EQUIPMENT CARE

The equipment has design limits and should not be

exceeded.

If the equipment appears to be unsuitable for the required

job then assume that it is not the correct tool for the job.

Contactyourlocalsupplier.

Keeptheequipmentcleanbyregularcleaningratherthan

at the end of the hire period.

Whennotinuse,storetheequipmentinacleananddry

environment, safe from potential theft.

GENERAL SAFETY & MAINTENANCE NOTES

SAFE WORKING LOAD

The safe working load is 200 Kg and must not be

exceeded.

Check all components are available and operational.

1. Inspect the unit components for signs of damage2. or incorrect functioning prior to use. Damaged or

incorrect components (or components showing signs

of excessive wear) must not be used and should

be returned to your local supplier. Once the unit is

assembled, use the CHECKLIST below.

The Deltadeck® is designed for use on at, level3. surfaces. Check that the ground is capable of

supporting the weight of the Deltadeck® and the

equipment being used.

If the Deltadeck® is being used outdoors and is

4.

exposed to signicant wind forces, it should be tied

orsecuredtoaxedstructure.Forfrequentoutdoor

use, it is recommended that the inspection and

maintenance regimes take that fact into account.

The safe working load of the Deltadeck® platform is

5.

200kguniformlydistributed;200kgtotalloadperunit.

Onepersononlyworkingonunitatanyonetime.

Castors must be locked when unit is in use.6. Ensure that the platform is free of persons and7. equipment, and that brake locks are off prior to

movement. Beware of soft or uneven ground and

overhead obstructions.

TheDeltadeck®shouldbemanoeuvredbyliftingthe8. unit at the feet and pulling in the required direction.

Using the castors to ‘wheel’ the unit makes it easier

to control.

Alwaysbewareofliveelectricalapparatus,cablesor9.

movingpartsofmachinery.

Topreventaccidentalinjuryensuresafepositioningof10.

handsandngerswhenassemblinganddismantling.

The Deltadeck® should always be climbed with11.

Operator’sCentreofGravitytowardstheplatform.

12. Never jump onto platforms. Ensure platform is free of

debris.

13. Do not use hoisting arrangements on Deltadeck®

unit. When raising or lowering components always

work within the unit base.

14. Ensure guardrails and gates are locked and secure

when platform is in use.

15. Deltadeck® units are not designed to allow them to be

lifted or suspended.

16.Neverusethisequipmentifyouareill,feelingtired,or

undertheinuenceofalcoholordrugs.

17.Wear practical, protective clothing, gloves and

footwear.

18.Avoidloosegarmentsandjewellerythatcouldcatch

in moving parts.

19. Ensure the work area is well lit and ventilated, if in

doubt, ask about lighting and ventilation equipment

fromyourlocalsupplier.

20.Keepchildren,animalsandbystandersawayfromthe

work area. Cordon off an exclusion zone using cones

andeitherbarriersortape,availablefromyourlocal

supplier. Make sure that anyone in the immediate

workareaiswarnedofwhatyouaredoing.

21. Do not use boxes, ladders or other such means to

gain additional height at the platform.

22. Care should be taken when using power tools, wash

jets or other such tools which can cause a lateral

force on the Deltadeck®.

23. Ensure that telescopic leg is free from contaminants

and lubricated at regular intervals.

Thisequipmentshouldbeusedbysuitablytrainedperson

whohasreadandunderstoodtheseinstructions.Anyone

with health/disability issues, should seek expert advice

before using it.

TRAINING

Theseinstructionsdonottaketheplaceofpropertraining.

Consult your supplier for details of specic training

courses for users of low level access units.

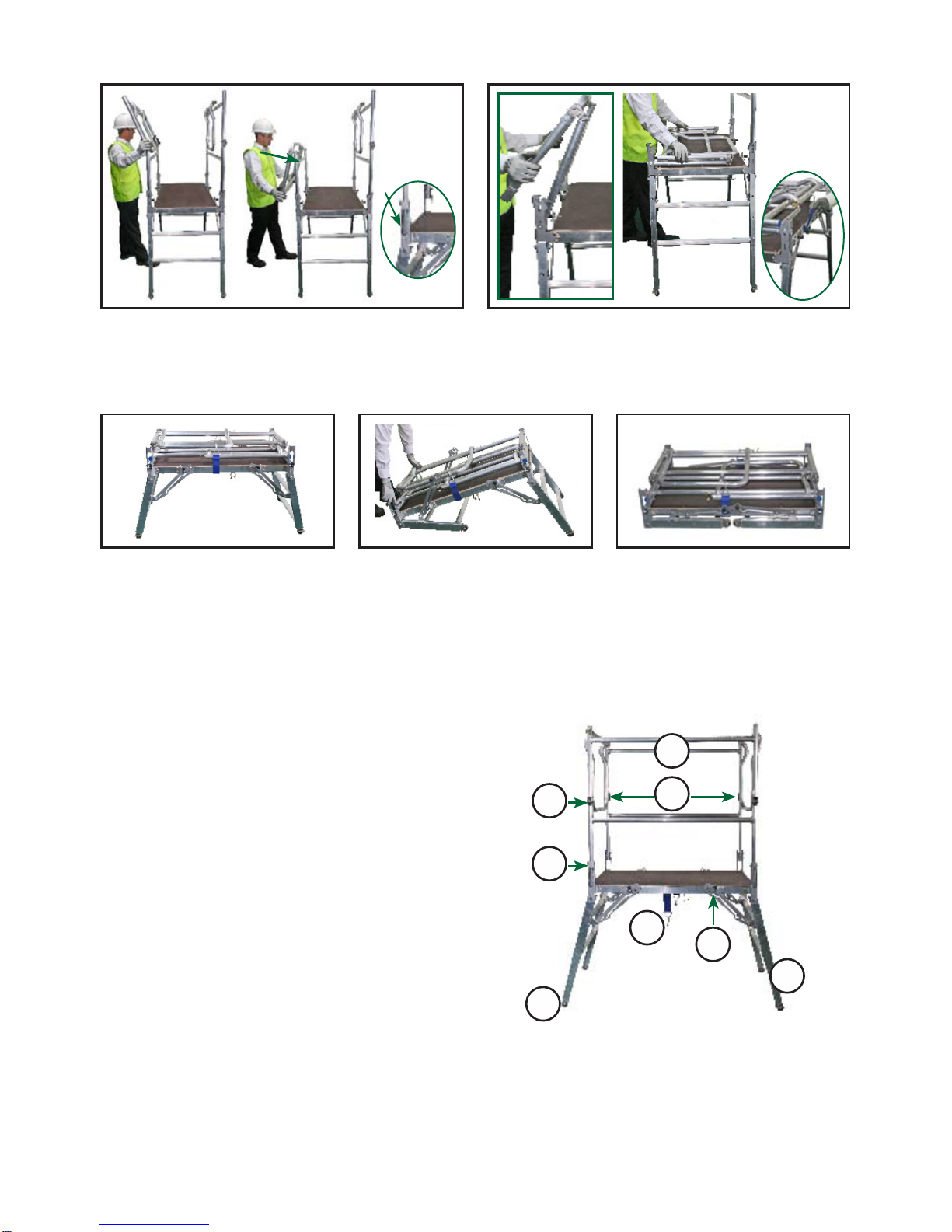

CHECKLIST PRIOR TO USE

The Deltadeck® must be checked after assembly, prior

to use and after any event that may have affected the

integrityoftheunit.Usethechecklistbelow.

Castors Locked

Adjustable legs and levers located and secure

Guardrailsttedandsecure

Platform is level and placed on a level and suitable

surface

If a box has not been ticked, do not use the unit until the

faultisrectied.Whereafaultisfound,accesstotheunit

must be stopped.