2

INTRODUCTION

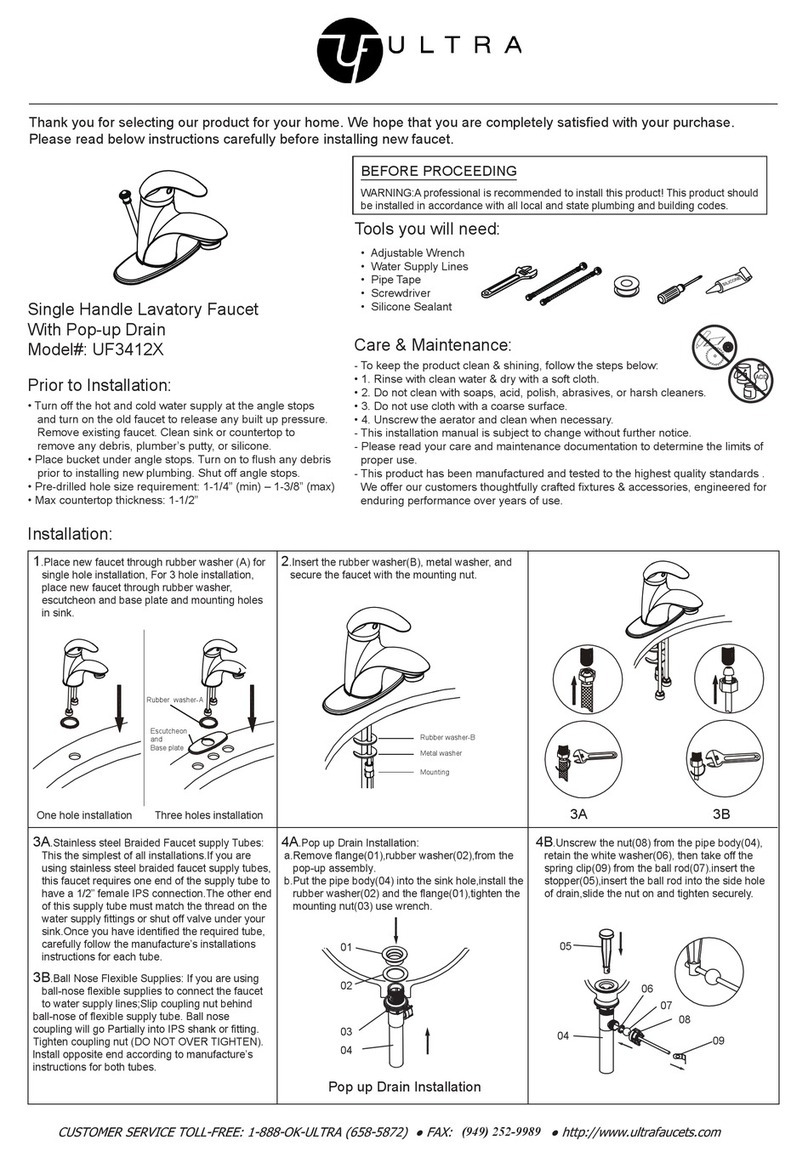

This owner’s guide shows you how to install, maintain and generally get the most from

your sequential thermostatic shower valve.

WE RECOMMEND INSTALLATION BY

A QUALIFIED PLUMBER ONLY

TECHNICAL DATA

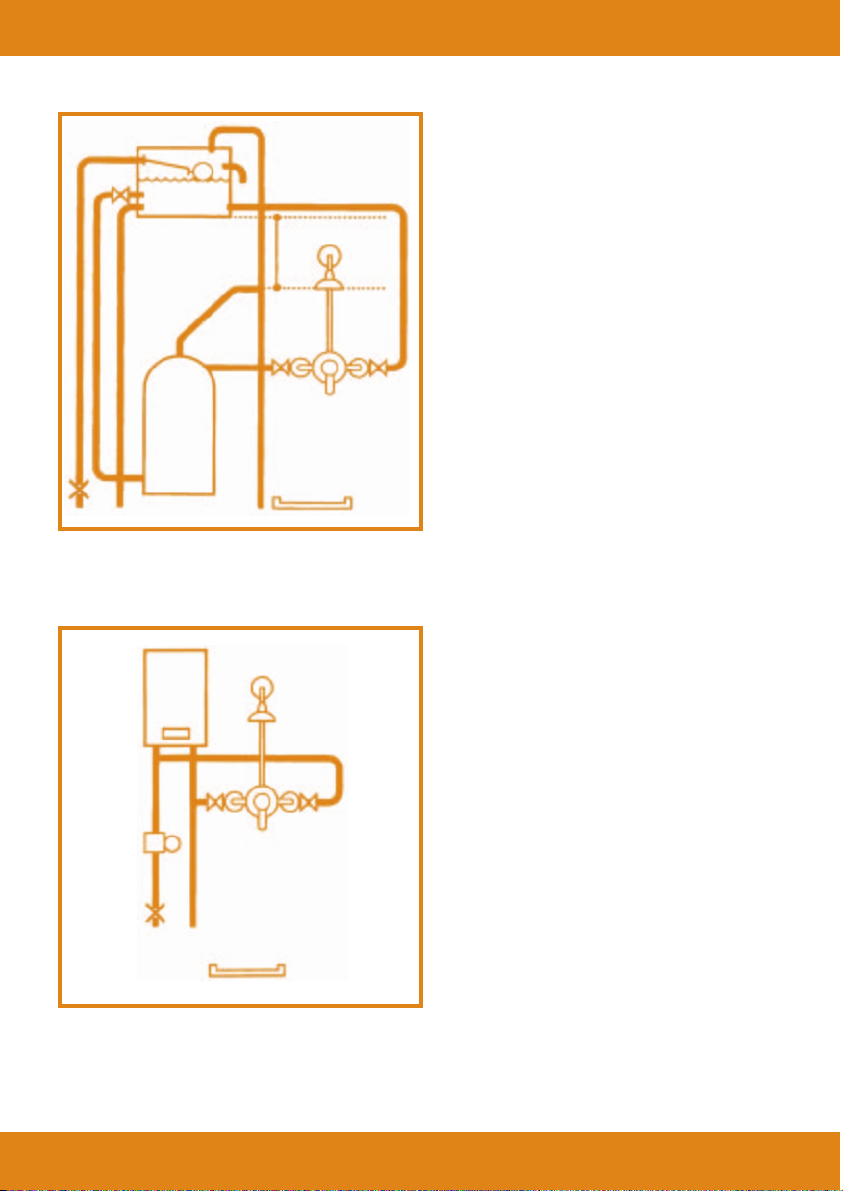

This shower valve is suitable for use on all common types of plumbing systems including gravity, pumped

and fully modulating combination boilers and high pressure unvented systems.

Minimum operating pressure 0.1 bar.

Maximum operating pressure 4 bar.

Important note: At static water pressures above 4 bar, you must install a pressure reducing valve in the mains

supply pipe set at 3 bar for optimum results.

As a guide to see if your water pressure is too high simply measure how many pints of water you get from your

kitchen tap, with the cold side fully turned on. If you exceed 8 pints (or equivalent) in 30 seconds then you require

a pressure reducing valve fitting to your incoming mains supply pipe immediately after stopcock to premises

.

TEST DATA

These valves have been pressure tested to 15bar.

Before proceeding, please note:

1. The valve must be installed in compliance with local water authority byelaws and water

supply byelaws.

2. Read all the instruction manual before proceeding

3. Only begin the installation when you have all the necessary tools ready.

4. Please check that all the components are in the shower valve box.

AFTERCARE

When installing or using tolls, extra care must be taken to avoid damaging the finish or the fitting. To

maintain the appearance of this fitting, please ensure it is cleaned regularly using a clean soft damp cloth

only. Abrasive cleaners or detergents must not be used as they may cause surface deterioration.

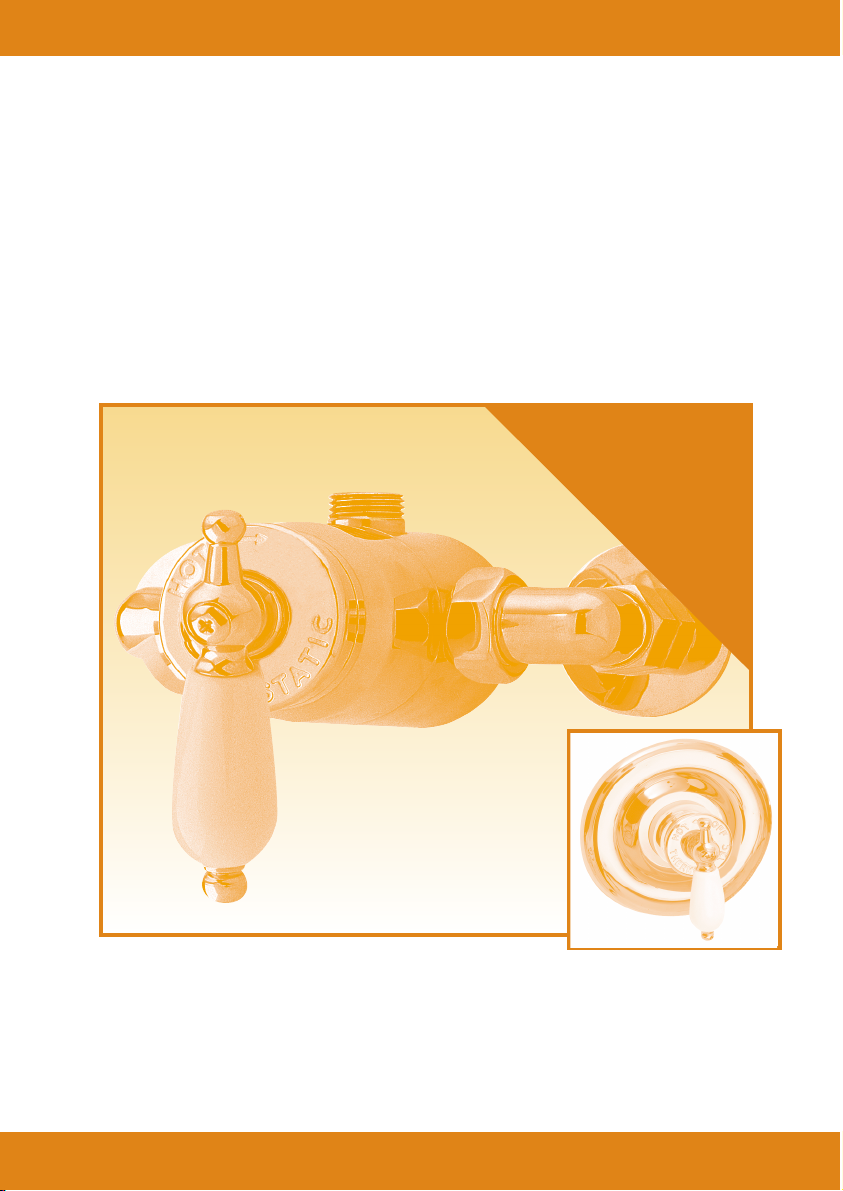

SEQUENTIAL THERMOSTATIC SHOWER VALVES

This shower valve uses a wax thermostatic cartridge to maintain a constant shower temperature. The valve is

anti-scald and will automatically shut down the shower if the cold water supply fails. The single sequential

control allows the shower to turn on at fully cold, further anti-clockwise movement will gradually blend in the

hot water up to a maximum showering temperature of a factory preset 43C when the shower valve is fully

opened (this may vary with certain installations).

You must ensure that the temperature of your hot water is at least 60°C for your shower to

reach the maximum temperature.

S

EQUENTIAL

T

HERMOSTATIC

S

HOWER

V

ALVE

Owner’s

Guide