2

CONTENTS

1. IMPORTANT SAFETY NOTES .............................................................................. 3

1.1 System safety ............................................................................................ 3

1.2 Batter es and small parts ............................................................................ 3

1.3 Use of tyre sealant ..................................................................................... 3

1.4 Before nstallat on ..................................................................................... 3

2. PLANNING THE SETUP ...................................................................................... 4

3. CHARGE THE MONITOR BATTERY ...................................................................... 4

4. INSERT SENSOR BATTERIES ............................................................................. 5

5. DECIDE WHICH TYRE POSITIONS WILL BE MONITORED .................................... 5

6. SET TARGET PRESSURES AND UNITS ................................................................ 6

6.1 Enter sett ngs mode ................................................................................... 6

6.2 Change un ts.............................................................................................. 6

6.3 Set tyre pressures ...................................................................................... 6

6.4 Ex t sett ngs mode ...................................................................................... 7

7. Reg ster sensors ................................................................................................ 7

7.1 Enter reg strat on mode .............................................................................. 7

7.2 Reg ster sensors ......................................................................................... 7

7.3 Ex t reg strat on mode ................................................................................ 7

7.4 Changes after reg strat on s complete ......................................................... 7

8. TESTING THE SETUP......................................................................................... 8

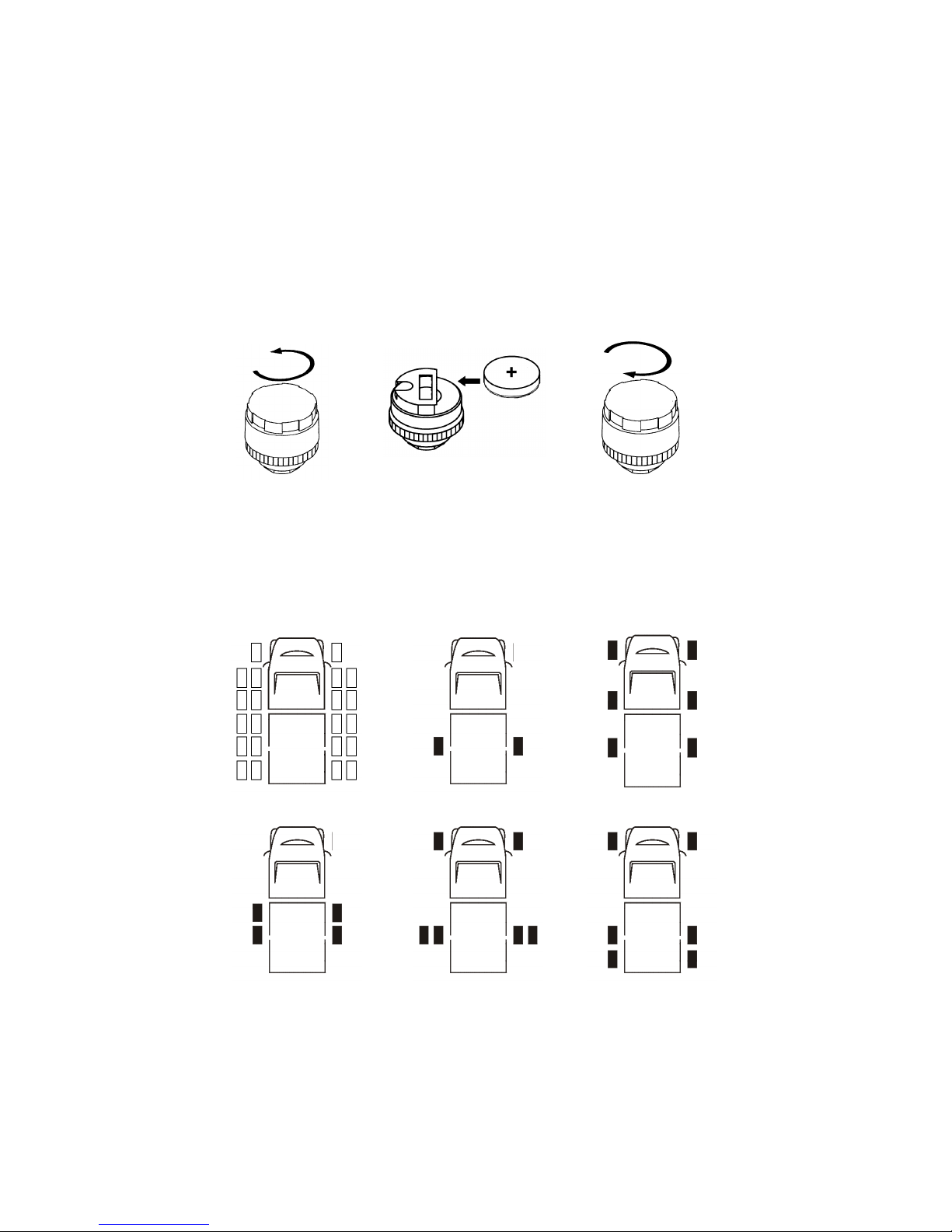

9. FITTING SENSORS AND ANTI-THEFT RINGS ...................................................... 8

9.1 Corros on ................................................................................................... 8

9.2 Ant -corros on precaut ons .......................................................................... 9

10 WHEEL BALANCING .......................................................................................... 9

11. CONNECTING AND DISCONNECTING A TRAILER .............................................. 9

12 WARNINGS AND ALARMS ............................................................................... 10

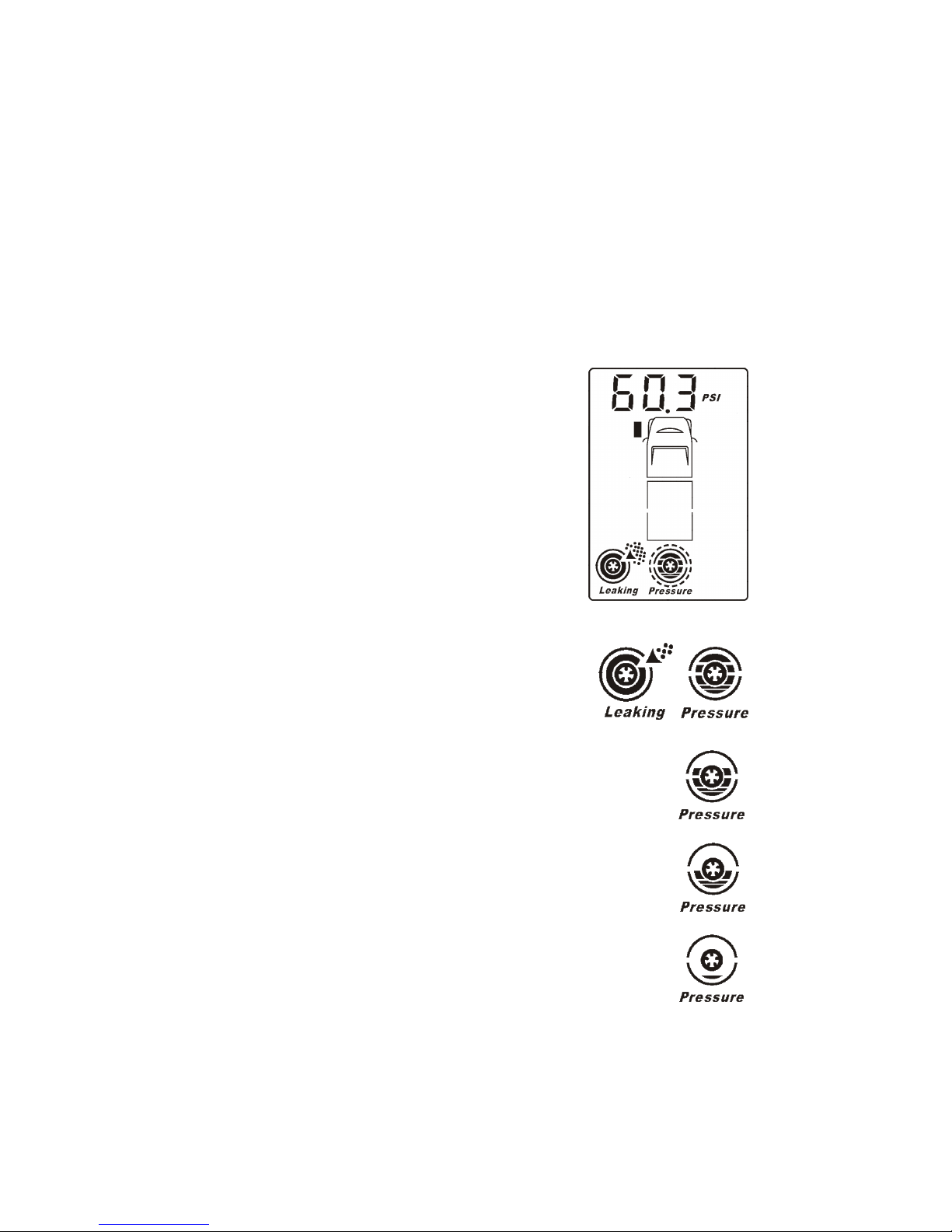

12.1 Blow-out ................................................................................................ 10

12.2 Rap d a r loss ......................................................................................... 10

12.3 Low tyre pressure................................................................................... 10

12.4 H gh tyre pressure .................................................................................. 11

12.5 H gh tyre temperature ............................................................................ 11

13. CHECKING TYRE PRESSURES ......................................................................... 11

14. TURNING ON AND OFF .................................................................................. 12

15. RESETTING THEMONITOR ............................................................................. 12

16. SIGNAL BOOSTER ......................................................................................... 13

17. TROUBLESHOOTING ..................................................................................... 13

17.1 Blank d splay .......................................................................................... 13

17.2 D ff culty n reg ster ng ............................................................................ 13

17.3 No s gnal noS ......................................................................................... 14

17.4 Incorrect pressure alerts ......................................................................... 14

17.5 False leak alert on stopp ng .................................................................... 14

17.6 D splayed pressure d sagrees w th a pressure gauge ................................ 14

18. MANAGING TYRE PRESSURES ....................................................................... 15

18.1 Effects of ncorrect tyre pressure ............................................................. 15

18.2 What s the correct pressure? .................................................................. 15

18.3 Effect of temperature ............................................................................. 15

19. SPECIFICATION AND STANDARDS ................................................................. 16

20. ADDITIONAL INFORMATION .......................................................................... 16

21. SERVICE AND WARRANTY ............................................................................. 16