Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

GeneralSafety.................................................5

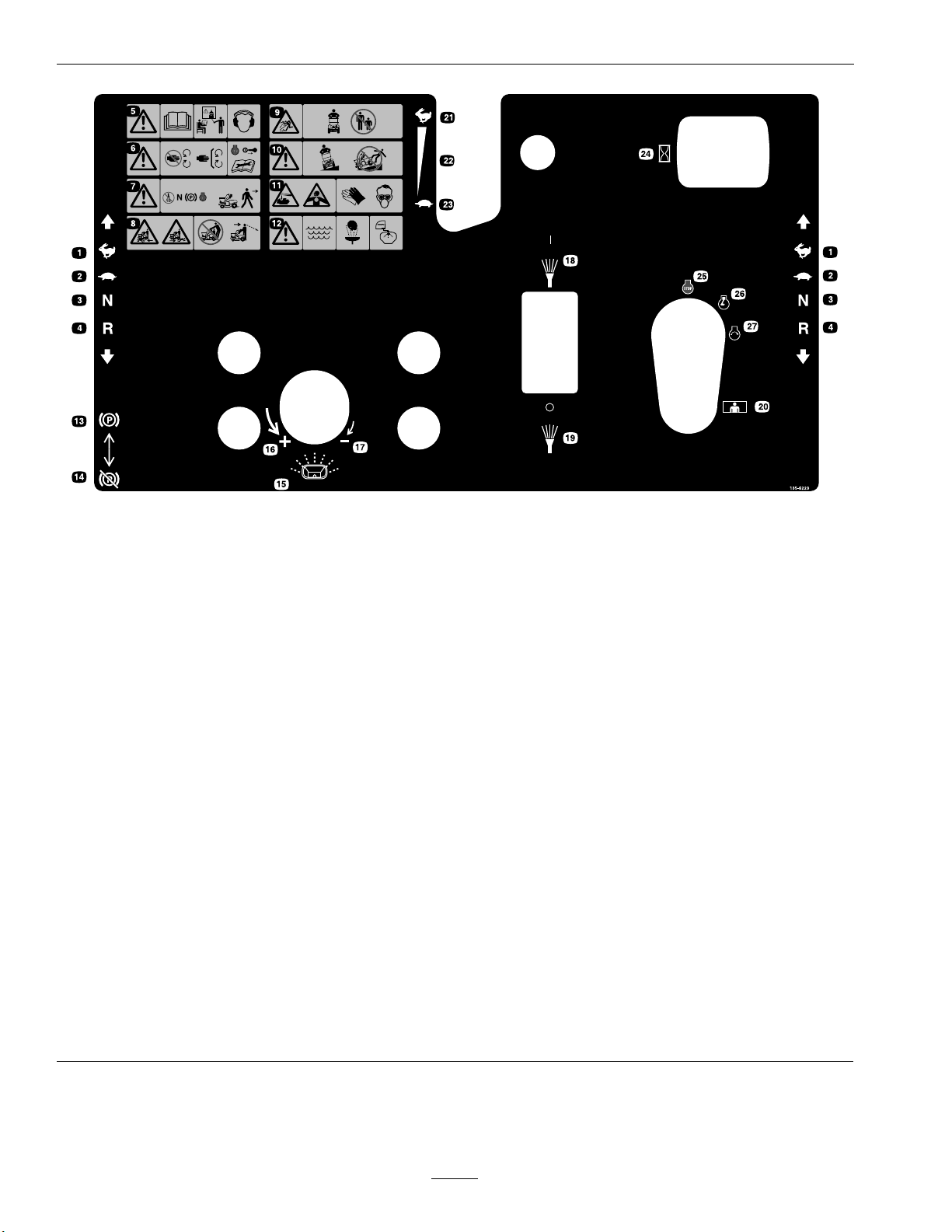

SafetyandInstructionalDecals.......................6

Specications........................................................12

Systems..........................................................12

Dimensions....................................................13

TorqueRequirements.....................................14

ProductOverview.................................................15

Operation..............................................................15

Controls.........................................................15

CasterWheelLockFootPedal........................20

BeforeOperation...........................................20

Pre-Start.........................................................21

OperatingInstructions...................................23

DuringOperationSafety.................................23

OperatingtheSprayer.....................................27

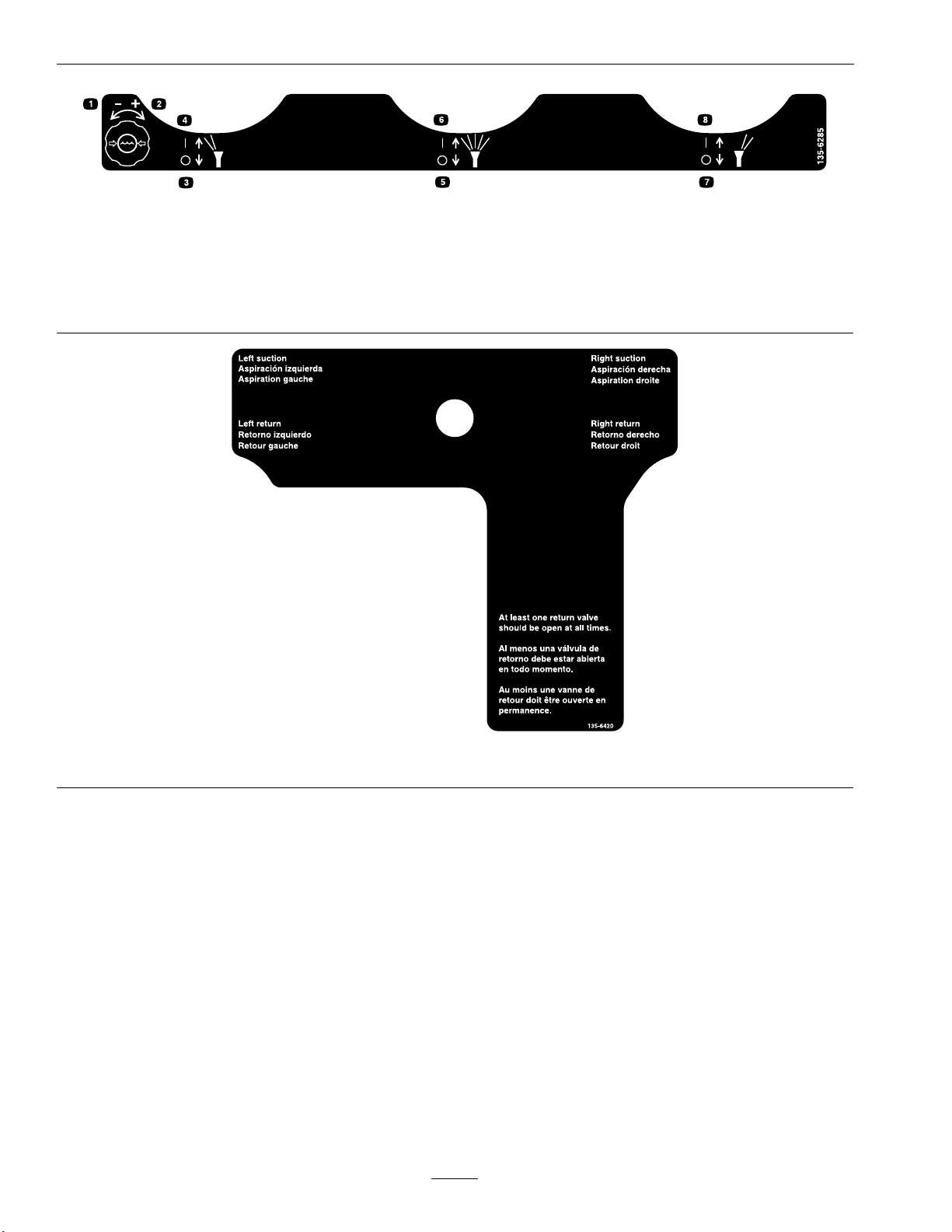

UsingtheSprayerTankShutoffValves............29

OperatingtheSpreader...................................32

SpreaderCalibration......................................34

AfterOperation..............................................40

Transporting..................................................40

Maintenance..........................................................42

MaintenanceSafety.............................................42

RecommendedMaintenanceSchedule(s)............43

PeriodicMaintenance........................................44

CheckEngineOilLevel..................................44

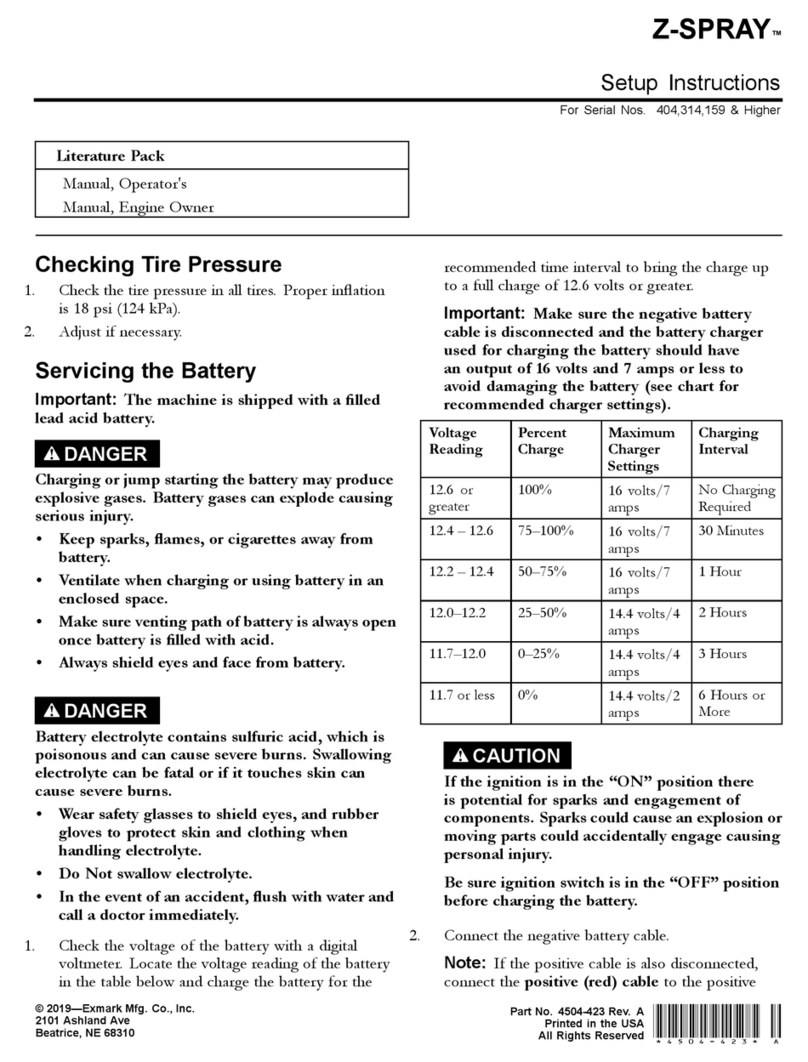

CheckBatteryCharge.....................................44

CheckSafetyInterlockSystem........................47

CheckforLooseHardware.............................48

ServiceAirCleaner.........................................48

ChangeEngineOil.........................................48

CheckHydraulicOilandTankLevel...............48

ChangeHydraulicSystemFilterand

Fluid..........................................................48

CheckTirePressures......................................49

CheckSpreaderSystem...................................50

CheckSprayerSystem.....................................50

CheckFuelFilterandTank.............................50

LubricateGreaseFittings................................51

CheckConditionofBelt.................................51

CheckSparkPlugs..........................................51

WheelMountScrewTorque

Specication...............................................51

Adjustments......................................................53

PumpDriveBeltTension................................53

AdjustingtheParkingBrake............................53

MotionControlLinkageAdjustment..............54

MotionControlTrackingAdjustment.............54

Cleaning............................................................55

CleanEngineandExhaustSystem

Area...........................................................55

RemoveEngineShroudsandClean

CoolingFins...............................................55

CleanDebrisFromMachine...........................55

WasteDisposal...............................................56

Storage..................................................................57

ExtendedorWinterStorage............................57

Troubleshooting....................................................58

Schematics............................................................60

CaliforniaProposition65Warning

Information...............................................62

4