Page 2 of 102

TVL 351

ISSUE 15

Contents

Contents ......................................................................................................................................................................... 2

1. Introduction ............................................................................................................................................................. 4

1.1. Purpose .......................................................................................................................................................... 4

1.2. Scope ............................................................................................................................................................. 4

1.3. Acronyms and Definitions .............................................................................................................................. 4

2. System Description ................................................................................................................................................. 5

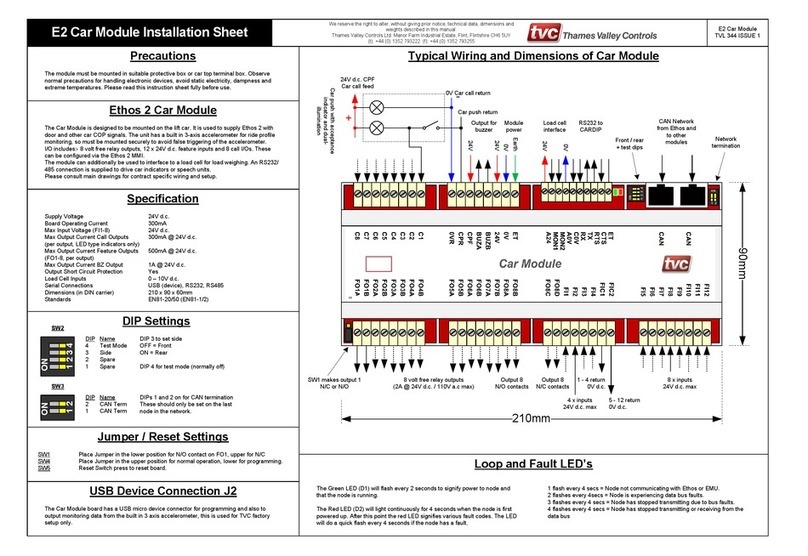

2.1. Safety Warnings / Precautions ...................................................................................................................... 5

2.2. Contacts ......................................................................................................................................................... 5

2.3. System Overview ........................................................................................................................................... 6

2.4. System Key Features. ................................................................................................................................... 7

2.5. Main Controller Specification ......................................................................................................................... 8

2.6. Environment ................................................................................................................................................... 8

2.7. Standards ....................................................................................................................................................... 9

2.8. Certificates ..................................................................................................................................................... 9

2.9. Help - Fault Finding Procedures .................................................................................................................... 9

2.10. Main Controller CPU Hardware ................................................................................................................... 10

3. MMI – Quick Start ................................................................................................................................................. 12

3.1. MMI Key ....................................................................................................................................................... 12

3.2. Screen Calibration ....................................................................................................................................... 12

4. Service and Feature Descriptions ........................................................................................................................ 14

4.1. Main Modes of Operation ............................................................................................................................ 14

4.2. Call Collective Modes .................................................................................................................................. 14

4.3. Group Operation .......................................................................................................................................... 15

4.4. Door Settings ............................................................................................................................................... 17

4.5. Indicator Settings ......................................................................................................................................... 17

4.6. Optional Service and Feature Descriptions ................................................................................................. 18

4.7. Checking Feature Descriptions .................................................................................................................... 21

4.8. Motion Feature Checks ................................................................................................................................ 22

5. Solutions and Event Logger ................................................................................................................................. 23

5.1. Solutions ...................................................................................................................................................... 23

5.2. Event Logger ................................................................................................................................................ 23

5.3. I/O Trace ...................................................................................................................................................... 24

6. List of Events ........................................................................................................................................................ 25

7. Parameter Adjustment and Storage ..................................................................................................................... 48

7.1. Parameter Adjustment ................................................................................................................................. 48

7.2. Precautions .................................................................................................................................................. 48

8. Parameter Modification Procedure ....................................................................................................................... 49

8.1. Lift Parameter Modification .......................................................................................................................... 49

9. Software Upgrade Procedure ............................................................................................................................... 50

9.1. Lift and Display Board Software Upgrade ................................................................................................... 50

9.2. ETSD Card Software Upgrade (only applies if ETSD card fitted) ............................................................... 52

10. Expansion Modules.......................................................................................................................................... 53

10.1. Call Modules ................................................................................................................................................ 53