Construcción

ConstrucciónConstrucción

Construcción

3

INDEX

INDEXINDEX

INDEX

1. PRODUCT DESCRIPTI

1. PRODUCT DESCRIPTI1. PRODUCT DESCRIPTI

1. PRODUCT DESCRIPTION

ONON

ON

................................

................................................................

.....................................

..........

.....

4

44

4

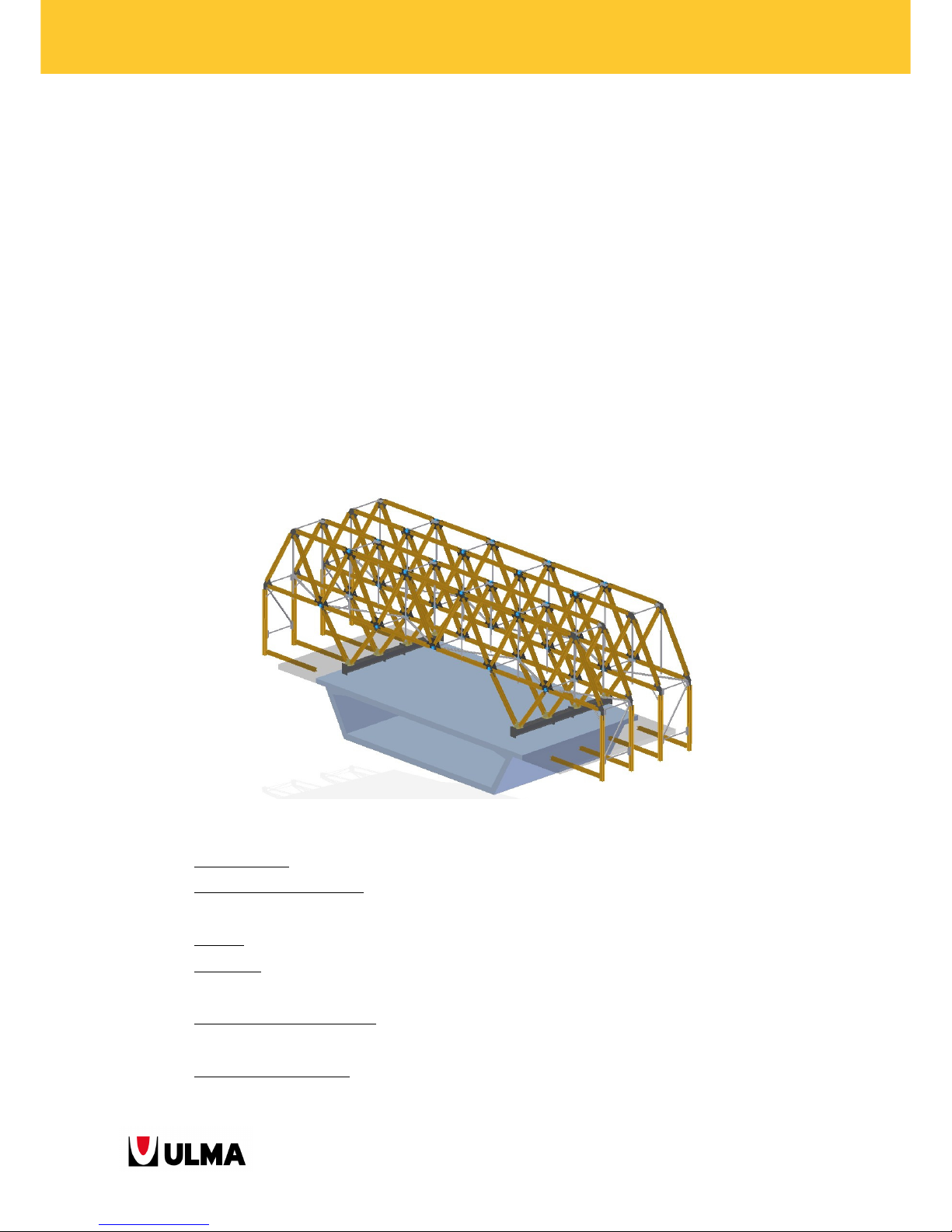

1.1. MK TRUSS ....................................................... 5

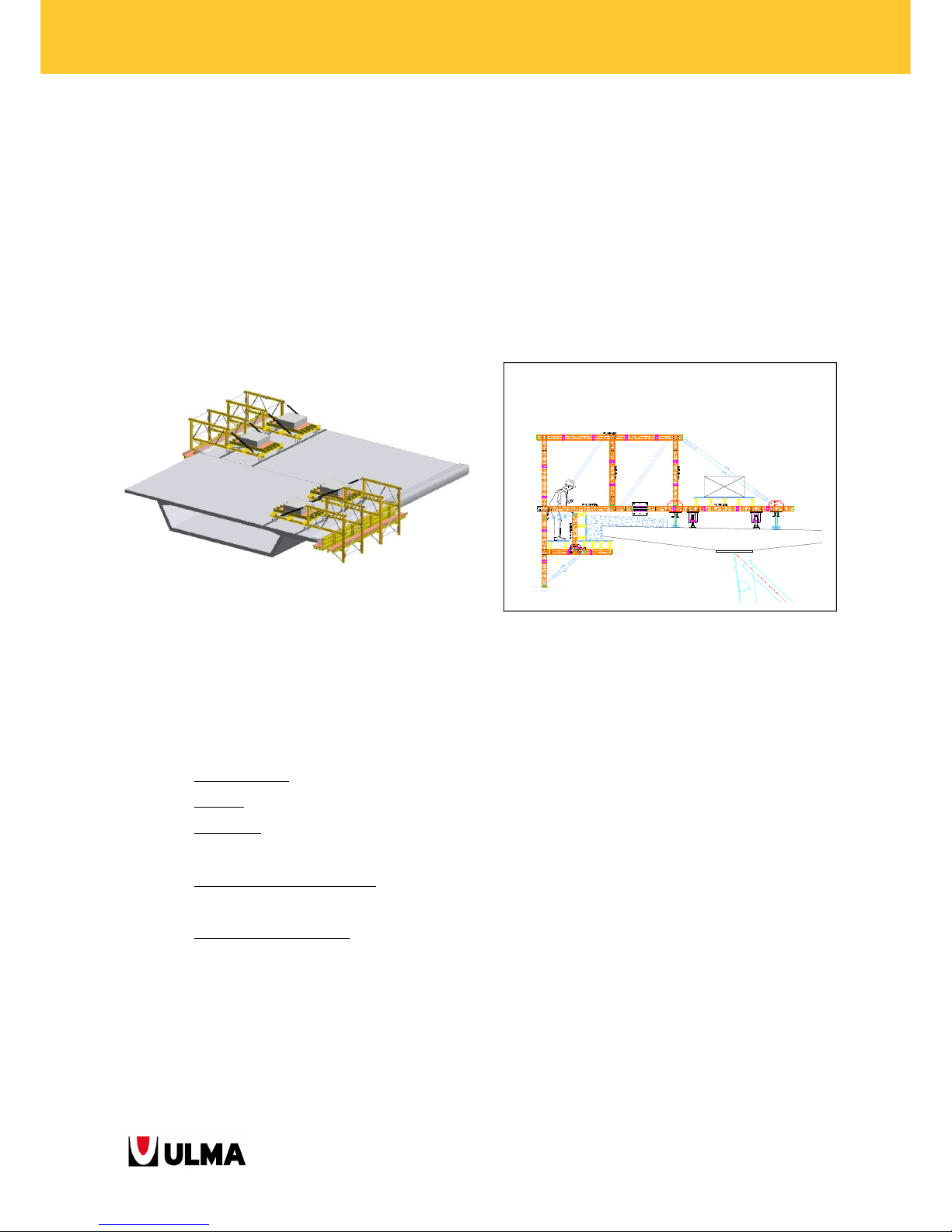

1.2. MK FORM CARRIERS ........................................ 7

2. SYSTEM COMPONENTS

2. SYSTEM COMPONENTS2. SYSTEM COMPONENTS

2. SYSTEM COMPONENTS

AND ACCESSORIES

AND ACCESSORIESAND ACCESSORIES

AND ACCESSORIES

......

............

......

13

1313

13

2.1. GRAPHIC DESCRIPTION ................................... 13

2.2. ITEMS DESCRIPTION ....................................... 17

3. ASSEMBLY, USE AND

3. ASSEMBLY, USE AND3. ASSEMBLY, USE AND

3. ASSEMBLY, USE AND

DISMANTLING

DISMANTLINGDISMANTLING

DISMANTLING

.................

..................................

.................

25

2525

25

3.1. TECHNICHAL ASSEMBLY INSTRUCTIONS.

GENERAL ASSEMBLY .............................................. 25

4. SOLUTIONS

4. SOLUTIONS4. SOLUTIONS

4. SOLUTIONS

................................

................................................................

......................................................

............................................

......................

29

2929

29

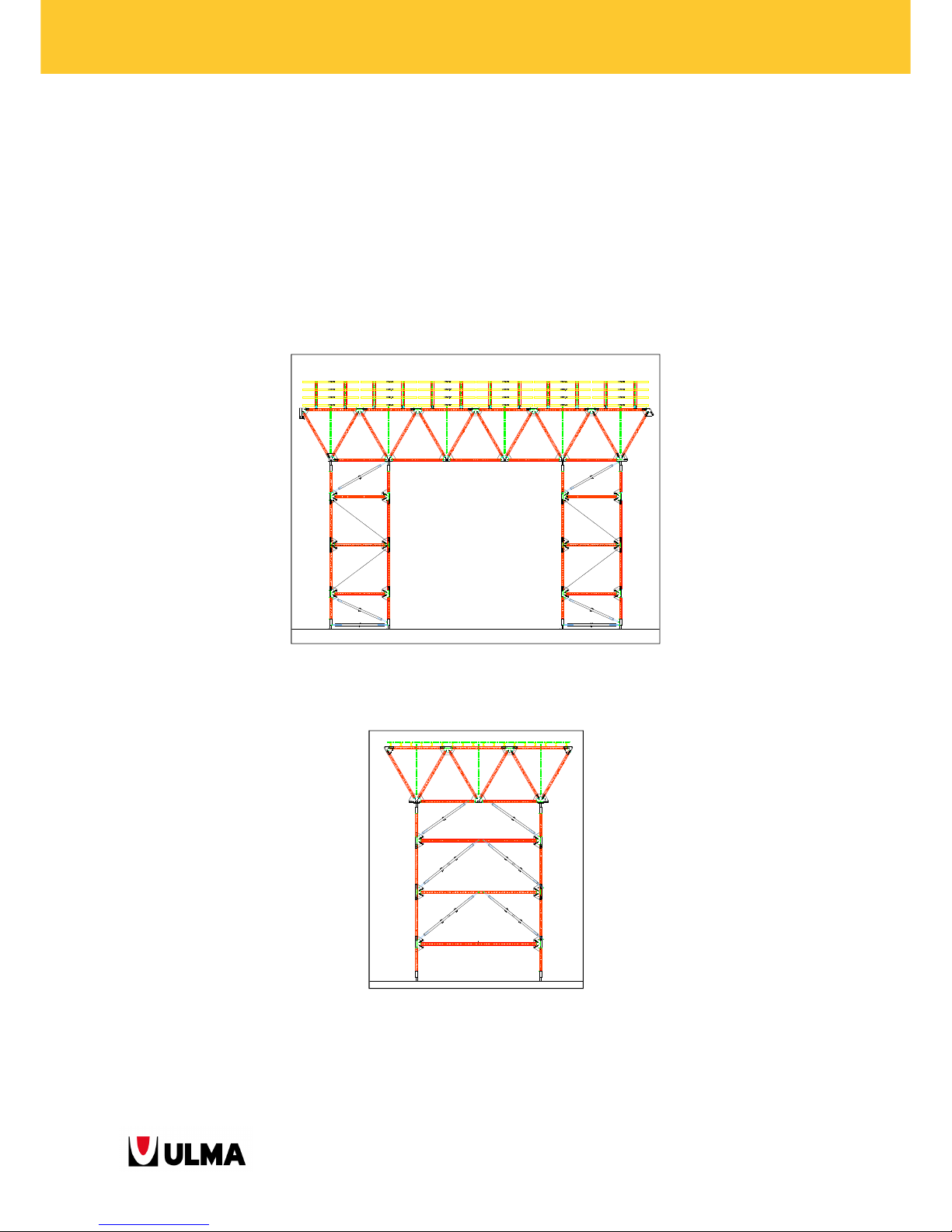

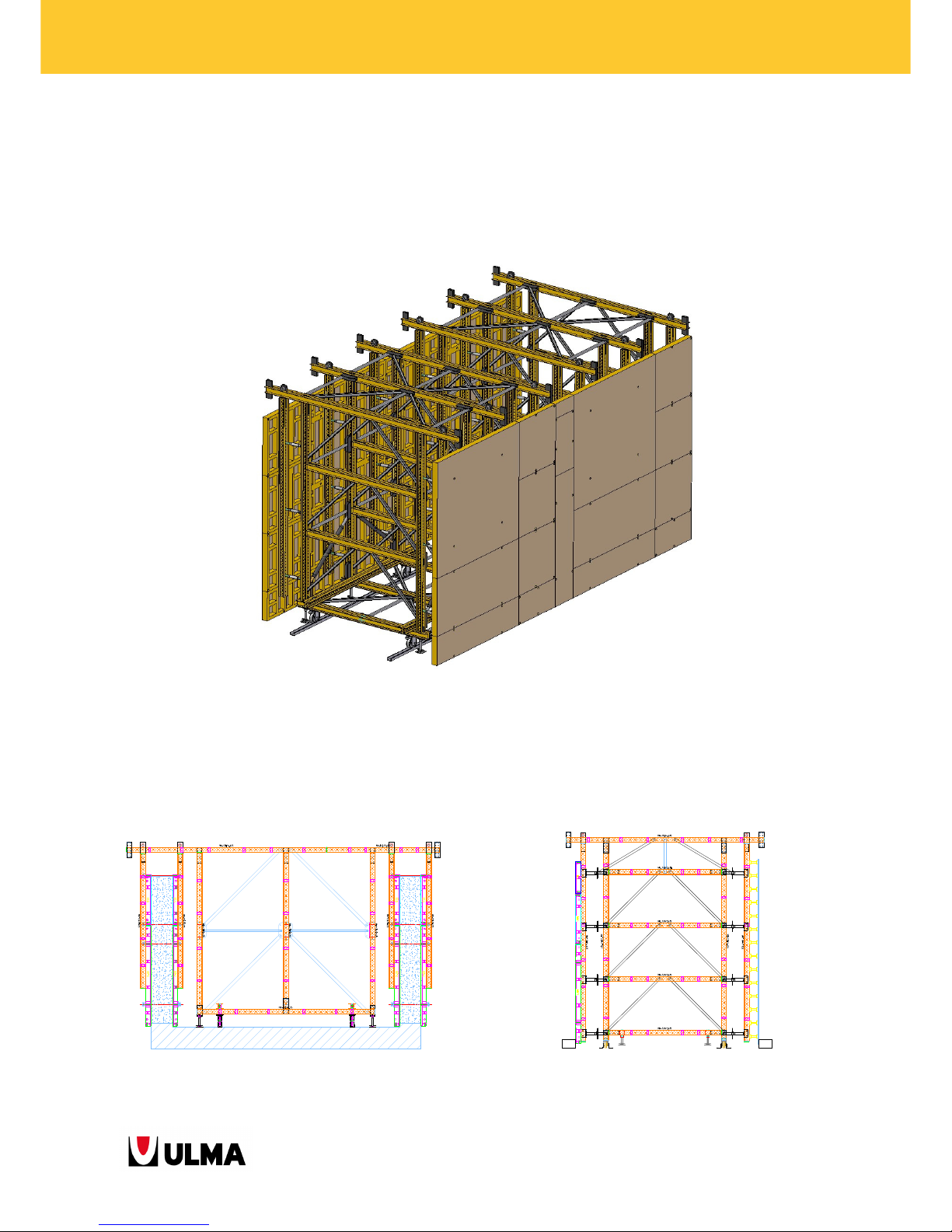

4.1. STRUCTURE TYPES .......................................... 32

4.2. STRUCTURE LAYOUTS ..................................... 34

4.3. BRACING BETWEEN STRUCTURES .................... 38

4.4. STRUCTURE CONNECTION WITH SHORING

SYSTEM .................................................................. 39

4.5. STRUCTURE LEVELLING .................................... 40

4.6. FORWARD MOVING OF STRUCTURES: ROLLING

SYSTEM .................................................................. 41

4.7. SAFETY AND ACCESS PLATFORMS ................... 42

5. SYSTEM PROPERTIES

5. SYSTEM PROPERTIES5. SYSTEM PROPERTIES

5. SYSTEM PROPERTIES

................................

................................................................

.......................................

..............

.......

43

4343

43

5.1. MAIN ITEM PROPERTIES ................................... 43

5.2. LIMITS FOR STANDARD STRUCTURES ................ 50

6. TERMS AND CONDITI

6. TERMS AND CONDITI6. TERMS AND CONDITI

6. TERMS AND CONDITIONS OF USE

ONS OF USEONS OF USE

ONS OF USE

....................

........................................

....................

55

5555

55

6.1. SAFE OPERATING GUIDELINES .......................... 55

6.2. TRANSPORT, HANDLING AND STORAGE ........... 58

6.3. INSPECTION AND MAINTENANCE ..................... 59

7. LEGAL REFERENCES

7. LEGAL REFERENCES7. LEGAL REFERENCES

7. LEGAL REFERENCES

................................

................................................................

.........................................

..................

.........

61

6161

61