris. Hardened debris is very difficult to remove. To clean it use an old brush

or hand brush with water. Never pressure wash or hose down the engine or

electric motor housing. Clean only with a cloth or compressed air.

Air Filter - If it is dirty, proceed as follows:-

Foam Element - Wash the element in a solution of washing-up liquid and water.

Allow the element to dry, then soak in clean engine oil and squeeze out the

excess oil. If the engine smokes during start-up then too much oil has been left

on the foam.

Paper Element - Tap the element on a hard surface or blow from inside using

compressed air to remove any excess dust within the filter. Replace every 200

hours or if it is extremely dirty.

Transmission Drive Chains

Clean and lubricate the 2 transmission drive chains once a year.

Tyre Pressure

Truxta tyre pressure should be regularly checked and maintained at 25PSI

(flotation and turf tyres)

SERVICE & MAINTENANCE - PETROL

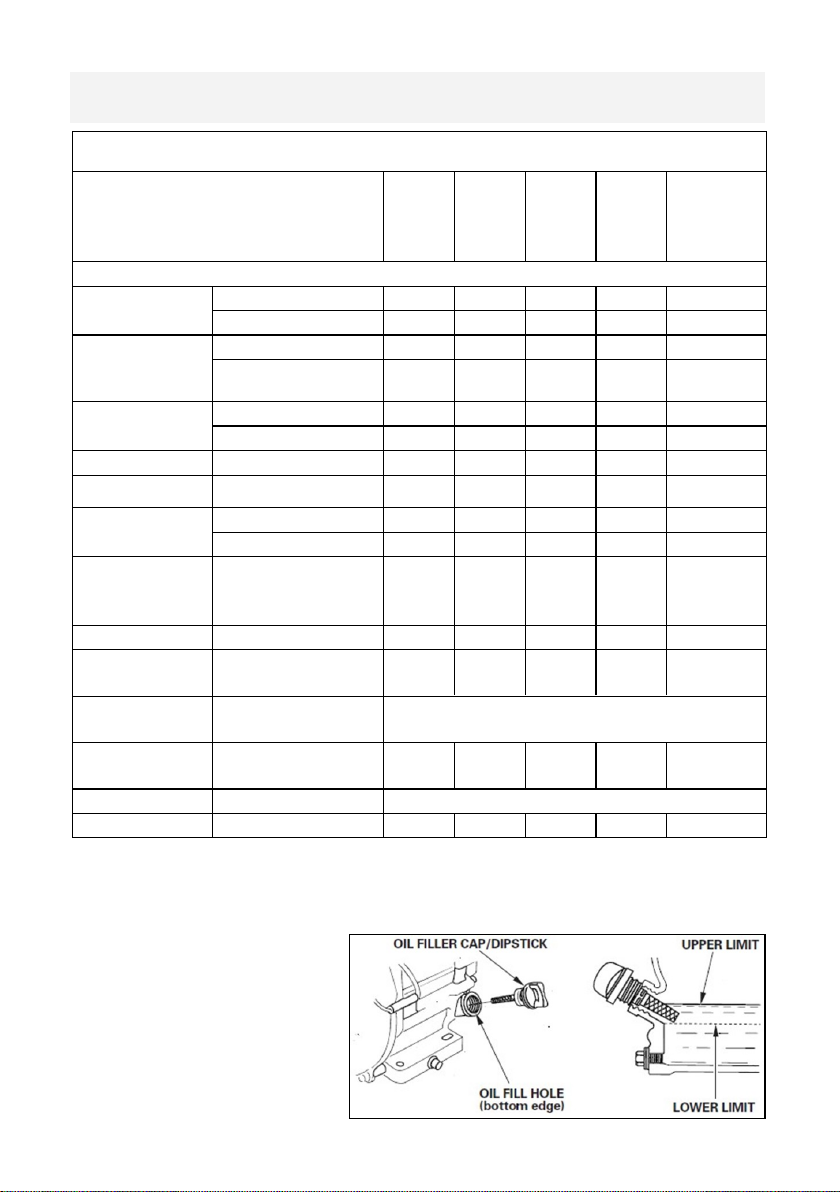

ROUTINE MAINTENANCE

Every

20

hours

Every

50

hours

Every 200 hours

ENGINE OIL

CHANGE

CHECK CONDITION

AIR FILTER

CLEAN / REPLACE

SPARK PLUG CHANGE

SPARK PLUG AND OIL DATA

Engine

Oil Type

Qty

(gals) Fuel Type Capacity

(gals)

Spark

Plug

Electrode

Gap (mm)

Hydrostatic

Transmission

Oil

PETROL

HONDA

S.A.E

10W30 0.17

UNLEADED

SP95 only -EU

Octane 91 min US

0.53 BPR5

ES 0.07-0.8 20W50

Page 12

SERVICE & MAINTENANCE - PETROL

REGULAR SERVICE - HONDA

Each Use First

Month

or 20 hrs

Every 3

months

or 50 hrs

Every 6

months

or 100

hrs

Every year

or 300 hrs

Perform at every indicated month or

operang hour interval, whichever comes

rst

ITEM

ENGINE OIL Check level o

Change oo

REDUCTION CASE

OIL applicable

Check level o

Change oo

AIR FILTER Check

Clean o * o *

Replace o**

SEDIMENT CUP Clean o

SPARK PLUG Check-adjust o

Replace o

SPARK ARRESTER

applicable types Clean o

IDLE SPEED Check-adjust o

VALVE

CLEARANCE Check-adjust o

COMBUSTION

CHAMBER Clean aer every 500 hours

FUEL TANK &

FILTER Clean o

FUEL TUBE Clean Every 2 years (replace if necessary)

Check oil level daily as shown

above, running the engine

with a low oil level can cause

engine damage.

Refill with Engine Oil type —

SAE 10W30

• * Internal vent carburettor with dual element type only.

• ** Replace paper element type only.

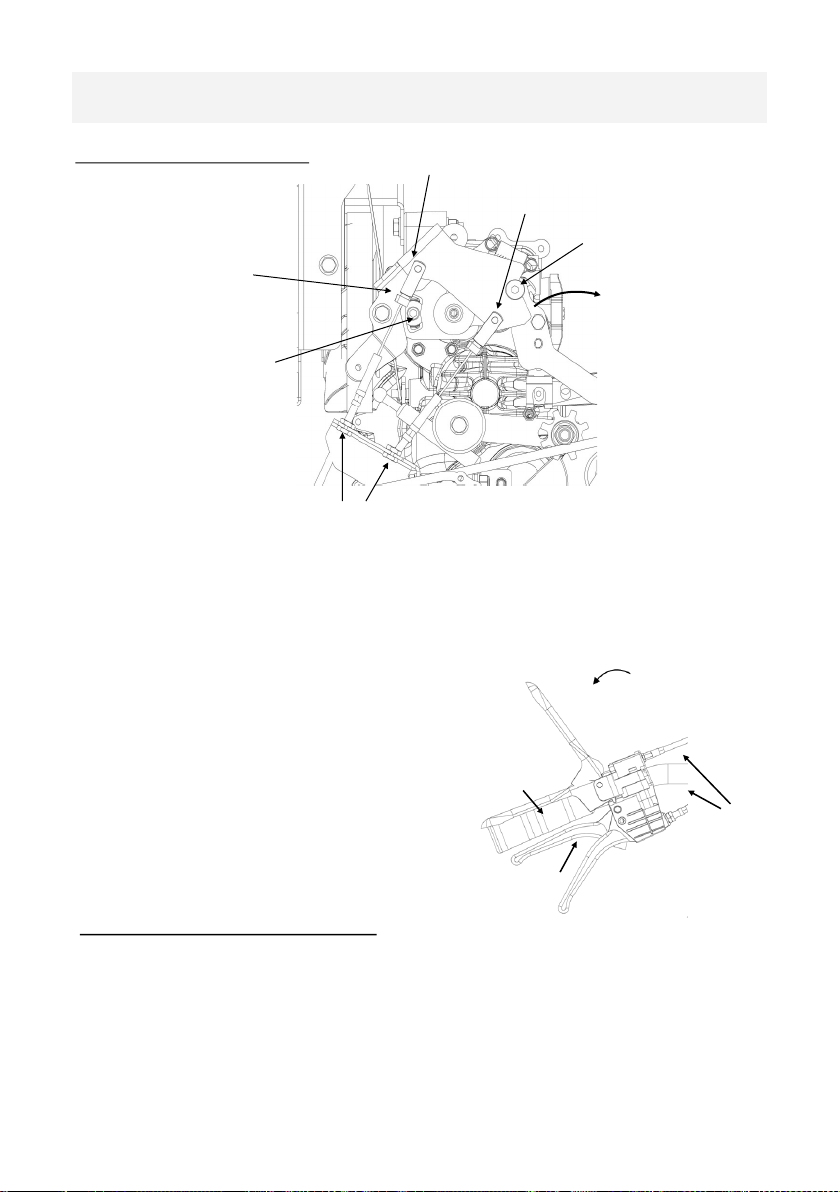

FORWARD CONTROL CABLE

REARWARD CONTROL CABLE

DIRECTION SAFETY

PIN (SHOWN IN

LOCKED POSITION)

CABLE ADJUSTMENT NUTS

PUMP

NEUTRAL

SETTING

DEPRESS

DEADMAN LEVER

TO DISENGAGE PIN

PUMP

DIRECTION

BRACKET

PUMP CONTROL SETTINGS

1: Adjust Deadman lever cable tension if required, see engage angle. Adjust cable

adjustment nuts. With Deadman lever in fully pressed position ensure the direction

safety pin is clear of control plate (see above)

2: Adjust forward/reverse direction levers cable tension if

required, ensure 3mm - 5mm gap when fully

pressed. Adjust cable adjustment nuts.

3: Ensure that with forward lever fully pressed

the pump direction bracket turns

15 degree forward direction 75 rpm @ wheels

4: Ensure that with rearward lever fully

pressed the pump direction bracket turns

5. degree rearward direction 30 rpm @

wheels

PUMP NEUTRAL SETTING

Adjust pump neutral setting if required if machine creeps forwards/backwards when

in neutral,

disconnect forward and rearward control cables

fully press Deadman lever to disengage the direction safety pin

loosen pump neutral setting screw

adjust angle of pump control bracket by rotating forward/backward until no creep

re tighten pump neutral setting screw when wheel rotation is 0 rpm

CABLE

ADJUSTMENT

NUTS

DEADMAN LEVER

10-20 degree

DEADMAN

LEVER

FULLY

PRESSED

DIRECTION

LEVERS

SERVICE & MAINTENANCE - PETROL

Page 13

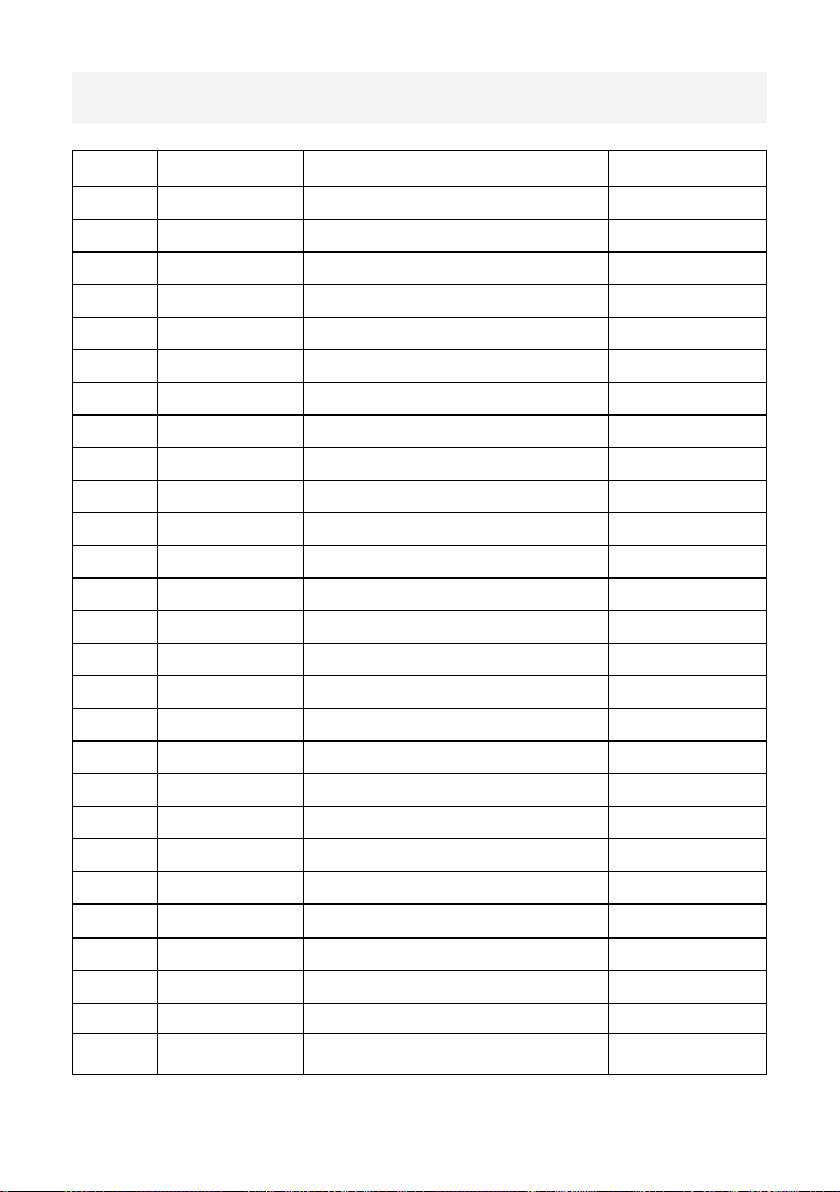

QUADRO TOP FRAME ASSEMBLY—PARTS LIST

ITEM

NO. PART N0 DESCRIPTION QTY

1 102-03600 FRAME WA RIGID 1

2 101-99914 PRESSING TIP HANDLE 1

3 102-99939 SPACER TIP LEVER 1

4 101-99945 ENGINE COVER 1

5 72-0200 MOULDING TIP HANDLE 1

6 75-01500 CABLE ASSY FWD and REV 2

7 75-02300 CABLE ASSY DEADMAN 1

8 75-00900 CABLE SKIP RELEASE 1

9 74-1022 HANDLE GRIP 2

10 7-10130 COACHBOLT M10 X 30 1

11 74-1023 HINGE 50x50x6 2

12 4-1005 WASHER FLAT M10 FORM A BZP 1

13 8-10006 NUT M10 NYLOC 1

14 7-6056 M6 X 15 BUTTON HD CAP 4

15 4-6001 WASHER M6 FORM A BZP 8

16 7-6007 SCREW - 6 X 15 CSK SCREW BZP 4

17 4-6018 WASHER M6 X 20 X1.2 BZP 4

18 8-6007 NUT M6 NYLOC 12

19 102-99929 TUBE HANDLE 2

20 7-6030-0 M6 X 30 CAP SCREW BZP 4

Page 14

QUADRO TOP FRAME ASSEMBLY—PARTS LIST

Page 15

QUADRO FRONT ASSEMBLY—PARTS LIST

ITEM NO PART NUMBER DESCRIPTION QTY.

1 60-6509LHF WHEEL ASSY 16X6.50X8 LHS FLOAT 2

2 60-6509RHF WHEEL ASSY 16X6.5X8 RHS FLOAT 2

3 100-00500 SKIP 300 W.A. 1

3a 100-00500GL SKIP 300 W.A. GALVANISED 1

4 100-01100 SKIP 450 W.A. 1

4a 100-01100GL SKIP 450 W.A. GALVANISED 1

5 101-02100 FRAME SKIP CARRIER W.A 1

6 102-03300 CHASSIS W.A. 1

7 102-99949 FRONT COVER 1

8 102-99950 TOP COVER 1

9 101-99929 PRESSING TIP RETAINER 2

10 102-03500 REAR AXLE W.A. 1

11 6-1300 DIFFERENTIAL AXLE 1

12 104-99925 GEAR 22T 1

13 102-99921 PRESSING BEARING FRONT 1

14 53-0110 BEARING BALL 25 bore mounted 1

15 53-0110 BEARING BALL 25 bore mounted 1

16 53-0120 BEARING BALL 19.05 bore mounted 2

17 102-03100 WHEEL HUB 2

18 102-99955 COVER FRONT PULLEY 1

19 102-99951 LATCH SKIP 1

20 102-03400 CHANNEL W.A. 1

21 4-1201 WASHER M12 FORM C BZP 1

22 9-10034 SHOULDER BOLT M10 X 16 1

23 102-99956 PIN SKIP LATCH 1

24 7-8080 M8X20 SERRATED HD SCREW 1

25 102-99954 COVER PLATE REAR AXLE 1

Page 16

QUADRO FRONT ASSEMBLY—PARTS LIST

ITEM NO PART NUMBER DESCRIPTION QTY.

26 102-99953 REAR COVER 1

27 6-0006 BANJO BOLT FITTING 1

28 6-0007 BANJO FITTING 1

29 21-2110 CHAIN 5/8" FRONT 1

30 21-2120 CHAIN 5/8" REAR 1

31 102-99958 PRESSING REAR AXLE COVER 1

32 102-99959 PRESSING REAR AXLE ADJUSTER 1

Page 17

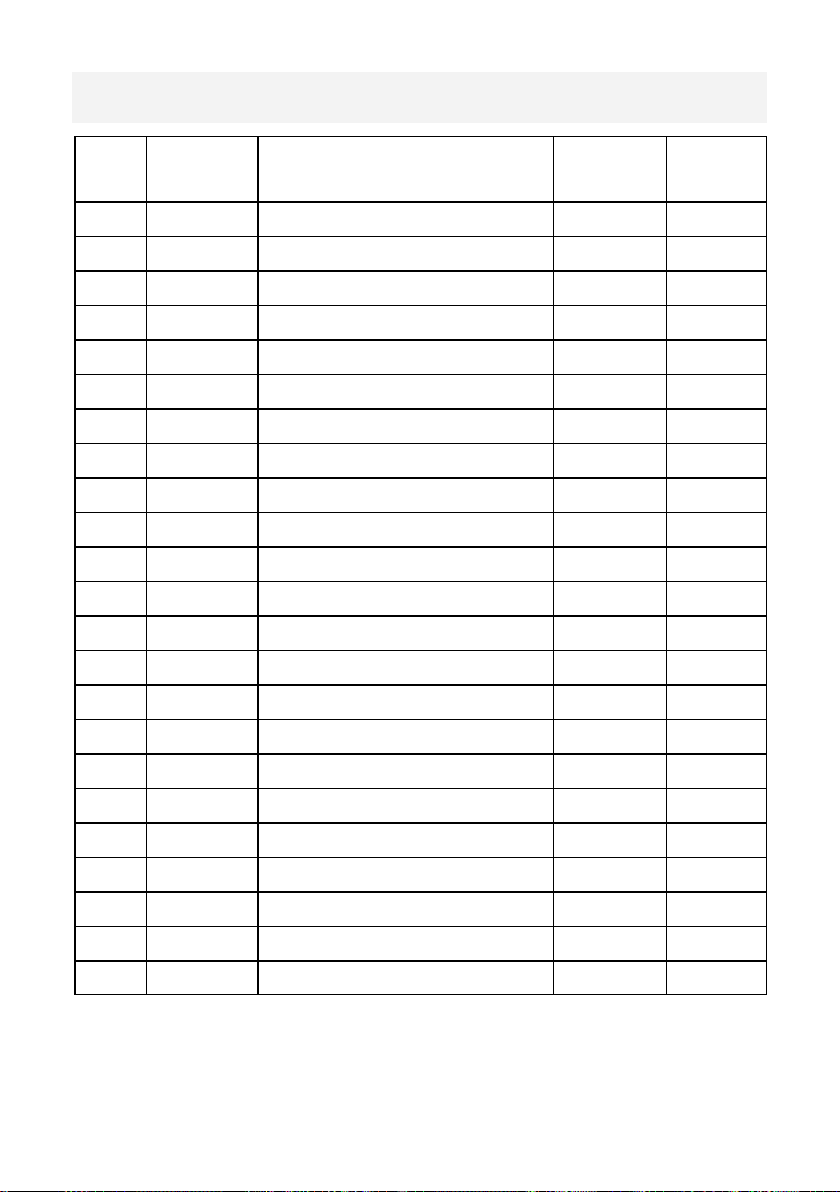

QUADRO REAR ASSEMBLY —PARTS LIST

ITEM

NO. PART NO DESCRIPTION QTY.

1 6-2000 TRANSMISSION UNIT 1

2 101-03700 SHAFT OUTPUT DRIVE WA 1

3 102-03200 BRACKET BASE RIGID WA 1

4 8-19001 UNF 3/4" NUT 1

5 20-1600 HONDA GX160 1 300 model

6 20-2000 HONDA GX200 1 450 model

7 101-99956 PRESSING ENGINE DECK 1

8 101-99926 PRESSING FOOT BRKT HONDA 1

9 101-99927 PRESSING DRAIN BRKT HONDA 1

10 21-3040 DRIVE PULLEY 1

11 21-0500 A V MOUNT 30x15xM8 4

12 102-99940 BOSS TENSIONER SUPPORT 8

13 4-8006 WASHER M8 FORM A BZP 8

14 8-8008 NUT M8 NYLOC BZP 8

15 102-99952 COVER LOWER LUG 1

16 6-0004 HOSE 10MM REINFORCED CLEAR 1

17 6-2001 EXPANSION TANK 71328 1

18 2-1010 SPRING EXT 1

19 101-99947 BRACKET LEVER DIRECTION 1

20 101-99948 PLATE BRAKE LOCK 1

21 2-1300 DAMPENER STRUT 1

22 102-99957 BRACKET DAMPENER 1

23 21-3080 BELT - AX24 1

Page 18

QUADRO REAR ASSEMBLY —PARTS LIST

Page 19

LOG POLES X 2 ATTACHMENT FOR TRUXTA (OPTT13-DIO)

1 73-1100 HOLDER STOP 2

2 73-1200 TUBE STOP 2

3 72-0400 MOULDING HUB COVER 2

4 4-1005 WASHER FLAT M10 FORM A BZP 8

5 8-10006 NUT M10 NYLOC 4

6 7-10005 SCREW SET M10 X 25 BZP 4

GREEDY BOARD ATTACHMENT (OPTT15-DIO)

1 73-1601 GREEDY BOARD SIDE LH 1

2 73-1602 GREEDY BOARD SIDE RH 1

3 73-1603 GREEDY BOARD REAR 1

4 7-6060 SCREW M6 X 14 SER HD BZP 10

5 4-6001 WASHER M6 FORM A BZP 10

6 8-6007 NUT M6 NYLOC 10

SKIP CONTROL HANDLE ATTACHMENT (OPTT16-DIO)

1 73-1700 BRACKET SKIP TIPPING 1

2 73-1703 HANDLE SKIP TIPPING 1

3 74-1022 HANDLE GRIP 1

4 3-0096 ROLL PIN 6 X 35 1

5 3-1018 CLIP LYNCH PIN 1

6 7-6060 SCREW M6 X 14 SER HD BZP 2

7 4-6001 WASHER M6 FORM A BZP 2

8 8-6007 NUT M6 NYLOC 2

Page 20

QUADRO ATTACHMENTS - PARTS LIST

FLATBED Q300 - OPTT17-DIO / FLATBED Q450 - OPTT18-DIO

ITEM NO. PART NO DESCRIPTION QTY.

1 73-0120 FLAT BED BOARD 450 2

73-0112 FLAT BED BOARD 300 2

2 7-10035 SCREW M10 X 35 BZP CSK 8

3 4-1005 WASHER FLAT M10 FORM A BZP 12

4 8-10006 NUT M10 NYLOC 12

5 73-2000 QUADRO FLAT BED BASE W.A. 1

6 7-10004 SCREW SET M10 X 20 BZP 4

7 73-1900 QUADRO FLATBED BACK W.A. 1

This manual suits for next models

1

Table of contents

Other Truxta Utility Vehicle manuals