SK00-9662-EQ-003-00

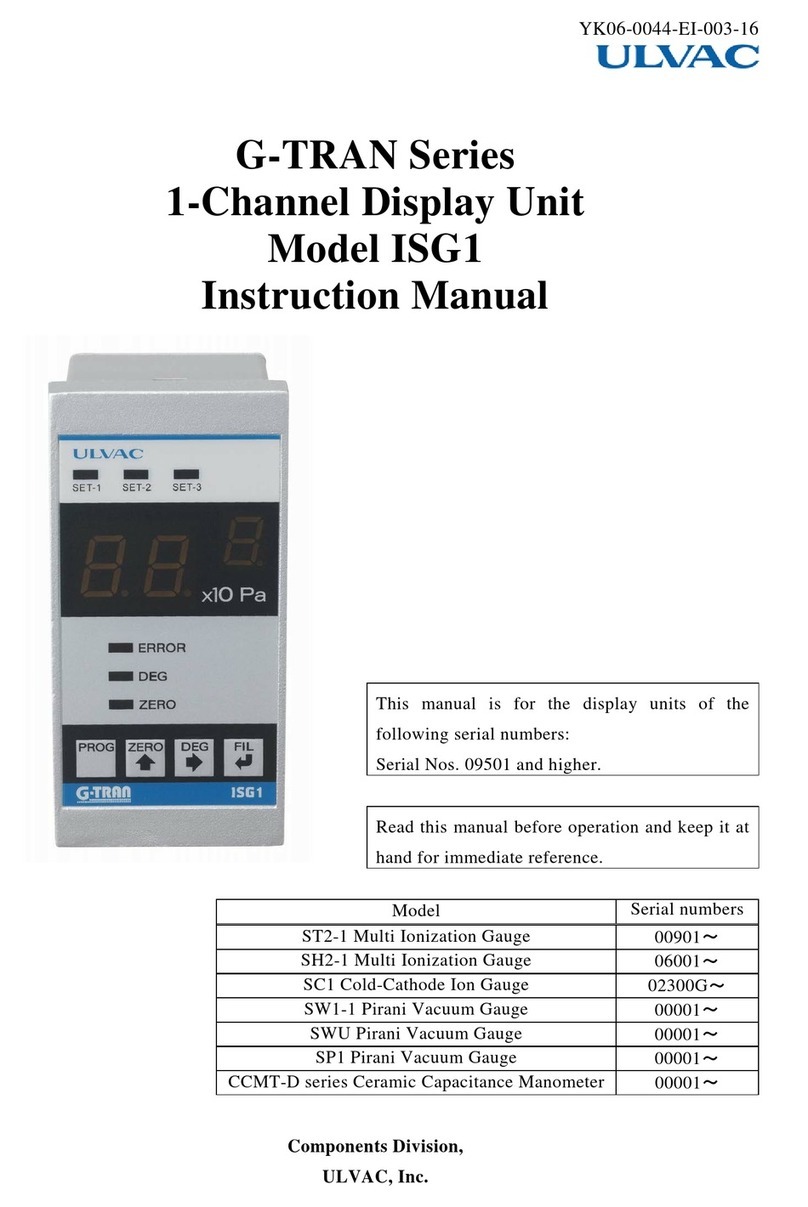

G-TRAN SERIES

Pirani Vacuum gauge SWU10-R

Quick Manual

Introduction

This quick manual is for quick check of operation and display of the product.

Please refer to instruction manual in advance for detailed information about

operation, precautions and safety for proper use. Available for download from

ULVAC website. https://showcase.ulvac.co.jp/ja

This manual is for the following gauges. Serial Nos. 00001 and higher.

Part Names and Functions

SWU10-R controller section

①

② ③

①

I/O connector

The I/O connector for the power supply and signals

(RJ-45 jack connector).

②

clamp The clamp to hold and lock the gauge head.

③

Mating screws (M3) for the clamp hood.

SWU10-R I/O connector

SH2/ST2

Multi-ionization gauge

SWU10-R LED

①POWER/ERROR LED

On : Operating normally

Flashing: Error such as a filament

break, this unit is malfunctioning

Off : Power off, this unit or the

SH2 / ST2 is malfunctioning

Attaching the Product

Loosen the clamp locking screws to loosen the clamp. Then attach the gauge

head with the procedure below.

①Align the pins for the gauge head and push it all the way in

②Clamp the gauge head with the clamp

③Tighten the locking screws to secure the gauge head

Handling Precautions

3.1. Precautions related to usage

・ Secure cables as much as possible so that force is not applied to cable

connectors.

・ Firmly insert the RJ-45 connector.

・ To perform accurate pressure measurements, allow the pressure sensor to

age for 20 minutes or longer before measuring.

3.2. Attaching this unit

・ Attach this unit so that the gauge head attachment opening surface is

parallel to the gas flow. In particular, ensure that gases do not enter the

gauge head interior like a beam.

・ As much as possible, attach the gauge head so the filament is vertical to

the force of gravity.

・ The Pirani vacuum gauge head filament is thin at φ25 µm, so avoid use in

a location with a large amount of vibration as much as possible. The

biggest cause of filament breaks is from mechanical shock, so use caution

regarding the installation location and handling.

・ Use an O-ring to attach the gauge head that releases little gas. There is a

risk of measurement errors or the gauge head lifespan will decrease if

materials that release a large quantity of gas, such as rubber tubes or grease,

are used in the gauge head connection.

Gas flow direction

Checking the Filament and Temperature Sensor for

Burnout

Filament

Approx. 5 Ω

Temperature

sensor

Approx. 1.1

kΩ

The diagram below shows the connection of the Pirani sensor head filament. Check

continuity referring to this diagram. The resistance of the filament is about 5Ω under

atmospheric pressure and that of the temperature sensor is about 1.1 kΩunder

atmospheric pressure.

Note)Beware of over-current

If the filament or temperature sensor is energized with an over-current of 2 mA or

more, it may burn out. Be alert to the current value on the measuring instrument.

Also measure the resistance value under atmospheric pressure because in vacuum, the

filament and other components are heated and an accurate resistance value cannot be

measured.

Specifications

Name Pirani vacuum gauge measuring unit

Model SWU10-R

Measurement principle Pirani vacuum gauge that uses thermal

conduction by gas molecule

Number of gauge heads 1pc

Applicable gauge head SWP-16,SWP-R1/8,SWP-P18,SWP-P15, SWP-

25, SWP-CF16, SWP-1S

Measurement pressure range

5.0×10

to 1.0×10

Pa

Output pressure range 5.0×10

to 1.0×10

Pa

Accuracy (N2) 1×10

Pa to 1×10

Pa: ±10%

5×10-2Pa to 1×10-1Pa: ±20%

1×10+4Pa to 1×10+5Pa: ±20%

Repeatability 1×10

Pa to 1×10

Pa: ± 2%

Sampling time 50 ms, 5x moving average

Measurement value output Output by serial communication

LED display POWER/ERROR LED

Gauge head material Filament:Pt

Other:SUS304, FeNiCo, Ni, Au, Glass, Ceramic

Gauge head withstand

pressure

2×10

Pa(abs)

*Take the withstand pressure for flanges,

clamps, and other components into account

separately.

Operating temperature range

10 to 40℃

Operating humidity range 15 to 85% RH (no condensation)

Storage temperature -20 to 65℃(no condensation)

Bake out 150℃(without electronics unit)

Mounting position Free

IP protection class IP30

Power supply voltage 5VDC±5%

I/O connector RJ-45 jack connector

Gauge head internal volume Pirani vacuum gauge head(SWP-16): 7.3cm3

Weight Controller: Approx. 38 g,

External dimensions φ40×51 (controller section only)

Standard Accessories

Quick manual(This paper) 1copy

Trouble shooting

Bad electrical wiring is a major cause of this unit malfunctions. If this unit

behaves in a manner you find unusual, first check the wiring between this unit and

the SH2/ST2. Refer to the SH2/ST2 instruction manual as well.

off even though power is being supplied

Repair the wiring and check continuity

with a tester.

The power supply voltage to the

SH2/ST2 is not within the specified

range

Check the power supply voltage with a

tester.

This unit or the SH2/ST2 is

malfunctioning

Requires inspection and repairs at

ULVAC.

The POWER/ERROR LED is flashing or the SH2

error signal

Filament break or short circuit

Measure filament continuity and

isolation between each pin and the case.

⇒Replace the gauge head when there is

a problem.

The gauge head is not attached

malfunctioning

Requires inspection and repairs at

ULVAC.

Pressure does not reach 5×10-2 Pa or lower even when pumping to vacuum

The actual pressure is not 5×10

Pa

or lower

Check the pressure with an ionization

vacuum gauge.

Room temperature, gas temperature

is different when measuring

This is normal. Measurements are

temperature dependent.

malfunctioning

Requires inspection and repairs at

ULVAC.

The pressure reading does not show a steady value.

The pressure is actually fluctuating

vibrations and fluctuating

Suppress vibrations as much as possible.

Measurements are affected by the

principle of the Pirani vacuum gauge.

Attached to a location with a gas

flow

Attach this unit to a location with no gas

flow.

Measurements are affected by the

principle of the Pirani vacuum gauge.

The environmental temperature is

fluctuating

Wait for the environmental temperature

to stabilize.

Measurements are affected by the

principle of the Pirani vacuum gauge.

temperature gases are flowing in

Implement corrective action such as

attaching the gauge head to a location

unaffected by gas temperature.

Measurements are affected by the

principle of the Pirani vacuum gauge.

Dirty gauge head interior

Affected by moisture and dirt

Attach the gauge head to a location as

unaffected as possible

Influenced by heat of vaporization by

gradual vaporization.

There is a leak in the gauge head

or the area where the gauge head is

attached

Gauge head leak ⇒Replace the gauge

head

Other leaks ⇒Stop the leak

Bad cable contact, increased wire

resistance

Check the cable connection and

resistance.

electromagnetic induction.

(By external noise)

Change the cable installation location.

Use this unit with the device generating

the noise turned off.

Review how the cables are installed

Examine separate measures for noise

18