Mnin

Assembly

Main

Assf'lnbly

Main

Assembly

Ml1iIJ

Assembly

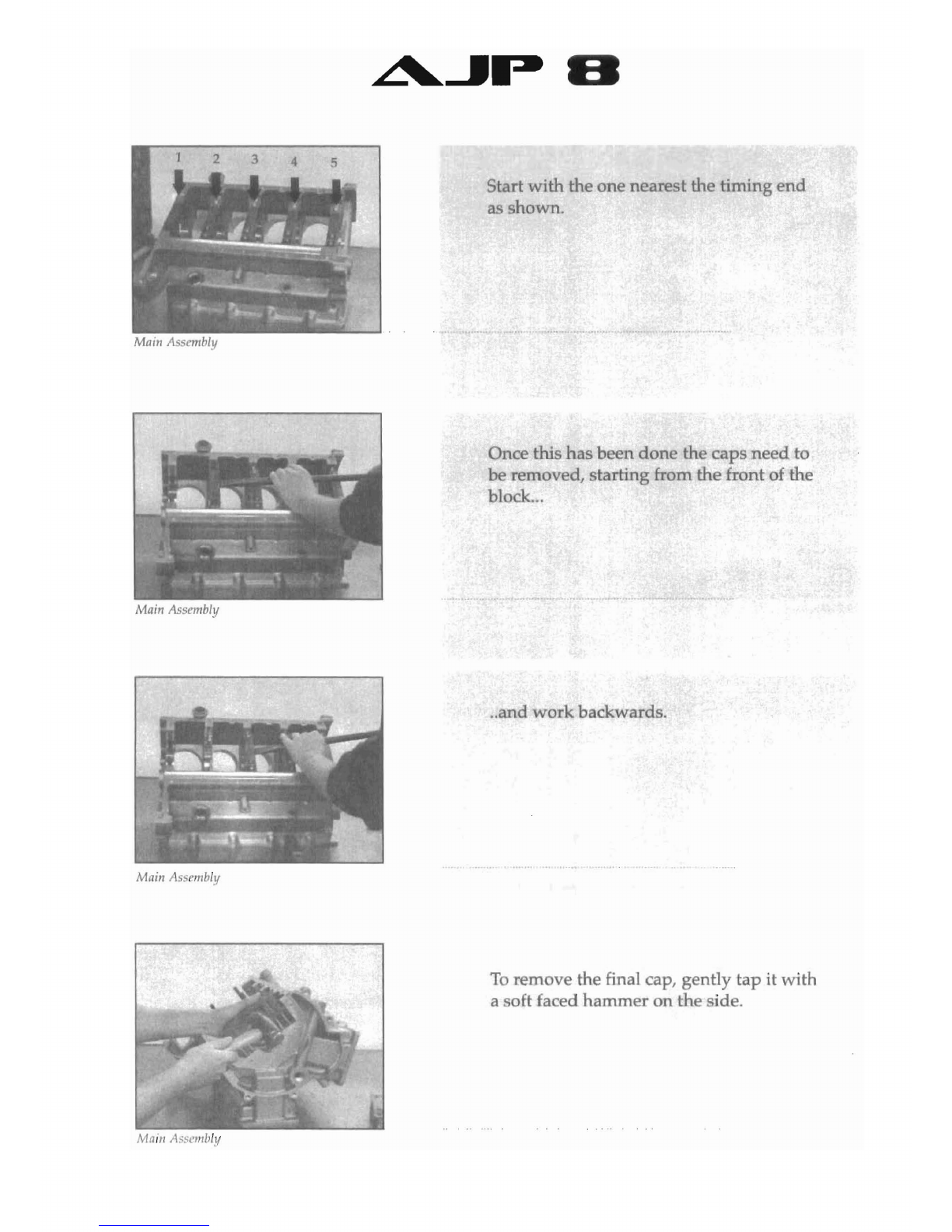

Start with the one neare tthe timing

end

as shown.

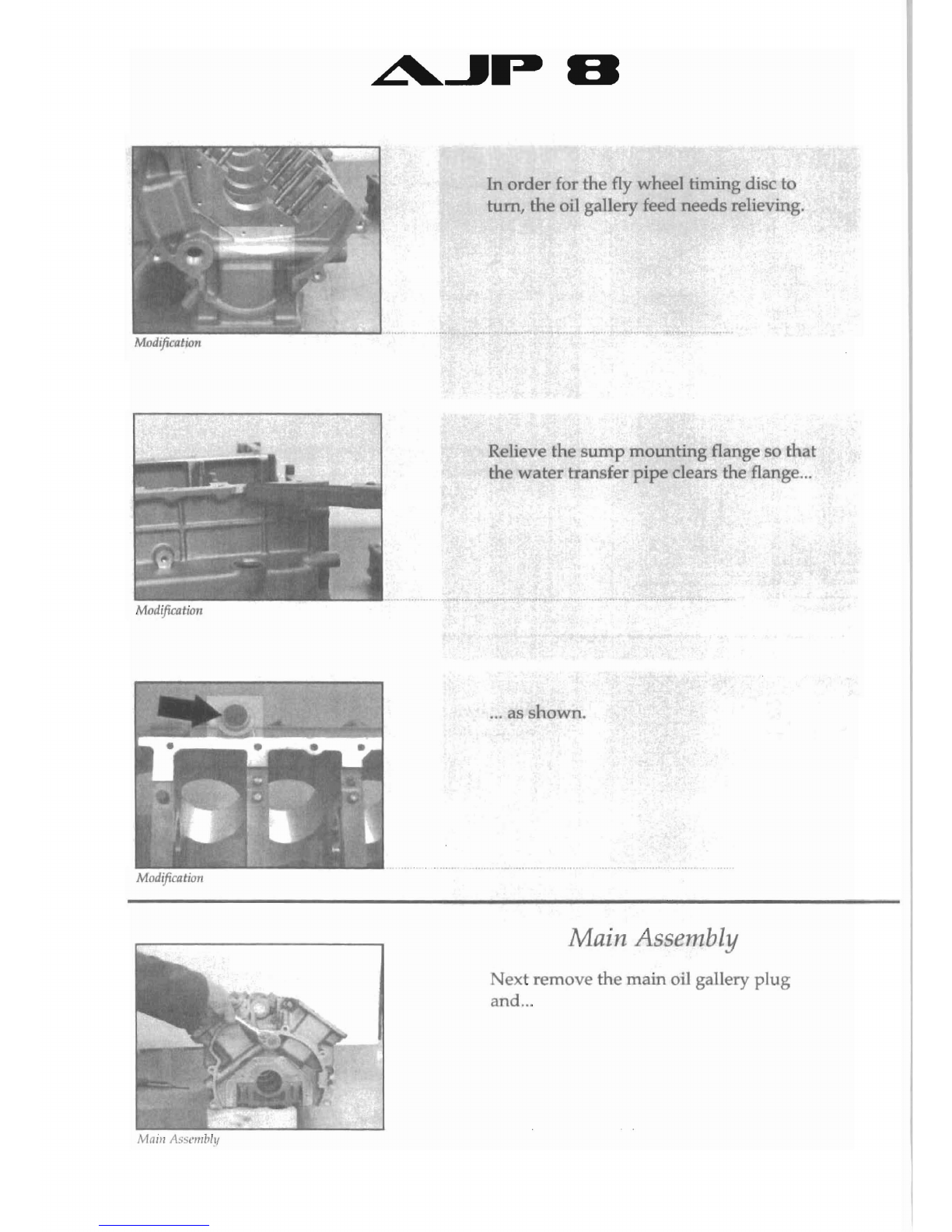

Once this

has

b n done the caps

need

to

be removed, starting from the front of the

block...

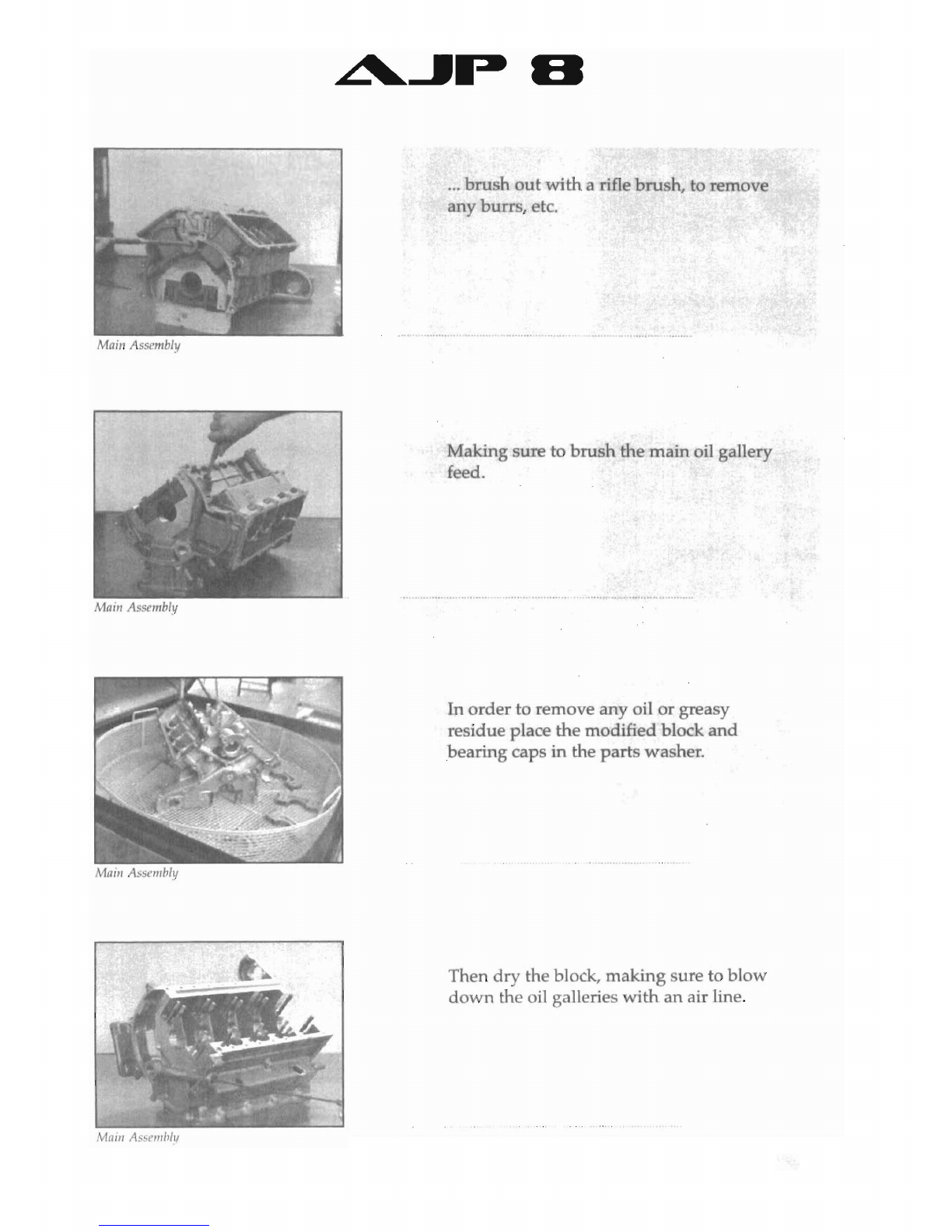

..

and

work

ba wards.

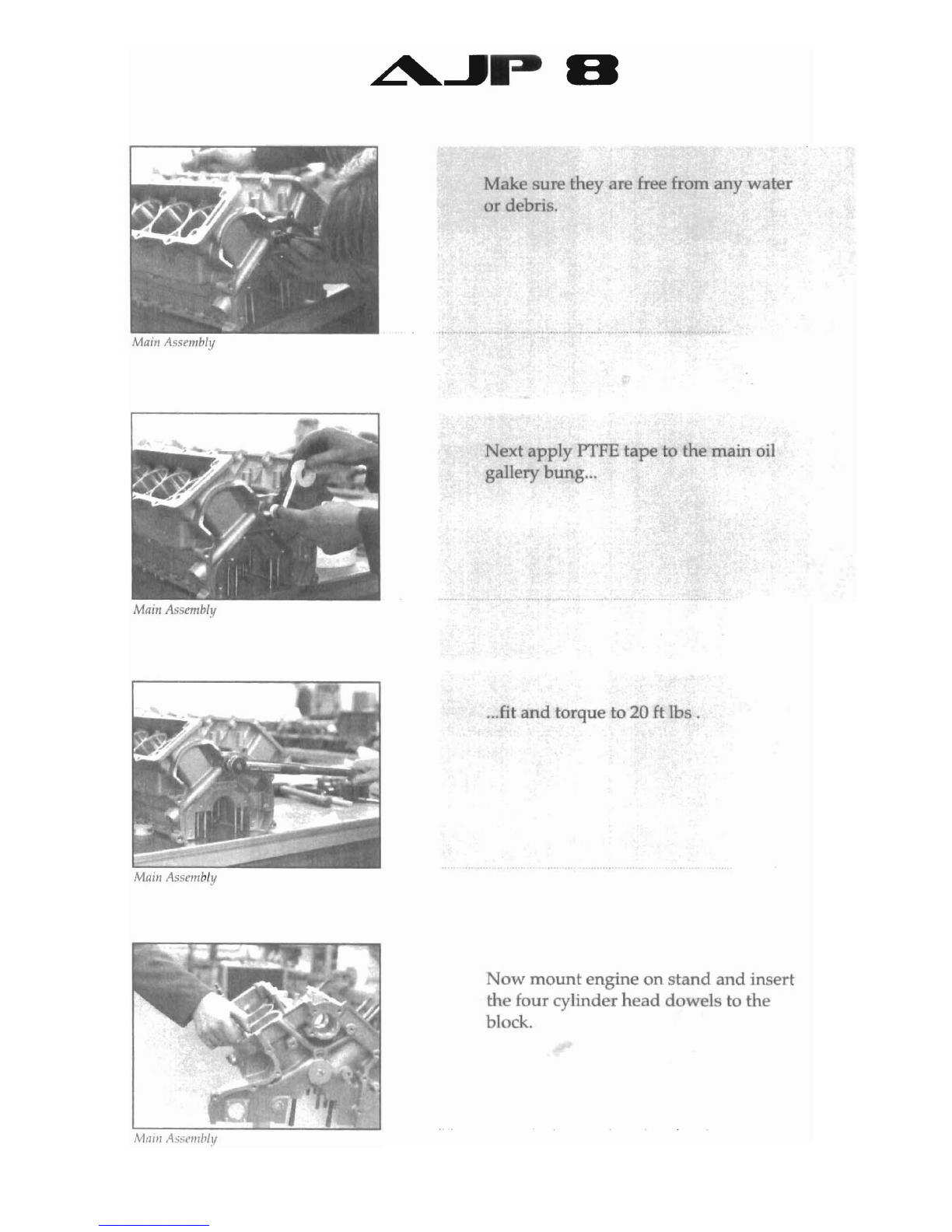

To

remove the final cap, gently tap

it

with

aoft faced hammer on the ideo