Truxta BENDI EB400 User manual

GB OPERATOR MANUAL

FR MODE D’EMPLOI

NL BEDIENINGSHANDLEIDING

DE BEDIENUNGSHANDBUCH

ES MANUAL DEL OPERADOR

IT MANUALE PER L’OPERATORE

CZE UŽIVATELSKÁ PŘÍRUČKA

GB MACHINE MODELS BENDI EB400 /EB500

NL MODELLEN BENDI EB400 /EB500

DE MASCHINENMODELLE BENDI EB400 /EB500

FR MODÈLES DE MACHINE BENDI EB400 /EB500

ES MODELOS DE MAQUINA BENDI EB400 /EB500

IT MODELLI MACCHINA BENDI EB400 /EB500

CS NÁHRADNÍCH SOUČÁSTÍ MODELY STROJE BENDI EB400 /EB500

Pl MODELE URZĄDZENIA BENDI EB400 /EB500

MINI DUMPER

MINI DÚMPER

2

GB - GENERAL SAFETY / WARNING SYMBOLS & DECALS

INDEX Page

GENERAL SAFETY / HEALTH & SAFETY / WARNING, SYMBOLS & DECALS 2

OPERATING INSTRUCTIONS - ELECTRIC / (ELECTRIC / BATTERY CHARGER ) 3

SERVICE & MAINTENANCE - ELECTRIC / (PROBLEM SOLVING / TROUBLE SHOOTING/ WIRING DIAGRAM) 4

ELEC WIRING DIAGRAM / LIFTING / SECURING 5-6

WARRANTY REGISTRATION 7

GENERAL SAFETY / WARNING SYMBOLS & DECALS

For your own personal protecon and for the safety of those around you, please read and ensure you fully understand the following safety informaon.

It is the responsibility of the operator to ensure that he/she fully understands how to operate this equipment safely.

If you are unsure about the safe and correct use of the TRUXTA, consult your supervisor or TRUXTA

• This equipment is heavy and must not be lied single-handedly, GET HELP

and use suitable liing equipment.

• Cordon o the work area and keep members of the public and unauthorized

personnel at a safe distance.

• Personal Protecve Equipment (PPE) must be worn by the operator when

ever this equipment is being used (see Health & Safety).

• Make sure you know how to safely switch this machine OFF before you

switch it ON in case you get into diculty.

• Never remove or tamper with any guards ed, they are there for your

protecon.

• Always check guards for condion and Security, if any is damaged or missing,

DO NOT USE THE TRUXTA unl the guard has been replaced or repaired.

• Do not operate the machine when you are ill, feeling red, or when under

the inuence of alcohol or drugs.

• Do not use the TRUXTA to transport people.

• Do not release the brake suddenly when travelling forward at speed with a

heavy load as the machine may topple forward.

• (Brake o). Close the throle if necessary so that motor braking controls the

speed. Always ensure that when moving downwards on a hill, the machine is

travelling in reverse.

• STEERING THE TRUXTA ON GRADIENTS.

DO NOT steer the TRUXTA le or right when travelling up or down a gradient.

Always travel in a straight line. When travelling across a graduated slope,

always travel in a forward direcon, maximum gradient 6 degrees (10%)

when travelling across with a TRUXTA.

• ENVIRONMENTAL — Safe Disposal.

Instrucons for the protecon of the environment. The machine contains

valuable materials. Take the discarded apparatus and accessories to the

relevant recycling facilies.

• VIBRATION

Some vibraon from the operaon is transmied through the handle to the

operator’s hands. DO NOT exceed the maximum usage mes.

(See Technical Data secon)

• PPE (Personal Protecve Equipment).

Suitable PPE must be worn when using this equipment i.e. Safety Goggles,

Gloves, Ear Defenders, Dust Mask and Steel Toe capped.

Footwear. Wear clothing suitable for the work you are doing. Tie back long

hair and remove any jewellery which may catch in the equipment’s moving

parts.

• Electric

Do not aempt to charge the electric machine if cable or connectors are

damaged

Do not connect or disconnect the machine with wet hands immediately

replace damaged charging parts .

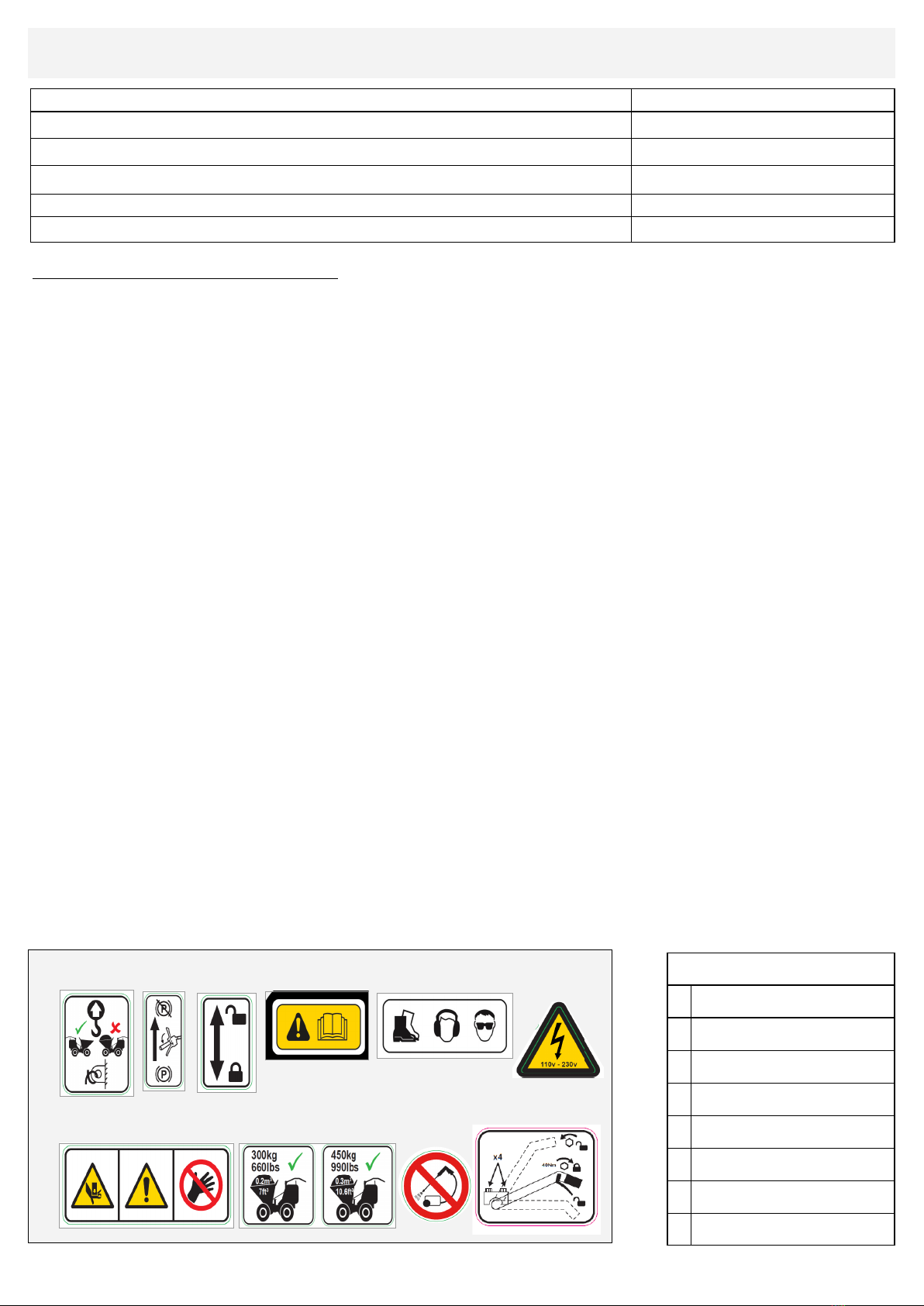

SAFETY DECALS

1LIFTING POINTS UN-LADEN

2BRAKE OVERRIDE, SKIP RETAINER

CATCH

3ALWAYS READ THE MANUAL BEFORE

USE / PPE

4VOLTAGE WARNING

5CRUSH ZONE WARNING

6PAYLOAD

7DO NOT PRESSURE WASHER INTO

AIR VENTS

8HANDLEBAR ADJUSTMENT ANGLE

1 2 3 4

5 67 8

3

OPERATING INSTRUCTIONS & CHARGING - SERVICE & MAINTENANCE - ELECTRIC TRUXTA - GB

OPERATING INSTRUCTIONS

Check Baery Condion - Orange light charging Green light charged

E Stop out ignion on

1&2 Forward & Reverse Controls

3&4. Stopping and Park brake

ON INCLINES Do not use TRUXTA on inclines / ramps above 25°

Do Not travel forwards down inclines.

TO MOVE TRUXTA Press yellow dead-man handle on right handle

down for any movement.

Right handle lower lever for forward moon.

RH & LH lower lever together for reverse moon.

TO STOP / PARK Release dead-man handle to stop.

Release lower forward / reverse levers.

Ideally Park on at surface.

OPERATING INSTRUCTIONS & CHARGING

Check mains lead is stored correctly and is secured to the machine.

Check mains lead is not damaged in any way and replace as necessary.

OPERATING THE TRUXTA

Pull out large red buon. (DEADMAN KILL SWITCH)

Turn ignion key on.

Depress dead man lever (RED) on right hand controls.

To Move Forward — squeeze right hand lever to move forward.

To Reverse — squeeze and hold le hand lever, then squeeze the right hand

lever to move the machine in reverse.

STOPPING THE TRUXTA

Release the right hand lever to stop the machine

Release the dead man red lever to engage the parking brake

In emergencies hit the large red buon (DEADMAN KILL SWITCH)

When machine is not in use, always push in the large red buon.

PARKING BRAKE - The Parking Brake operates automacally when the dead

man lever (RED) is in the upright posion. The brake is on unl the dead-man

(RED) lever is compressed to release it.

MOVING the TRUXTA with NO POWER

For manual brake release when the machine has no power

Push brake release lever forward and hold the dead-man lever down, the

TRUXTA can now be moved manually.

CHARGING THE ELECTRIC TRUXTA

1. TRUXTA has a built-in 24v charger

2. Turn o ignion switch.

3. Push in the large red buon.

4. Connect the cable provided to a mains supply 110-230 v. Charger is dual

voltage.

5. Check baeries are charging by observing small window on right- hand side

of baery box.

6. The CHARGING light is normally ORANGE which changes to GREEN when the

baery is fully charged.

7. The charger is a Smart Charger, it can be le connected to the baeries aer

full charge (green light) without harming baeries. The charger uses minimum

power in this stand-by mode (aer baery is fully charged), maintains the

baeries at full charge and extends baery life.

Machine Cleaning

Clean the machine aer it has been used to prevent the collecon of

hardened debris. Hardened debris is very dicult to remove. To clean it use

an old brush or hand brush with water. Never pressure wash or hose down

the electric motor housing. Clean only with a cloth or compressed air.

Lubricate the single grease nipple on the centre joint once a year.

Tyre Pressure

Truxta tyre pressure should be regularly checked and

maintained at 25PSI (otaon and turf tyres).

GB - ELECTRIC TRUXTA - DIAGNOSTICS & TROUBLESHOOTING

4

ELECTRIC TRUXTA - DIAGNOSTICS & TROUBLESHOOTING

The machine controller detects a wide variety of faults or errors.

Diagnosc informaon can be obtained on the 3100R fuel gauge display where an error code in the format ''Err ##''.

The troubleshoong chart below describes the Error code faults and their possible causes.

Whenever a fault is encountered the rst acon should be to turn o the ignion and push in the E stop buon. Then pull out the E stop buon and turn the ignion back

on to see if the fault clears. This is the RESET procedure:.

If the Error code does not clear aer the machine RESET, turn o the ignion switch and remove the 35-pin connector. Check the connector for correcon or damage,

clean it if necessary, and reinsert it.

If the Error is sll seen then the wiring and connecons on the machine should be checked for breakages or loose connecons.

The table below should be used as a reference once the above checks have been carried out.

Error code Descripon of Error Possible Cause /

Reason for Error Check points Technical Bullen

(see website)

1HW

Fail-safe Motor fault voltage (hardware failure) 1. Motor voltage does not correspond to throle

request.

2. Short in motor or In motor wiring.

10 Main brake driver over

current Short circuit or overloaded controller driver, Early

controllers were re-programmed

15 Main

Current dropped Main contractor failed open. 1. Clean the contactor switch TB10001

17 Main

Contactor Welded Main contractor on fault 1. Main contactor failed closed, replace contactor.

33 Supervisor DIR Check

Fault

If fault is on an external signal, check that

signal rst. If no problem with the external

signal, likely indicates an internal controller

fault.

Early controllers were re-programmed

34 External Supply Fault Under voltage 1. Check control wiring circuit, potenometer wiring in

parcular. TB10010

36 EM-Brake Driver

Open Drain Hold voltage is set at 90% 1. Check bullet connectors to brake, check connuity or

2. The motor brake has failed.

54 Pre-charged Failed Pre-charge fault

1. Low baery voltage - 25V (11/12V) is good

condion, 22V (9/10V) or lower is bad baeries

condion.

2. Short circuit on tracon motor outputs.

TB10008

80 HPD

Sequencing HPD fault present > 10 seconds 1. Misadjusted throle

2. Broken throle potenometer or throle

mechanism. TB10004

92 Motor Open Tracon motor not connected. Controller can not see the motor.

Could be a short circuit in the motor.

1. Check the resistance across the motor leads.

99 Under-voltage Cutback Baery voltage too low Baery voltage < undervoltage threshold.

1. Bad connecon at baery or controller.

2. Check no corrosion on the baery terminals.

Quick checks if no reading on fuel gauge and machine does not operate:

1. Check 10A fuse in the control panel. Fuse holder is located to the right hand side of the main control panel, turn CCW to release the fuse holder.

2. Check main fuse located behind the rear motor housing cover & 100A fuse. Open the rear cover which is xed in posion with 2 x M6 screws, ensure the cover is

supported during this process. Main fuse is located on the le hand side of the baery housing.

When changing the 100 amp fuse, ensure that the posive baery lead is fully dis-connected. Electrical maintenance should be carried out by a qualied person.

To maximize the life of your AGM baery, it is important that it is

properly charged. As with all lead-acid baeries, both over- and under-

charging an AGM baery will result in shortened service life.

The TRUXTA mini dumpers are ed with an on-board SMART charger

which maintains the baery full charge condion without resulng in

over charging.

The AGM baeries are sealed for life units and do not require any uid

top up.

Please read the following instrucons:

Charging system Inspecon

The charger’s AC (mains) cord should be free of breaks or cuts and the

wall plug socket should be clean and free from debris.

The cable connectors from the on-board charger should be clean and

properly mate with the baery terminals to ensure a sound connecon.

Baery Inspecon

• Check baery cables are not damaged.

• Connectors should be free of corrosion.

• DC Cable post or eyelet connectors are ght to avoid arcing.

Charging Guidelines

• Fully charge baeries aer baeries have been dis-charged to ¼ full on baery

gauge. The on-board charger mains cord should be plugged into the mains AC

supply. Leave baeries to complete full charge and do not disconnect unl fully

charged. Once fully charged the on-board SMART baery charger will maintain

the baery fully charged status.

• Do not opportunity charge baeries i.e. if the baeries have only dis-charged

to ¾ full on the baery gauge, there is no need to connect the charger to the

AC supply. It is recommended to use the dumper unl the baeries have dis-

charged to ¼ full on the baery gauge, then place the dumper onto a full

charge cycle.

• Charge in a venlated area as gasses may be released through the pressure

relief valve if the baeries are excessively over-charged.

• Never charge a frozen baery.

• Ideal charging temperatures: (0°C to 40°C) 32°F to 104°F

AGM Baery Charging

5

ELECTRIC TRUXTA - WIRING DIAGRAM – GB

6

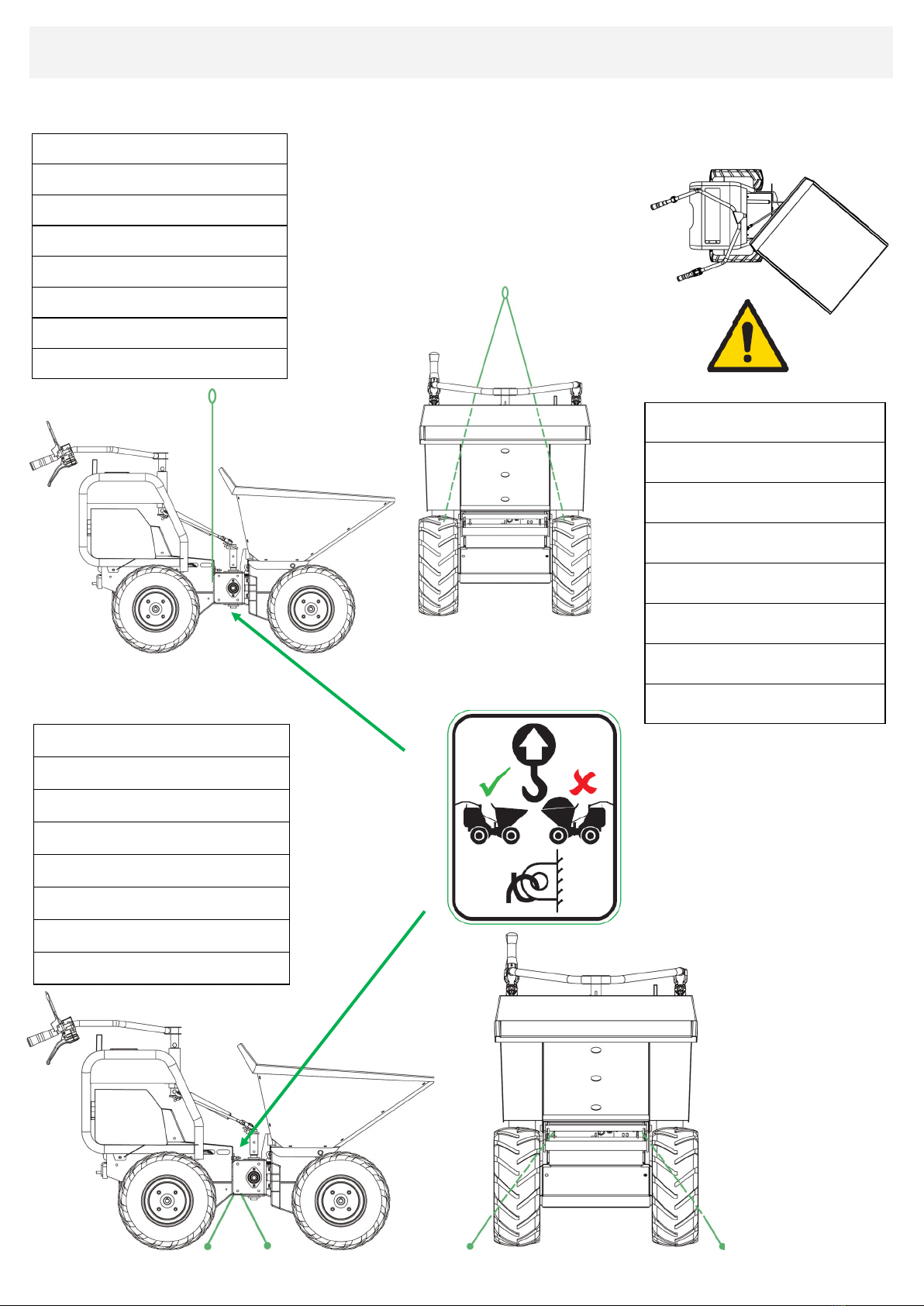

LIFTING PLAN

PLAN DE LEVAGE

HIJSPLAN

HEBEPLAN

PIANO DI SOLLEVAMENTO

PLAN DE ELEVACIÓN

PLAN PODNOSZENIA

PLÁN ZDVIHÁNÍ

BEWARE OF ROTATING WHEN LIFTING

ATTENTION À LA ROTATION PENDANT LE

LEVAGE

PAS OP VOOR RONDDRAAIEN TIJDENS HIJSEN

VORSICHT VOR ROTATION BEIM HEBEN

FARE ATTENZIONE ALLA ROTAZIONE DURANTE

IL SOLLEVAMENTO

CUIDADO CON LA ROTACIÓN AL LEVANTAR

UWAŻAĆ NA OBRACANIE SIĘ PODCZAS

PODNOSZENIA

PŘI ZDVIHÁNÍ DÁVEJTE POZOR NA OTÁČENÍ

SECURING FOR TRANSPORT

FIXATION POUR LE TRANSPORT

VASTZETTEN VOOR TRANSPORT

SICHERUNG FÜR DEN TRANSPORT

PROTEZIONE PER IL TRASPORTO

FIJACIÓN PARA EL TRANSPORTE

ZABEZPIECZENIE DO TRANSPORTU

ZABEZPEČENÍ PRO PŘEPRAVU

GB - LIFTING PLAN SECURING FOR TRANSPORT / FIXATION POUR LE TRANSPORT

GUARANTEE AND WARRANTY CARD - GB

De TRUXTA-garantie geldt voor ontwerp-, materiaal- en constructiefouten.

De TRUXTA-garantie dekt niet:

Wijzigingen, toevoegingen of herstellingen die niet door Tufftruck of diens erkende agenten

werden uitgevoerd.

Garantieclaims

Bewaar het garantieformulier voor uw administratie.

Any warranty issues please do contact your place of purchase.

To Register your Warranty please complete the warranty form and post to Tufftruk Limited, Unit 5,

Prince Street Business Park, Prince Street,

Leek, Staffordshire ST13 6DB

scan photocopyandemailthecompletedwarrantyformto sales@tufftruk.co.uk

Also foryour records, please complete this warranty registration in operator manual.

DATE OF PURCHASE

PLACE OF PURCHASE/ COMPANY

CUSTOMER NAME

ADDRESS

MACHINE MODEL NO

SERIAL NO OF MACHINE

Details van de ONDERDELEN kunt u terugvinden op de Truxta website www.truxta.com

Zodra u het onderdeelnummer en de beschrijving van het onderdeel hebt, kunt u een TRUXTA-verdeler contacteren of u direct aan Turuk richten via

sales@turuk.co.uk.

GB Your new TRUXTA is warranted to the original purchaser for a period of

one-year

(12 months) from the original date of purchase. The TRUXTA warranty is against

defects in design, materials and workmanship.

The following are not covered under the TRUXTA warranty:

1. Damage caused by abuse, misuse, dropping or other similar damage caused

by or as a result of failure to follow assembly, operaon or user maintenance

instrucons.

2. Alteraons, addions or repairs carried out by persons other than Turuk or

their recognised agents.

3. Transportaon or shipment costs to and from TRUXTA or their recognised

agents, for repair or assessment against a warranty claim, on any machine.

4. Materials and /or labour costs to renew repair or replace components due to

fair wear and tear are not covered by warranty.

TRUXTA and/or their recognised agents, directors, employees or insurers will

not be held liable for consequenal or other damages, losses or expenses in

connecon with or by reason of or the inability to use the machine for any

purpose.

Warranty Claims All warranty claims should rstly be directed to the point of

purchase: your TRUXTA reseller / distributor. Keep a record of the warranty

form for your records

Any warranty issues please do contact your place of purchase.

For warranty claims: Tel +44 (0) 1298 84687or Email; sales@turuk.co.uk

For your records, please complete this warranty registraon form

Keep a record of the warranty form for your records

To Register your Warranty please complete the warranty form and post to

Tufftruk Limited, Unit 5, Prince Street Business Park, Prince Street,

Leek, Staffordshire ST13 6DB

Alternatively visit the website

www.truxta.com/service and register warranty online.

WARRA NTY REGISTRATION FORM

DATE OF PURCHASE:

PLACE OF PURCHASE/ COMPANY:

CUSTOMER NAME:

ADDRESS:

MACHINE MODEL NO:

SERIAL NO OF MACHINE:

SPARE PARTS details can be found on Truxta website www.truxta.com

Once you have the part no. and description of required item please contact your TRUXTA retailer of Tufftruk direct to [email protected]

7

Other manuals for BENDI EB400

1

This manual suits for next models

1

Table of contents

Other Truxta Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Toro

Toro 7359 Operator's manual

Taylor-Dunn

Taylor-Dunn B0-150-00 Service and Replacement Parts Manual

Great Dane

Great Dane 42101203 Operator's manual

Terex

Terex Evoquip Bison 120 Operation manual

Kubota

Kubota RTV-X900 Operator's manual

Kendon

Kendon Stand-Up TRIKE/SPYDER/SIDECAR Ride-Up SRL owner's manual

Muck-Truck

Muck-Truck Power Barrow PRO MKI Operations & parts manual

Polaris

Polaris RANGER RZR XP 4 900 2013 Owner's manual for maintenance and safety

Toro

Toro Workman GTX Operator's manual

Marlon

Marlon 10' Single Multi Trailer owner's manual

Toro

Toro WORKMAN GTX 07131 Operator's manual

Anderson

Anderson M-115 owner's manual