1. SAFETY INSTRUCTIONS .....................................................................................................................................5

2. IMPORTANT INFORMATION .............................................................................................................................5

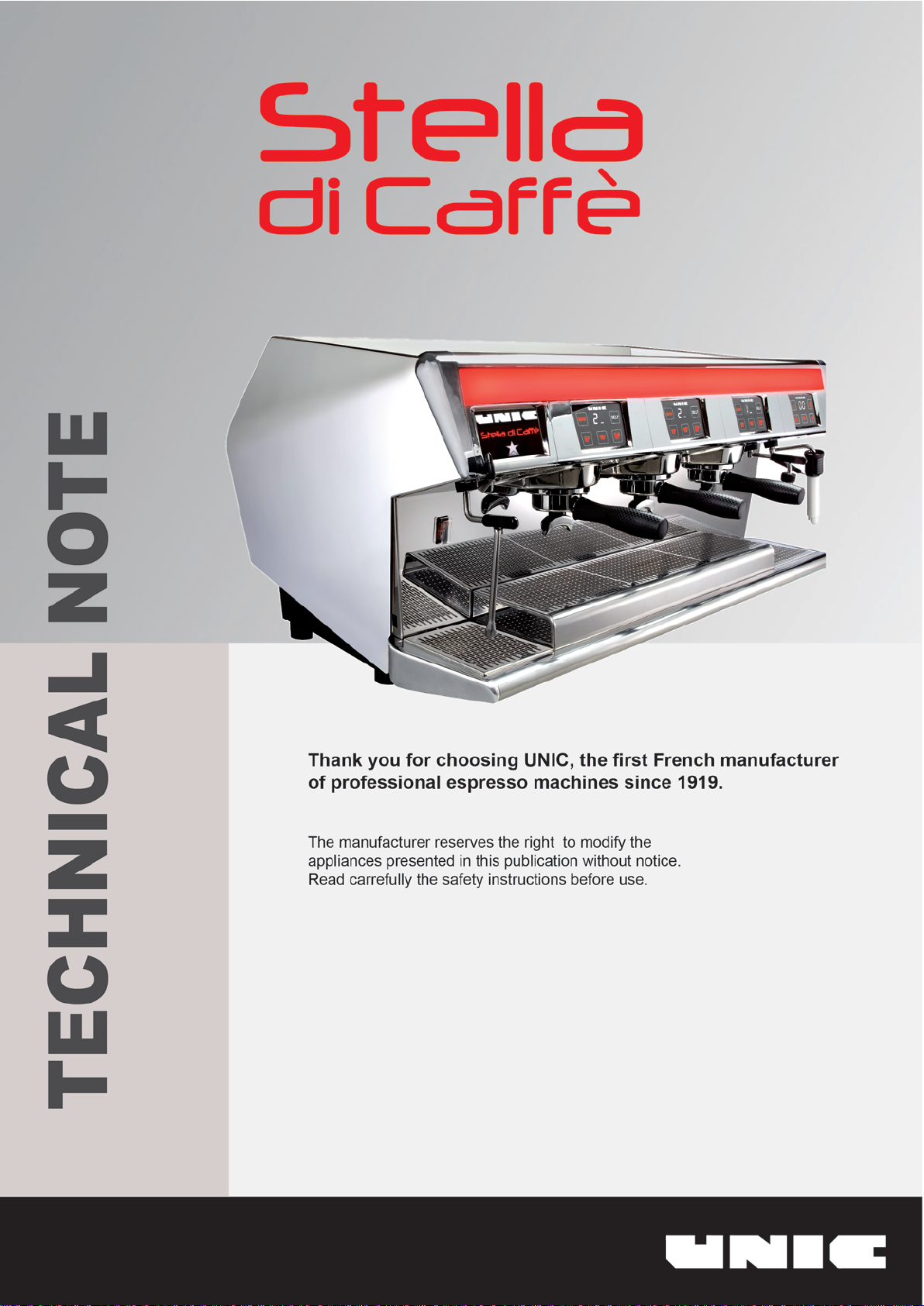

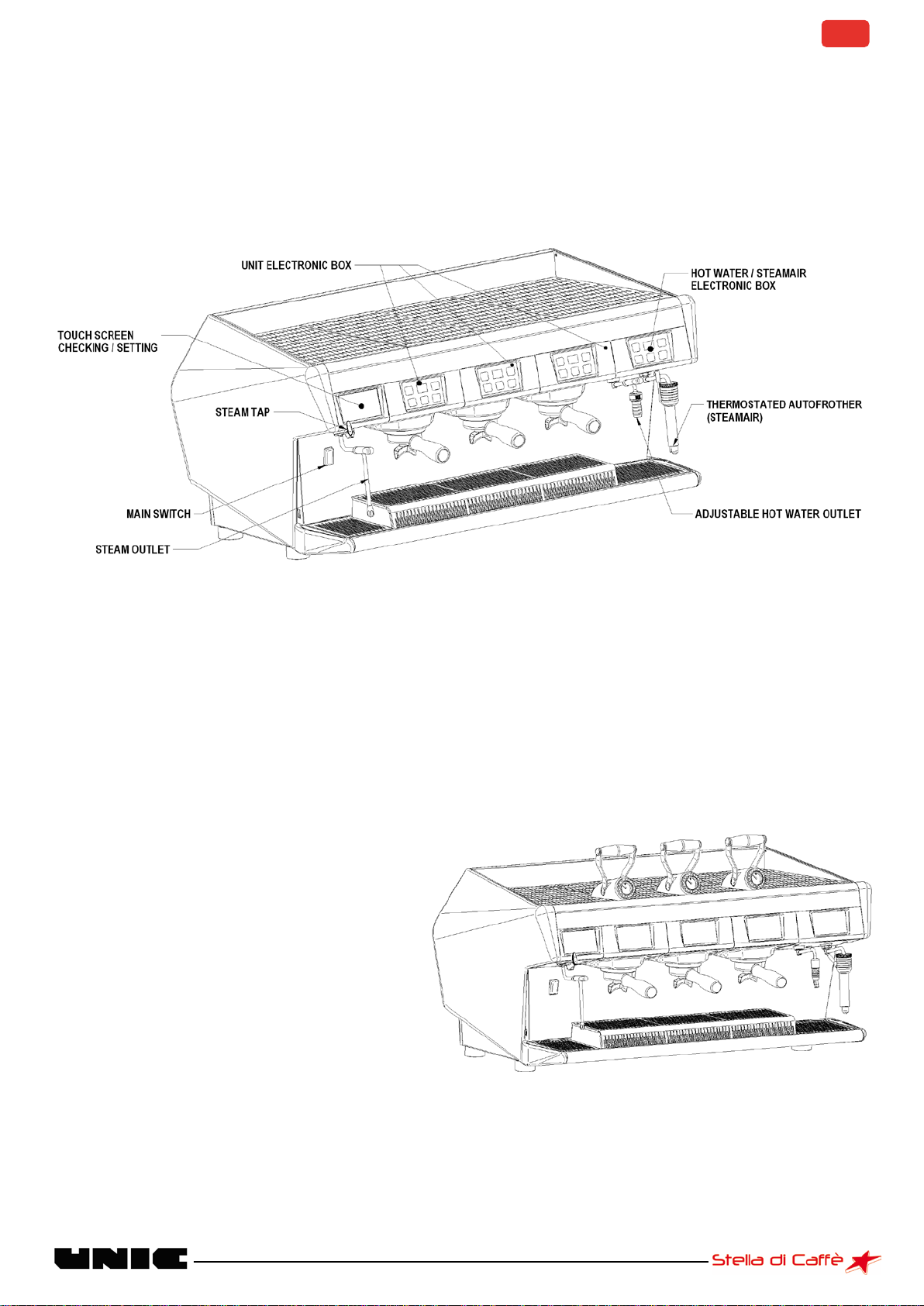

3. PRESENTATION OF THE STELLA DI CAFFE ..........................................................................................................6

STEAM

AIR

OPTION ................................................................................................................................................... 6

DUAL CONTROL OPTION (DCL)..................................................................................................................................... 6

4. FEATURES OF THE STELLA DI CAFFE ..................................................................................................................7

Unpacking the machine...................................................................................................................................... 7

Preparation of the location and installation of the machine ............................................................................. 7

5. COMMISSIONING .............................................................................................................................................7

WATER CONNECTION .................................................................................................................................................. 7

Water supply ...................................................................................................................................................... 7

Draining .............................................................................................................................................................. 8

ELECTRICAL CONNECTION ............................................................................................................................................. 8

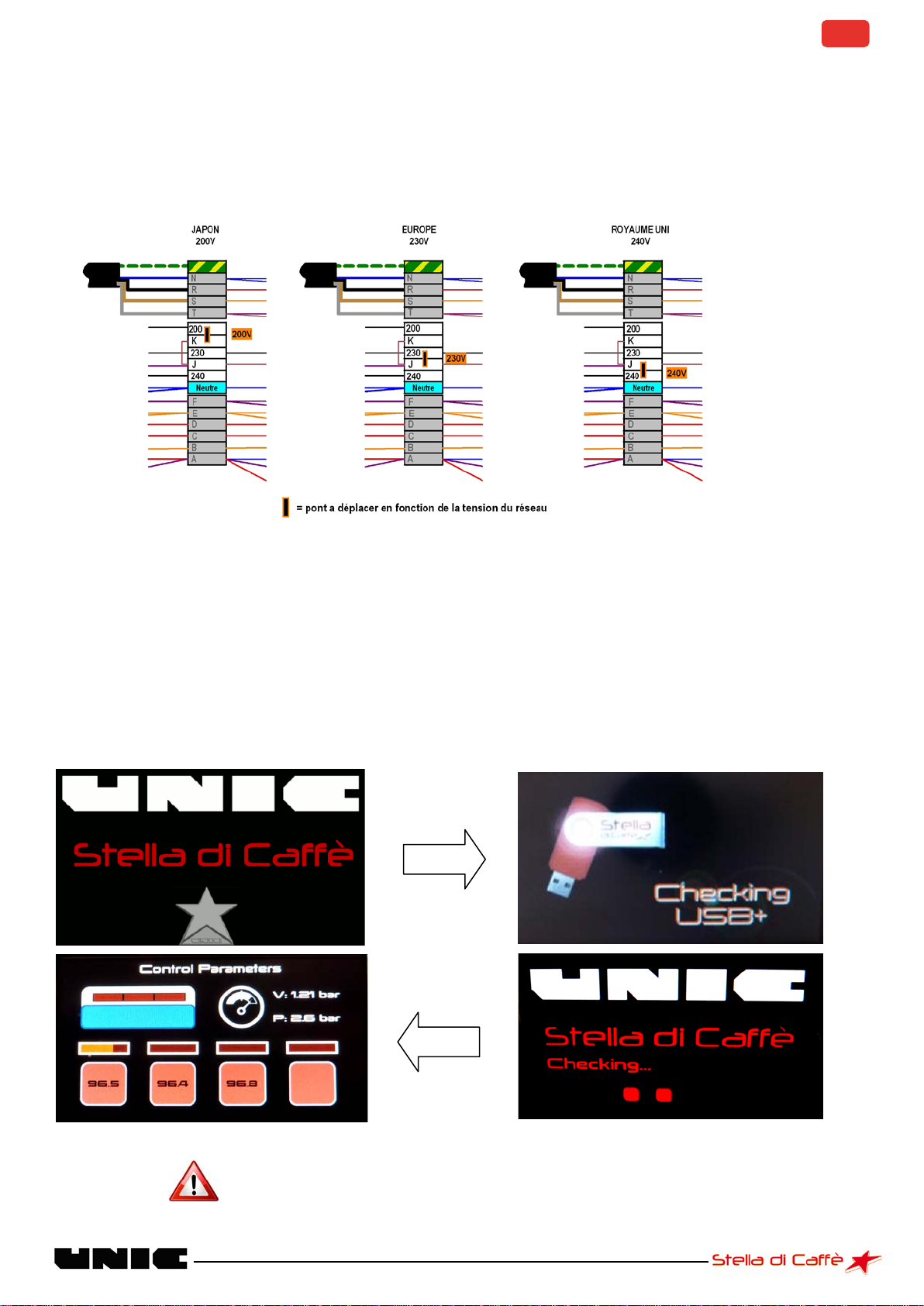

CHECK THE TOROIDAL TRANSFORMER IN RELATION TO THE MAINS VOLTAGE.......................................................................... 9

SWITCHING ON........................................................................................................................................................... 9

FILLING THE BOILERS.................................................................................................................................................. 10

Steam boiler...................................................................................................................................................... 10

Group boilers .................................................................................................................................................... 10

SWITCHING ON THE HEATING ...................................................................................................................................... 10

WHEN THE MACHINE IS WARMED UP ........................................................................................................................... 10

INSPECTION AND ADJUSTMENT ................................................................................................................................... 11

Adjusting the temperature ............................................................................................................................... 11

Adjusting the high pressure valve..................................................................................................................... 11

Adjusting the pump pressure............................................................................................................................ 12

Adjusting the water inlet solenoid valve .......................................................................................................... 12

6. INTERFACE .....................................................................................................................................................13

MENU DESCRIPTION .................................................................................................................................................. 13

BROWSING THE MENU ............................................................................................................................................... 14

SPECIAL MENU FUNCTIONS......................................................................................................................................... 14

7. PROGRAMMING.............................................................................................................................................15

CODES (LEVELS 1, 2AND 3)........................................................................................................................................ 15

To enable a level ............................................................................................................................................... 15

Change the password (level 1, 2 and 3)............................................................................................................ 15

SETTINGS................................................................................................................................................................. 16

Date & Time (levels 1, 2 and 3)......................................................................................................................... 16

Language (levels 1, 2 and 3) ............................................................................................................................. 16

Sound (levels 1, 2 and 3) ................................................................................................................................... 17

Wallpaper (levels 1, 2 and 3) ............................................................................................................................ 17

Light bar backlighting and keyboards (levels 1, 2 and 3) ................................................................................. 18

MACHINE ADJUSTMENT (LEVEL 1, 2AND 3) .................................................................................................................. 19

GROUP ADJUSTMENT (LEVEL 1, 2AND 3)...................................................................................................................... 19

Temperature adjustment (level 1, 2 and 3) ...................................................................................................... 20

Dose adjustment (levels 1, 2 and 3).................................................................................................................. 20

Pre-infusion adjustment (levels 1, 2 and 3) ...................................................................................................... 21

Self time adjustment (levels 1, 2 and 3)............................................................................................................ 23

STEAM ADJUSTMENT (LEVEL 1, 2AND 3) ...................................................................................................................... 23

STEAM

AIR

&HOT WATER ADJUSTMENT (LEVELS 1, 2AND 3)......................................................................................... 24

MISCELLANEOUS (LEVELS 1, 2AND 3) .......................................................................................................................... 25

Continuous/stop cycle key ................................................................................................................................ 26

Counter ............................................................................................................................................................. 28