6

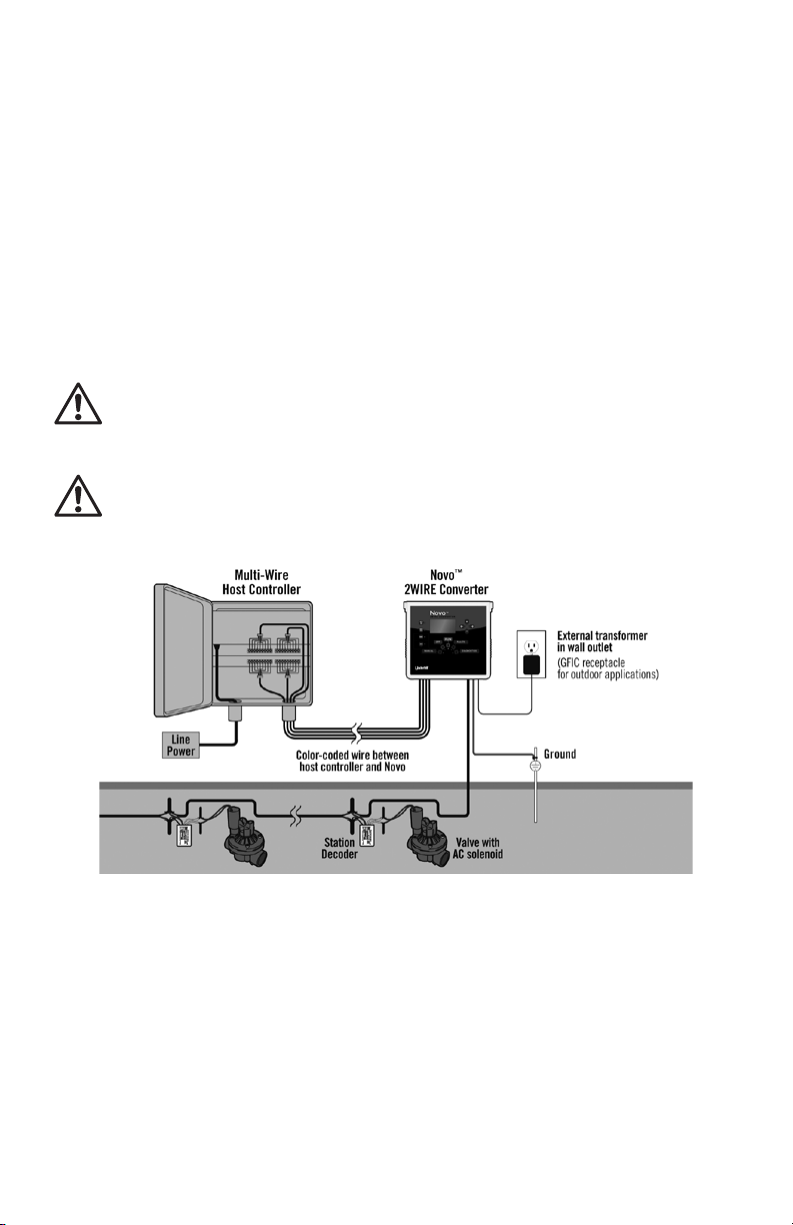

Table 1 below provides the wire color-coding on each of the four terminal blocks

for the Novo. Confirm these wires are connected to a host controller’s station

outputs accordingly.

Table 1

NOVO STATION WIRE TERMINATIONS

Terminal Block Location Terminal Block Location

Lower Left Upper Left

Term

Blk

Sta

#

Sender

Wire Color

Term

Blk

Sta

#

Sender

Wire Color

JP8/9 Com White JP9/9 Com White

JP8/8 8 Violet JP9/8 16 Violet

JP8/7 7 Blue JP9/7 15 Blue

JP8/6 6 Green JP9/6 14 Green

JP8/5 5 Yellow JP9/5 13 Yellow

JP8/4 4 Orange JP9/4 12 Orange

JP8/3 3 Red JP9/3 11 Red

JP8/2 2 Brown JP9/2 10 Brown

JP8/1 1 Black JP9/1 9 Black

Terminal Block Location Terminal Block Location

Lower Right Upper Right

Term

Blk

Sta

#

Sender

Wire Color

Term

Blk

Sta

#

Sender

Wire Color

JP11/9 Com White JP12/9 Com White

JP11/8 24 Violet JP12/8 32 Violet

JP11/7 23 Blue JP12/7 31 Blue

JP11/6 22 Green JP12/6 30 Green

JP11/5 21 Yellow JP12/5 29 Yellow

JP11/4 20 Orange JP12/4 28 Orange

JP11/3 19 Red JP12/3 27 Red

JP11/2 18 Brown JP12/2 26 Brown

JP11/1 17 Black JP12/1 25 Black

Zip-tie the multi-conductor cable assemblies together. Strip back approximately

3/8-1/2” of wire insulation and terminate in the appropriate station outputs of the

host controller. Be certain to follow the same color-coding in the table above.

3. Connecting to the 2Wire Communication Path

Locate the three large, green-colored terminal blocks labeled L1, L2 and

“GND”. See Figure 6-1.

2WIRE INPUTS AND GROUND TERMINALS

Figure 6-1

Remove approximately 3/8” to ½”of wire insulation of the 2Wire communication

cable. Terminate a colored wire of the 2Wire path into the terminal labeled“L2”

and another colored wire into the terminal labeled “L1”.

4. Installing a Ground Wire (lightning protection) to a Ground Rod