Content

Preface................................................................................................................................................. 1

Features............................................................................................................................................... 2

Technical Specifications.......................................................................................................................3

Instrument installation........................................................................................................................ 4

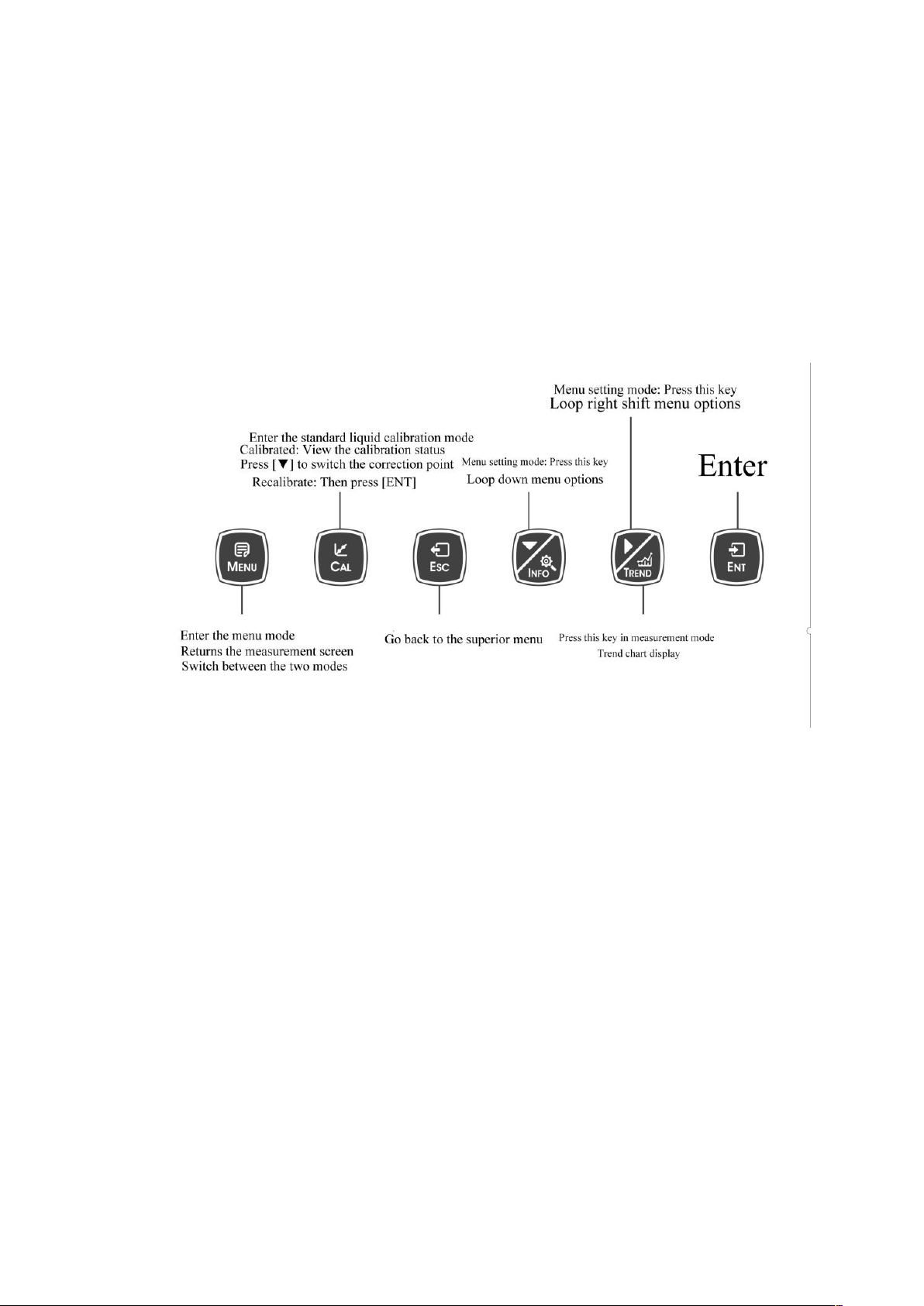

Keypad descriptions............................................................................................................................ 6

Display description.............................................................................................................................. 7

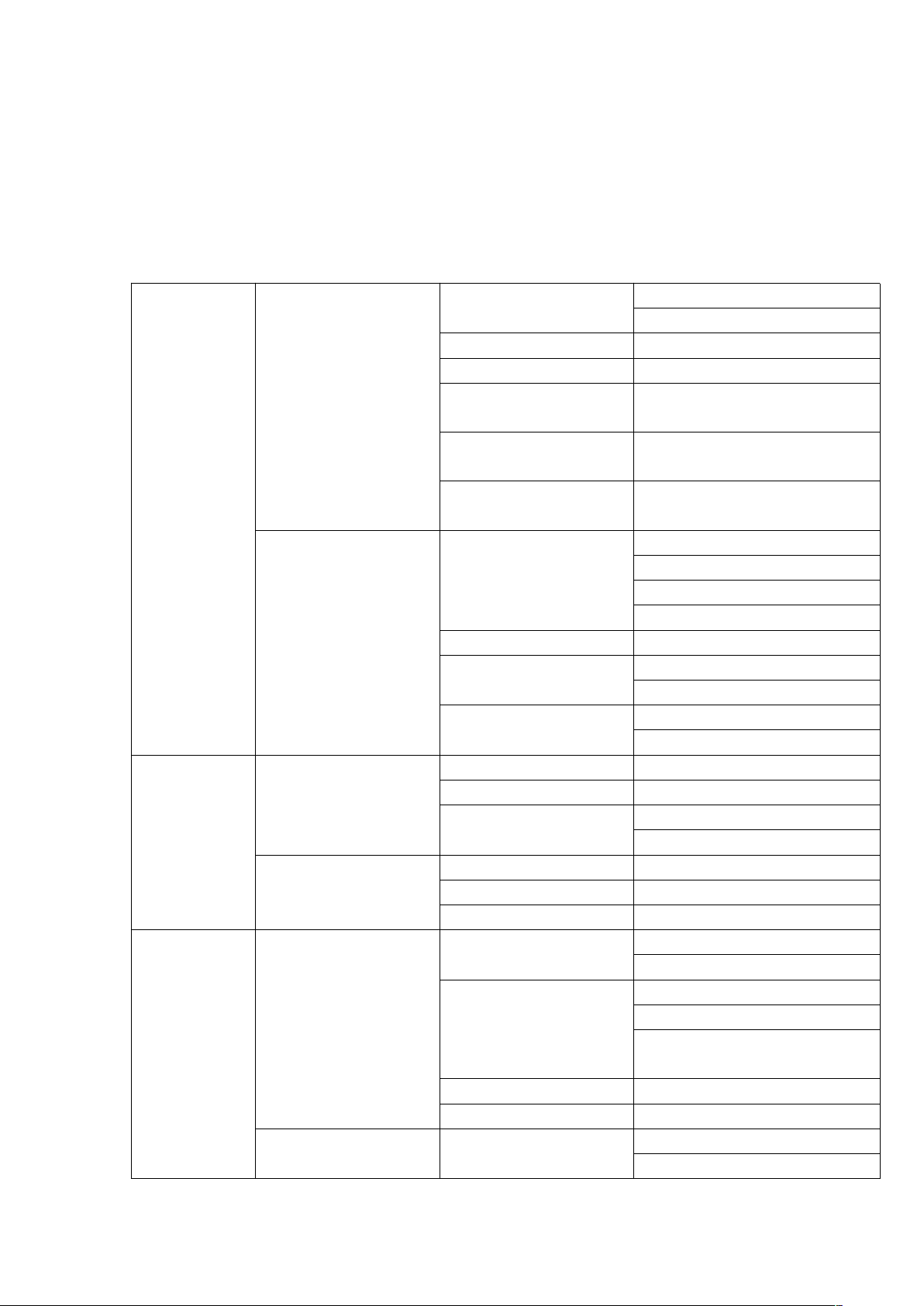

Menu Structure................................................................................................................................... 8

Calibration......................................................................................................................................... 11

Graphic Trend(Trend Chart)...............................................................................................................12

MODBUS RTU General Information..................................................................................................13

MODBUS RTU Transmission Mode................................................................................................... 14

MODBUS RTU CRC Check.................................................................................................................. 16

Implementation of MODBUS RTU in Instrument............................................................................. 16

Instrument MODBUS RTU function code..........................................................................................16

MODBUS function code 0x10: write multiple registers................................................................... 18

Data format in instrument................................................................................................................ 19

Read instruction mode......................................................................................................................22

Saturated Oxygen Meter in Water at Different Temperatures......................................................... 23

Daily maintenance.............................................................................................................................24

Frequently Asked Questions............................................................................................................. 25

Package Set........................................................................................................................................26

Warranty............................................................................................................................................27

Notes................................................................................................................................................. 28