TSE DP20-4H User manual

CONDUCTOR HANDLING EQUIPMENT

5301 Shreveport-Blanchard Hwy

Shreveport, Louisiana 71107

Toll Free: 800.825.2402

Telephone: 318.929.2368

FAX: 318.929.4853

www.tse-international.com 1

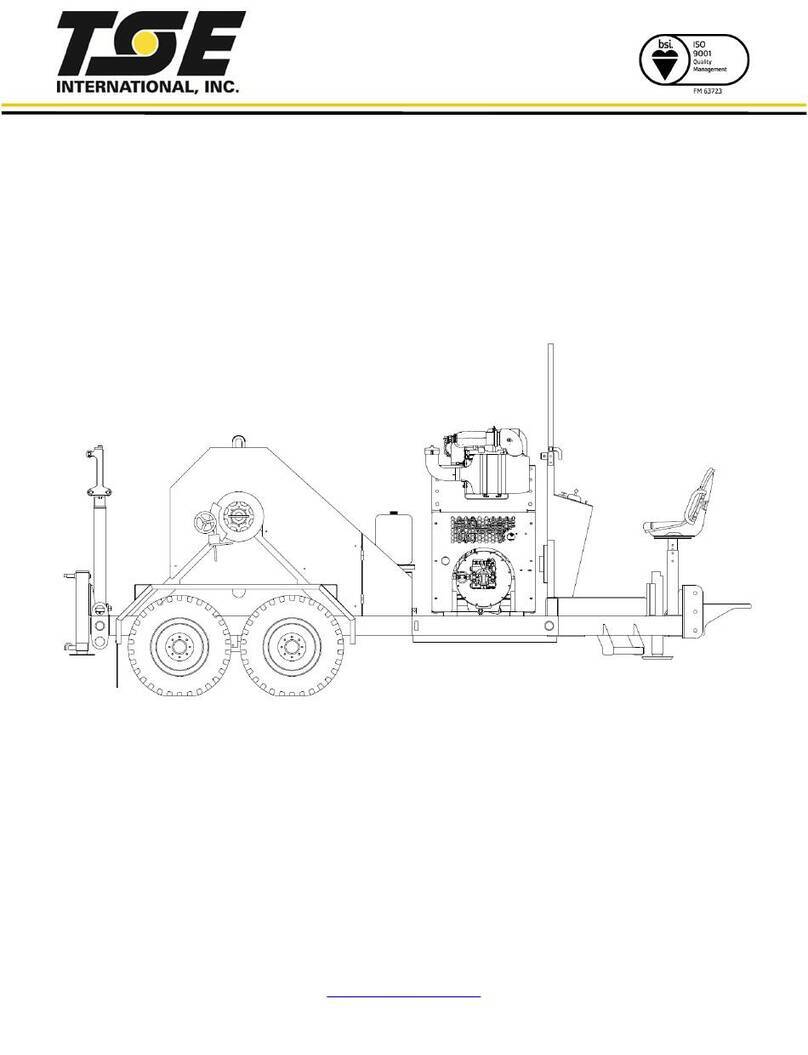

DP-20-4H

DRUM PULLER

At TSE, engineering is a process of continuous product improvement; therefore, specications are subject to change without notice.

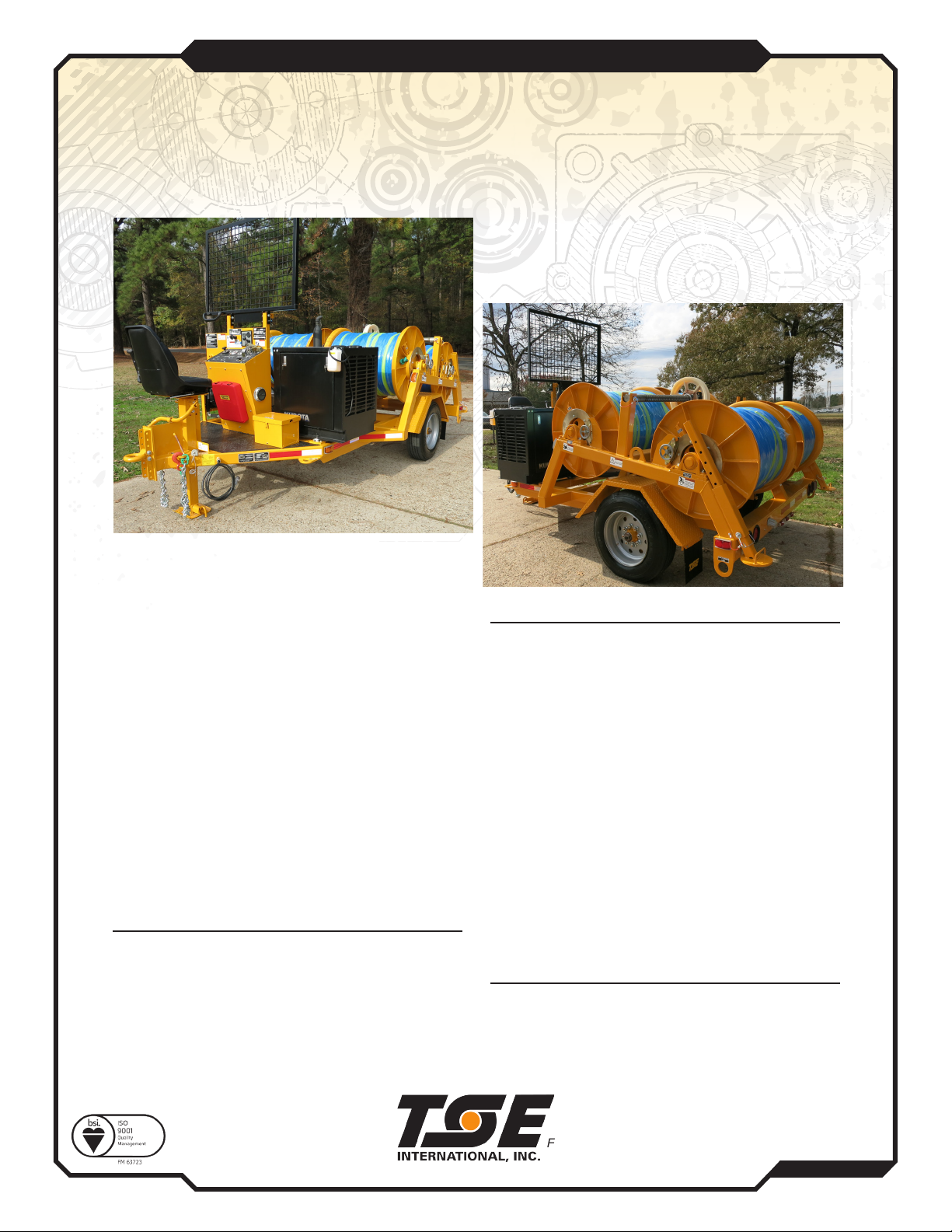

The TSE Model DP-20-4H is a versatile, hydraulically

powered four drum puller designed for medium

distribution stringing. It can also be used as a pilot line

winder for heavier distribution. Power is transmitted from

the engine to the reels through a common hydraulic drive

train. A diamond leadscrew levelwind, accommodating

one reel at a time, aids in an even wrap during pulling.

Each reel is equipped with a mechanical clutch to allow

selective reel rotation and a mechanical brake to retard

overspin. The maximum desired linepull can be preset

prior to pulling so that the reel drive will stall if a restriction

to the line occcurs avoiding damage to the conductor,

towers and hardware.

The central operator’s console allows the operator to

completely control the pulling operation with optimum

visibilty of the pulling rope. Operator controls include

linepull, linespeed, holding brake and engine controls.

DIMENSIONS & WEIGHT (APPROX.)

Length ................................................... 15’

Width .....................................................8’

Height .................................................... 6’-4 “

Weight ................................................... 7,820 lbs.

(with rope)

STANDARD FEATURES

• 2,000 lb. linepull capacity on single full drum of rope.

• Proven hydrostatic pulling system with a hydraulic oil

cooler.

• Four pulling reels, each with a capacity for 6,000’ of

1/2” diameter rope.

• 35 hp water cooled diesel engine.

• Single axle with leaf spring suspension.

• Variable linespeed and linepull control.

• Mechanical clutch and mechanical bronze brake for

each reel.

• Spring applied-hydraulic pressure released holding brake.

• Central operator’s position for maximum safety and

visibility.

• Deluxe, adjustable operator’s seat and protective screen.

• Engraved operator’s console.

• Swing out automatic diamond leadscrew levelwind,

adjustable for individual use with all four reels.

• Steel lockable battery box.

• Front and rear drop leg mechanical jacks.

OPTIONAL EQUIPMENT

• Additional swing out automatic levelwind.

• Lockable console cover.

• Hydraulic front and/or rear jacks.

www.tse-international.com

5301 Shreveport Blanchard Hwy – Shreveport, Louisiana 71107 – USA

P: 318-929-2368 F: 318-929-4853

TSE International Inc. Warranty Policy

1. Contact the TSE International Inc. service department to discuss problem

and obtain a warranty claim number. Claim numbers will remain valid for

30 days allowing for sufficient time for submission to TSE. Warranties

claimed without a valid claim number may be denied.

2. Please retain any defective parts for a period of 60 days. TSE reserves the

right to inspect and/or evaluate any parts submitted for warranty

consideration. Should TSE elect to inspect the parts, a RGA (Return Goods

Authorization) number will be issued and the parts are to be returned

prepaid to TSE. Items not returned within 30 days will result in the RGA

closure and may result in a denial of the claim.

3. Warranty submission must be on the standard TSE International Inc. claim

form. Claims that are not will be classified as pending until proper forms are

submitted. All claims must have an estimated cost associated with each

item under discrepancy.

4. Major subcomponents are warranted under separate manufacturer

warranties. It is the responsibility of the owner/dealer of the equipment to

fill out and register all subcomponent manufactures warranties. In the

event of failure, arrangements can be made to deal with the subcomponent

supplier directly. Examples for subcomponent manufactures are:

Engines– John Deere, Cummins, Caterpillar, etc.

Claims submitted as per above TSE International Inc. Equipment Warranty policy

will be resolved within 30 days of receipt

www.tse-international.com

5301 Shreveport Blanchard Hwy – Shreveport, Louisiana 71107 – USA

P: 318-929-2368 F: 318-929-4853

Recommendations for improving this publication

are encouraged and should be forwarded to:

TSE INTERNATIONAL

5301 Shreveport-Blanchard Hwy.

Shreveport, Louisiana 71107

This is not a tension stringing operation procedures manual. No attempt is made or

implied herein to instruct the user in methods peculiar to the individual application of

the equipment described in this manual. The contents of this manual are intended as a

basis of for operation, maintenance, and parts listing of the unit in its intended and

anticipated use, as it stands alone in conjunction with other equipment.

The Equipment described in this manual is potentially dangerous if improperly or

carelessly operated. For the protection of personnel and equipment, only competently

trained operators who are critically aware of the proper procedures, operating

parameters, and limitations, potential dangers, and application of this equipment should

be allowed to touch the controls at any time.

www.tse-international.com

5301 Shreveport Blanchard Hwy – Shreveport, Louisiana 71107 – USA

P: 318-929-2368 F: 318-929-4853

PREMIUM CUSTOMER SERVICES

TSE supports its innovative products with Premium Customer Service. Our

comprehensive Service Department provides TSE customers with the service, parts,

and technical assistance they need to maintain their equipment in top operating

condition.

For Customer Service on Your

Model

Serial No.

PLEASE CALL 1-800-825-2402

Our People Care: Our Equipment is the Proof.

18-5048-01

DP20-4H

www.tse-international.com

5301 Shreveport Blanchard Hwy – Shreveport, Louisiana 71107 – USA

P: 318-929-2368 F: 318-929-4853

HOW TO ORDER REPLACEMENT PARTS

In order that we may promptly send the exact replacement part required in the least

amount of down time for you, the information listed below is necessary.

To order the replacement part, locate the part from the drawings in this manual and give

the following information:

1. Unit Model No. (From the plates on the unit’s frame)

2. Unit Serial No. (From the plate on the unit’s frame, will contain numbers only)

3. Part Number (If available)

4. Description (If part no. not available)

5. Quantity Required

On large components such as transmissions, engines, multiple pump drives, etc., the

manufacturer’s serial number and spec. number is necessary to ensure receiving the

proper replacement part.

www.tse-international.com

5301 Shreveport Blanchard Hwy – Shreveport, Louisiana 71107 – USA

P: 318-929-2368 F: 318-929-4853

WARNING

The equipment described in this manual is neither designed nor intended for any

application, alone or with in conjunction with any other equipment, that involves the

lifting or moving of persons.

Safe operation of this equipment is dependent on use in compliance with the

procedures outline in this section and the maintenance and inspection procedures in

SECTION Ill with consideration of prevailing conditions.

The equipment described in this manual is potentially dangerous if improperly and

carelessly operated. For the protection of personnel and equipment, only competently

trained operators who are critically aware of the proper procedures, operating

parameters and limitations, potential dangers, and application of this equipment should

be allowed to touch the controls at any time.

There is potential DANGER of ELECTRICAL SHOCK when operating this machine.

Ground the unit in accordance with the regulations of the using organization. Various

methods of bonding, isolation and grounding can be used; a means suitable to the user

should be selected and rigidly adhered to by ALL operating personnel.

Keep all shields and guards in place. Keep hands, feet and clothing away from power

driven parts and moving parts. Observe all warning decals placed on the machine.

Make certain all personnel are clear of this equipment before starting engine or

operation.

Before leaving the operators position, make sure that directional controls are in the

neutral position and all brakes are set.

www.tse-international.com

5301 Shreveport Blanchard Hwy – Shreveport, Louisiana 71107 – USA

P: 318-929-2368 F: 318-929-4853

EQUIPMENT WARRANTY

TSE International Inc. (hereinafter sometimes referred to as “TSE”) warrants that it will

repair f.o.b. its factory, or furnish without charge f.o.b. its factory, a similar part to

replace any material in its machinery which, during the earlier of 90 days after the said

machinery is put into operation or six months after the date of shipment of the

machinery from the plant, is proved to the satisfaction of the company to have been

defective at the time it was sold, provided that all parts claimed defective shall be

returned, properly identified, to TSE’s factory, charges prepaid.

This Warranty to repair applies only to new and unused machinery, which, after

shipment from the factory of TSE, has not been altered, changed, repaired or treated in

any manner whatsoever unless such alteration, change, repair or treatment has been

previously authorized in writing by TSE or has been performed by the authorized

service representative of TSE.

This Warranty to repair is the only Warranty either express, implied or statutory, upon

which the said machinery is sold; the companies liability in connection with this

transaction is expressly limited to the repair or replacement of defective parts, all other

damages and warranties, statutory or otherwise, being hereby expressly waived by the

purchaser.

No representative of TSE has authority to change this Warranty or this contract in any

manner whatsoever and no attempt to repair or promise to repair or improve the

machinery covered by this contract by any representative of TSE shall waive any

consideration of the contract or change or extend this Warranty in any manner

whatsoever.

www.tse-international.com

5301 Shreveport Blanchard Hwy – Shreveport, Louisiana 71107 – USA

P: 318-929-2368 F: 318-929-4853

GROUNDING EQUIPMENT AND METHODS

Grounding Equipment and Methods information is covered in the following publication:

“IEEE GUIDE TO INSTALLATION OF OVERHEAD TRANSMISSION LINE CONDUCTORS

IEEE STD 524-2003”

The above publication is available through the following organization:

THE INSTITUTE OF ELECTRICAL AND ELECTRONICS ENGINEERS, INC.

3 PARK AVENUE

NEW YORK, NY 10016-5997

USA

www.tse-international.com

5301 Shreveport Blanchard Hwy – Shreveport, Louisiana 71107 – USA

P: 318-929-2368 F: 318-929-4853

DECALS

Your equipment was shipped from the factory with the decals on the following sheet.

Should any of these decals be missing, they could prevent the proper operation and/or

maintenance of the unit which may result in personal injury or property damage.

If any of these decals are missing, please contact us for a replacement.

Order the decal(s) by stating the decal description, number, and quantity.

TSE INTERNATIONAL

5301 SHREVEPORT-BLANCHARD HWY.

SHREVEPORT, LA 71107

ATTENTION: SERVICE MANAGER

TELEPHONE: 800-825-2402

FAX: 318-929-4853

Table of contents

Other TSE Construction Equipment manuals