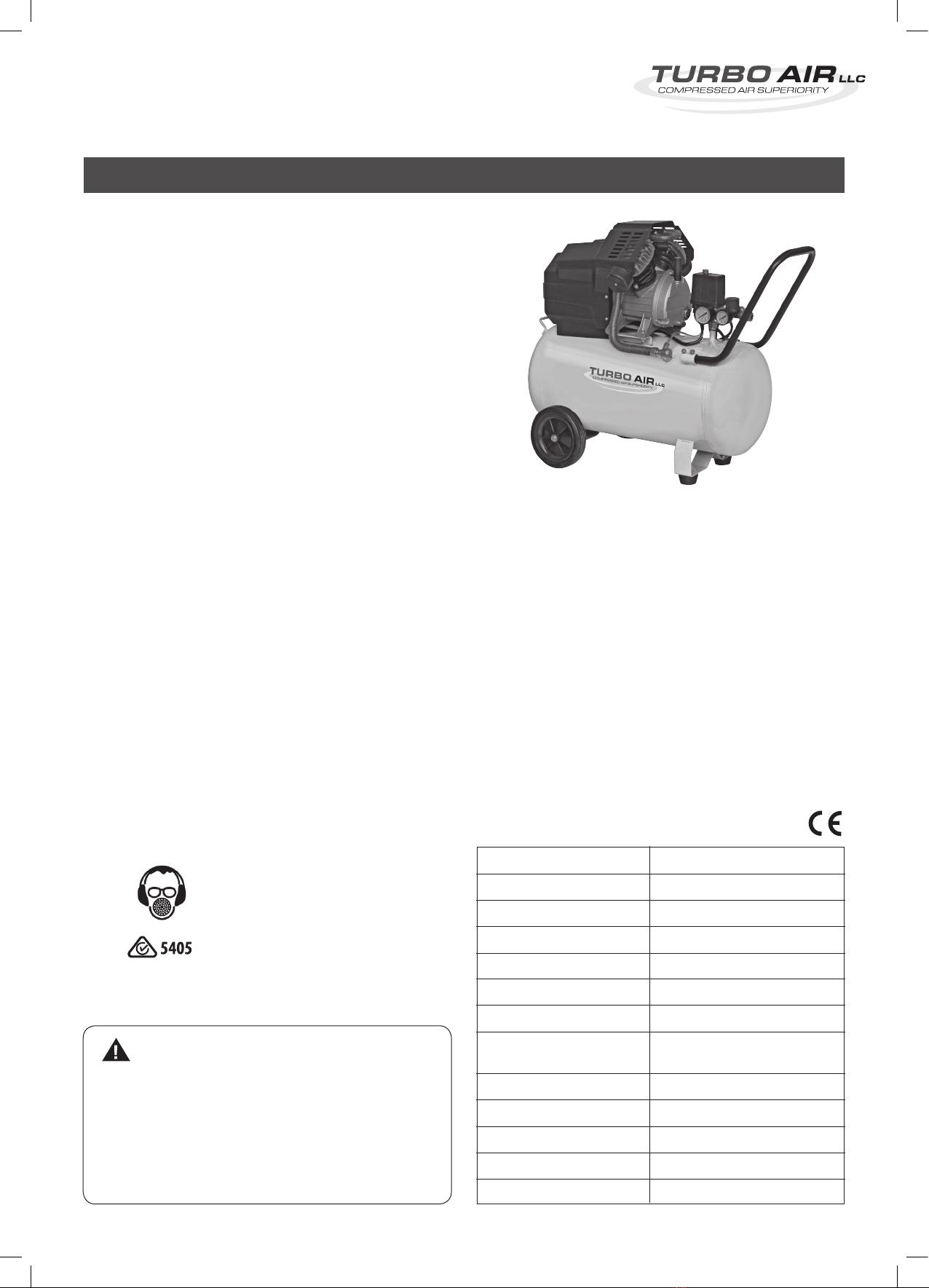

DIRECT DRIVE COMPRESSOR

3.

Congratulations on the purchase of your

TURBO AIR Direct Drive Compressor!

This product is manufactured to high quality standards

and will give you many years of service if you follow the

instructions for use and maintenance in this manual. If you

require any help with your product, whether it is a warranty

claim, spare part or user information, please visit www.

euroquip.co.nz rst and register your product online.

Once registered, please log a request online or call us on

0800 387 678. Your new Turbo Air compressor has been

manufactured under stringent AS/NZS Quality Standards to

meet superior performance criteria.

COMPRESSOR USAGE

This compressor has been designed for home workshop use and

ideal for the many tasks around home and in the shed that are

so much easier and quicker using the power and convenience of

compressed air.

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as

waste. All tools, hoses and packaging should be sorted, taken to

the local recycling centre and disposed of in an environmentally

safe way.

DESCRIPTION OF SYMBOLS

The rating plate on your tool may show symbols. These represent

important information about the product or instruction on it’s use.

Wear hearing protection

Wear eye protection

Wear breathing protection

Conforms to relevant standards for

electromagnetic compatibility.

INTRODUCTION

SPECIFICATIONS:

• Powerful3.0HPInductionMotor

Designed for Aus / NZ conditions

• CastIronV-TwinPump

Super duty

• Large50LTankCapacity

Provides volume for high air demand applications

• 8Bar(115psi)

High pressure air delivery

• TwinOutletswithPressureRegulator

Includes 2 x quick release couplers

• HighCapacity300L/minFAD

(Free air delivery)

MODEL: TA3050

POWER: 3.0HP / 2250W

VOLTAGE: 230V~50Hz

NO LOAD SPEED: 2850rpm

CURRENT: 10A

MAX. OUTPUT: 360L/min, 12.7cfm

TANK CAPACITY: 50L

AIR OUTLET: 6.35mm (1/4”)

ARO Coupler x 2

CUT IN PRESSURE: 0.6Mpa (Factory Set)

MAX. OUTPUT PRESSURE: 0.8MPA (115psi)

FREE AIR DELIVERY: 300L/min

DIMENSIONS: 760 x 380 x 740mm (LxWxH)

WEIGHT: 37kg

CAUTION!

Carefully read through this entire instruction manual before

using your new compressor. Take special care to heed the

cautions and warnings. Your Iron Horse Compressor has

many features that will make your job faster and easier.

Safety, performance and dependability have been given top

priority in the development of this machine, making it easy

to maintain and operate.