Contents

1.

Introduction ................................................................................................................ 1

1.1

Product Introduction.................................................................................................. 1

1.2

Product Features ....................................................................................................... 2

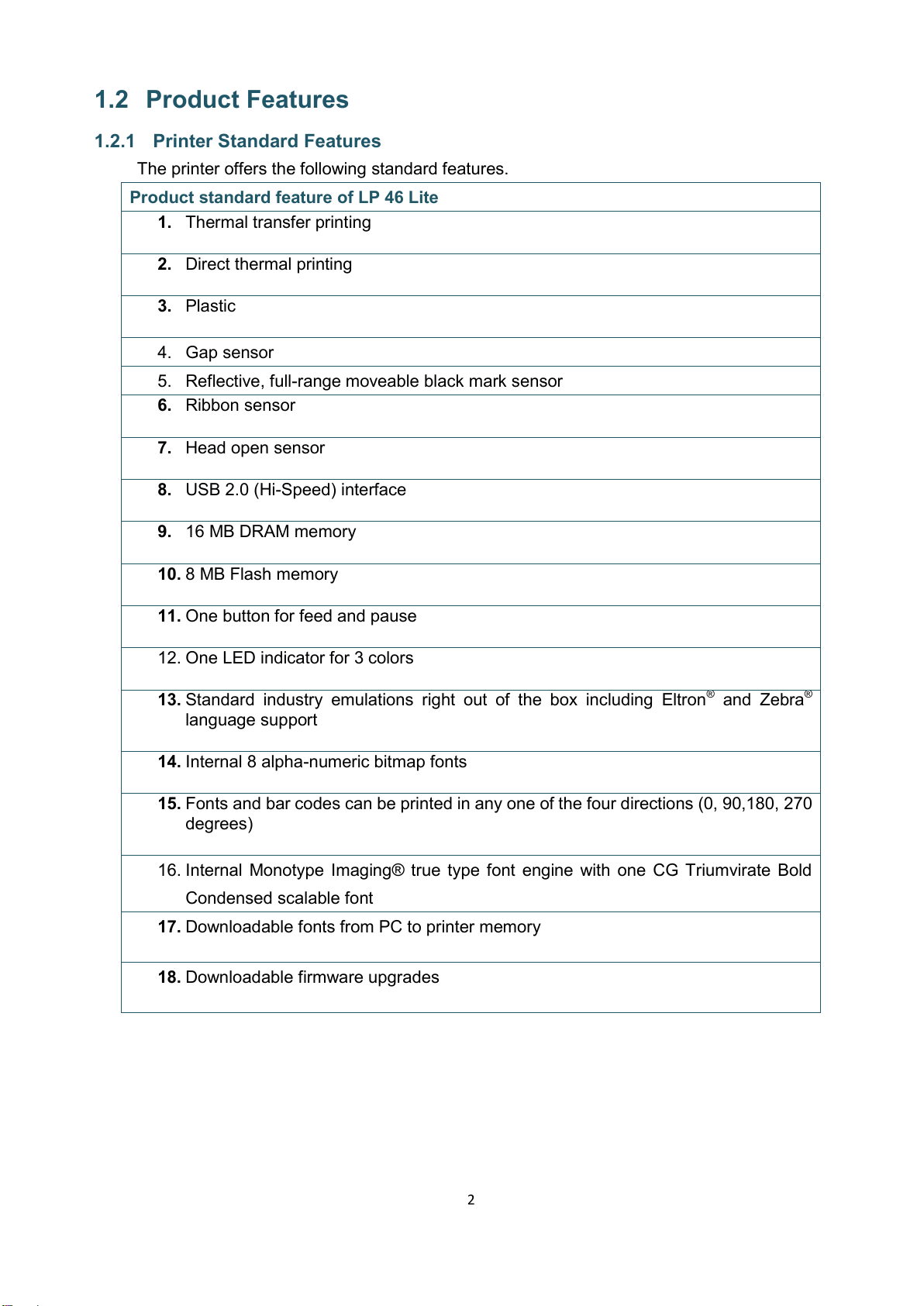

1.2.1

Printer Standard Features ............................................................................... 2

1.2.2

Printer Optional Features................................................................................ 3

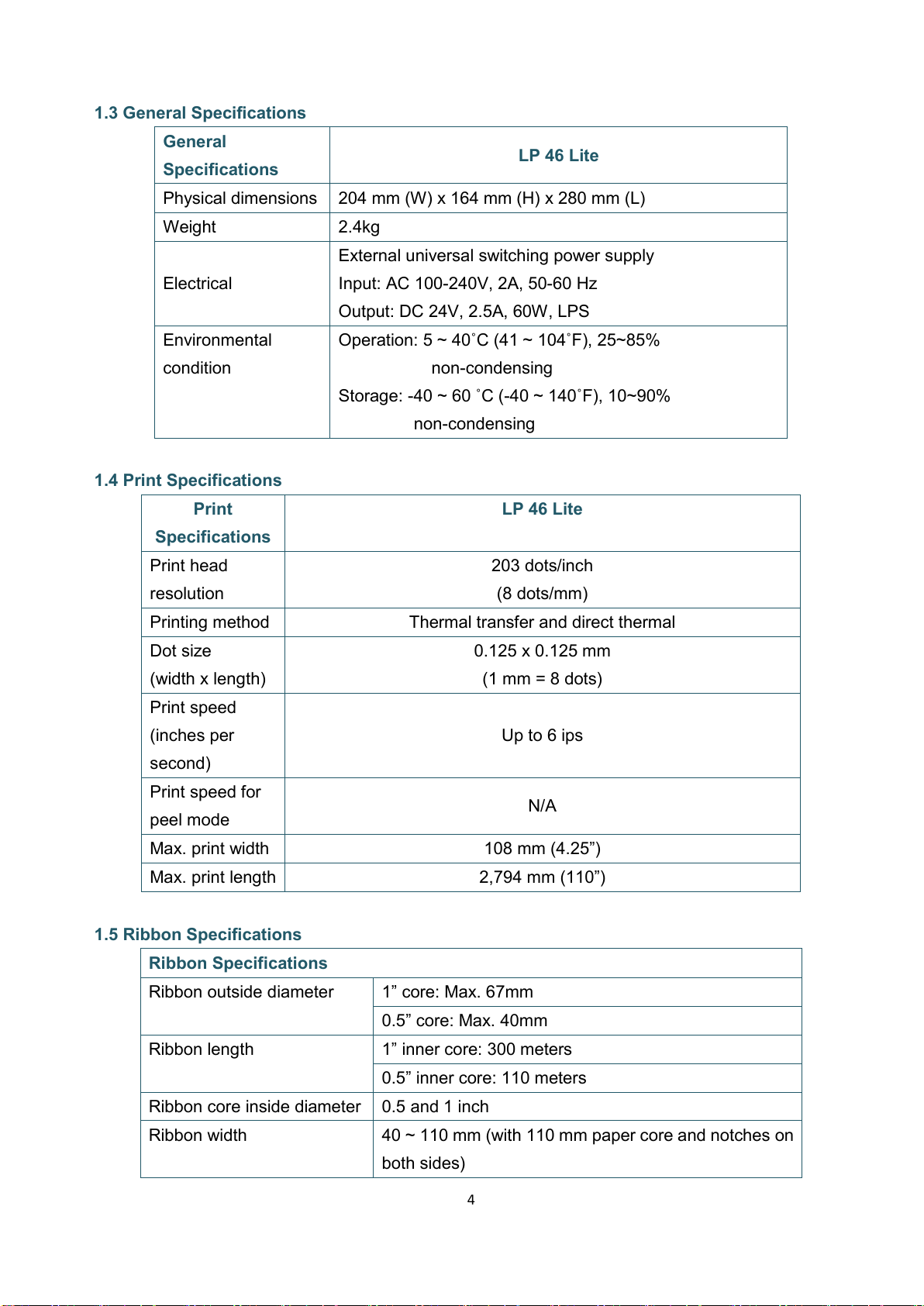

1.3

General Specifications................................................................................................ 4

1.4

Print Specifications .................................................................................................... 3

1.5

Ribbon Specifications................................................................................................. 3

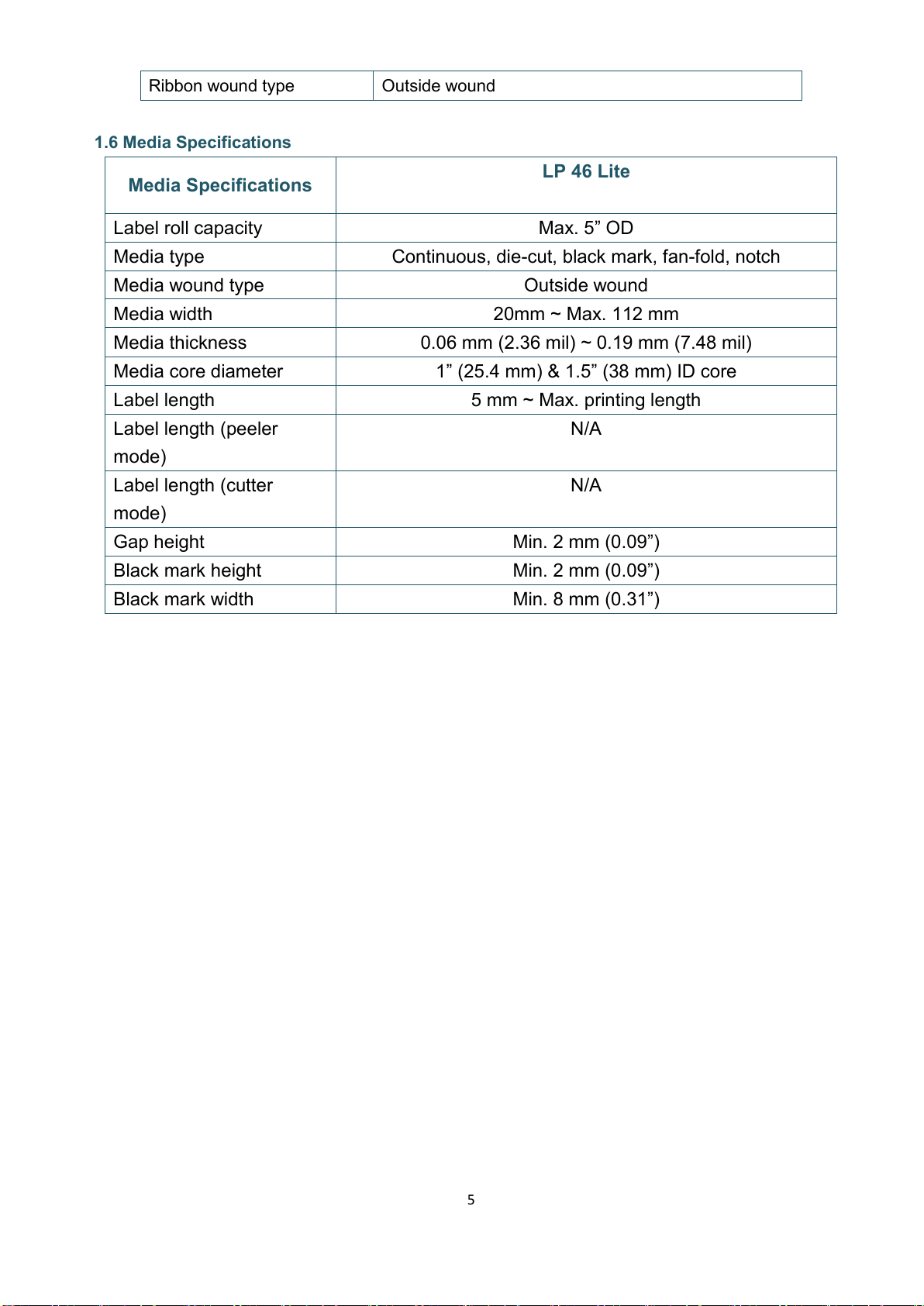

1.6

Media Specifications.................................................................................................. 4

2.

Operations Overview................................................................................................... 5

2.1

Unpacking and Inspection .......................................................................................... 5

2.2

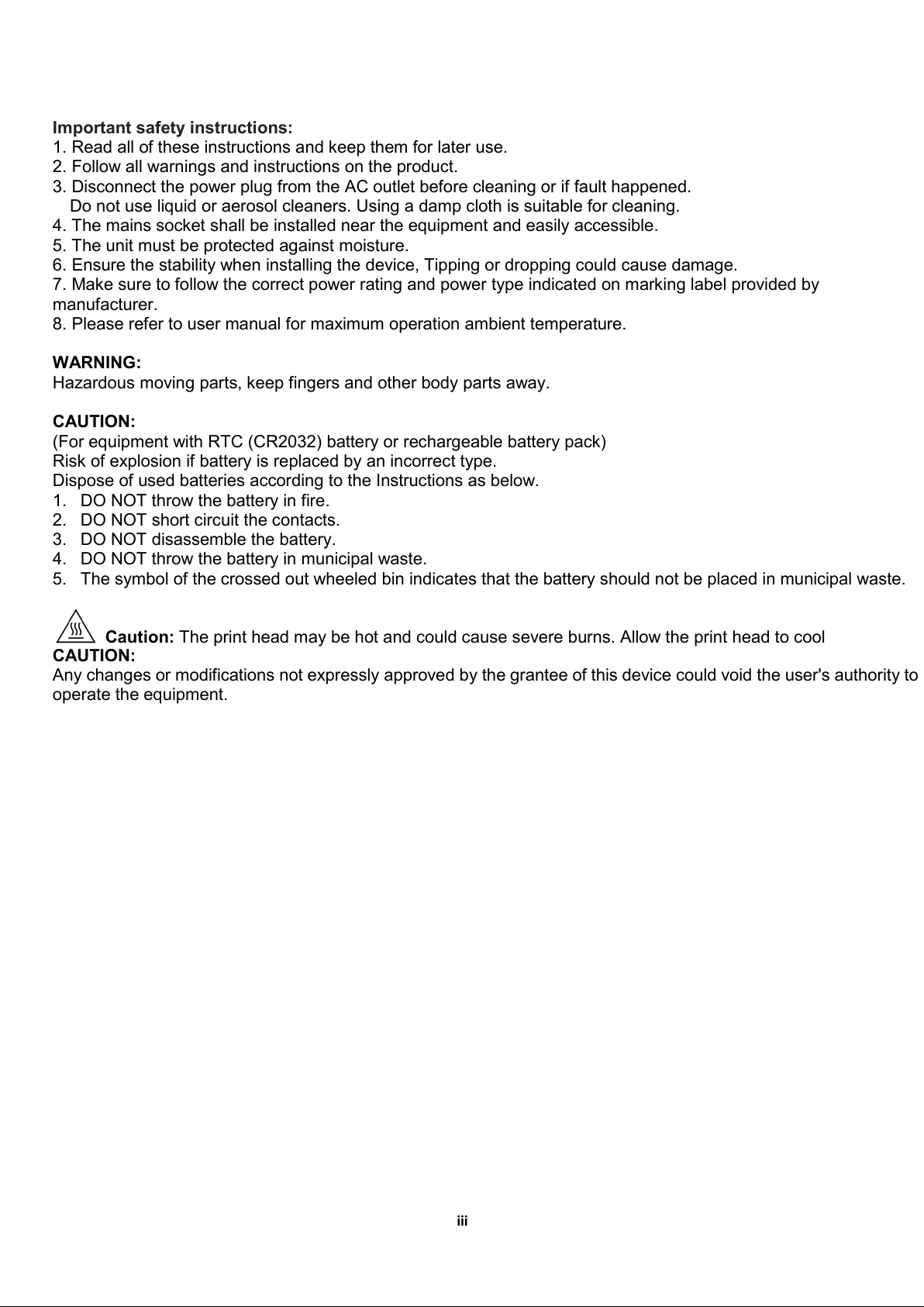

Printer Overview ....................................................................................................... 6

2.2.1

Front View...................................................................................................... 6

2.2.2

Interior View .................................................................................................. 7

2.2.3

Rear View....................................................................................................... 9

3.

Setup ........................................................................................................................10

3.1

Setting up the Printer...............................................................................................10

3.2

Loading the Ribbon ..................................................................................................11

3.3

Loading the Media ...................................................................................................14

3.3.1

Loading the Roll Labels ......................................................................................... 14

3.3.2 External Label Roll Mount Installation (Option)..................................................... 17

4.

LED and Button Functions ..........................................................................................18

4.1

LED Indicator ...........................................................................................................18

4.2

Regular Button Functions.........................................................................................18

4.3

Power-on Utilities....................................................................................................19

4.3.1

Gap/Black Mark Sensor Calibration ...............................................................20

4.3.2

Gap/Black Mark Calibration, Self-test and Dump Mode .................................20

4.3.3

Printer Initialization......................................................................................23

4.3.4

Set Black Mark Sensor as Media Sensor and Calibrate the Black Mark Sensor .24

4.3.5

Set Gap Sensor as Media Sensor and Calibrate the Gap Sensor.......................24

4.3.6

Skip AUTO.BAS .............................................................................................25

5.

Diagnostic Tool..........................................................................................................25