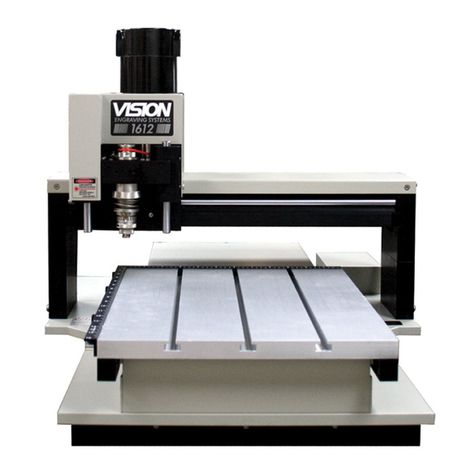

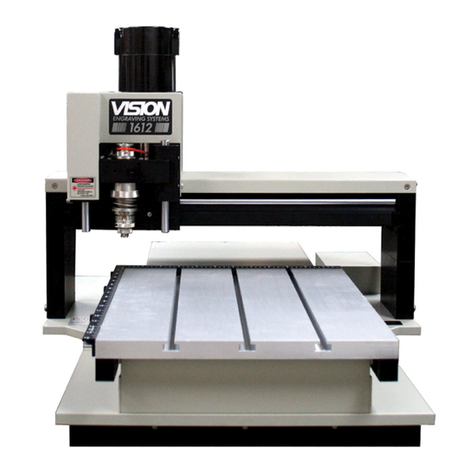

Vision 1612, 1624, 2424 and 2448 Series 5 Installation Guide10

© 2020 Vision Engraving & Routing Systems

2.3 Connections

On the rear of the Vision Series 5 controller, there are 13 connection ports. Plug in all of the cables

unless noted below.

1. The Aux Table plug connects to a 15 pin connector on the Vision 2424 and 2448. NOTE: This is not

used with the 1612 or 1624.

2. The Table plug connects to a 25 pin connector on the Vision 1612, 1624, 2424 and 2448.

3. The Rotary plug connects to a 9 pin connector on the Vision Rotary attachment. NOTE: This is not

used unless a rotary attachment is configured with the machine.

4. The 90V Spindle plug connects a 4 pin round connector that comes from the Vision 1612, 1624, 2424

and 2448.

5. The Vacuum plug connects to a 2 pin round connector that comes from an optional vacuum chip

removal system. If your machine is equipped with the optional Vacuum Chip Removal System, a

remote On/Off cable is connected from the controller to automatically turn the vacuum pump on and

off when the job is being run. NOTE: This will not be used if a vacuum chip removal system is not

configured with the machine.

6. The Pump/Mist plug connects to a misting system or water pump. NOTE: This is not used unless a

misting system or water pump is configured with the machine.

7. The Computer plug connects to the Ethernet port on the computer. This is typically plugged into the

USB to Ethernet adapter supplied with the machine.

8. The Pendant network plug connects to the back of the touch screen LCD pendant.

9. The 4 pin Pendant plug connects to the back of the touch screen LCD pendant.

10. The Mod Bus plug connects to the 3 hp router spindle power inverter. NOTE: This is only used if the

3 hp router motor is configured with the machine.

11. The power input plug connects to either the power source. IMPORTANT: Only use the 110 volt AC

or 220 volt AC power source that is displayed on the yellow label. Using the incorrect input power

can cause serious damage to the machine.

12. The Analog plug is used to control optional spindles such as a 50,000 RPM spindle. NOTE: This is

not used unless an optional spindle is configured with the machine.

13. The Aux plug is an expansion port that can be used for new products at a later date. NOTE: This is

not currently used.