buyTSI.com - 800.223.4540

Every 6 months check battery condition

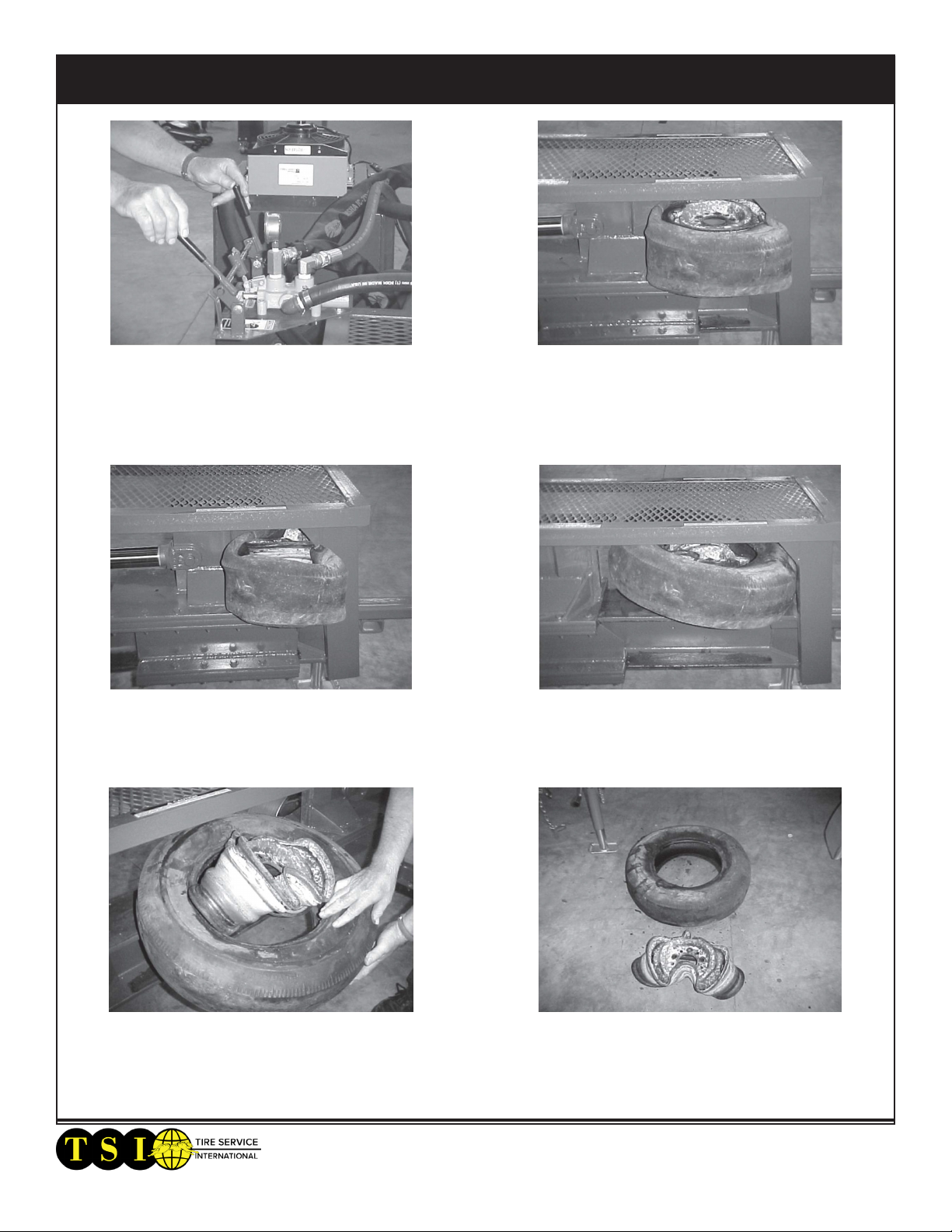

This photo illustrates the adjustment location of

the hydraulic pump pressure to the valve. The

gauge should read 2800-3000 PSI when the ram is

fully extended. To increase pressure, rst remove

large Hex nut. Then using a Hex Allen wrench-

turn adjustment screw to the right 1/4 turn at a

time & recheck until pressure is 2800-3000 PSI.

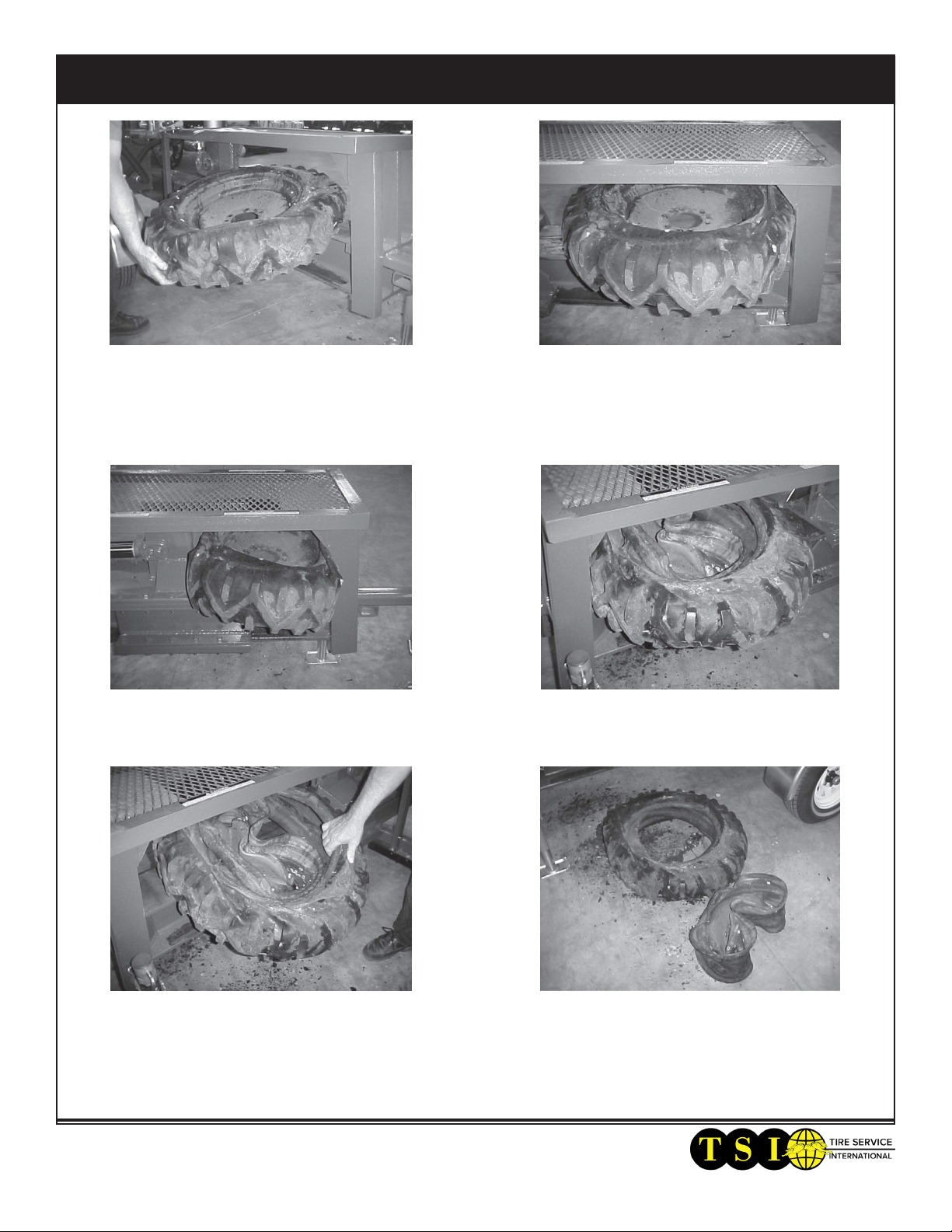

Replace oil ler every 6 months. Use TSI P/N

10130E for the replacement element

Check hydraulic oil reservoir level by viewing

the sight glass. Oil level should be approximately

3” -5” from the top.

NOTE: HYDRAULIC FLUID SHOULD BE

DRAINED ANO REFILLED EVERY 6 MONTHS.

USE UNIVERSAL AUTOMATIC TRANSMIS-

SION FLUID-SAE 20 OR SAE 30

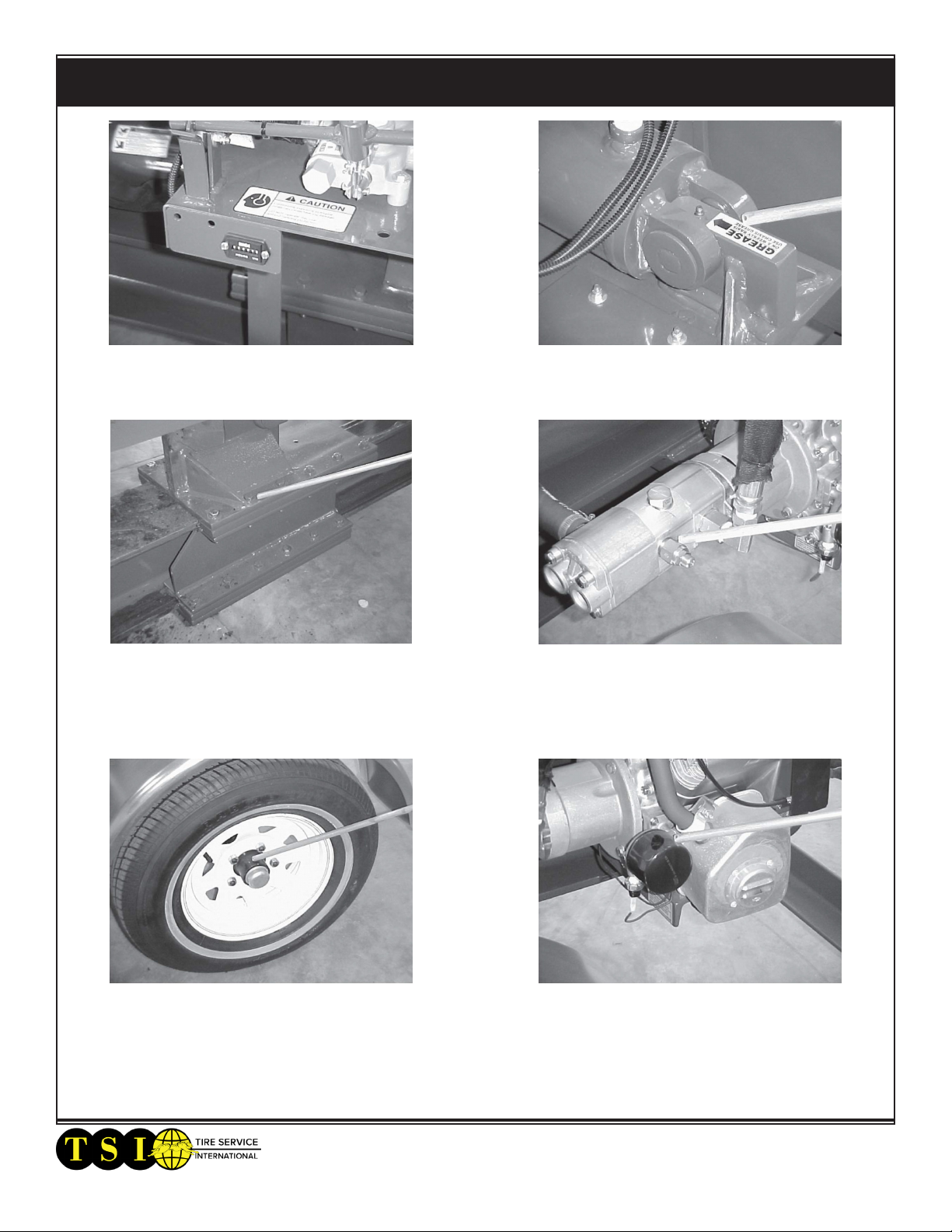

If the valve “kicks out” on the arms return stroke,

the detent will have to be tightened slightly.

Loosen lock nut as shown. Tighten outer nut 1/4

turn and tighten lock nut. Continue to crush. If it

“kicks out” again, readjust it another 1 /4 turn.

Maintenance