Turner OCTO® Assembly Guide

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland Section 1 Page 4 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

SECTION 1.1 Introduction

1.1 INTRODUCTION

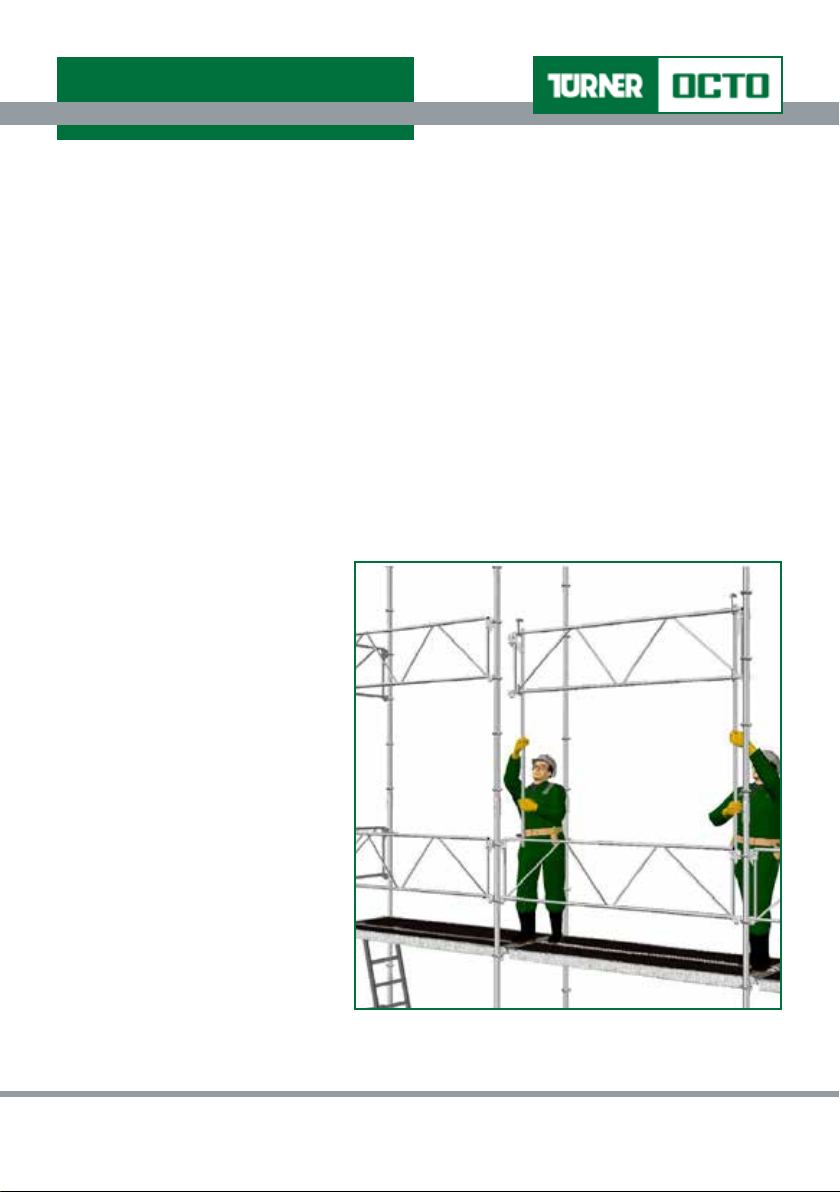

This Assembly Guide contains the necessary information required to correctly assemble

Turner OCTO®System Scaffolds in accordance with appropriate methods of safe assembly.

The provision and utilisation of collective protection equipment and methodology is

recommended where practicable for installers of Turner OCTO®System Scaffolding.

Installers / Dismantlers of Turner OCTO®System Scaffolding must also be competent,

relative to the type of scaffold to be erected, dismantled or altered.

This Assembly Guide provides instruction for foot tied, non-foot tied, and pedestrian

categories (as listed within the Assembly Guide) built from the ground or other suitable

foundation.

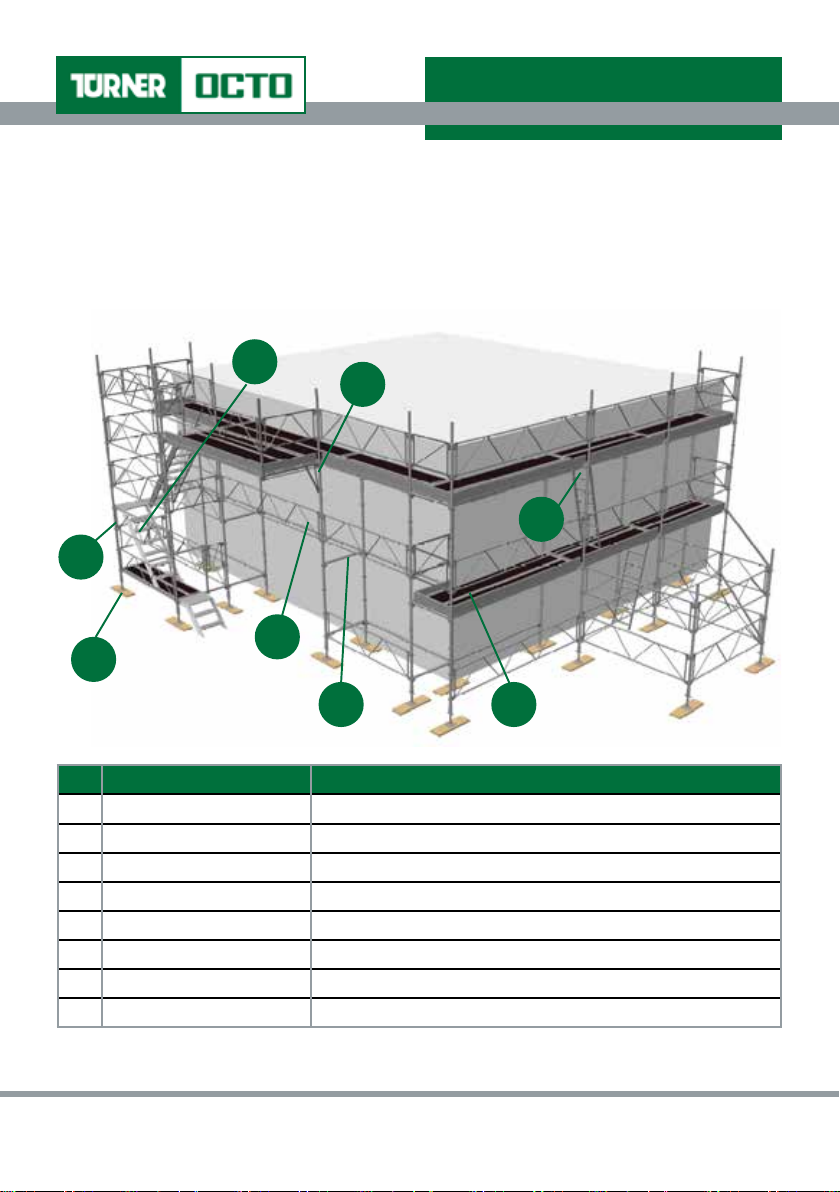

Types of Turner OCTO® System standard conguration included within this Assembly Guide

are detailed on the Contents Page and limited to the maximum heights as indicated in

Section 1.7 Maximum Heights (page 57).

This Assembly Guide should be used in conjunction with a suitable Risk Assessment and

Method Statement (by user) relative to the project to be undertaken. It must be noted that

all employers have a responsibility to ensure that work methods (practices) and adequate

facilities / resources (including work equipment) are provided to eliminate or minimise risks,

in accordance with current legislation.

A complete separate safe system of work (Method Statement) is required for all other types

of scaffold.

Sufcient training, combined with necessary experience, must also be considered and be

appropriate to achieve competency to build or dismantle a particular scaffold type in question.

Please ensure you read and fully understand the manual, and follow the content during

scaffold erection and ensure that the scaffold is complete prior to use and / or handover.

This Manual must be made available to the user / installer of the Turner OCTO®Scaffold

System at all times.

Only competent and qualied personnel should undertake assembly, dismantling and

alteration (and organisation, planning and supervision) of basic Turner OCTO®standard

congurations, and consideration should be given to providing additional (minimum) training

beforehand, if required.