1110

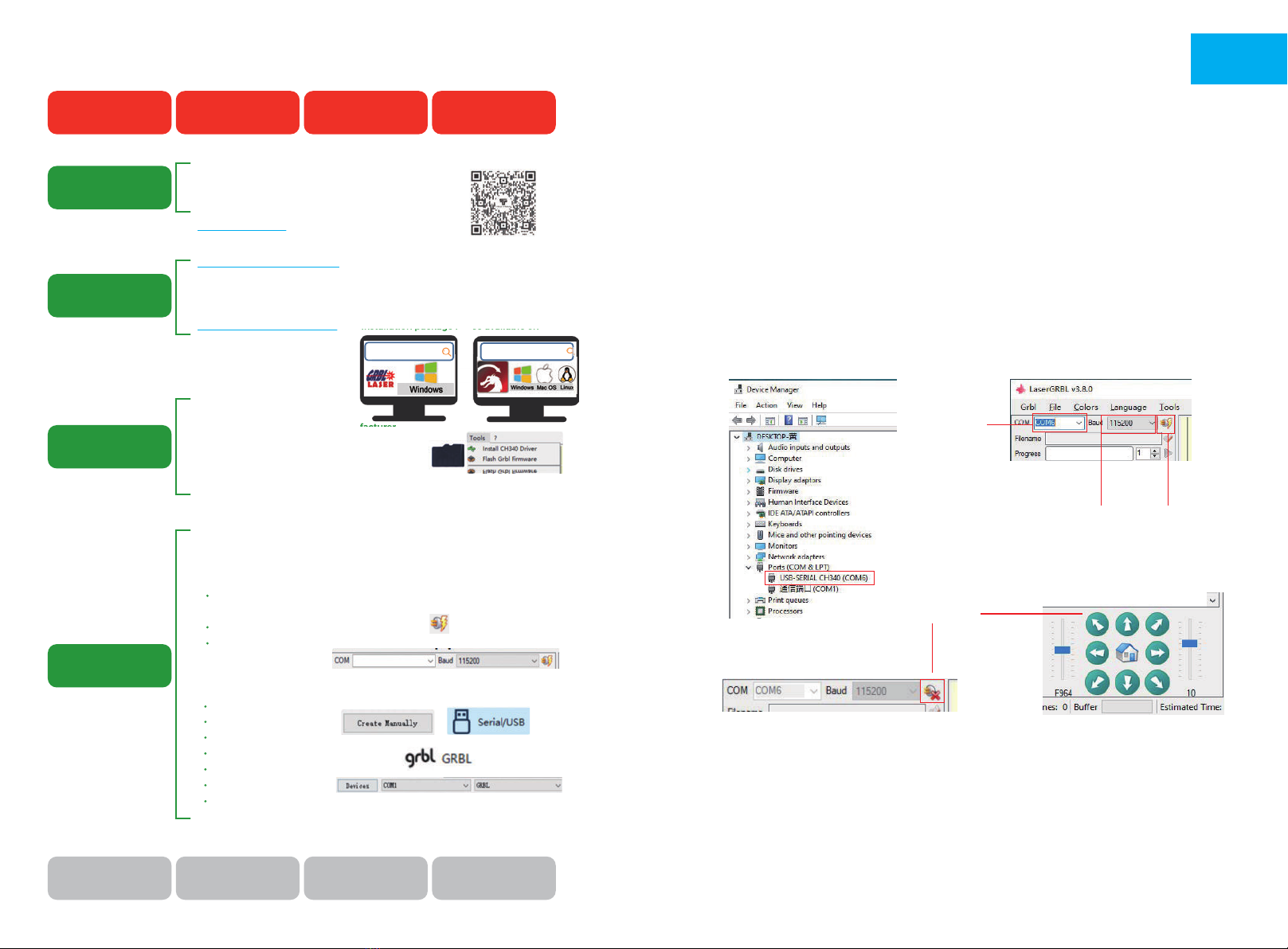

1. Connect the machine with the computer installed with LaserGRBL

software with USB data cable.

2. Plug in the power.

3. Open LaserGRBL on the computer.

4. Select the specific port number and baud rate——115200 (Figure A.10)

5. Click the lightning sign. When the lightning sign changes to the red “X”

and the direction sign is lit, it indicates that the connection is successful.

(Figure A.11)

Generally, the COM port does not need to be selected manually, unless

multiple serial port devices are connected to the computer, you can find the

port of the machine in the device manager of the windows system (as shown

in Figure A.09). A simpler way is to try the displayed port number one by one.

CONNECT PC

A.11

A.10

Successful

Choose the

correct port

Choose baud rate 115200 Lightning sign

Note:

If you cannot find the correct port in the “Ports”, you may need to

Method 1: Click "Tools" in the menu to install CH340 driver (This function is

not available in some software versions);

Method 2: Copy the "CH340ser. Exe" file in the TF Card (USB flash disk) to the

computer and install it.

EN

Driver Name: CH340SER.EXE

Where is the program?

1. The TF card attached by the manufacturer.

Search: CH340SER

2. Open the LaserGRBL software on your computer

The "Tools" menu of the LaserGRBL software.

LightBurn is a paid software, only 30 days for free.

https://lightburnsoftware.com/ (The installation package is also available on

the TF card from the manufacturer)

LightBurn For Windows, MAC

HOW TO START ?

Engraving Learning Process!

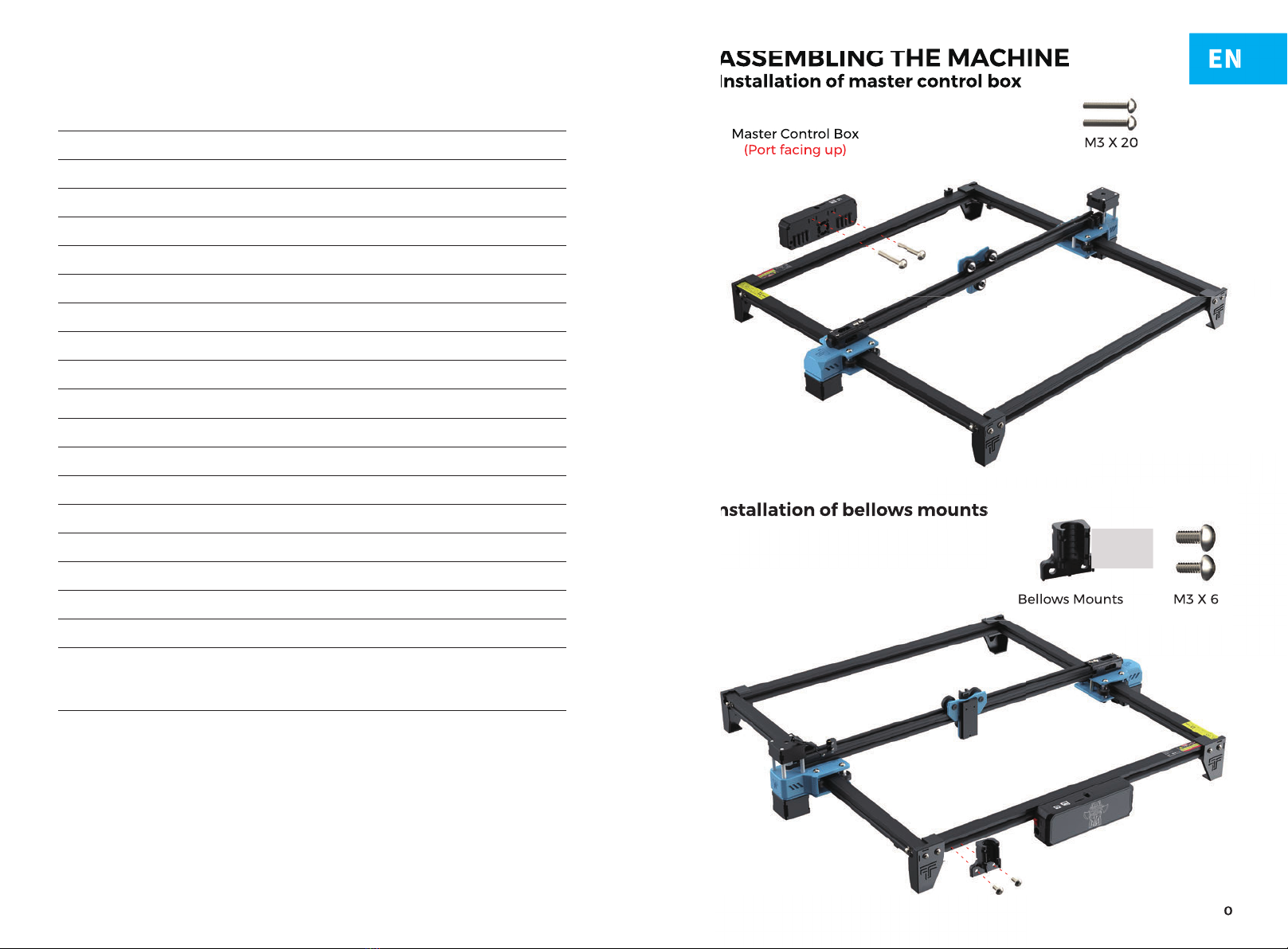

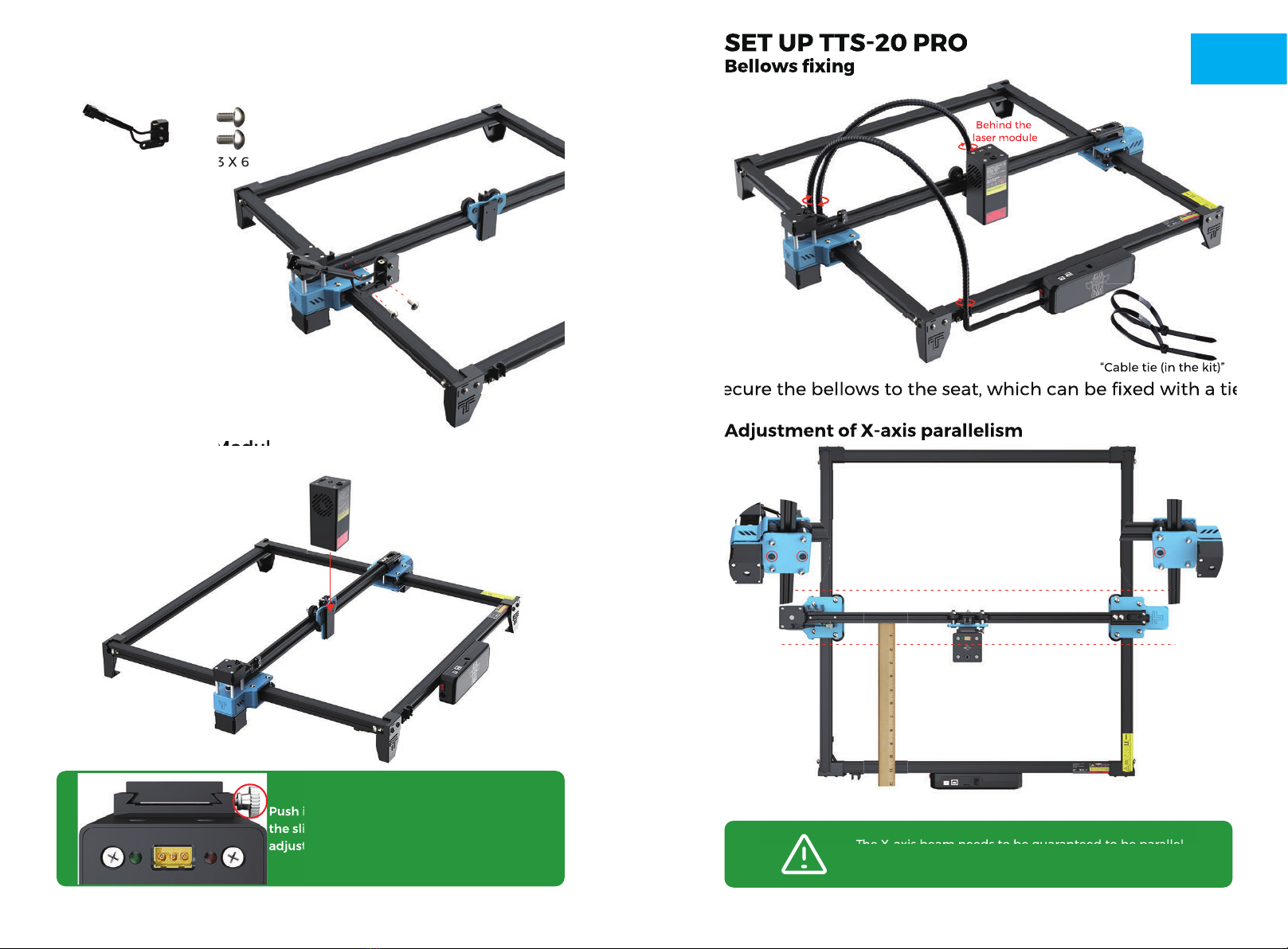

Assemble the machine

How to Assemble

the machine

How to Install

control software

How to Install

driver on computer

How to connect

the Machine &

the computer

Install the control

software on the

computer

Install the driver

on the computer Connect the machine

to the computer

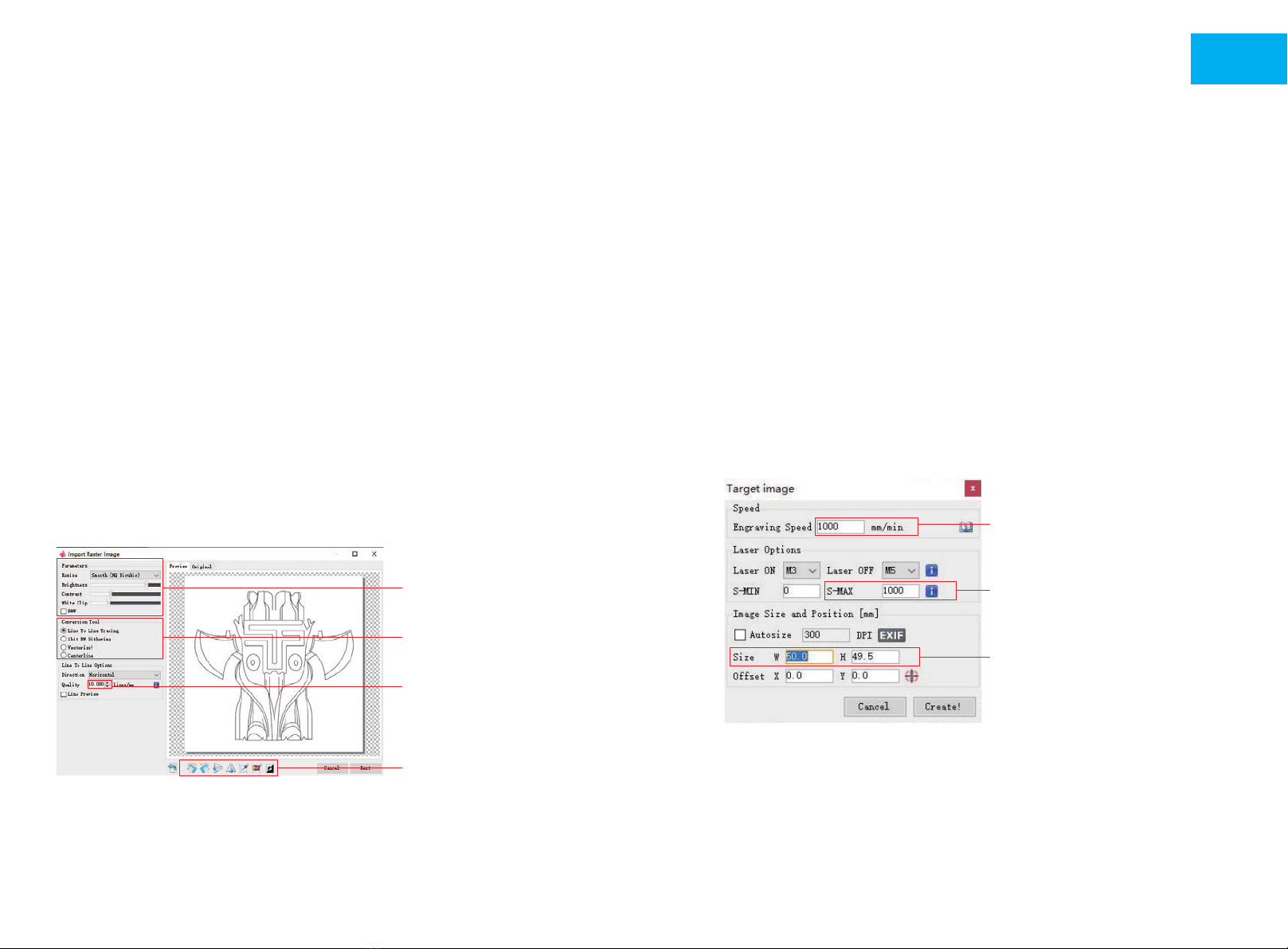

Learn to use LaserGRBL

or lightburn.on websites

Learn to focus laser

via manual or video

Test speed and power

(Results for different

materials)

Communicate and share

via Facebook and YouTube

1. Read the product manual in detail and follow the steps in the manual

to assemble the machine.

2. Tutorial Video Watch it on Youtube!

www.youtube.com Search : TWO TREES Official

Note: Install the driver unsuccessfully will cause the computer to fail to connect

to the machine

Operating steps:

1. Turn on the machine.

2. Connect the machine to the computer with the USB cable.

3. Open LaserGRBL software

In the COM checkbox, choose the COM number of the machine. (usually not

COM1)

In the Baud checkbox, choose 115200.

Click on the "Connect" button to connect successfully.

(detailed operation)

Please check the back of the manual for

4. Open LightBurn software(Activated)

Choose “Create manually” .

Choose “GRBL” ,NEXT.

Choose “Serial/USB” .

Set the length of the working area.

Set Origin: Front left.

Turn off auto "home“, NEXT.

In the COM checkbox, choose the COM number of the

machine. (usually not COM1, MAC not showing COM)

Downloaded in LaserGRBL website, it's free.

http://lasergrbl.com/download/ (The installation package is also available on

the TF card from the manufacturer)

LaserGRBL For Windows

Watch video

"Connect" button

1. The TF card attached by the manufacturer.

(The installation package is also available on

lasergrbl.com

(The installation package is also available on

lightburnso�ware.com