●Once you have placed the spindles into the cross logs it is time to put the cross logs into the headboard

posts. If there is resistance please use some force to square up the headboard so it does not appear

crooked. Some cracking sounds are to be expected and do not affect the structure or durability of the bed.

4. Gluing Headboard/Footboard: A Little Glue goes a long way-Glue takes about 15 min to dry and the

entirety of all glue takes about 4 hours to completely set up before assembling side rails.

Once the “Dry Fitting '' process is done and you are satisfied with how the headboard looks; the spindles, crosslogs,

and headboard post look sturdy it is time to glue them into place. When gluing keep in mind that it is important to

first glue the spindles into the cross logs then, immediately glue the cross logs into the headboard posts

before the glue on the spindles dry. This allows you to manipulate the structure and square the

headboard/footboard up before the drying process begins.Repeat the dry fitting process and gluing for the

footboard before moving on.

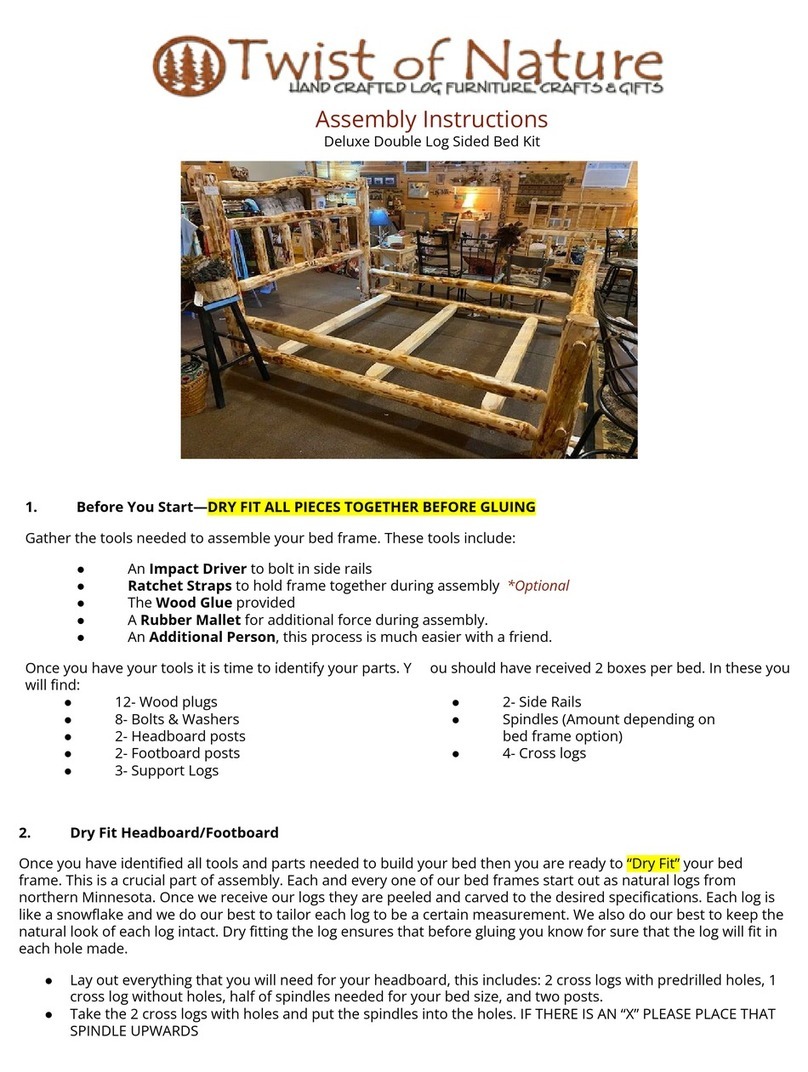

1. Side Rails & Mattress Supports

If you have a bed that has the 3 kicker blocks for the mattress supports, go ahead and screw those

down into the middle of the mattress support. This is an extra form of support for the heavier mattresses.

Now that your headboard and footboard are fully assembled and the glue has dried it is now time to connect them

with your side rails and mattress supports. This is where additional help is useful. Grab the 2 side rails, 4 bolts, 4

washers, 3 mattress supports and your impact driver.

●On the bottom of each of your bed posts of the headboard and footboard there is a hole that goes all the

way through. This is where you will be putting the ends of your side rails. When placing the side rails into

position keep in mind that the flat side of the side rail faces inward allowing your mattress supports to be

spindled into the side rail on each end. This is where a 2nd person is handy to hold the mattress supports

into place while bolting the side rails to the head and footboards. Bolt 3 sides loosely and keep one side

open while you insert the mattress supports.

●When you have your side rails in their appropriate position you can now place a washer and bolt onto the

open end of the hole and bolt your side rails into place. When bolting the last side rail, you may hear some

cracking, which is normal. A Rubber mallet sometimes helps to knock the last side rail into place.

●The 2 wood plus can be placed in the remaining open holes on the footboard for a finished look.

You have completed the bed assembly. If you have any questions or concerns please reach out and our team will be

happy to help. We have been in the log furniture business for over 25 years and have always been more than happy

to help our customers in any way we can, especially when it comes to assembling our beds!

If you choose not to order your bed with a clear lacquer finish we do recommend that you add a lacquer finish to

your bed. You can do that by first coating the wood in a sanding sealer then coating it in a water based lacquer. We

use a semi-gloss top coat and sand between coats to ensure that the wood is smooth. Adding a finish to your log

bed will protect it from various things like oils on your hands, gives the wood added durability and creates a clean

finished look to your furniture.

Timberjack/Timberjack Deluxe Bed Kit Measurements:

Cross Logs(with spindle

holes )

Deluxe Version