Three-phase squirrel cage induction motors in flameproof enclosure type ASA and E2-ASA

frame size 63 – 355

The motors can be fed from PWM frequency converters (VACON or

similar) according to the torque/speed characteristic M=f(Hz) given in

Annex 7 For that application the motors are equipped with direct

temperature control using the embedded PTC sensors (130 °C

5 °C).

The thermistors must be connected to a thermistor circuit relay functioning

independently of any measurement or control devices required for

operation and that is dedicated to reliably trip off the supply of the motor

according to the requirements of the “Essential Health and Safety

Requirements” in Annex II, item 1.5.1 of the ATEX Directive 94/9/EC.

Emergency stop controls of safety devices must be fitted with restart

lockouts. A new start command may take effect on normal operation only

after the restart lockouts have been intentionally reset.

2.2 The motors are manufactured using insulation materials of class F

The windings insulating resistance should not be lower than:

o20 MOhm in cold condition

o3 MOhm in warm condition

2.3 The motors rated duty is the continuous duty S1, according to EN

60034 –1 par. 4.2.1. but frequency converter feeding according par.

2.1 is also allowed. The motors fed from frequency converters can

operate under S9 duty, according to EN 60034 –1 par. 4.2.9.

2.4 The normal degree of protection according to EN 60529 of the

motors operating in Zone 1 is IP55. On request, motors having IP

56, IP 65 or IP 66 protection degree are also available.

2.4.1 The protection degree of the motors operating in Zone 21 is IP65; on

request, IP66 protection degree is also available.

2.5 The method of cooling of the motors according to EN 60034 –6 is IC

411.

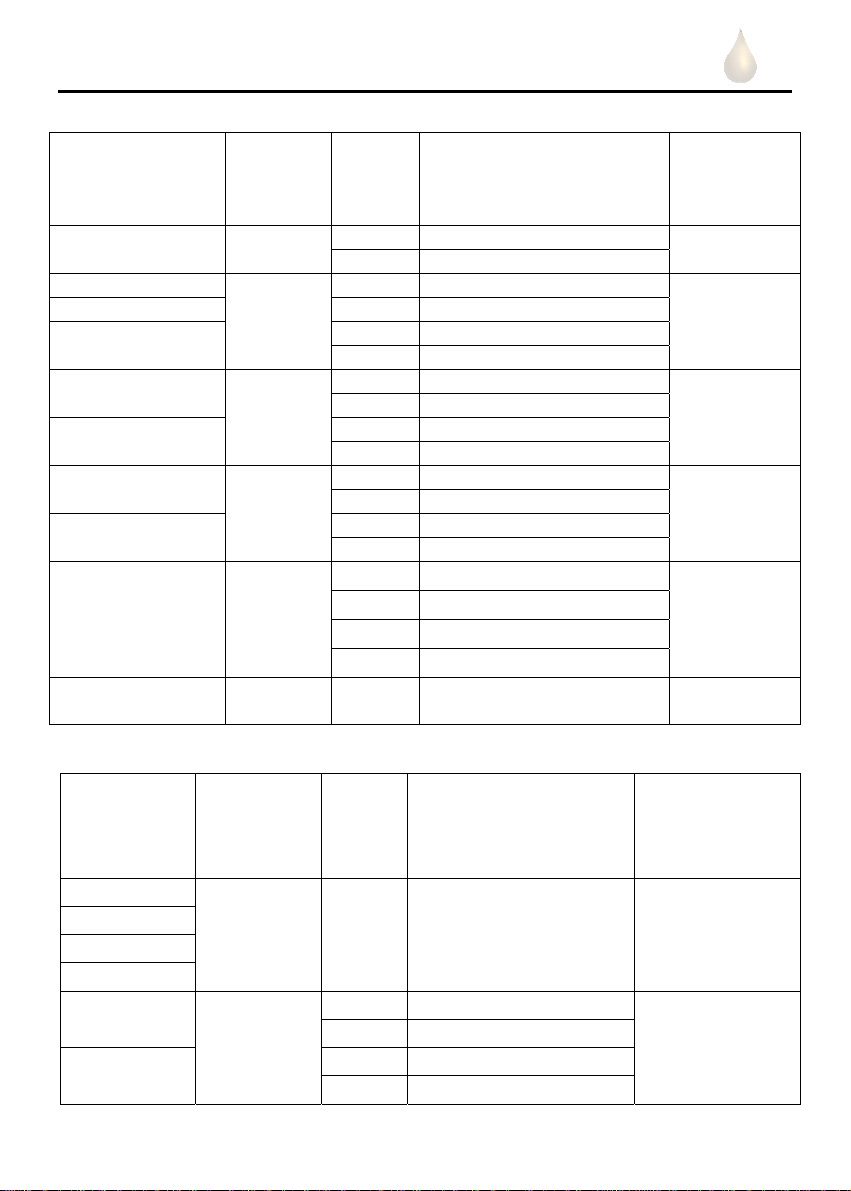

2.6 The motors could be manufactured in the following mounting

arrangements:

IM 1001, IM 1002, IM 2001, IM 3001, IM 1011, IM 3011 for the

frame sizes 80-355 and IM 3601 only for the frame sizes 63 -160,

according to EN 60034-7

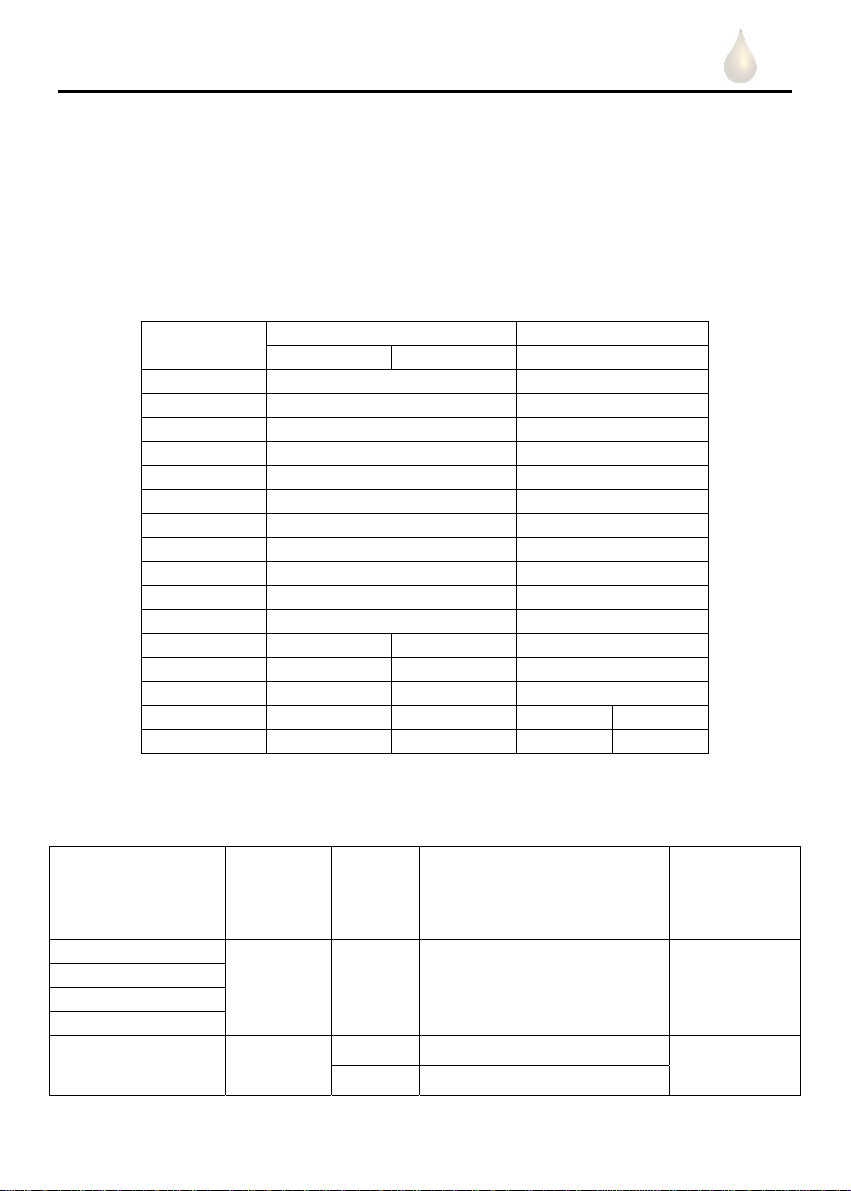

The overall and mounting dimensions are indicated in:

- Annex 3 - Tables 5.1 and 5.2 for the constructive types IM 1001

- Annex 3 - Tables 6.1 and 6.2 for the constructive types IM 3001