BASIC OPERATION

WARNING

Your Powermover was designed to move heavy objects and loads on nearly level surfaces.

Do not operate on slopes.

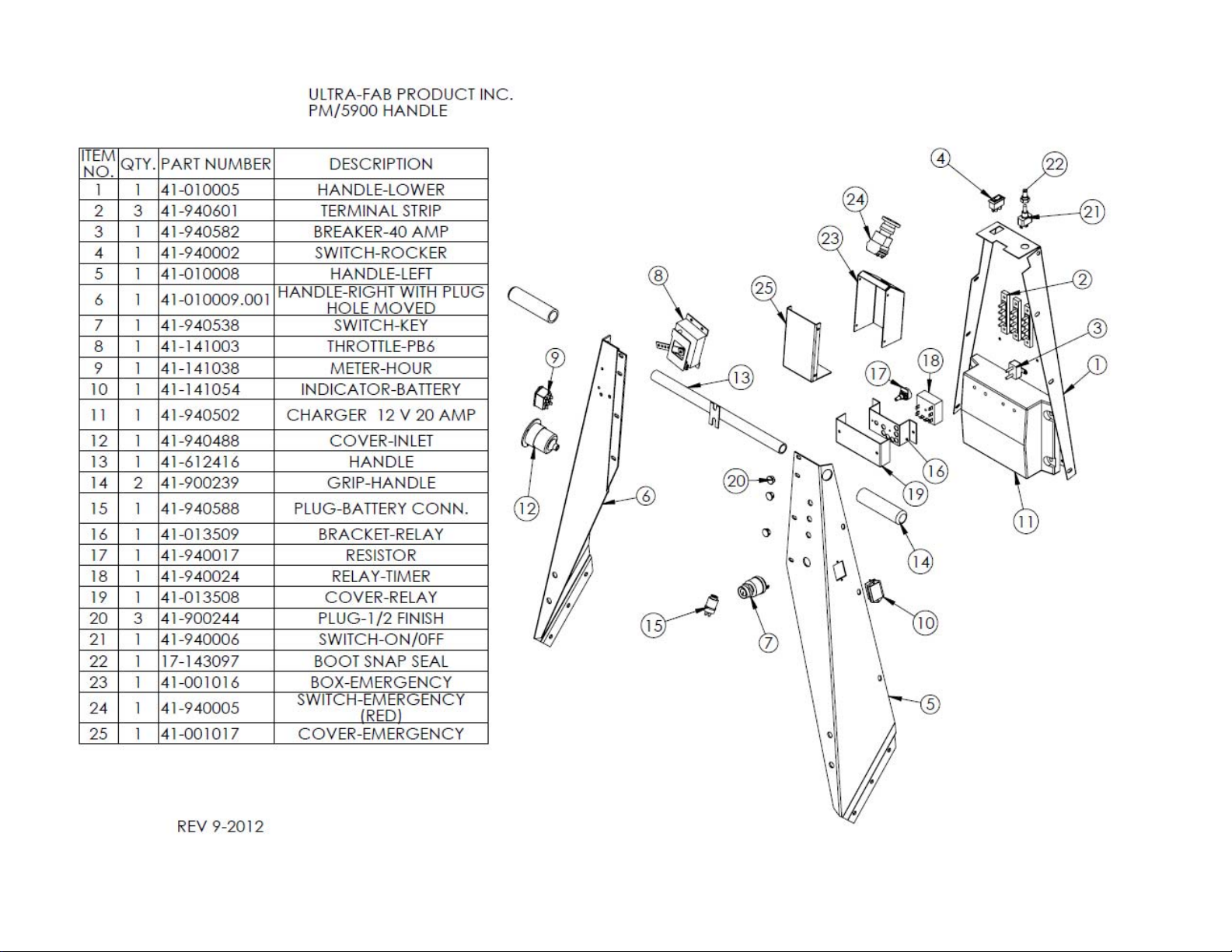

KEYED SWITCH

Your Powermover requires a key to turn the ignition switch on. Be sure to turn the key to the off

position when your Powermover is not in use.

VARIABLE SPEED CONTROL

The speed control is operated with the right index finger and has a one second delay built into it. When

you pull the speed control lever you will hear a click and experience a short delay before the

Powermover begins to move. Do not pull the speed control lever to its maximum position until you get

the feel of how the Powermover accelerates. The procedure should be slow at first and then faster as

you become more experienced. Caution: Before pulling the speed control lever be sure the

forward/reverse switch is in the desired position.

FORWARD/REVERSE SWITCH

This is a simple rocker type switch and can be operated by using your right thumb. Caution: Make

sure you have selected the desired direction before activating the switch.

HYDRAULIC SWITCH (OPTIONAL)

Your Powermover may be equipped with a hydraulic lift. If it has a lift there is a switch on the handle to

control the up/down motion of the mast. Pull back on the switch to raise the mast and push forward on

the switch to lower the mast. Note: The switch is spring-loaded and requires you to hold the switch on

until the mast reaches the desired height.

BRAKE CONTROL (OPTIONAL)

If your Powermover has the seven way connector mounted on the top front of the Powermover, then

it has a push button switch on the handle to activate the receptacle. This button is used to activate the

trailer brakes if they are plugged into the standard seven way connector allowing the trailer brakes to

stop the load.

MAGNETIC BRAKING ¾ HP PERMANENT MAGNETIC MOTOR (Standard PM5700)

The ¾ hp motor, with its standard hookup, will brake the Powermover, when the speed control is

released with a three second delay. There is an emergency button that allows the unit to brake

immediately when pushed.

MAGNETIC BRAKING 2HP CONTINUOUS DUTY MOTOR (PM 5900)

The continuous duty motor, with its standard hookup, will brake the Powermover, when the speed

control is released with a three second delay. There is an emergency button that allows the unit to brake

immediately when pushed.

CHARGING SYSTEM

Your Powermover is equipped with a built-in-charging system. It requires a standard three prong

extension cord to use the battery charger. The male end plugs in to a standard 120 volt outlet and the

female end plugs into the receptacle located on the right of your Powermover. When your Powermover

is not in use you should leave the charger plugged in. When you first plug your charger in you will see a

red light come on. This is normal. When the batteries are near a full charge you will see a red and a

green light. When the red light goes out and only the green light is on you have reached a full charge. It

will not damage the batteries to leave the charger plugged in. You also have a battery level indicator

that will show the amount of charge left in your battery. It is located on the handle of your Powermover.