Full product range & more information: www.lumenalights.com

INSTALLATION:

IMPORTANT: Cable should be laid inside armoured conduit to protect from water-logging, chemicals found in soil and

damage. If buried, it should be buried to at least 0.5m below ground to reduce damage risk. If this method is not used, cable

warranty will be void.

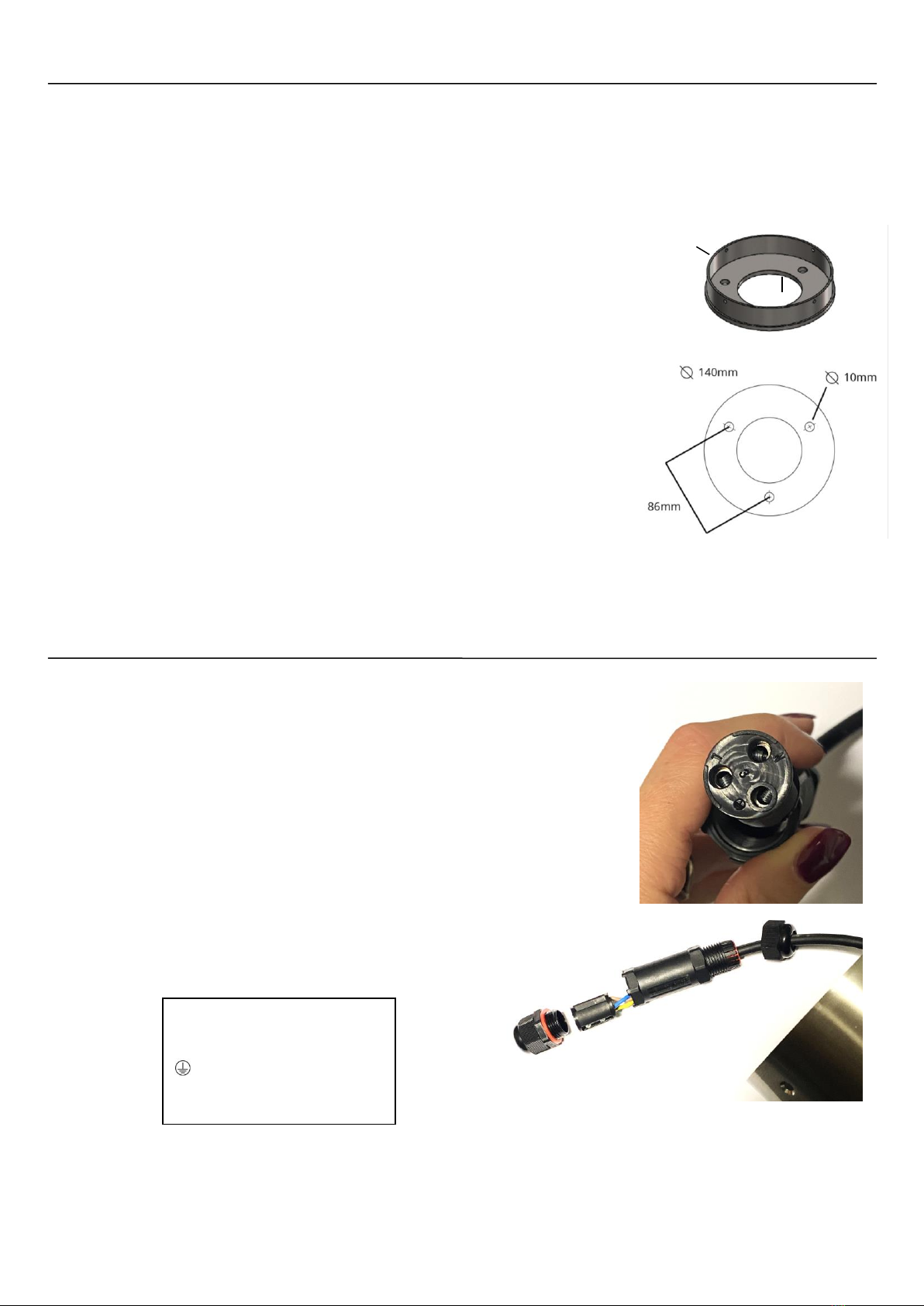

This bollard should be securely fixed to a solid surface. It should not be installed directly into soil. For fixing to a new concrete base, root

fixing bolts will be required (sold separately). Anchor bolts have been supplied for fixing into existing paving slabs, concrete or similar.

Alternatively, heavy duty fixing screws / bolts can be used. Ensure they are stainless steel or zinc plated to avoid corrosion.

1. Remove 4 x socket screws at the foot of the bollard tube with a 2.5mm socket wrench

(supplied) and lift the bollard body from the mounting base.

2. Position bollard base in the desired location, ensuring the supply cable is central to the

base with plenty of slack for ease of wiring (approx. 300mm recommended) and the PIR

will be facing in the correct direction (in line with one of the 4 holes on the base).

3. Secure the base in place with the correct fixings for your surface (3 x heavy duty anchor

bolts have been supplied for optional use).

4. Lay the bollard on a soft covering, e.g. blanket, beside the base to expose the in line

connector and wire the bollard to the power supply as per below (see WIRING).

5. Reposition the tube back over the bollard base and secure in place with the 4x socket

screws removed in step ‘1’, ensuring the PIR sensor faces the correct direction.

6. Remove 4 x M4 socket screws from bollard head using a 2.5mm socket wrench (supplied).

7. Insert E27 light bulb (see LAMP INSTALLATION / REPLACEMENT below).

8. Carefully place the head over the bulb, being careful not to knock or damage the bulb, and

check that the holes are aligned with those at the top of the tube.

9. Replace head and secure in place with the screws removed in step ‘6’, ensuring the clear

rubber o-rings are still in position. Alternate the tightening of screws to prevent

misalignment.

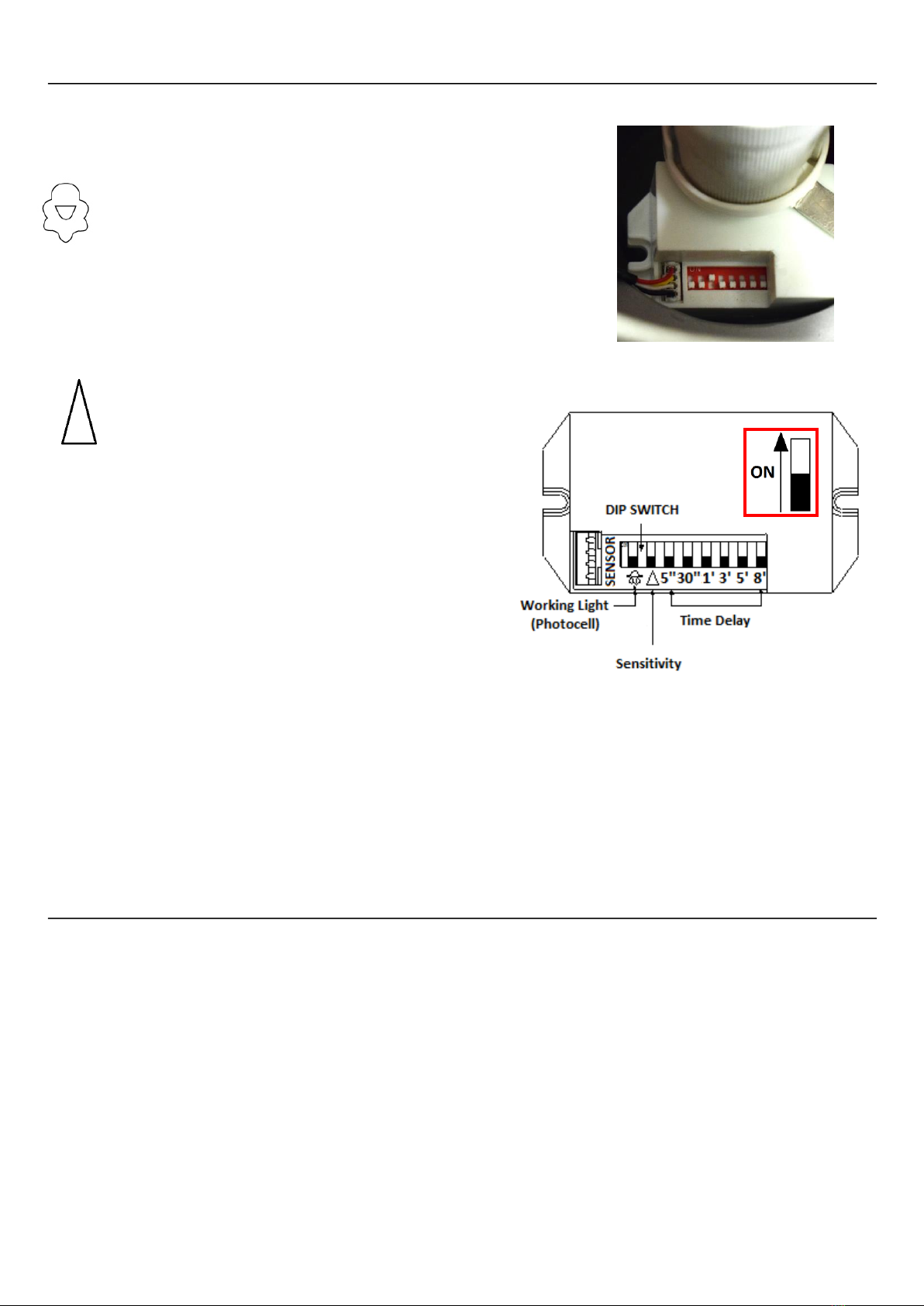

10. Test the bollard. If the photocell setting is set to “ON”, the sensor will need to be mostly

covered to enable daytime testing. Settings can be adjusted via the dipswitch (see PIR SETTINGS below).

IMPORTANT: Do not overtighten the surface mount base as this could lead to fracture. Do not use high power tools.

WIRING:

Always ensure the power supply is turned off prior to wiring

The in-line connector supplied can be used with 3 core cable up to 1.5mm² (10mm diameter). To

wire:

1. Unscrew and remove the male end cap & nut (anti-clockwise) completely to expose the

connector block.

2. Unscrew the female end cable at the cable end and pass over the cable slightly to allow

movement of the connector.

3. Push the cable further inside the in-line connection to fully reveal the connector block

4. Pass the mains power feed through the fully removed end cap and wire each inner cable

to the correct terminal, securing in place with the terminal screw. Ensure the screw

clamps the conductor, not the inner sheath, and that all cables are secure with no loose

conductor strands (see terminals info).

5. Push the connector block back inside the in-line connector casing fully, ensuring the red

rubber grommet has not dislodged at the male end of the casing,

and refasten the female end cap tightly.

6. Refasten the male end cap & nut fully to clamp the power cable.

Ensure the red o-ring is in place before fastening.

NOTE: At the male end cap, the nut fastens to the casing, the cap clamps around the cable. Ensure both are secure.