Product Manual

Page 3 of 19 2022-10-31

TABLE OF CONTENTS

1INTENDED TO USE............................................................................................................4

2UNPACKING AND INSPECTION.......................................................................................4

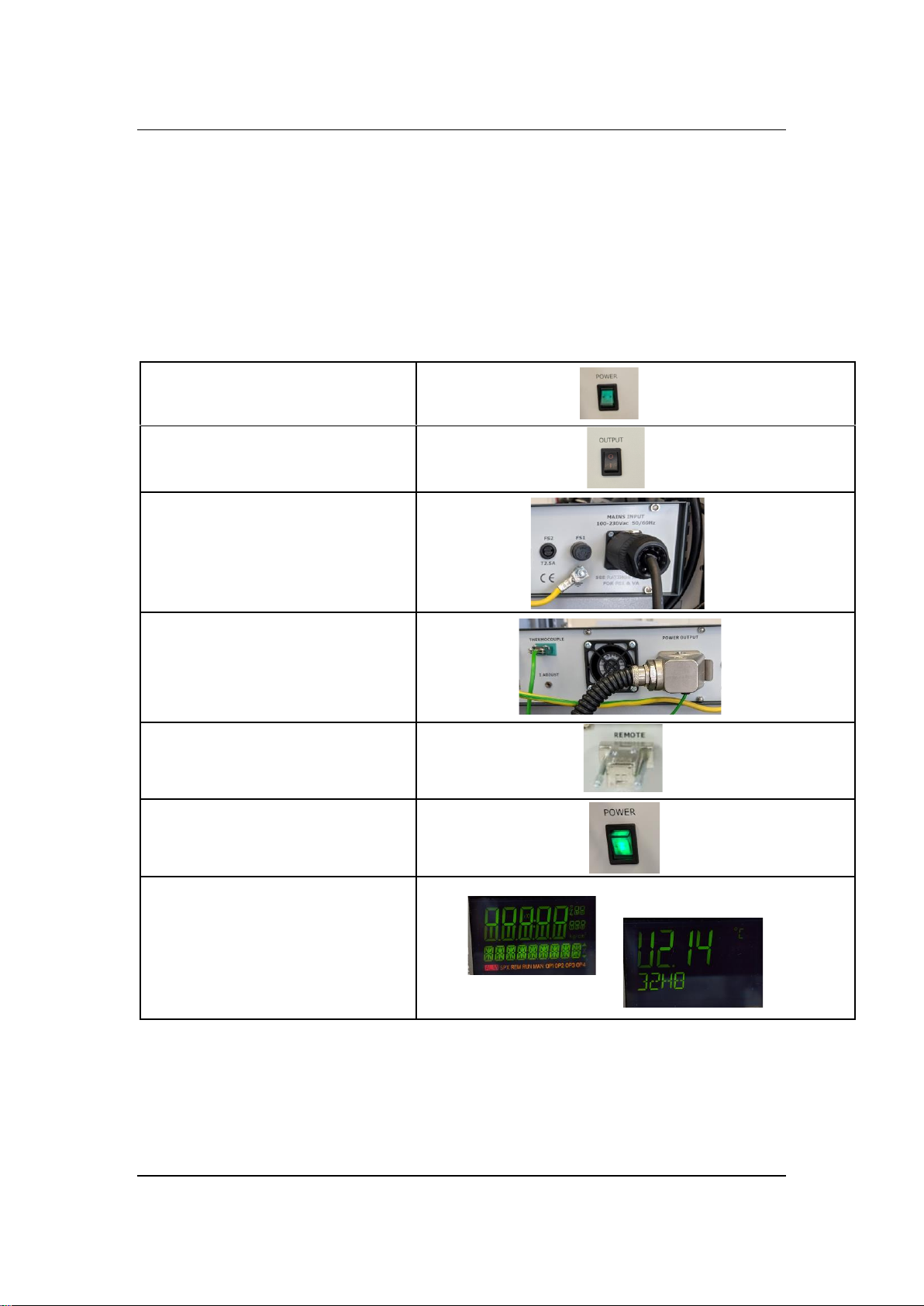

3INSTALLATION..................................................................................................................6

3.1 Mains Input Power ..................................................................................................6

3.2 Fusing......................................................................................................................6

3.3 Mains Input..............................................................................................................6

3.4 Earth Stud ...............................................................................................................6

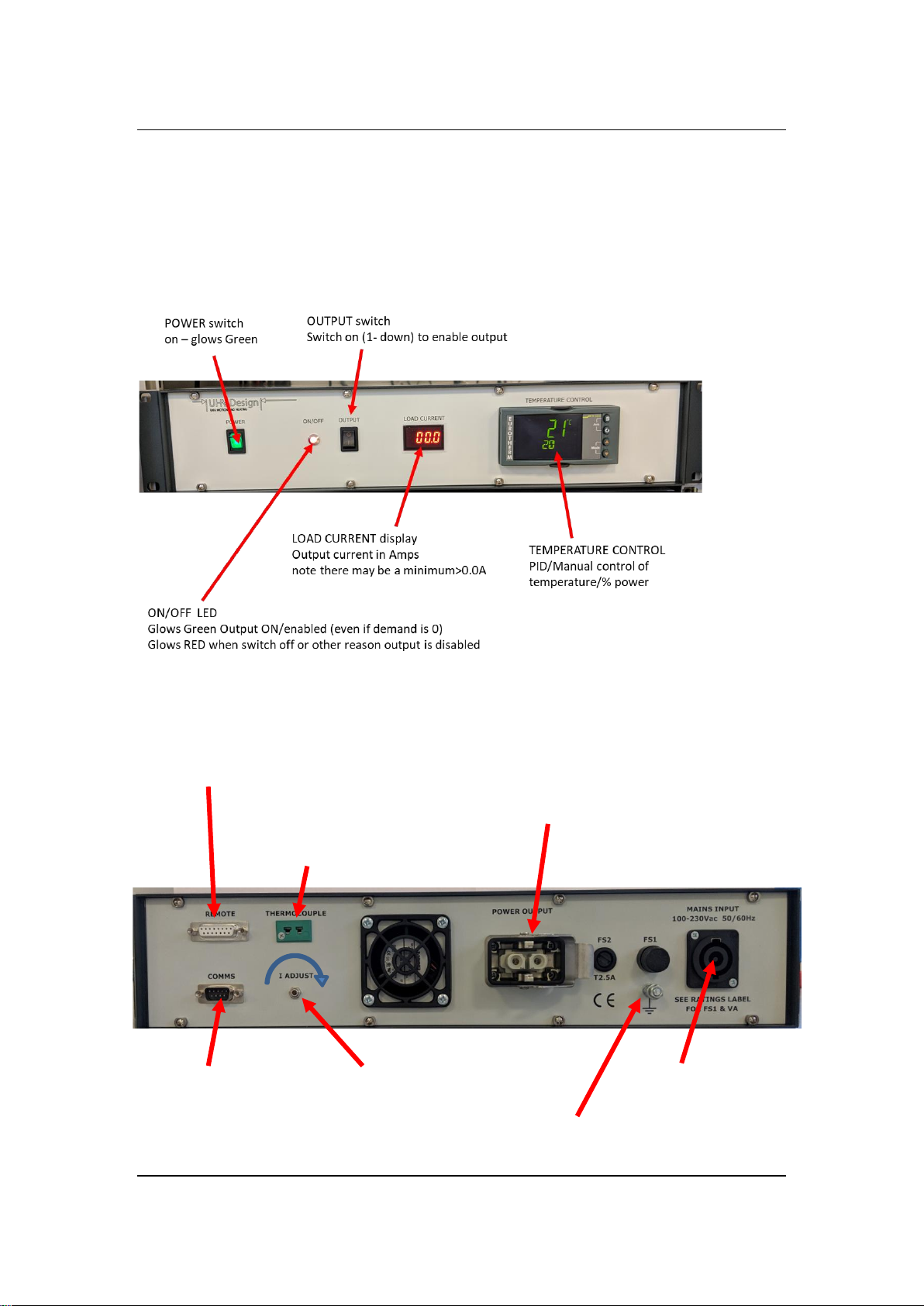

4OVERVIEW CONTROLS AND CONNECTORS ................................................................7

4.1 Front Panel Controls and Indicators .......................................................................7

4.2 Rear panel Controls and Connectors......................................................................7

4.3 Temperature Controller -Eurotherm 32h8...............................................................8

4.4 Current meter/I Adjust.............................................................................................8

4.5 Remote / Output Current & Voltage Monitor Signals..............................................8

4.6 Communications .....................................................................................................9

5OPERATION –QUICK START, CONNECT AND ON .....................................................10

5.1 Operation Quick Start –Manual Temperature control..........................................11

5.2 Operation Quick Start –Auto Temperature control ..............................................12

5.3 Operation Quick Start –Other key settings ..........................................................13

6SOFTWARE OPTIONS.....................................................................................................14

7APPENDIX A SPECIFICATIONS ...................................................................................16

8APPENDIX B MAINTENANCE & SERVICE ...................................................................17

9APPENDIX C WARRANTY & REPAIR...........................................................................18

10 APPENDIX D WIRING DIAGRAM...................................................................................19