prevent abrasion.

The system as supplied by Turbo air was

thoroughly cleaned and dehydrated at the factory.

Foreign matter may enter the system by way of

the evaporator to condensing unit piping.

Therefore, care must be used during installation

of the piping to prevent entrance of foreign matter.

Use only refrigeration grade copper tubing

properly sealed against contamination.

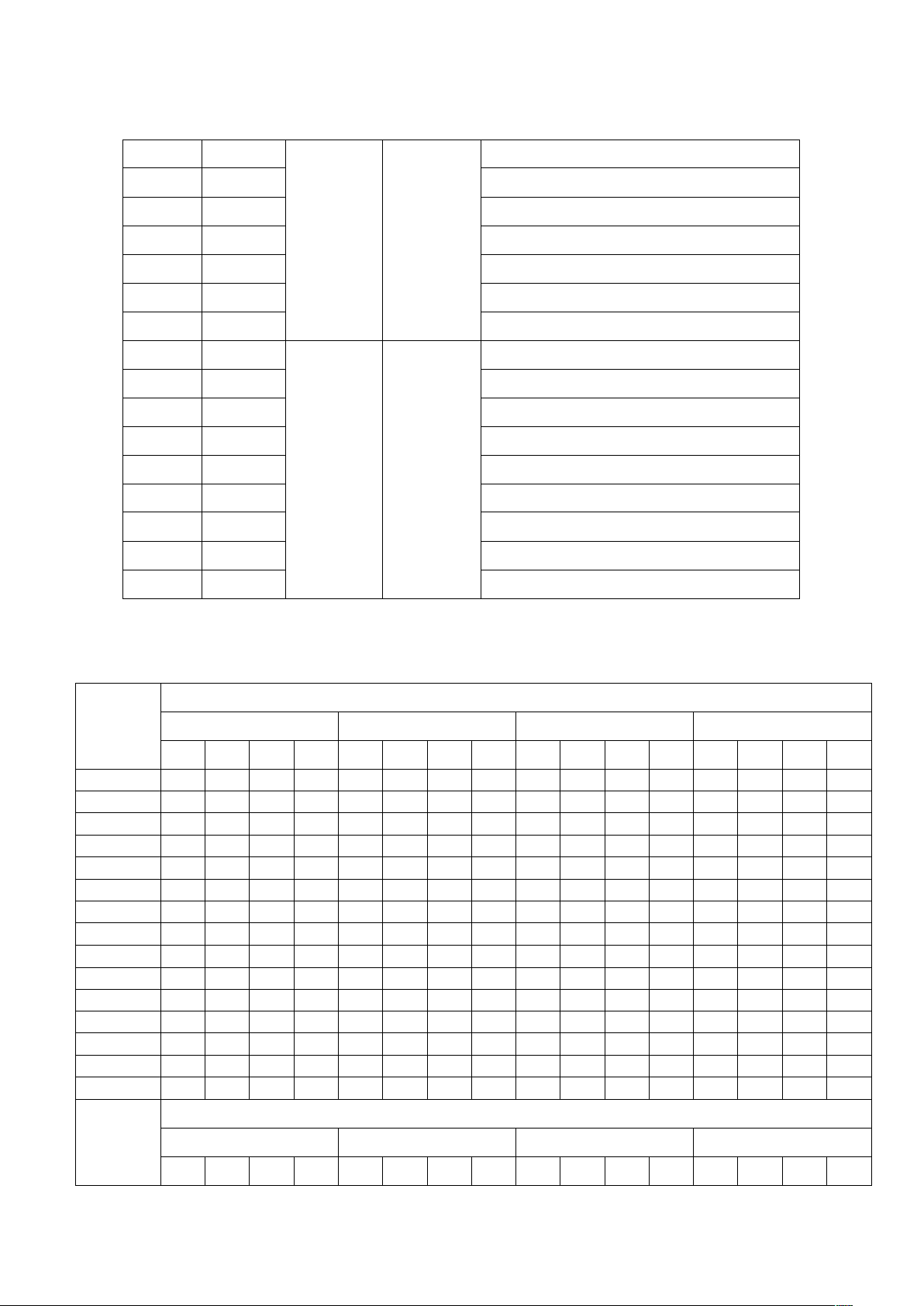

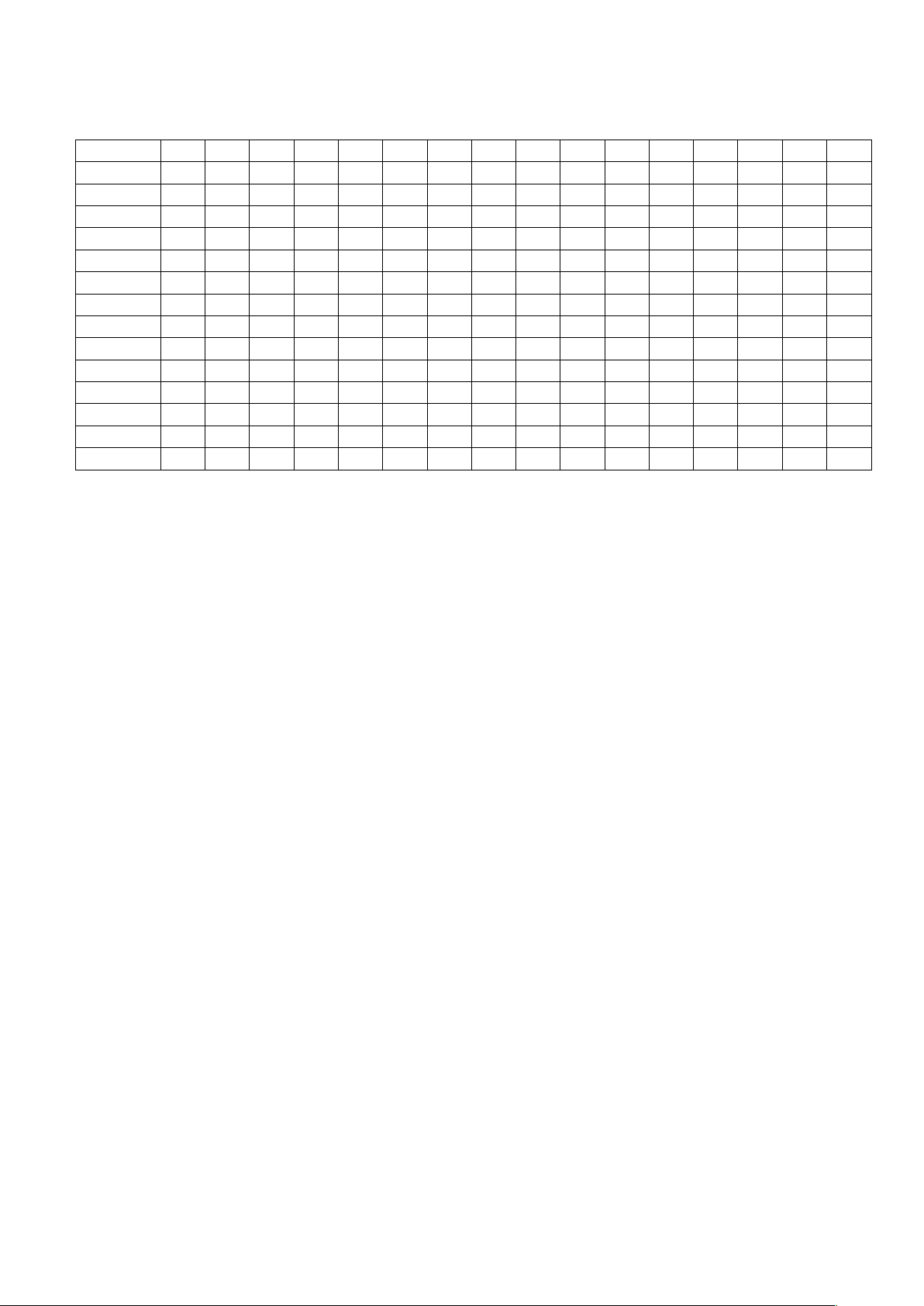

Figure 8. Suction piping installation on an

evaporator.

Figure 9. suction piping installation on

multiple evaporators.

Figure 10. Installation of expansion valve bulb.

Refer to Figure 8 through 9. Suction line risers

must be carefully selected, have an oil trap at the

bottom and at 15 foot intervals up the riser. They

should be the same size as the vertical riser

connected to its outlet. Riser should not be larger

in diameter than horizontal runs.

Refer to Figure 10.

Expansion valves are supplied with clamp for

securing bulb to the suction line. The bulb must

be secured at the evaporator outlet, on the side of

a horizontal run of suction line, before any trap.

Do not over tighten bulb clamps or deform the

bulb in anyway. Install all refrigeration system

components in accordance with applicable local

and national codes and in conformance with good

practice required for the proper operation of the

system.

All piping must be protected where it passes

through walls or ceilings. Precautions should be

taken to see that the piping does not touch any

structural the transmission of vibration into the

building.

The piping chase must be thoroughly sealed to

protect the tube and prevent ambient air from

entering the refrigerated space. Seal around the

drain line where it passes through the wall. Air

leaks can cause equipment problems. Damage the

structure and product, increase load, increase