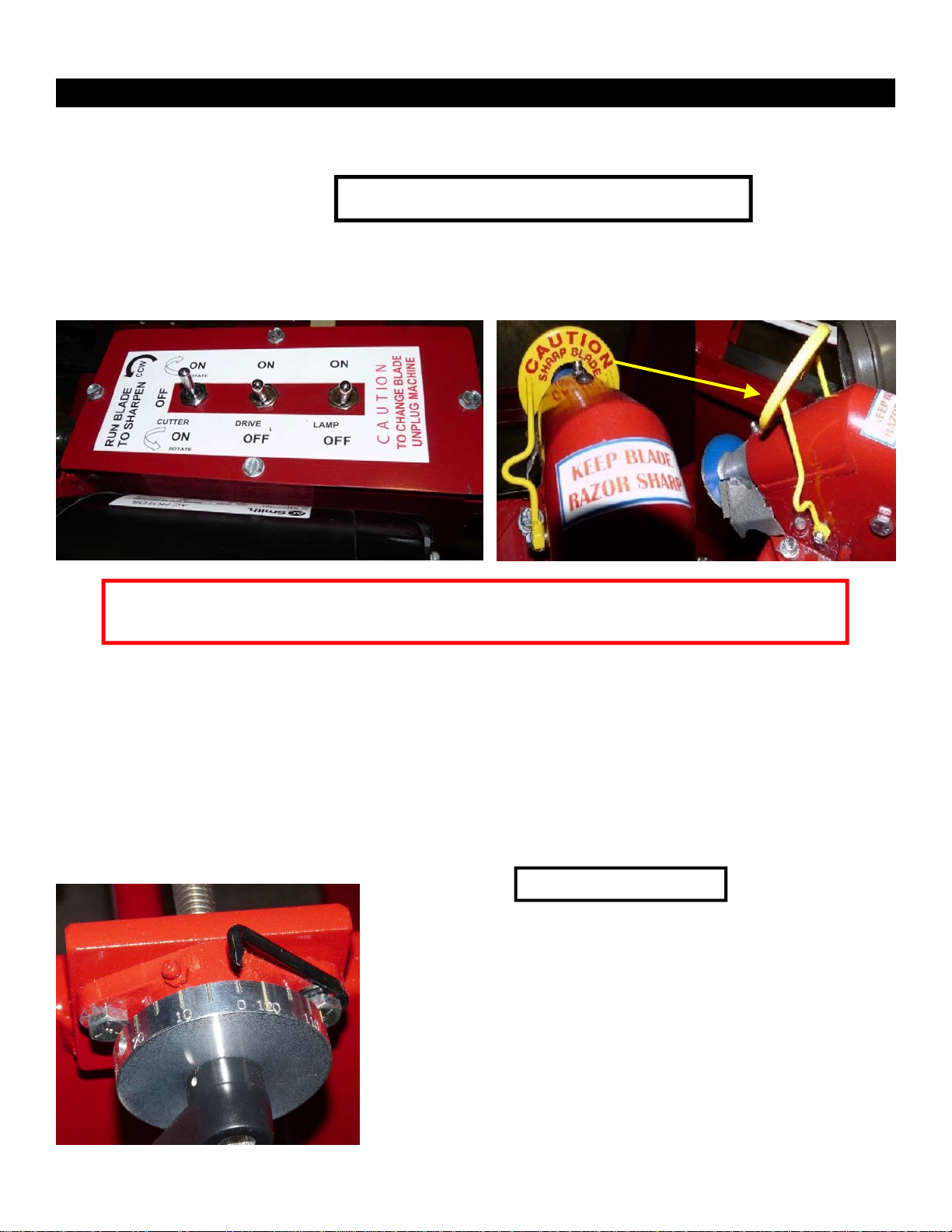

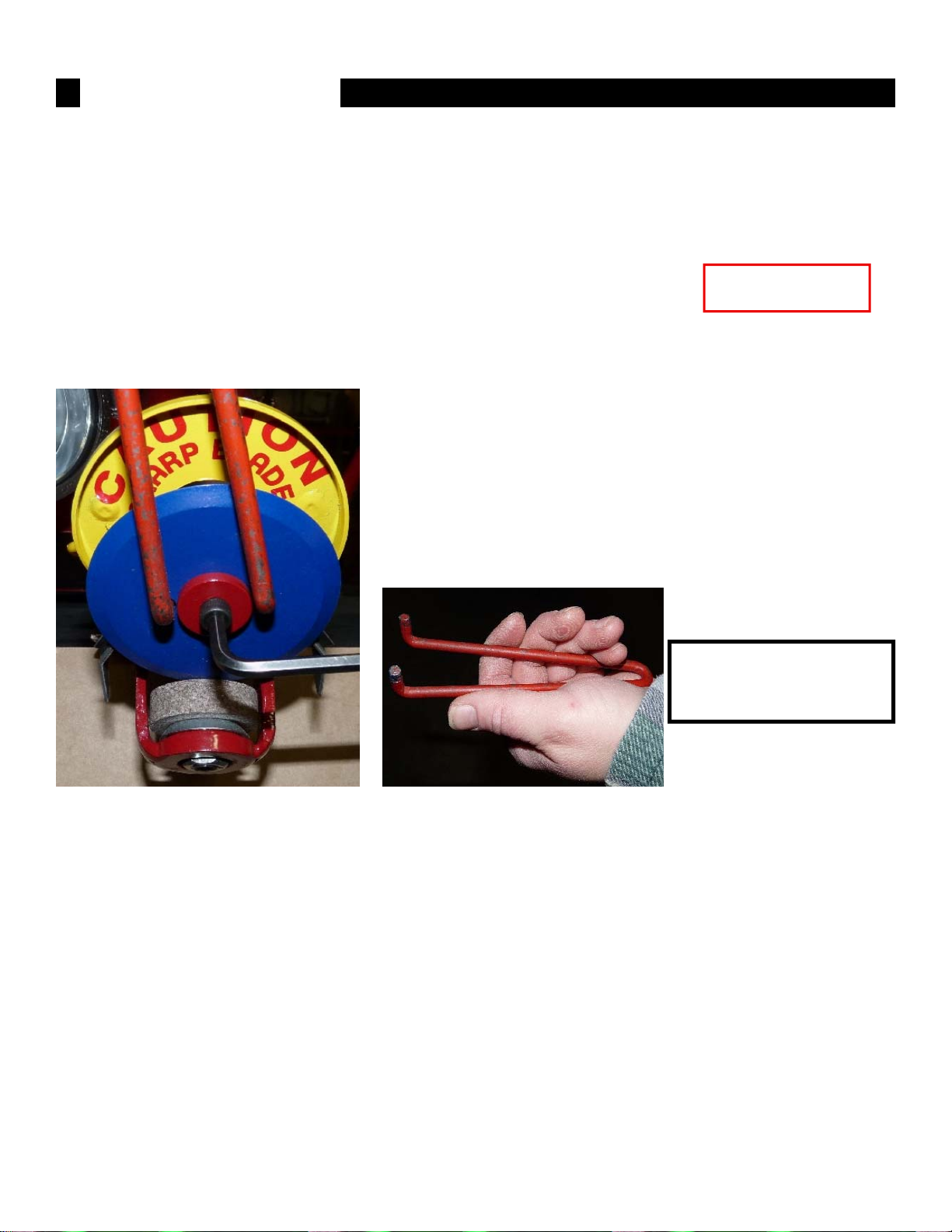

KEEP CUTTER BLADE RAZOR SHARP - KEEP THE CUTTING AREA CLEAN

Remember

KEEP HANDS AWAY FROM SPINNING

TIRE AND CUTTING BLADE

8. Do other half of tire by repeating steps 5 thru 7.

Reposition cutter blade location at the center of the tire where you first started. Turn the cutter blade

motor ON, this time Reverse the motor direction by toggling the switch toward the new direction of

truing. Set your cut and proceed to do the left side of the tire.

TSI highly recommends Truing both sides, halves of the tire in stages for each change of depth in

the tire before making the final cut. Slowing down the crossfeed drive screw traversing the top deck

and cutter blade results in a smoother end result.

It is possible a novice will prefer repeating the operation several times by taking lighter cuts until all

the high spots in the tread have been removed. Over time, after Truing many tires an operator can

gain more confidence, skill and a better understanding of what the machine can do.

When complete back cutter blade away from tire and turn cutter motor OFF. Lower safety cover.

Retract drive roller from wheel and turn motor OFF. Turn lamp OFF.

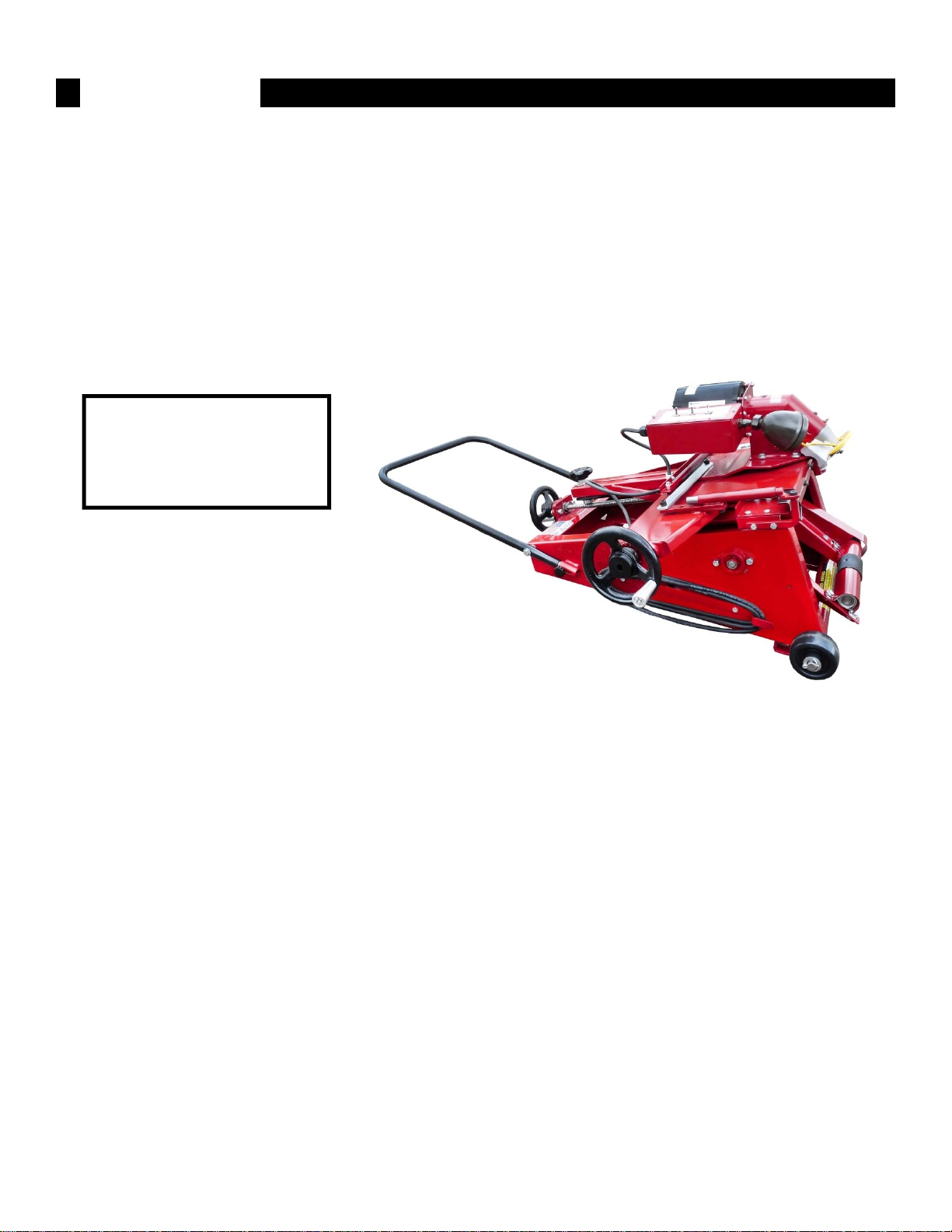

Slide PortaTruer away from tire a few inches. Clean off the unit.

Re-position cutter head and top deck to start position, making ready for the next tire or to stow away.

If tire was Trued using a wheel balancer simply pull the unit temporarily out of the way. Clean off the

machine or area before more Truing occurs.

Page 8

Please Note: While the Amermac PortaTruer can true tires on its own wheel bearings and maintain

extreme accuracy; an absolutely true tire can still be out of balance due to other factors such as rim,

hub, or drum defects and should be checked for correct balance by any good on-the-car balancer or

removed from the vehicle, balanced and remounted.

MAINTENANCE

Maintenance - Based on Truing approximately 100 tires a week.

Daily

Keep the machine clean. Remove rubber chips and debris with a brush or air nozzle. Too much

accumulated debris can complicate operation of machine as well as add to hazardous working

conditions. We recommend cleaning working contact areas after each tire is trued.

Check Blade and Sharpening Stone.

Verify Blade Safety Cover is operational.

Give the machine a good visual inspection. Check key areas of movement and make sure parts

haven’t become loose from being moved around or inadvertently bumped.