4 Major specifications

2.93ton×1.4m (With outriggers extended fully)

Maximum lift above groud(Hook) Approx 8.8m

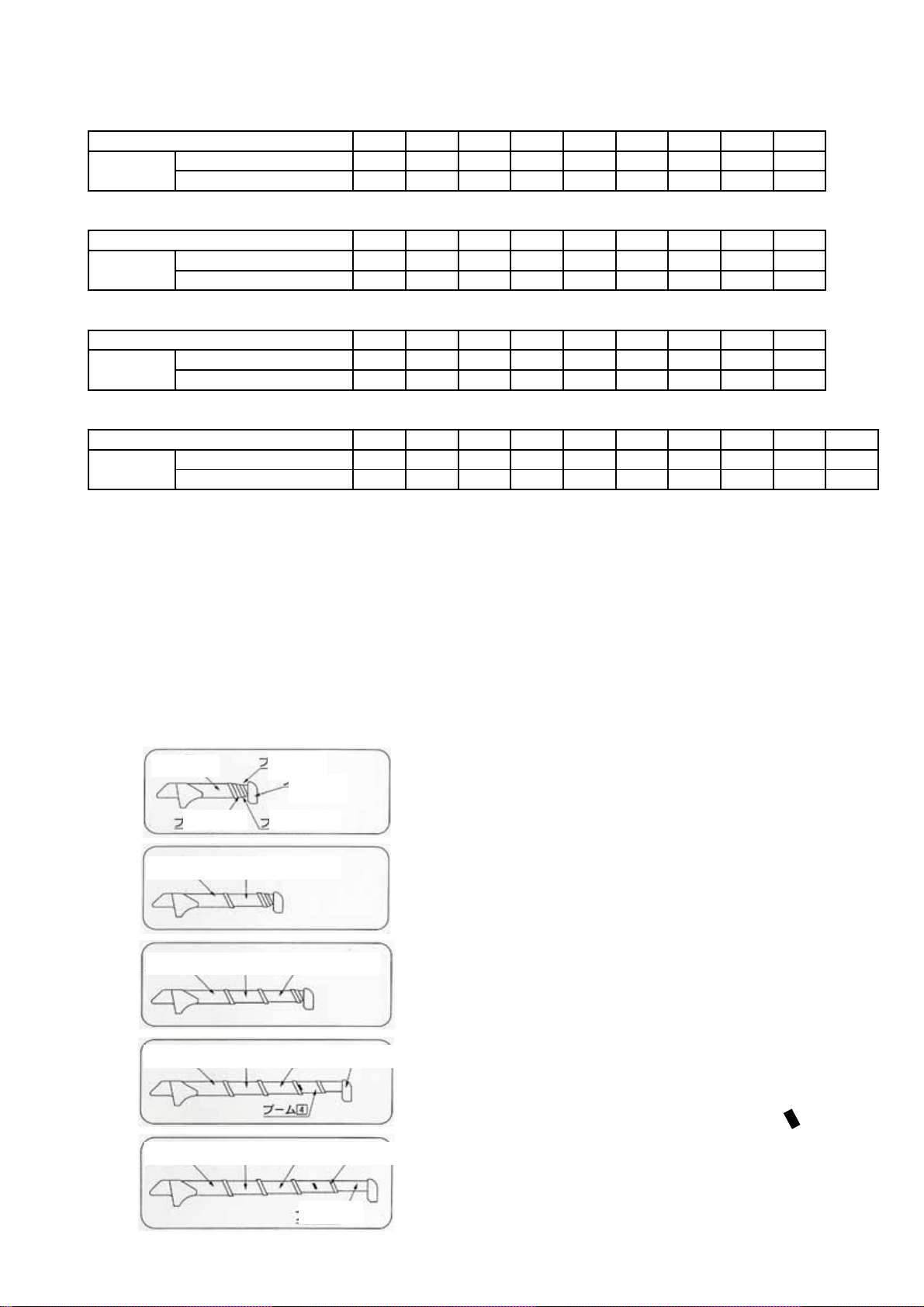

Boom to be extended to: 2.53m~4.075m~5.61m~7.13m~8.65m

Maximum working radius 8.41m

40m/min (At 4th layer on the drum)

Hoisting speed of hook 10m/min (At 4th layer on the drum, with 4-part line hooking)

Extending speed of boom 6.12m/20sec

Raising speed of boom 0°~78℃/11sec

Slewing speed 1.5 rpm

Slewing range 360° (Continuous)

Construction IWRC 6×WS (26) Class B (Breaking load: 43.2kN)

Diameter1×length 8mm×54.0m

Outrigger 2-section for bend and 3-section

Hydraulic Rated pressure Crane:20.6MPa(210kgf/c㎡)、Crawl:21.6MPa(220kgf/c㎡)

pump Rated discharge Approx.38ℓ/min

Rated rotation Approx.2000rpm

Hydraulic oil tank capacity 27ℓ

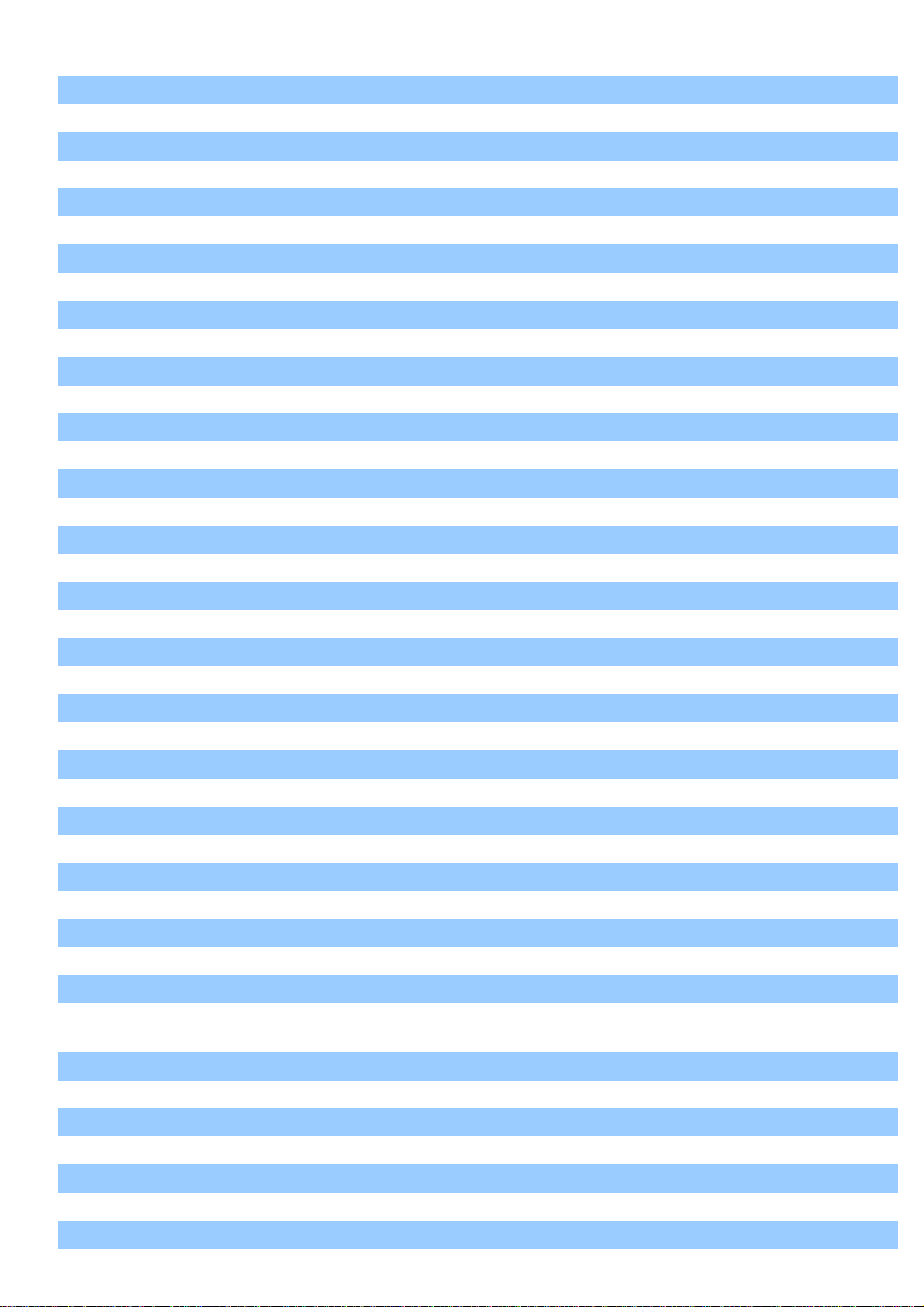

Equipment and construction

Boom telescoping Boom:5-section,Hexagonal box beam

Telescoped by direct pushing of hydraulic cylinder and by wire rope

Boom derricking Direct pushing by hydraulic cylinder(With hydraulic automatic locking device)

Hoisting Hydraulic motor Axial plunger type

Reduction gears Spur-gear reduction

Brake Automatic mechanical brake

Slewing Hydraulic motor Trochoid type(With hydraulic automatic locking device)

Reduction gears Worm-gear+Spur-gear reduction(Supported by ball bearings)

Brake Worm self-lock

Hydraulic pump Variable delivery piston pump

Hooking capacity 2.9t Number of slinging rope:4

Safety device Hydraulic automatic lock

Automatic stop for overwinding/Overwinding alarm/Load indicator

Load indicator(With angle meter)/Level/Alarm buzzer

Hook safety latch

Interlock for crane-crawl lever and outriggers

Weight Approx.1850kg

Crawling device

Crawling Endless rubber crawler

Crawler 180×40×72FR

Length of ground contact 1050mm

Pressure of ground contact 48.0kPa (0.49kgf/c㎡)

Crawling speed Forward/Backward:0~2.3Km/h

Hill-climbing ability 20°

Engine Rated output 9.6kW/2000rpm (13PS/2000rpm)

Crawling Independently driven by hydraulic power

Parking brake Disc brake with hydraulic motor built-in

Starting engine Electric starter

Fuel tank Capacity:7liters

(With hydraulic automatic locking device)(2nd&3rd sections:sequential

actuation,4th&5th sections:simultaneous actuation)

extension.Double acting hydraulic cylinders

with pilot-operated check valves,direct pushing type.

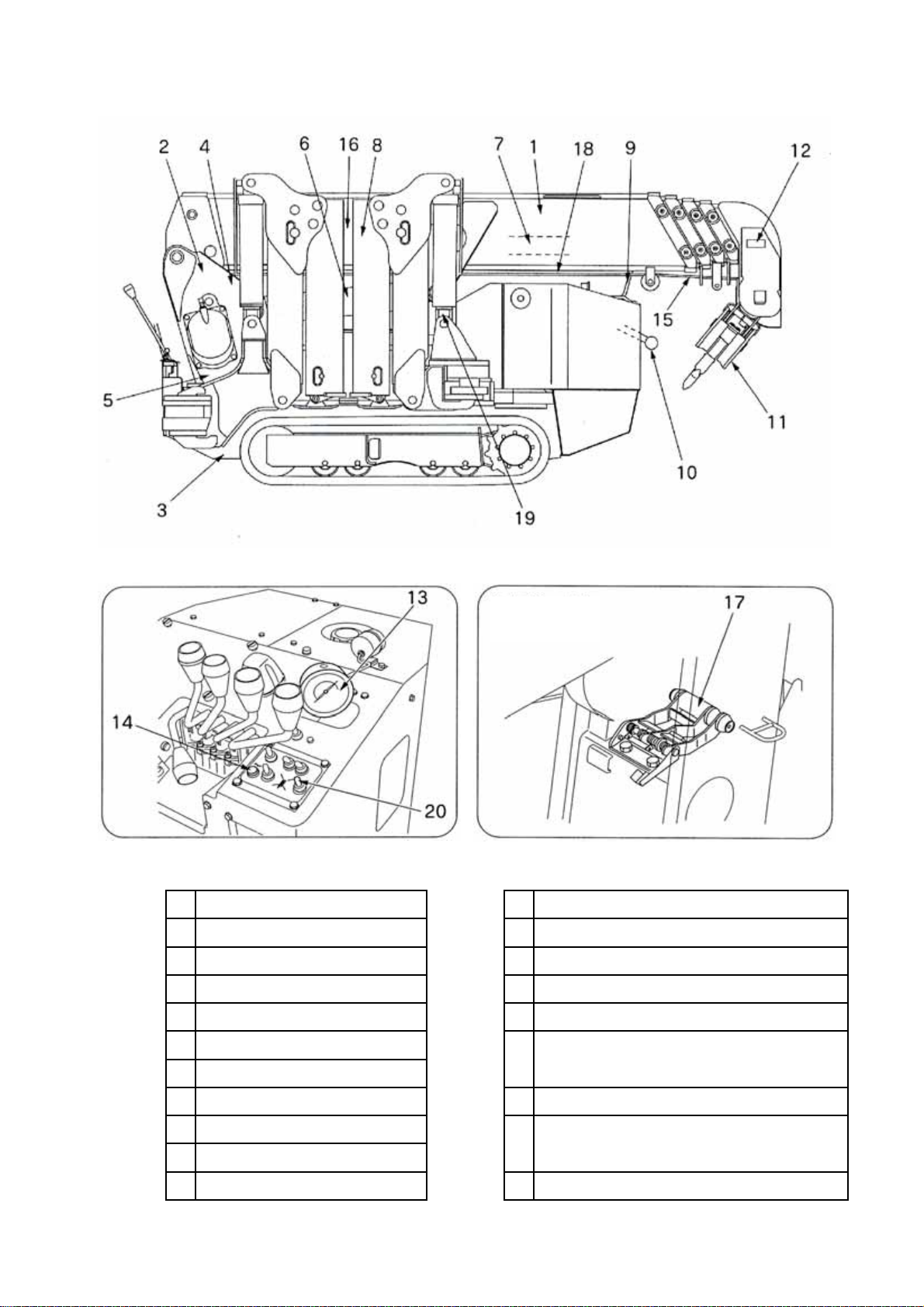

Major specifications (Speed,indicated in the table below is at oil temperature range of 45~

55℃

o

eratin

with noload

and at rated

um

dischar

e.

Crane capacity(maximum lifting load)

Speed of winding-up(Rope speed)

Hoisting

rope

(4-1)