Ultimate Jets - Diamond assembly manual - Revision 4 -01/01/2015

INTRODUCTION

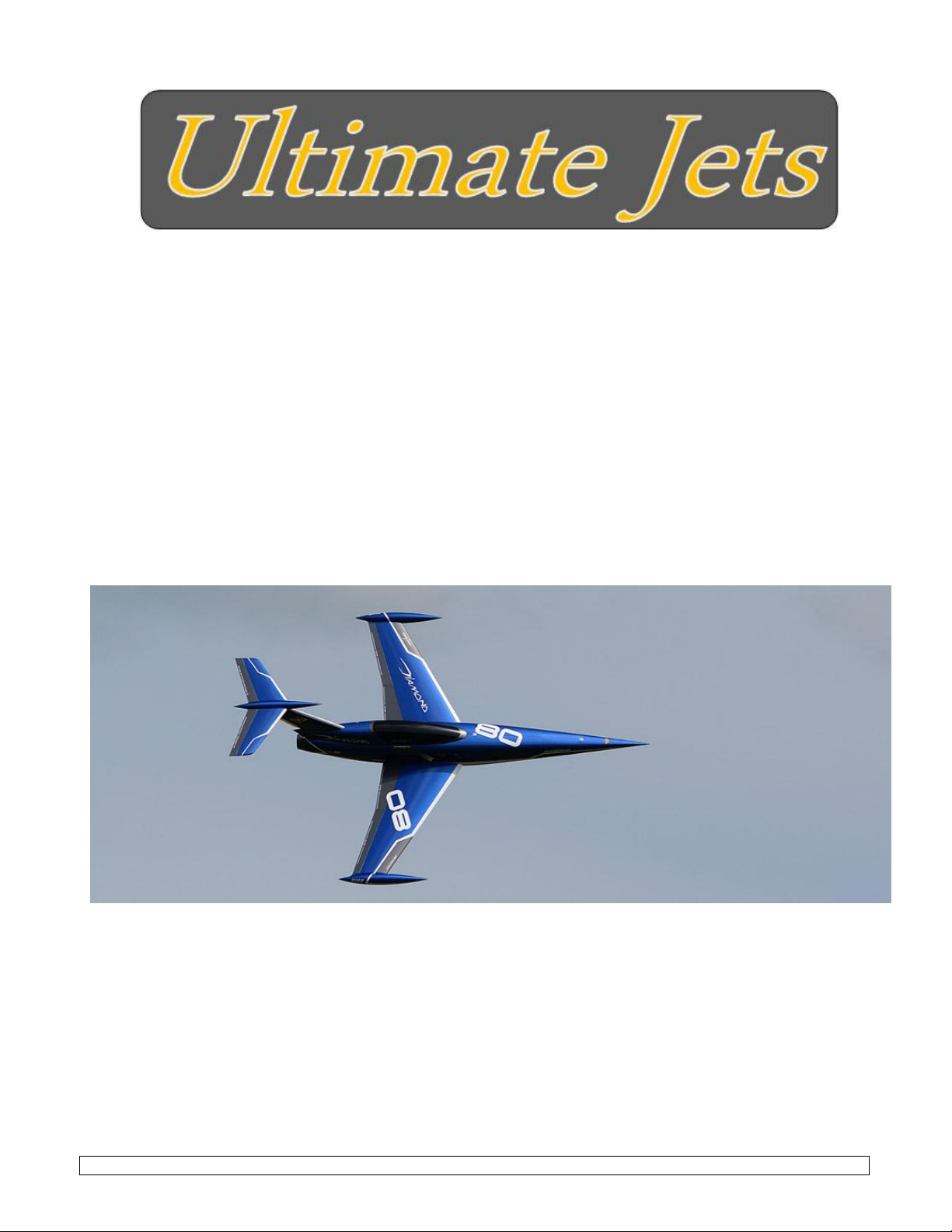

The Diamond is our new performance jet. It is fully composite, delivered assembled and painted.

It was designed for advanced jet pilots with following objectives :

-Very easy to fly.

-Short take off and landing due to custom designed laminar airfoil, large flaps and low wing loading

-Very fast assembly

-Easy access to engine (big side engine hatch)

-Easy access to fuel tank, ECU and radio with a large fuselage canopy hatch

-Easy battery access with removable nose section and reinforced carbon fiber servo covers

It is designed for a 160 to 220 N thrust turbine.

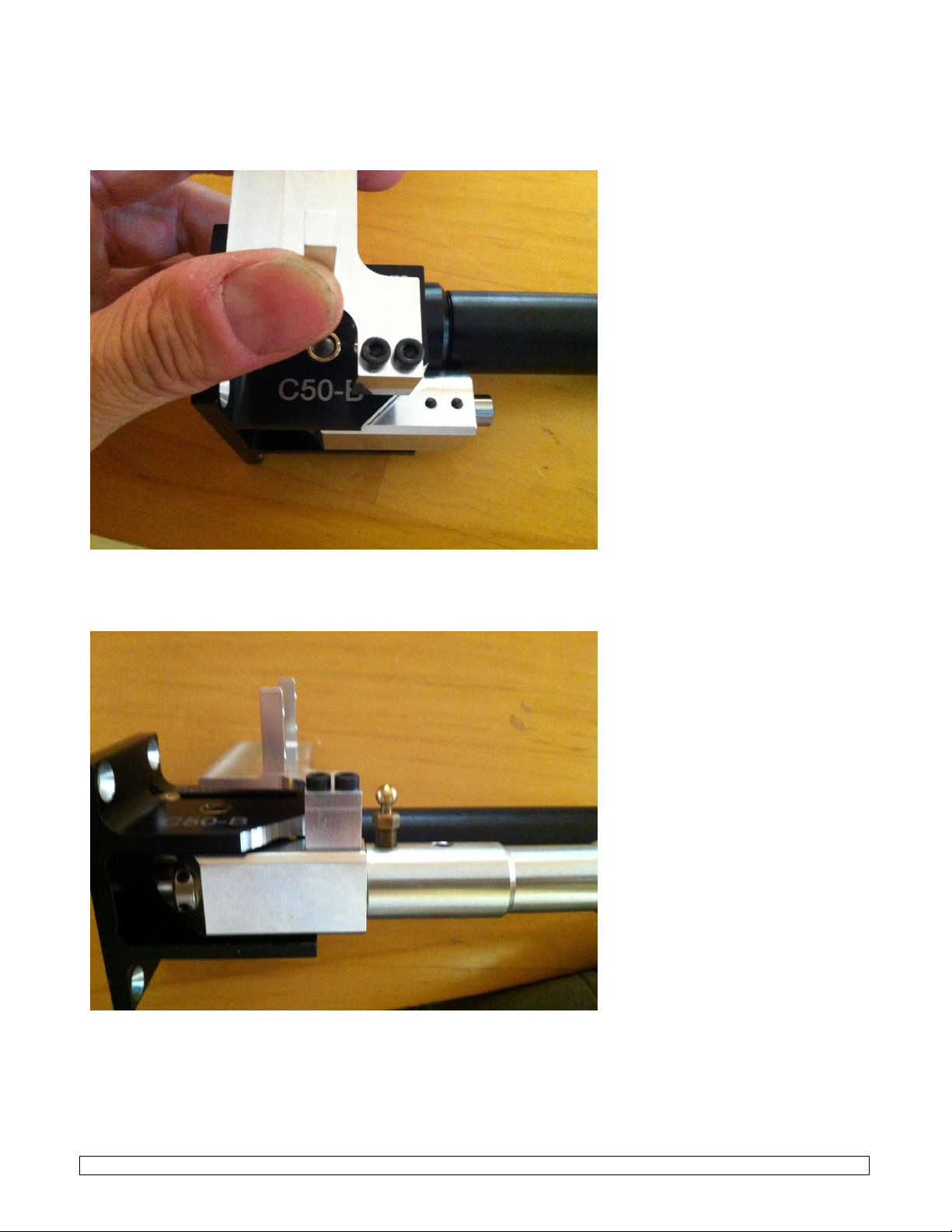

The model comes finished, fully molded in composite material and painted in the molds. All the bulkheads

are glued. All control surfaces are hinged. No gluing is required. This model has plug in wings, fin and

stabilizers as well as removable nose cone and nose tray for easier transport.

All necessary hardware is included in the box.

The assembly only requires a few hours to fit the engine and the remote control components.

The Diamond ARF model includes :

- High quality epoxy-glass fuselage painted.

- All plywood and wood parts premounted.

- Fully molded wings, stabs and fin painted

- Two aero grade aluminum wing tube.

- Access hatch and canopy requiring no additional work.

- All hardware (screws, servo cover, ...)

- Instructions in English with pictures.