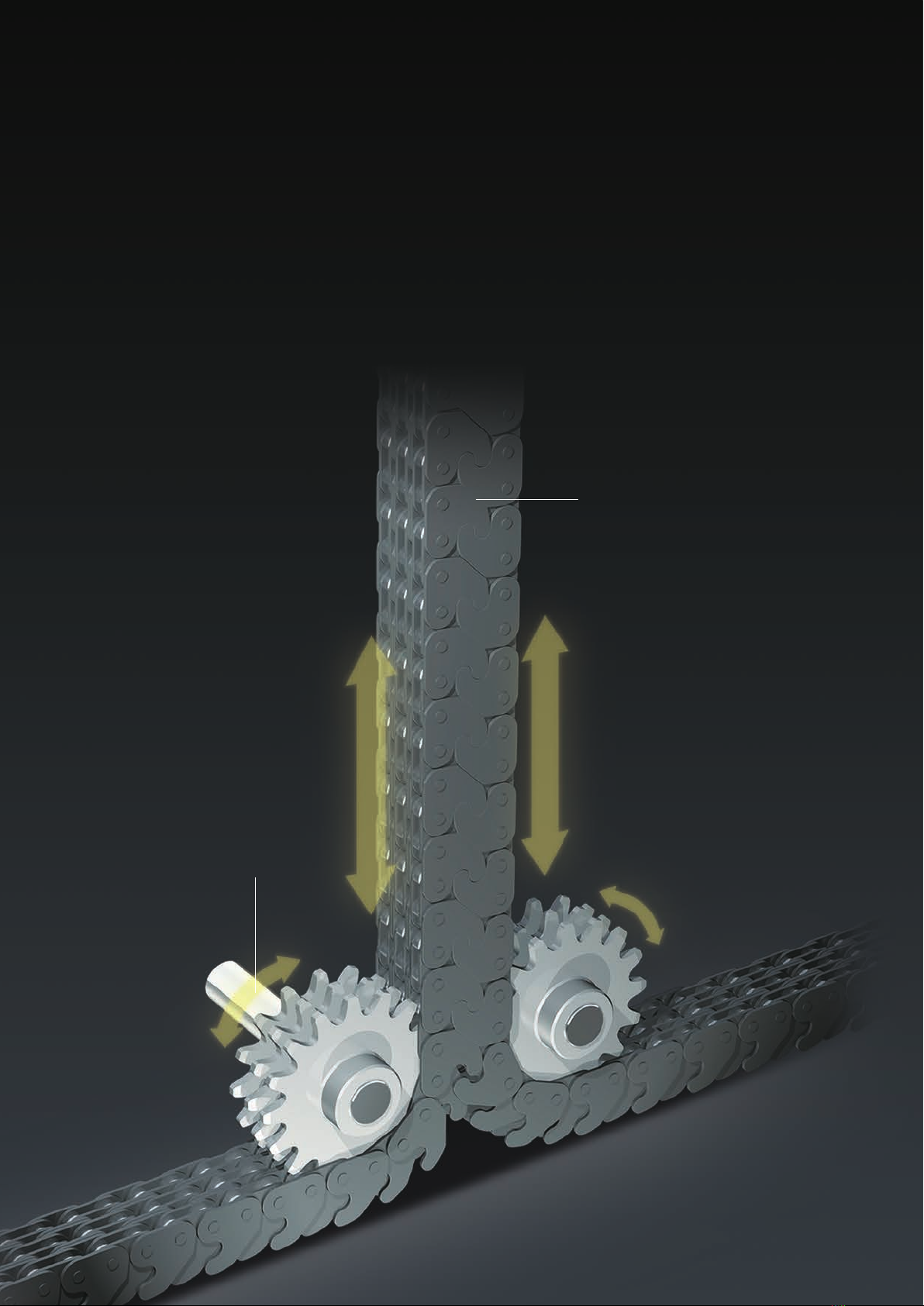

ZIP CHAIN LIFTER

FEATURES

Comparison with

other devices

ZIP CHAIN LIFTER provides an innovative table lifter that directly transmits lifting thrust through ZIP CHAIN.

It operates 3 to 10 times faster than hydraulic lifters and supports high-frequency operation, which provides energy

savings as high as 50%.

With ZIP CHAIN LIFTER, the mass and thrust of the lifting

mechanism is supported directly by ZIP CHAIN, preventing

excessive force from being applied to the scissor arm

hinges, rollers, and bearings.

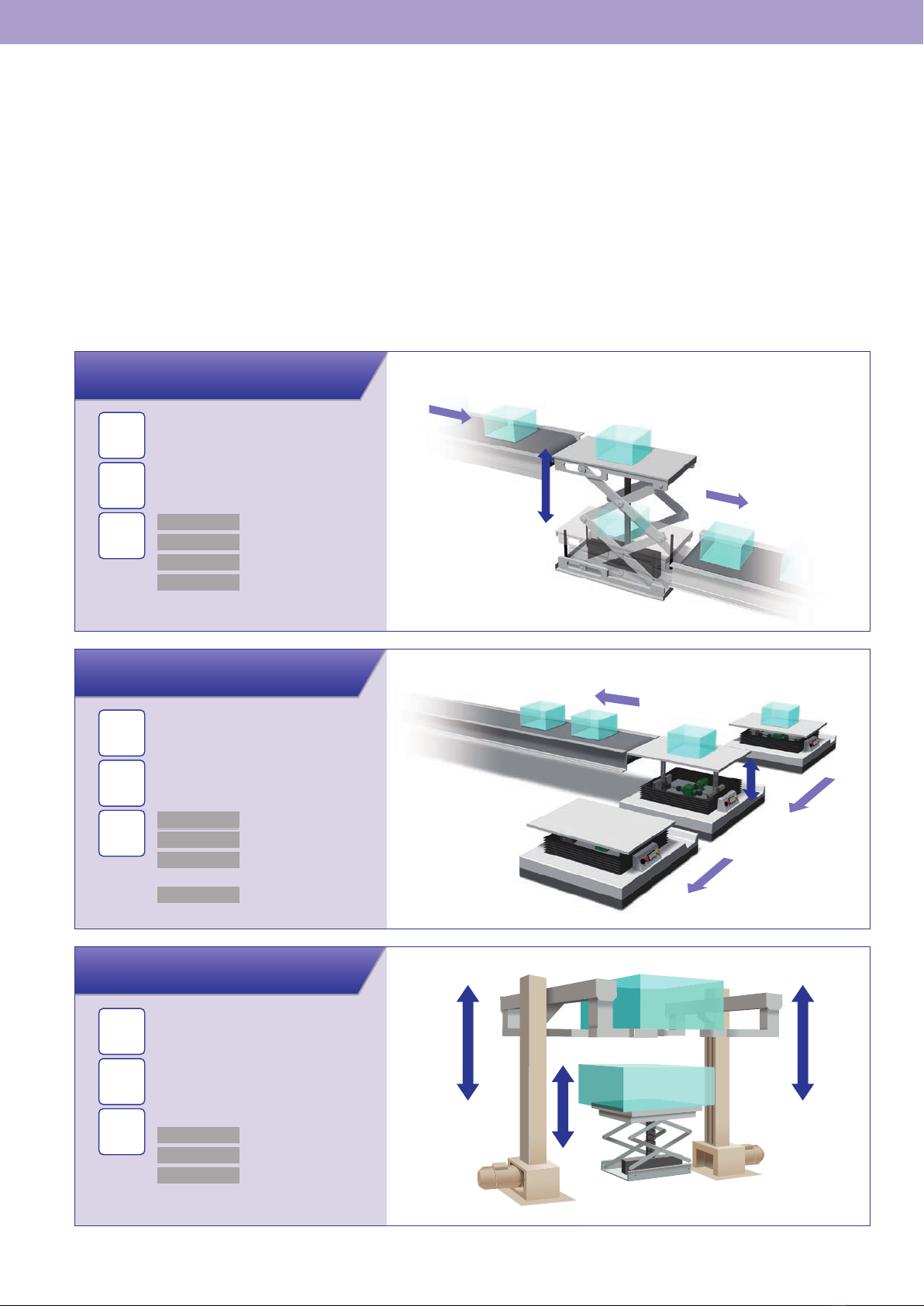

When lifting from the lowest

position, electric and hydraulic

cylinders push the lifter in a

diagonal direction and require a

large amount of power (1/sin

θ

times the lifting thrust).

Standard 1,000kg ZIP CHAIN LIFTER

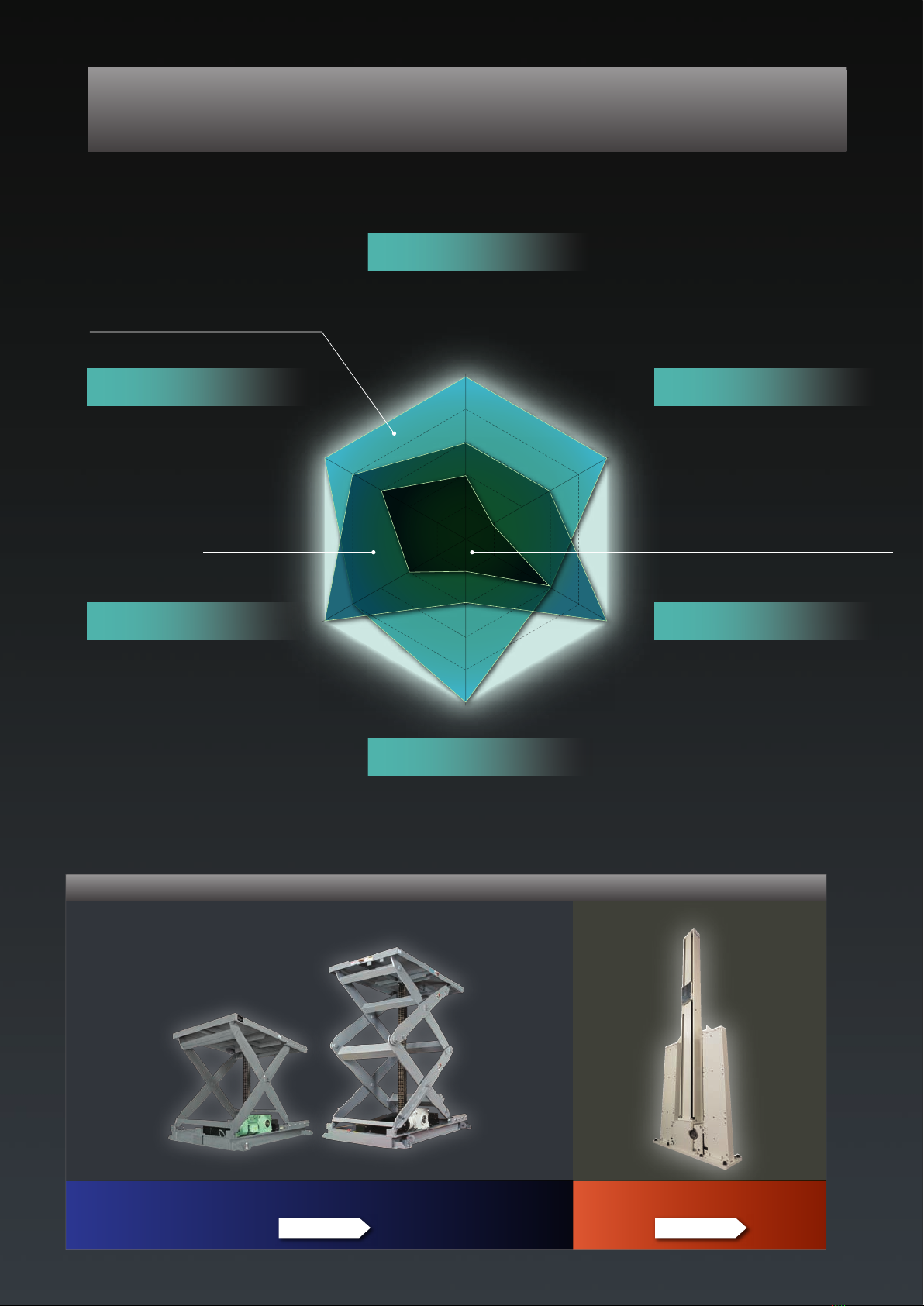

COMPARISON WITH OTHER LIFTING METHODS

●Exceptional durability

ZIP CHAIN pushes the top plate directly, ensuring the motor

torque is transmitted efciently.

●Efficient transmission drive

ZIP CHAIN LIFTER Electric and hydraulic lifters

Ex.: At

θ

= 10°,

a thrust of 5.8 times the thrust force is required.

Standard 1,000kg lifting weight models in two different speeds.

Lifting weight

●Specications

Stroke

Speed with three-phase motor

Speed with servomotor

●Features

Operation cycle

Stopping accuracy

Expected life

1,000 kg

±1 mm

13.5 seconds

1,000 mm

5.5 m/min 11

m/min

19 m/min

(Single-stage pantograph) 1,600 mm

(Dual-stage pantograph)

More than

1

million

cycles

Speed

ZIP CHAIN LIFTER

Max. 100 m/min

good good good good

poor

poor

poor

poor

poor

poorpoor

good

Continuous operation

Oil temperature rise

Intermittent operation only

With servomotor

With servomotor

Difculty with intermediate stops

More than 1 million complete round trips

100,000 round trips

100,000 round trips

Max. 15 m/min

Max. 15 m/min

Electric screw-jack lifter

Hydraulic lifters

High frequency Stopping accuracy Expected life

Speed

ZIP CHAIN LIFTER achieves high-

speed operation at a maximum lifting

speed of 100m/min. This lifter works

through a mechanism that directly

pushes up the lift table at a stable

speed in proportion to motor rpm,

enabling lifting operation at a constant

speed. Synchronized operation of

multiple lifters is also possible.

●ZIP CHAIN LIFTER

It maintains a stable speed

through the entire stroke range.

The speed varies throughout the stroke.

It slows down in the middle.

●Hydraulic lifter

Lifting stroke

Lifting speed

Lifting stroke

Lifting speed

High-frequency operation

In the case of a hydraulic lifter, it

is necessary to increase the

tank capacity of hydraulic units

during high-frequency

operation. Since ZIP CHAIN

LIFTER is an electric

high-speed lifter, there is no

tank and high-frequency

operation is possible.

Supports high-speed operation

such as continuous lifting at a

rate of one lift cycle per minute

thanks to its efcient operation.

Expected life

ZIP CHAIN LIFTER has a

mechanism that directly pushes

the lift table, which places a

smaller load on the

hinges/rollers and enables

longer life (over one million

strokes).

4