7

FUNCTION TEST SEQUENCE

This is a functional test for the dryer. To activate this mode, perform the following steps:

1. Turn the cycle selector knob to the 12 o’clock position.

2. Press and hold the SELECT and PAUSE CANCEL buttons simultaneously for 6 seconds.

3. Immediately after, press and hold the PAUSE CANCEL and START buttons for 4 seconds.

The control will enter the test mode, the buzzer will sound 3 times and all LEDs will rapidly

flash.

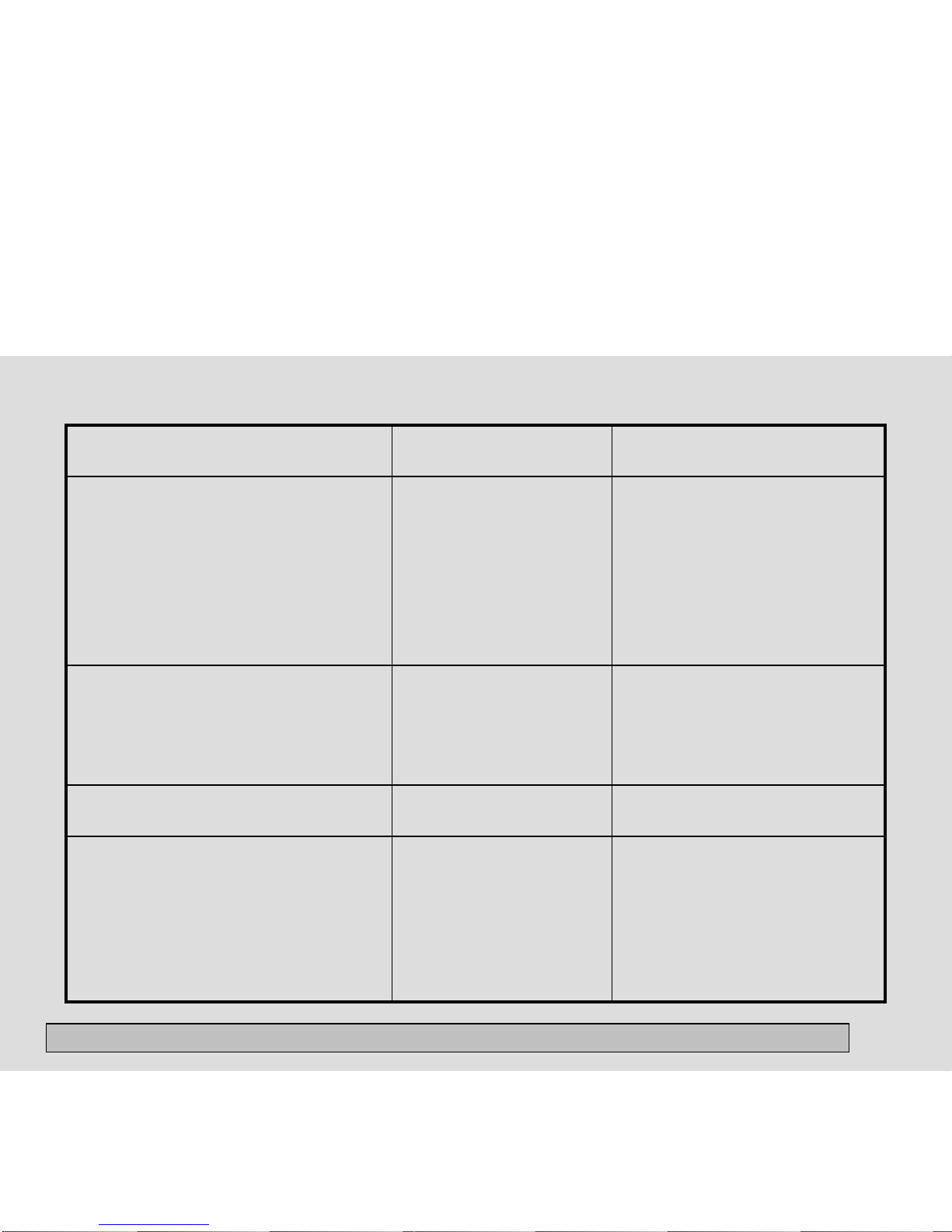

After entering the test mode, the selector can now be rotated to select the following tests:

1 Turn Drive motor runs; heat source is on. DRYING LED is lit. Control thermistor

reading is displayed. **

2 Turns Drive motor runs; heat source is off. COOL DOWN LED is lit.

3 Turns Drive motor runs; heat source is off. DRYING and COOL DOWN LEDs are lit.

The MORE DRY LED should be ON. Opening the door (press in on door switch plunger) and

placing a finger on both moisture sensor bars at the same time will make the DAMP LED

come on.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007