POWER INDICATOR and Low Battery “lock-out” function

A 5 LED battery state indicator (clock) is fitted in the PowerTug

4 green LEDs indicate full charge. A reduced number of LEDs lit through to RED indicate progressive discharge.

Note: An optionally fitted “lock out “ signal from this indicator to the control processor will prevent machine

operation if the batteries are in an excessively discharged state.

This indicator should illuminate once the key switch is turned on. PowerTug can be used while green indication is

shown.

Note: The electronic control unit fitted to PowerTug contains a power saving timer. If the power switch has been

turned on, but the machine has not been used for 25 minutes or more the circuit will shut down. To use the

machine again the keyswitch must be turned OFF then ON again.

The keyswitch should be turned to the “off” position if machine is “in use” but with no demand.

ANTI-CRUSHING SAFETY FEATURE: (“BELLY SWITCH”)

A switch pad is fitted in the handlebar assembly facing the operator. Should the machine be reversing towards

the operator, gentle depression of this switch will immediately cause PowerTug to switch to a forward motion,

and stop when the (switch) pressure is removed.

This is to prevent the operator being accidentally crushed by PowerTug and the load while reversing.

AUDIBLE ALERT

The PowerTug is fitted with an “automotive type” electric horn for warning of approach. The horn switch is placed

at the centre/top of the handlebar assembly. Press to sound.

ANTI - RUNAWAY FEATURE

The motor controller fitted to PowerTug is able to detect movement due to the “Back EMF” created by the dc

motor. Should the voltage increase to a certain level the controller will apply an opposite voltage to stop the

movement.

This occurs even when the power switch is OFF (or no batteries are fitted)

FAULTS

In the event of the battery indicator not illuminating when the batteries are known to be in a “good” condition,

check the fuses.

For any other fault condition consult the supplier.

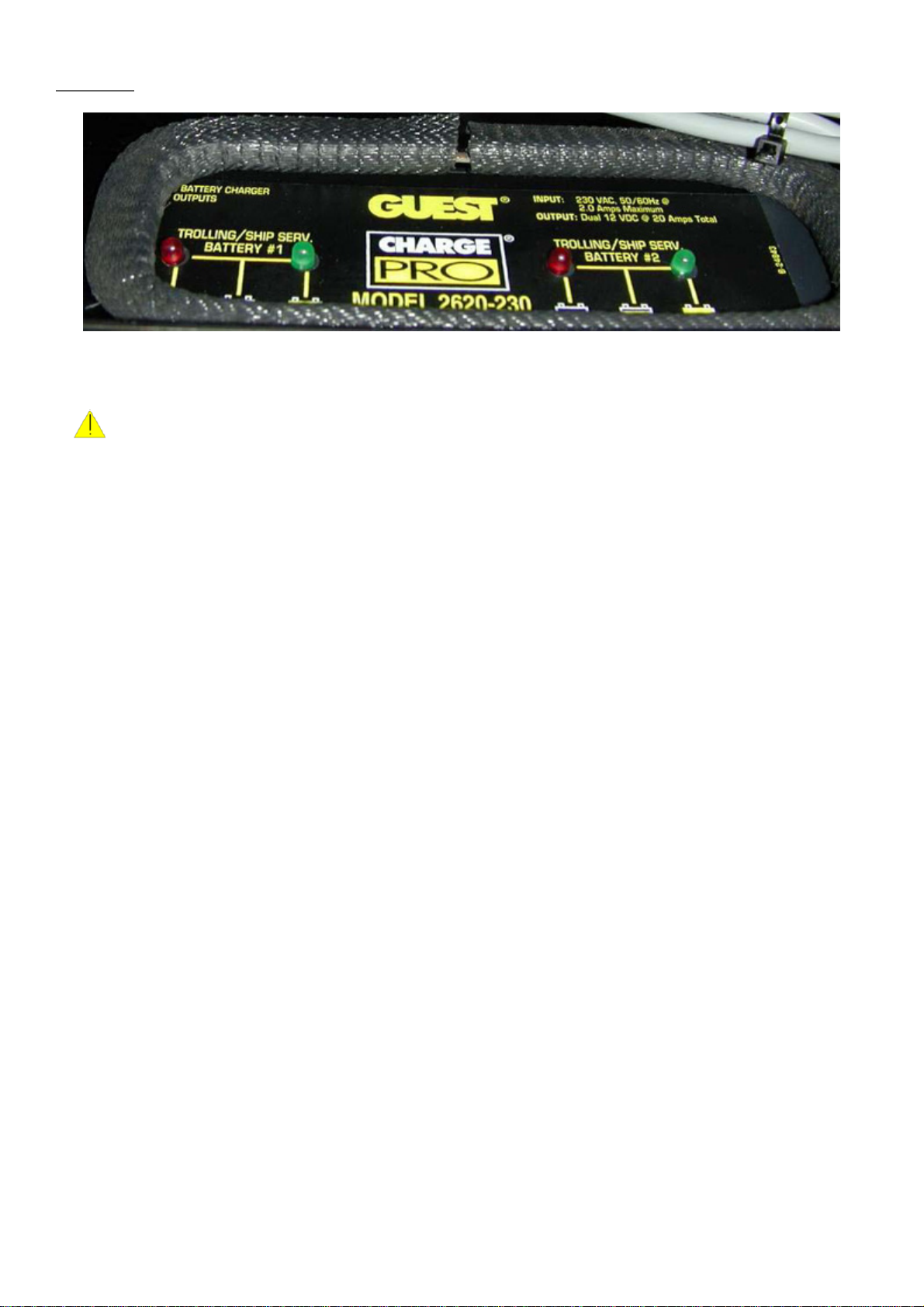

BATTERY CHARGING

The PowerTug is fitted with an EU Compliant Guest model 220 24V output battery charger intended for 230V ac;

50/60Hz operation. Charging this unit in any manner other than by the charger provided may result in serious

damage.

For the UK market, the charger is supplied fitted with a UK 3 pin (BS1368A) plug which has a 3 Amp fuse

installed. Replace fuse or damaged plug only with the same type and rating.

(In other countries local electrical regulations apply.)

During charging the mains lead to the charger will be connected to the socket at the rear of the machine. Once

the mains lead is connected to the machine and the lead is connected to a 230V power source then the machine

will not operate.

Batteries supplied with PowerTug are of a heavy-duty sealed valve regulated type. Life and performance

depends upon keeping them charged at all times. They should not be stored in a discharged condition.