Simpro Multi-Tip MT1200 User manual

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022

USER MANUAL

Copyright © 2022 Simpro Handling Equipment Ltd.

No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the written

permission of Simpro Handling Equipment Ltd.

For the purposes of standards compliance and international conformity, this document uses

Système International (SI) units. These may be converted to Imperial units as follows:

1 kilogram (kg) = 2.2 pounds (lb)

1 metre (m) = 1000 millimetres (mm) = 39.37 inches (in) = 3.28 feet (ft) = 1.09 yards (yd)

The following stylistic conventions are used throughout this document:

Point of interest

Safety hazard

§ Section reference (hyperlink in PDF edition)

Simpro partcode (hyperlink in PDF edition)

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 2

Contents

1. Product Overview ......................................................................................................................... 5

1.1 Key Features ........................................................................................................................................ 6

1.2 Construction ........................................................................................................................................ 6

1.3 Mechanism .......................................................................................................................................... 6

1.4 Safe Working Load .............................................................................................................................. 6

1.5 Duty cycle ............................................................................................................................................ 7

1.6 Service life ............................................................................................................................................ 7

1.7 Noise emissions .................................................................................................................................... 7

1.8 Environmental restrictions ................................................................................................................... 8

1.9 Ingress protection................................................................................................................................ 8

1.10 Notes..................................................................................................................................................... 8

2. Operating Instructions ..................................................................................................................9

2.1 Before operation ................................................................................................................................. 9

2.2 Emplacing and removing bins........................................................................................................... 9

2.2.1 Cradle identification........................................................................................................................................9

2.2.2 Type-E Cradle (standard) ..............................................................................................................................11

2.2.3 Type-C Cradle ................................................................................................................................................ 11

2.2.4 Type-A Cradle ................................................................................................................................................ 11

2.2.5 Type-A Cradle with base ..............................................................................................................................12

2.2.6 Type-D Cradle ................................................................................................................................................ 12

2.2.7 Type-X Cradle (custom)................................................................................................................................. 12

2.3 Operation of controls........................................................................................................................ 13

2.4 Battery charging................................................................................................................................ 14

2.5 Safety Norms...................................................................................................................................... 15

3. Care and Maintenance.............................................................................................................17

3.1 Quick Troubleshooting Guide .......................................................................................................... 17

3.2 Cleaning............................................................................................................................................. 18

3.3 Cradle jams........................................................................................................................................ 18

3.3.1 Cradle jams while raising............................................................................................................................... 18

3.3.2 Cradle jams while lowering ........................................................................................................................... 18

3.4 Electrical System (battery)................................................................................................................ 20

3.4.1 International conformance...........................................................................................................................20

3.4.2 Voltmeter ........................................................................................................................................................ 20

3.4.3 Batteries .......................................................................................................................................................... 20

3.4.4 Battery charger .............................................................................................................................................. 21

3.4.5 Charging lead ................................................................................................................................................ 21

3.4.6 Emergency stop .............................................................................................................................................21

3.4.7 Circuit breaker................................................................................................................................................ 21

3.4.8 Solar panel...................................................................................................................................................... 21

3.5 Electrical System (3-phase mains) ................................................................................................... 22

3.5.1 International conformance...........................................................................................................................22

3.5.2 Transformer .....................................................................................................................................................23

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 4

3.6 Electrical System (1-phase mains) ................................................................................................... 24

3.6.1 International conformance...........................................................................................................................24

3.6.2 Transformer .....................................................................................................................................................24

3.6.3 Variable Speed Drive..................................................................................................................................... 24

3.7 Hydraulic System ............................................................................................................................... 25

3.7.1 Powerpack ..................................................................................................................................................... 25

3.7.2 Control valves................................................................................................................................................. 25

3.7.3 Lift ram.............................................................................................................................................................25

3.7.4 Hydraulic fluid.................................................................................................................................................25

3.7.5 Maintenance.................................................................................................................................................. 25

3.7.6 Hydraulic system schematic.......................................................................................................................... 26

3.8 Preventative Maintenance Inspections.......................................................................................... 27

3.8.1 Pre-inspection checklist ................................................................................................................................. 27

3.8.2 Monthly inspection......................................................................................................................................... 27

3.8.3 Annual inspection .......................................................................................................................................... 29

4. Assembly, Handling and Storage.............................................................................................. 31

4.1 Assembly ............................................................................................................................................ 31

4.2 Moving................................................................................................................................................ 31

4.3 Lifting .................................................................................................................................................. 31

4.4 Transport............................................................................................................................................. 31

4.4.1 Horizontal transport ........................................................................................................................................32

4.5 Storage............................................................................................................................................... 32

5. Safety Assessment ....................................................................................................................... 33

5.1 Safety features................................................................................................................................... 33

5.2 Reasonably foreseeable misuse ...................................................................................................... 33

5.3 Hazard and Risk Assessment Guide................................................................................................. 33

5.4 OSH Compliance Specification Guide ........................................................................................... 38

6. Spare Parts ................................................................................................................................... 41

7. Warranty....................................................................................................................................... 43

8. EC Declaration of Conformity ................................................................................................... 45

9. Notes.............................................................................................................................................46

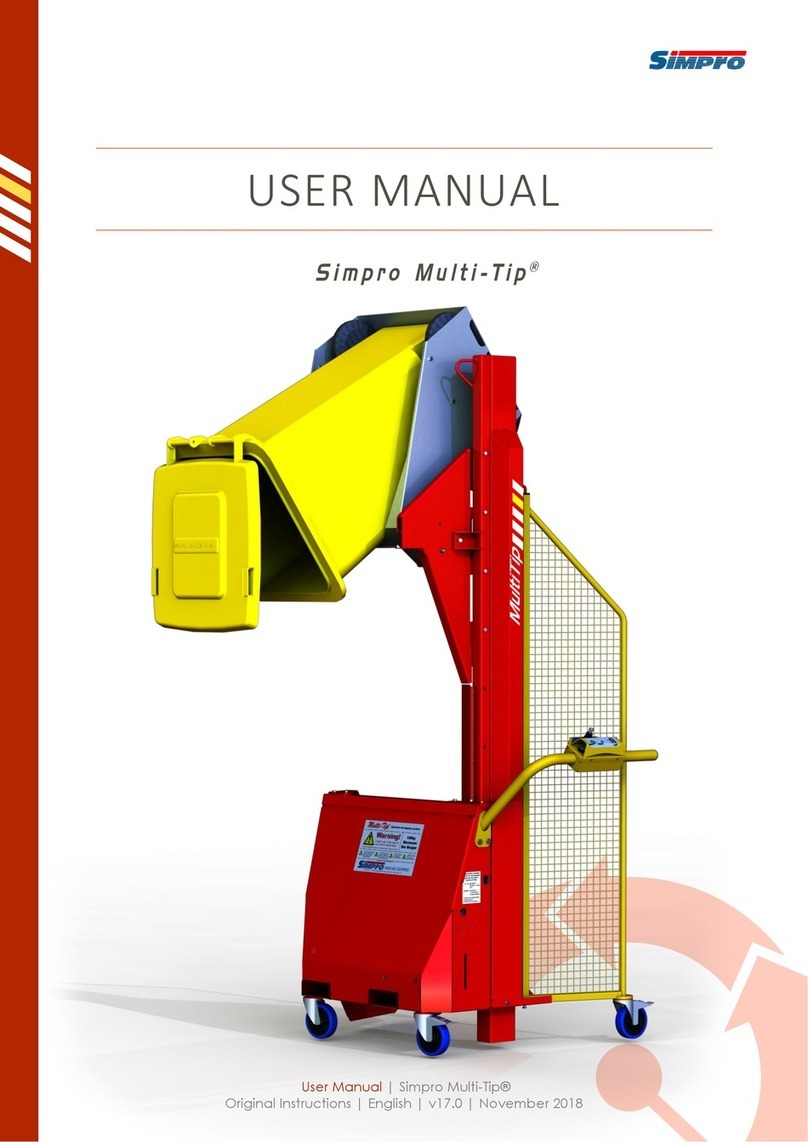

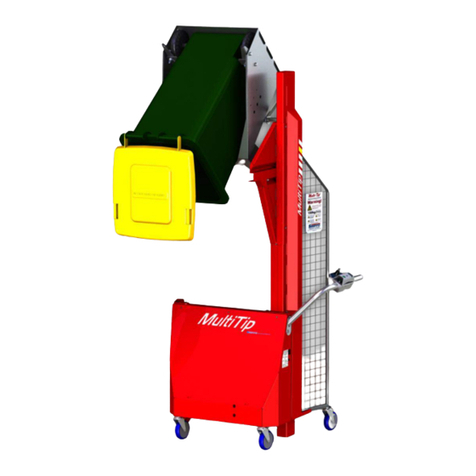

1. Product Overview

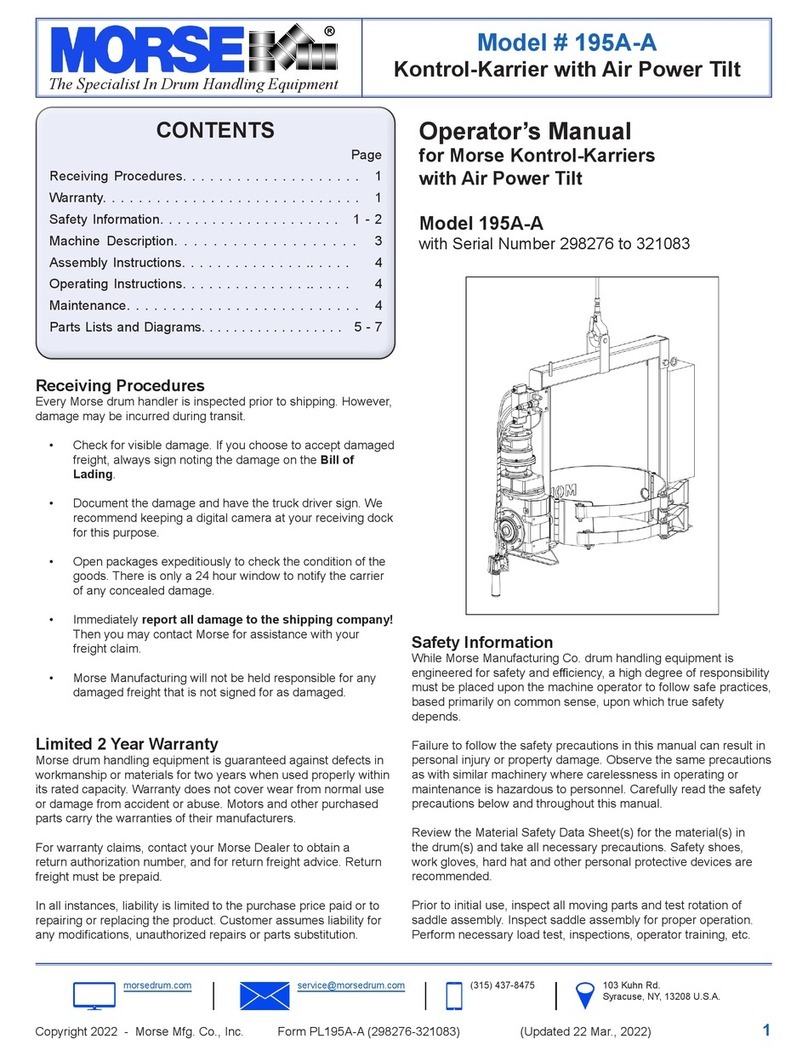

Congratulations on your purchase of a Simpro Multi-Tip. The Multi-Tip is everything a bin lifter

should be; safe, cost-effective, and easy to use. With a 150kg lifting capacity and 15-second

tipping cycle, it is an ideal solution for schools, recycling centres and small businesses.

Featuring an innovative monomast design, the Multi-Tip affords operators a clear view of

operations to ensure safety. No cage-guard is required, because the two-hand control

system prevents operators from accessing moving parts

while using the machine. The open design is also

simple to clean and maintain.

The standard Multi-Tip dumps bins at

1600mm, and is available with

cradles to suit almost all common

waste bins and carts. However,

the modular architecture makes it

simple to customise the machine

for non-standard applications

such as emptying BRUTE® bins,

205-litre drums, or fish bins at

heights of 1200mm, 1600mm or

1800mm.

Like all Simpro products, the Multi-Tip is safe, durable, and

requires little maintenance.

As far as compliance and relieving me of hard work, this is the best -

absolutely the best!

Graham Hawkes –Caretaker –One Tree Hill College

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 6

1.1 Key Features

Key features of the Multi-Tip include:

1. A unique tipping action whereby bins are lifted straight up, and then gently rolled

forward around the lip of the container being emptied into. Benefits of this design

in and high stability in use.

2. A large lifting capacity of 150kg.

3. A reliable, maintenance-free design.

4. Castor wheels and grab-handles for ease of movement.

5. A powder-coated frame and zinc-plated cradle for corrosion protection.

6. A modular cradle architecture which can be easily adapted to suit different bins, and

does not require clamping or fastening simply place the bin into the cradle and

1.2 Construction

The Multi-Tip consists of a steel frame with one vertical mast, a bin cradle, one hydraulic ram,

guarding, castor wheels, powerpack cover, grab handle with control buttons, power lead or

battery, hydraulic powerpack and control systems.

1.3 Mechanism

When operated, the bin cradle moves vertically in the masts, and is inverted at the

appropriate height by track. A hydraulic ram provides

the force to lift the bin. The ram is operated by a hydraulic powerpack, which is normally

powered by a battery. Electronic control systems allow the operator to raise or lower the bin

in a controlled manner.

1.4 Safe Working Load

The Safe Working Load of the standard Multi-Tip is 150kg (330lb).

Safe Working Load (SWL) is a gross figure, referring to the weight of the bin, its contents,

and any other objects placed on the cradle.

Custom machines may be specified with different Safe Working Loads. The rating plate

should be the first point of reference when determining SWL on any given machine.

Never attempt to lift bins that are heavier than the factory-specified Safe Working Load.

1.5 Duty cycle

The duty cycle of the Multi-Tip depends on the installed powerpack, available power supply,

environmental factors, and the manner in which the machine is being used. The figures given

below are indicative only.

Power supply

Duty Cycle (tipping ~100kg bins at 1600mm)

Net throughput

Number of bins

Units

24V/20Ah GEL Battery*

5,000kg

50 bins

Per charge

24V/20Ah GEL Battery on

continuous charge

2000kg

20 bins

Per hour

24V/40Ah GEL Battery with

Solar Panel Kit**

2,000kg

20 bins

Per day

Mains, 3-Phase ~415VAC

12,000kg

120 bins

Per hour

Mains, 1-Phase ~230VAC

6,000kg

60 bins

Per hour

12V/20Ah GEL Battery***

2,500kg

25 bins

Per charge

12V/55Ah GEL Battery***

6,000kg

60 bins

Per charge

*Two 12V/20Ah batteries in series (standard from 2022) **Subject to weather, latitude, and panel orientation (see §3.4.8) ***Discontinued 2022

Power supply

1.6 Service life

The nominal service life of the Multi-Tip is as follows.

Average Gross Bin Weight

Nominal service life

< 50kg

100,000 cycles

50kg –100kg

75,000 cycles

100kg –150kg

50,000 cycles

> 150kg

10,000 cycles

1.7 Noise emissions

The noise emissions of the Multi-Tip do not typically

Hearing protection is recommended if operating the machine for extended periods.

ISO standards for machinery safety specify that noise emissions are to be measured in A-

weighted decibels (dB(A)), a unit of volume which is adjusted to reflect the sensitivity of

human hearing. The measurements are taken at a point 1.6 metres above the ground at

s working position.

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 8

1.8 Environmental restrictions

The Multi-Tip may be used indoors or outdoors. However, the following restrictions apply:

1. A minimum floor area of two square metres, with a clear passage to exits;

2. Height above sea level not more than 1000m;

3. Ambient temperature not higher than +40℃and not lower than -10℃;

4. At ambient temperatures above 35℃, the relative humidity should not exceed 50%; at

lower temperatures, higher relative humidity is permitted;

Never operate the machine in explosive, corrosive, acidic or alkaline environments.

1.9 Ingress protection

Item

IP Rating

Push buttons, switches, and lamps

IP66

Door interlock

IP66

Coded magnetic switch

IP66

Motor

IP54 (note additional protection provided by covers)

Overall

IP54 (optional upgrade to IP66 or IP69K)

1.10 Notes

1. This User Manual describes approved procedures for the operation, maintenance,

and routine inspection of the Simpro Multi-Tip hydraulic bin-tipping machine.

2. This manual is written in English, and is to be conside

the purposes of EU Machinery Directive 2006/42/EC.

3. Operator(s) must read and understand this manual before using the machine.

4. If the machine is to be leased, sold, or otherwise transferred, then this manual shall

accompany the machine.

5. This is a generic manual. Simpro reserves the right to change the design of our

products at any time. In cases where a discrepancy exists between the manual and

the actual product, the manual is to be used as a reference only.

6. Contact your authorized Simpro agent if any problems or faults are encountered with

the machine.

7. Errors in this manual should be reported by email to info@simpro.world.

2.Operating Instructions

Before the machine is used for the first time, a site-specific Hazard and Risk Assessment

should be completed as per §5.3.

2.1 Before operation

Before operating a Multi-Tip, check that the machine is stable and safe to use as follows:

1. The machine is on firm ground with a slope ratio of less than 1:12.

2. All covers and safety guards are in place.

3. The wheel brakes are applied.

4. All personnel other than the operator are well clear of the machine.

5. The cradle is fully lowered.

6. The key is inserted and turned to the ON position.

7. The battery indicator (if fitted) shows an acceptable level of charge.

2.2 Emplacing and removing bins

The Multi-Tip cradle is designed to allow bins to be emplaced and removed easily, while also

holding them securely throughout the tipping cycle.

It is important to understand how to correctly place bins onto the cradle, as improper

placement may result in bins falling out of the machine when inverted.

2.2.1 Cradle identification

A range of different cradles may be fitted to the Multi-Tip, depending on the bins it will be

emptying. Use the following table to identify the correct instructions for your machine.

Cradle

Usage

Bin Compatibility

Cradle Image

See

Type-E

(EN840

base-lift

cradle)

Standard waste

and recycling

applications in EU,

UK, AU, NZ, Asia,

Africa, and parts of

South America

EN840 mobile

garbage bins

(wheelie bins)

-60L

-80L

-120L

-140L

-240L

§2.2.2

Type-C

(EN840

comb-lift

cradle)

Specialised waste

and recycling

applications

(primarily with 360-

litre bins) in EU, UK,

AU, NZ, Asia,

Africa, and parts of

South America

-60L

-80L

-120L

-140L

-240L

-360L

§2.2.3

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 10

Cradle

Usage

Bin Compatibility

Cradle Image

See

Type-A

(ANSI bar-

lift cradle)

Standard waste

and recycling

applications in

USA, Canada, and

parts of South

America

ANSI Z245.60

(Type-B) Trash

Carts

-32 gal

-48 gal

-64 gal

-96 gal

§2.2.4

Type-A

with base

(ANSI bar-

lift cradle

with base)

Specialised waste

and recycling

applications in

USA, Canada, and

parts of South

America

BRUTE® Bins

205L Drums

Plastic Tubs

Customs Bins

-10 gal

-20 gal

-28 gal

-32 gal

-40 gal

-44 gal

-55 gal

§2.2.5

Type-D

(DIN9797)

Food processing

applications

DIN9797

Eurobins

-120L

-200L

-300L

§2.2.6

Type-X

Custom

applications

BRUTE® Bins

205L Drums

Plastic Tubs

Customs Bins

§2.2.7

2.2.2 Type-E Cradle (standard)

2.2.2.1 Emplacing bins

Place the wheelie bin onto the cradle. For full-size 240L bins,

both wheels should be positioned into a catch (on either side of

the cradle). For smaller bins such as 60L, 80L, 120L and 140L, only

the left-hand wheel needs be positioned into a catch. Once

the bin is correctly emplaced, walk to the control panel.

The wheel catches are designed to work with standard

EN840 wheelie bins from leading brands such as Europlast, Sulo,

ESE, Weber, Craemer, OnePlastics and Trident.

Some smaller bin manufacturers use axles of different lengths. If the distance between

the wheels is slightly too large or small, the wheels may jam against the catches,

preventing a secure emplacement. Should this occur, simply unbolt and remove the

right-hand wheel catch. All bins can be securely retained using the left-hand catch only.

Some smaller bin manufacturers use tyres which are too wide to fit inside the wheel

catches. Should this issue occur, simply insert additional packers (flat washers) onto the

wheel catch mounting bolts, to increase the spacing as needed.

2.2.2.2 Removing bins

Using the grab-handle provided, gently remove the wheelie bin from the cradle.

2.2.3 Type-C Cradle

2.2.3.1 Emplacing bins

Place the wheelie bin into the machine, positioned centrally against

the cradle backplate. Take care that the lifting teeth are properly

hooked into the bin combing; smaller bins such as 60L and 80L may

need to be tilted or lifted sli

bin is correctly emplaced, walk to the control panel.

2.2.3.2 Removing bins

Using the grab-handle provided, gently remove the wheelie bin

from the cradle. Some bins may need to be tilted or lifted slightly to

detach them from the cradle teeth.

2.2.4 Type-A Cradle

2.2.4.1 Emplacing bins

Place the trash cart into the machine, positioned centrally against the

cradle backplate. Take care that the lifting hooks are properly

engaged with the front of the cart; some carts may need to be tilted or

lifted

emplaced, walk to the control panel.

2.2.4.2 Removing bins

Using the grab-handle provided, gently remove the trash cart from the

cradle. Some carts may need to be tilted or lifted slightly to detach

them from the lifting hook.

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 12

2.2.5 Type-A Cradle with base

2.2.5.1 Emplacing bins

Place the bin, drum, or container onto the cradle, positioned centrally

against the backplate. Once the bin is correctly emplaced, walk to

the control panel.

When moving heavy non-wheeled containers, it is

recommended to use a dolly, hand truck or forklift

attachment.

The catch arm(s) should be positioned to hold the top

edges of the bin, with a maximum free travel of 25mm (1

inch). The arm(s) can be unbolted and repositioned to

allow emptying bins of many different sizes.

2.2.5.2 Removing bins

Holding the upper lip of the bin, drum, or container, gently remove it from the cradle.

2.2.6 Type-D Cradle

2.2.6.1 Emplacing bins

Wheel the Eurobin into the cradle, positioned centrally, until it is

firmly against the buffers. Take care that both trunnions are

properly seated into the lifting arms; some Eurobins may need

to be tilted or lifted

the Eurobin is correctly emplaced, walk to the control panel.

2.2.6.2 Removing bins

Using the grab-handle provided, gently remove the Eurobin

from the cradle

2.2.7 Type-X Cradle (custom)

2.2.7.1 Emplacing bins

Place the bin, drum, or container onto the cradle, positioned

centrally against the backplate. Once the bin is correctly

emplaced, walk to the control panel.

When moving heavy non-wheeled containers, it is

recommended to use a dolly, hand truck or forklift

attachment.

The catch arm(s) should be positioned to hold the top edges

of the bin, with a maximum free travel of 25mm (1 inch). The

arm(s) can be unbolted and repositioned to allow emptying

bins of many different sizes.

2.2.7.2 Removing bins

Holding the upper lip of the bin, drum, or container, gently remove it from the cradle.

2.3 Operation of controls

The Multi-Tip controls are designed to allow safe, intuitive operation of the machine.

It is important to understand how to use the controls correctly. Improper operation may

result in a safety hazard, or damage to the machine.

1. Before operation, check that the machine is stable and safe to use as per §2.1.

2. Place the full bin on the cradle, taking care that it is correctly positioned as per §2.2.

3. Standing at the operator controls, visually confirm that no other person is within two

metres of the machine.

4. Simultaneously press and hold the SAFETY button under the left side of the shroud,

and the RAISE button under the right side. The cradle will start to lift.

5. When the cradle reaches the fully-raised position, the sound will change. Immediately

release the SAFETY and RAISE buttons, and wait for the bin to empty.

6. When emptying is complete, simultaneously press the SAFETY and LOWER buttons,

holding both down until the cradle rests back on the ground.

7. Remove the empty bin as per §2.2.

8. Repeat from step 2. as required.

Release the SAFETY button to stop the cradle at any time.

Do not continue pressing the RAISE and SAFETY buttons after the cradle has reached the

fully-raised position. This will drain the battery, and can overheat the hydraulic fluid.

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 14

2.4 Battery charging

The Multi-Tip batteries should be recharged whenever the voltmeter reads less than 24.0V.

To recharge the batteries, simply plug one end of an IEC C13 power lead

into the C14 socket on the machine, and the other end into a 1-phase mains power outlet.

A full charge usually takes around 5 hours. The machine can be used while charging.

The onboard charger automatically adapts to different inputs (85-264VAC 50/60Hz 1-ph),

manages the charging cycle to maximise battery life, and prevents overcharging.

The charger delivers enough power to empty a 100kg bin in about 3 minutes, which

means that a battery-powered Multi-Tip can be left plugged in and used as a mains-

powered machine (see §1.5).

For optimum battery life, the Multi-Tip should be placed on charge overnight and on

weekends, even if the batteries are already fully charged.

The charger is in an enclosed plastic case, and is protected against short-circuit, current

overload, over-voltage, and over-temperature.

2.5 Safety Norms

The following safety norms must be observed for the safe use of a Multi-Tip bin lifter.

Only trained and authorised personnel may use the

machine.

Operators must read and obey all instructions

displayed on the machine.

Never operate the machine on soft ground, or

ground with a slope ratio greater than 1:12.

Never operate the machine on the edge of a raised

loading dock or platform.

Never operate machine with any covers or guards

removed.

Never attempt to empty the contents of closed-top

drums, unless the machine is securely bolted down.

All persons other than the operator must keep at

least 2 metres clear while the machine is in use.

Always keep hands and feet well clear of the bin and

cradle when operating.

Never place limbs, feet or foreign objects under or

through the guarding panels.

Never attempt to empty over-filled bins, or bins

weighing more than 150kg.

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 16

Before connecting machine to mains supply,

ensure voltage and frequency correspond with

that listed on the rating plate.

Do not use an extension lead longer than 15

metres to connect the machine to mains power.

Do not operate if power lead, insulation or power

plugs are damaged.

Do not connect a damp power plug or socket.

Ensure the power supply socket is fitted with a

residual current device.

Ensure there is complete continuity between the

machine and an effective earthing system which

complies with local and national regulations. The

manufacturer cannot be held liable for the

consequences of an inadequate earthing system.

3.C are and Maintenance

The Multi-Tip is designed to give many years of service with minimal maintenance. In the

event a fault or malfunction does occur, refer to the Quick Troubleshooting Guide in §3.1

before contacting your Simpro agent for support.

Contact your Simpro agent if repair or service work is required.

All repair and service work must be carried out by qualified personnel.

Replacement parts must be supplied by Simpro or an authorized Simpro agent, and must

be of the same design and specification as the original parts.

A detailed Service Manual giving specific testing and repair instructions is available on

request from Simpro.

3.1 Quick Troubleshooting Guide

Please refer to the Quick Trouble Shooting Guide below before requesting technical support.

Problem

Possible Causes

Remedy

See also

The machine

will not lift

bins, and the

motor does

not run

Flat battery

The battery needs to be charged if

voltmeter reads less than 24.0V.

§2.4

Battery 0250050004

Tripped circuit

breaker or fuse

Wait 1-2 minutes for circuit breaker to

reset (or replace blown fuse). Avoid

operating machine with flat battery.

§3.4.7

Breaker 0790050374

Fuse 0790050107

Faulty up/down

switch or wiring

Check and rectify replace if

necessary.

Up/Down switch

0790050454

Faulty motor

solenoid (battery

models only)

The motor solenoid should click when

the UP and SAFETY buttons are pressed

if not it may need to be replaced.

24V Motor solenoid

0880050015

The machine

will not lift

bins,

although the

motor runs

Bin too heavy

Remove material from bin to reduce

the weight.

§1.4

§3.3.1.1

Pressure-relief

valve set too low

Contact your agent for instructions on

adjusting the pressure setting.

§3.7.2.2

3-phase motor

running in reverse

Swap two of the phase wires in the

power plug (3-phase machines only)

§3.5.1

Cradle will

not come

down from

the fully

raised

position

Mast sliding block

jamming in mast

Lightly lubricant inside of mast, slider

block and rollers with silicone spray

§3.3.2.2

Mast block

0090120001

Lift ram jamming

Contact your agent for support.

§3.3.2.2

MT1600 Ram

0230090001

Faulty up/down

switch, wiring, or

lowering valve

coil

DOWN and SAFETY buttons are

pressed if not, check the up/down

switch, wiring and lowering valve coil.

§3.3.2.1

Up/down switch

0790050454

24V Lowering valve

Coil 0250090067

Cradle

jamming

part-way

down

Mast bent or

damaged

Check and straighten replace if

necessary.

§3.3.2.2

Tipping guide flap

sticking or

damaged

Check and rectify replace if

necessary.

§3.3.2.2

Tipping guide flap

0230040001

User Manual // Simpro Multi-Tip®

Original Instructions // English // v83.0 // October 2022 // Page 18

3.2 Cleaning

The machine may be cleaned with a low-pressure water jet, a microfiber cloth, and a mild

cleaning solution. Cleaning should be carried out with the cradle in the fully-lowered position.

Do not clean the machine with a high-pressure water jet or waterblaster.

See §1.9 for IP ratings of the machine and major subcomponents.

3.3 Cradle jams

Occasionally the bin cradle may become jammed at some point in the tipping cycle. This is

usually a minor issue which can be easily rectified.

The cradle is not powered down it is lowered by gravity alone.

See §3.7.6 for a schematic diagram of the hydraulic system.

3.3.1 Cradle jams while raising

If the cradle jams while raising the cause may be either an overweight bin, or a mechanical

fault, such as a bent tipping guide or misaligned roller.

3.3.1.1 Overweight bin

1. Lower the cradle to ground level and remove the bin.

2. Remove some material from the bin, then try again.

If the pressure-relief valve is adjusted incorrectly, the cradle can stall even when lifting

bins that are within the Safe Working Load as per §1.4. The pressure-relief valve

may only be adjusted by a qualified technician, with prior authorisation from Simpro.

3.3.1.2 Mechanical fault

1. If possible, lower the cradle to ground level and remove the bin.

2. Attempt to visually identify the cause of the jamming. The most likely causes are:

a. The lifting chain may have derailed from the guide at the top of the mast.

b. The mast may have been bent or damaged.

c. Lack of lubrication on the follower roller , or the main cradle axle

d. The roller arm may be pressing against the tipping guide, due to the cradle

sitting out of level or being incorrectly adjusted.

3. With the cradle lowered, rectify the problem by straightening and/or realigning the

mechanical components as required. If the mast is bent, you may need to contact

your agent for support.

4. Run the machine through several full cycles to ensure the problem has been resolved.

3.3.2 Cradle jams while lowering

If the cradle jams on the way down, or has jammed on the way up but will not come down, it

may be due to a hydraulic, electrical, or mechanical fault.

0090120000

3.3.2.1 Hydraulic or electrical fault

When the SAFETY and LOWER buttons are pressed simultaneously, the lowering valve should

e problem may be either a hydraulic or

electrical fault.

1. Manually remove the bin if it is safe to do so.

2. Use a forklift or hoist to physically support the cradle in position.

Never place any part of your body underneath the cradle unless it is securely supported.

3. Remove the powerpack cover.

4. Check that the lowering valve coil is receiving an electrical signal. An LED

lamp should glow on the coil plug when the SAFETY and LOWER buttons are pressed

simultaneously. If it does not, check the up/down switch and wiring.

5. If the coil is receiving an electrical signal but not opening, it may need to be cleaned:

a. Remove the coil from the valve stem.

b. Unscrew the lowering valve cartridge.

c. Clean the cartridge with compressed air.

d. Replace the lowering valve components by reversing this procedure.

6. Detach the forklift/hoist from the cradle, and test to see if the cradle lowers correctly.

7. Run the machine through several full cycles to ensure the problem has been properly

resolved. If the lowering valve is still not operating correctly, it may need to be

replaced contact your agent.

3.3.2.2 Mechanical fault

If the l

buttons are pressed), the problem may be a mechanical fault.

1. Manually remove the bin if it is safe to do so.

2. Use a forklift or hoist to physically support the cradle in position.

Never place any part of your body underneath the cradle unless it is securely supported.

3. Attempt to visually identify the cause of the jamming. The most likely causes are:

a. The lifting chain may have derailed from the guide at the top of the mast.

b. The mast may have been bent or damaged.

c. Lack of lubrication on the follower roller, or the main cradle axle

d. The roller arm may be pressing against the tipping guide, due to the cradle

sitting out of level or being incorrectly adjusted.

4. Rectify the problem by straightening and/or realigning the mechanical components

as required. If the mast is bent, you may need to contact your agent for support.

5. Detach the forklift/hoist from the cradle, and test to see if the cradle lowers correctly.

6. Run the machine through several full cycles to ensure the problem has been resolved.

0250090067

0250090055

This manual suits for next models

2

Table of contents

Other Simpro Lifting System manuals

Simpro

Simpro Multi-Tip User manual

Simpro

Simpro Dumpmaster User manual

Simpro

Simpro MegaDumper User manual

Simpro

Simpro MegaDumper Series User manual

Simpro

Simpro QUIKSTAK QS10MM User manual

Simpro

Simpro Multi-Tip User manual

Simpro

Simpro Microstacker User manual

Simpro

Simpro EUROVER User manual

Simpro

Simpro Multi-Tip 1600 User manual

Popular Lifting System manuals by other brands

Stenhoj

Stenhoj MASCOT 1.25 Operation and maintenance instructions

morse

morse 400A-96SS-125 Operator's manual

JLG

JLG LIFTLUX 210-25 Operation and safety manual

Titan Lifts

Titan Lifts HD2P-10000AC-D Installation, operation & maintenance manual

morse

morse 195A-A Operator's manual

Lifton

Lifton DUO user manual