Liberty Open - Operator & Maintenance Manual

Contents

1. Introduction…………………………………………………………………………………………………… 4

2. Safety Precautions……………………………………………………………………………………….... 5

2.1. General………………………………………………………………………………………………………... 5

2.2. Prohibited use……………………………………………………………………………………………… 5

2.3. WARNING – Overload………………………………………………………………………………….. 5

2.4. Repair and maintenance……………………………………………………………………………… 5

2.5. WARNING – Risk of crushing………………………………………………………………………… 5

2.6. Safety actions prior to working on the platform lift……………………………………... 6

2.7. Safety precautions when working under the platform…………………………………. 6

3. Standard Features…………………………………………………………………………………………… 7

3.1. Finish…………………………………………………………………………………………………………… 7

3.2. Standards & Compliance……………………………………………………………………………… 7

3.3. Safety Gear………………………………………………………………………………………………….. 7

3.4. Platform Sizes……………………………………………………………………………………………… 7

3.5. Application………………………………………………………………………………………………….. 7

3.6. Travel Speed……………………………………………………………………………………………….. 7

3.7. Safe Working Load (SWL)……………………………………………………………………………. 7

3.8. Manual Lowering ………………………………………………………………………………… 7

3.9. Safety Features…………………………………………………………………………………………… 7

3.10. Lift Enclosure……………………………………………………………………………………………. 7

4. Operating Instructions…………………………………………………………………………………… 8

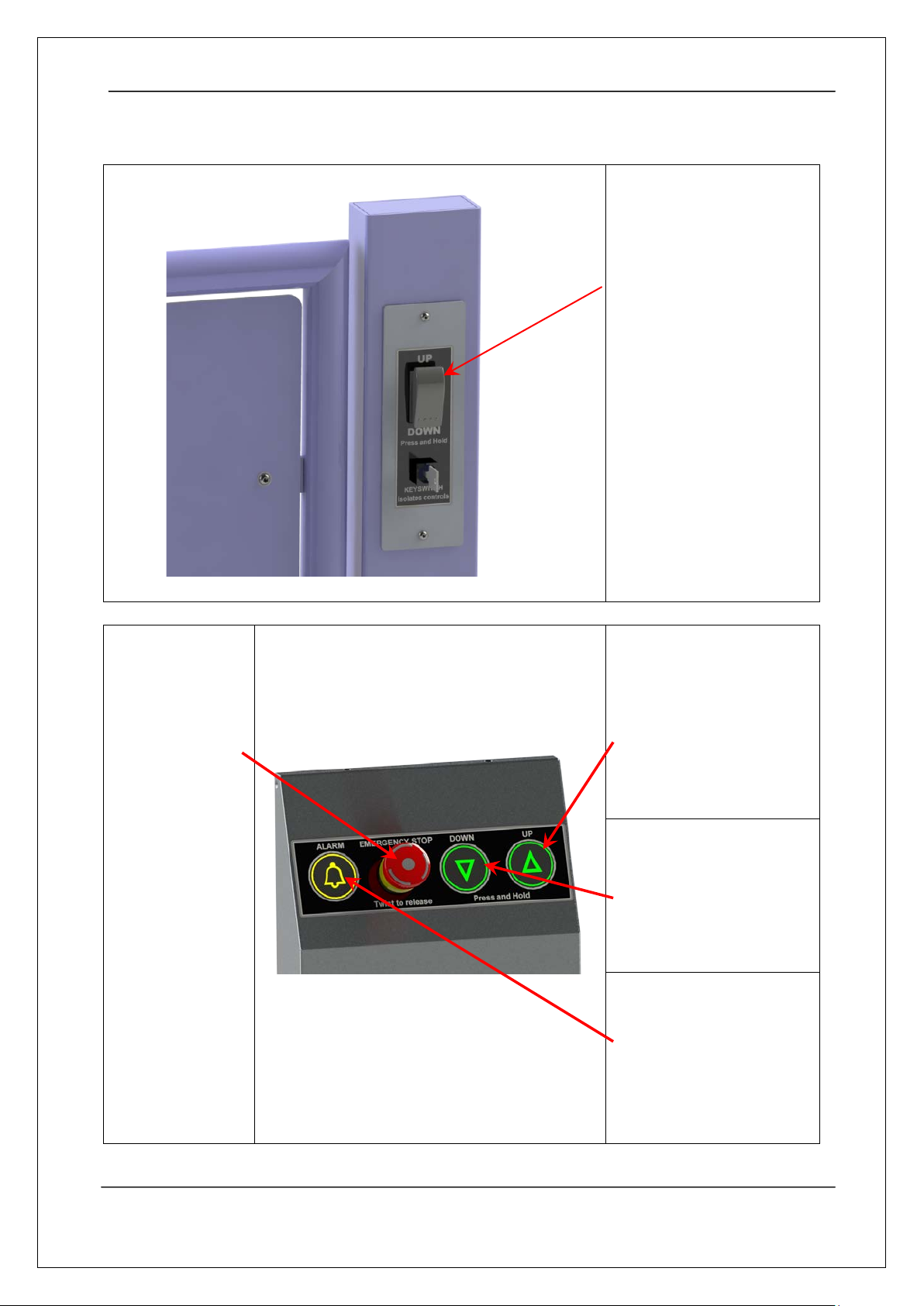

4.1. Call Stations – Internal Standard Controls………………………………………………….. 8

4.2. In-Car Internal Standard Controls (2-Stop)…………………………………………………. 8

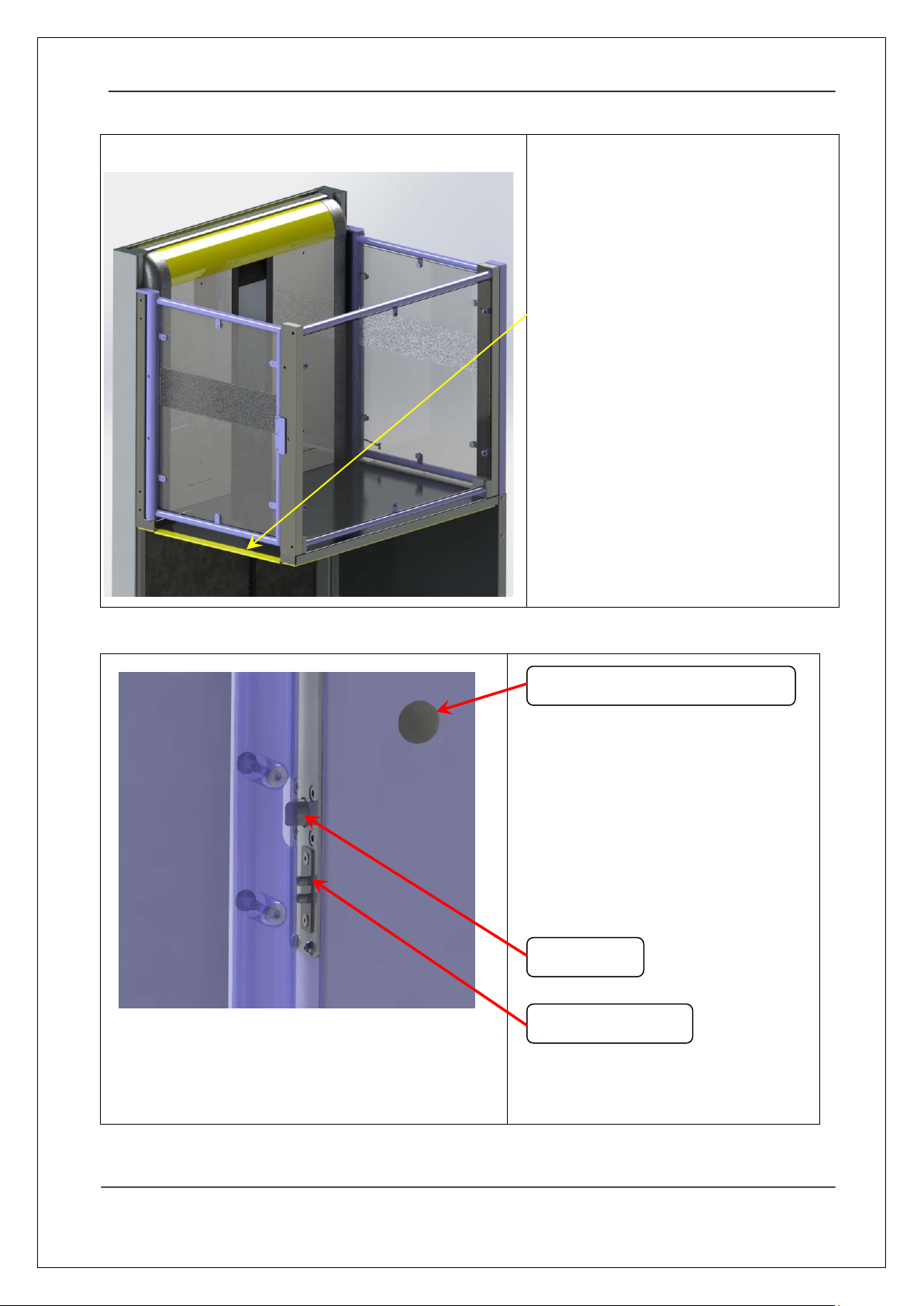

4.3. Sensitive Safety devices – ‘Safety Edges’……………………………………………………. 9

4.4. Gate Interlocks………………………………………………………………………………............. 9

4.5. Operation of the Platform lift (Overview)…………………………………………………… 10

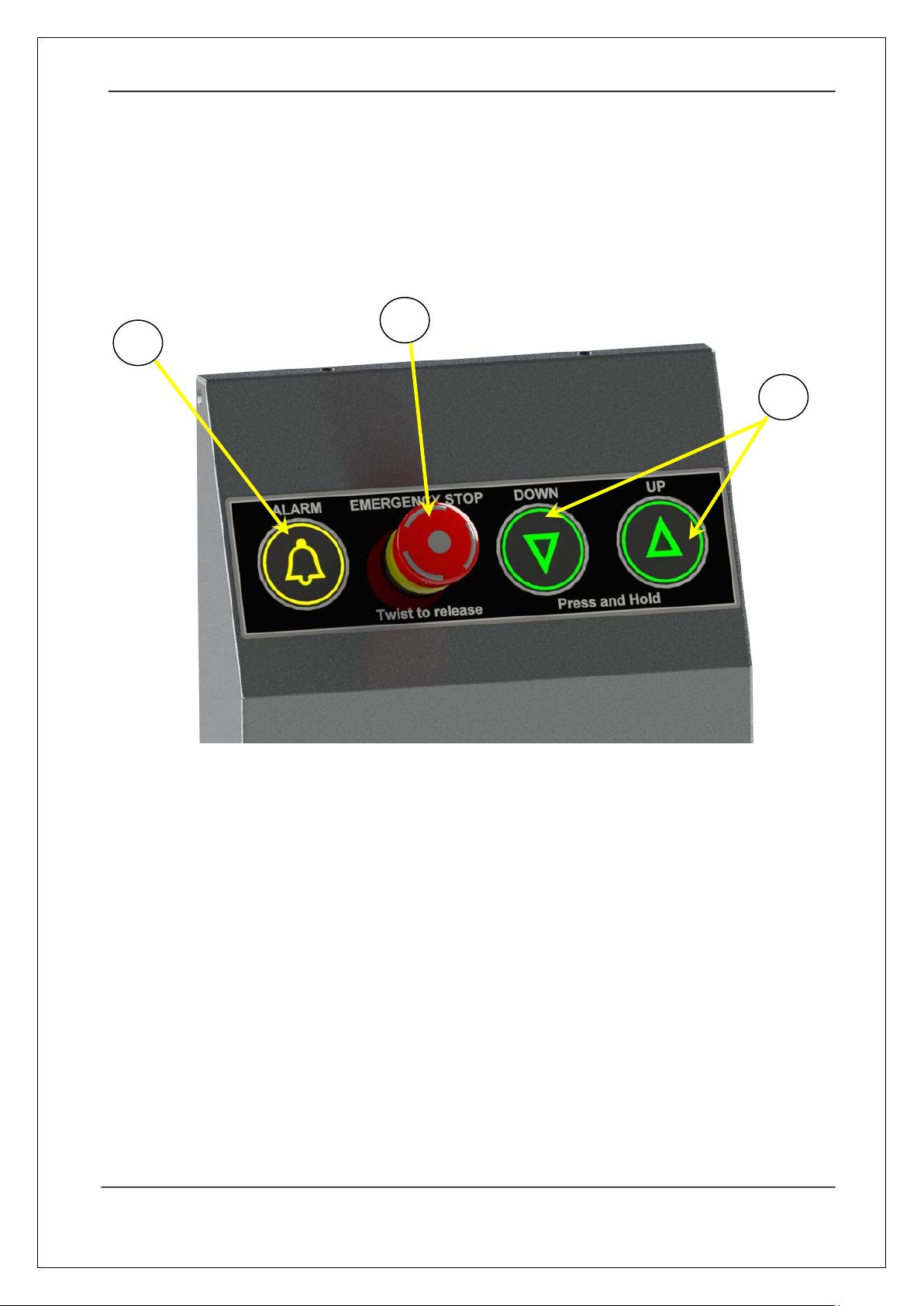

4.5.1. The Control Panel…………………………………………………………………… 10

4.5.2. Principle of Operation………………………………………………………………… 10

4.6. Calling the Lift…………………………………………………………………………………………….. 11

5. In the event of a failure……………………………………………………………………………….. 13

5.1. Raising the alarm………………………………………………………………………………………. 13

5.2. Emergency In-Car lowering……………………………………………………………………….. 13

5.3. Manual Lowering………………………………………………………………………………………. 13

5.4. Manual release of gates…………..............…………………………………………………… 15

6. Routine care and maintenance…………………………………………………………………….. 16

6.1. Domestic applications……………………………………………………………………………….. 16

6.2. Public access applications………………………………………………………………………….. 16

7. Operating difficulties and fault finding…………………………………………………………. 17

8. Emergency breakdown service……………………………………………………………………... 18

9. Service and Inspection………………………………………………………………………………….. 19

10. Lift technical specification………………………………………………………………………….. 23

11. Manufacturer information…………………………………………………………………………. 32

12. Manufacturer’s warranty…………………………………………………………………………… 33

EC Declaration of Conformity……………………………………………………………………………… 34

OP00 7100_A.doc

Page 3of 34