2

General information

TABLE OF CONTENTS

1GENERAL INFORMATION ............................................................................................................................................................................ 4

1.1 Symbols used in the manual ........................................................................................................................................................................ 4

1.2 Appropriate use of appliance ....................................................................................................................................................................... 4

1.3 Water treatment ............................................................................................................................................................................................ 4

1.4 Information for user ...................................................................................................................................................................................... 4

1.5 Safety warnings ............................................................................................................................................................................................ 5

1.6 Technical data plate ...................................................................................................................................................................................... 5

1.7 General warnings ......................................................................................................................................................................................... 6

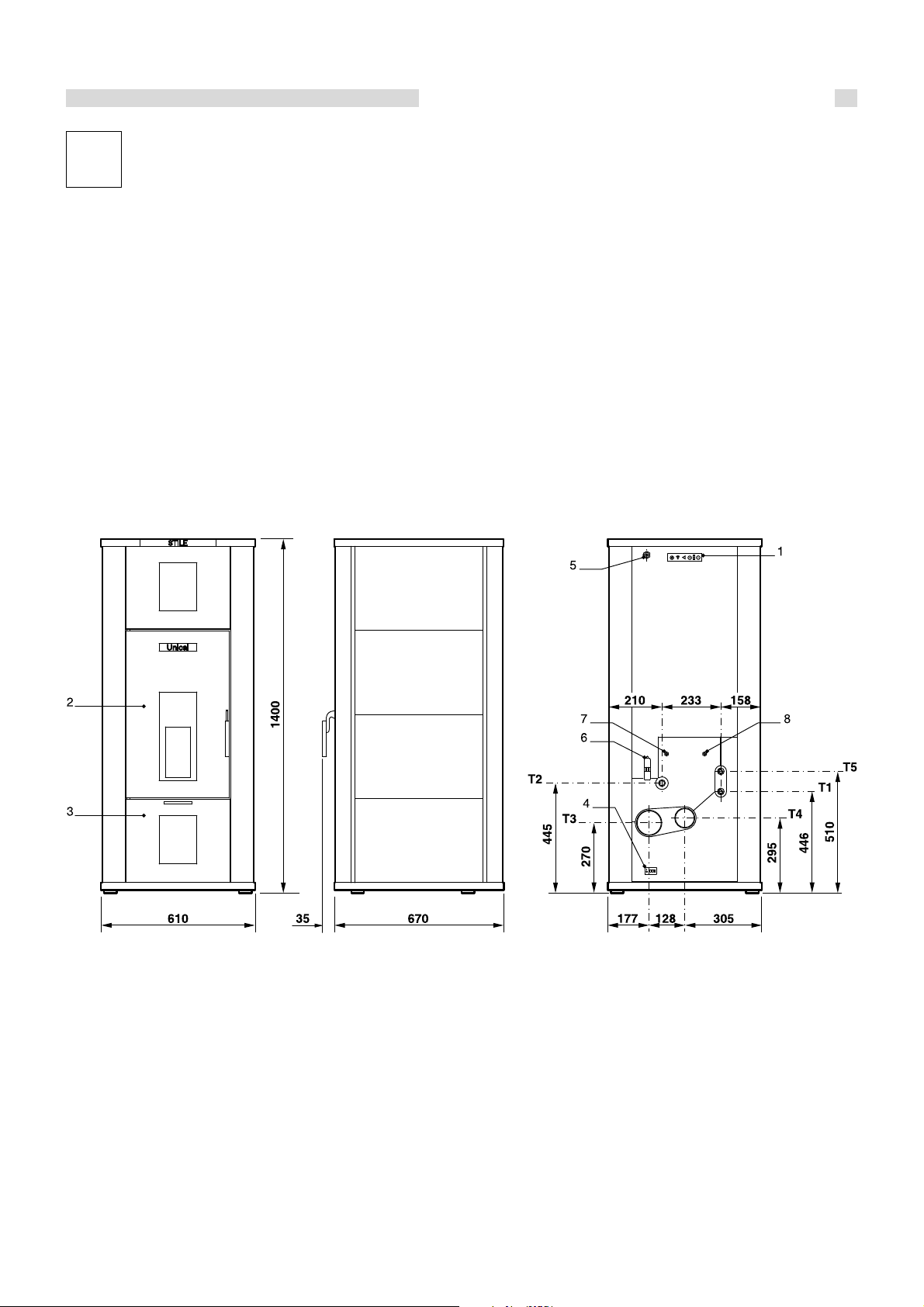

2TECHNICAL FEATURES AND DIMENSIONS ........................................................................................................................................... 7

2.1 Technical features ........................................................................................................................................................................................ 7

2.2 Dimensions and hydraulic connections ...................................................................................................................................................... 7

2.3 Technical data ............................................................................................................................................................................................. 11

2.4 Supply.......................................................................................................................................................................................................... 11

2.5 Main components ....................................................................................................................................................................................... 12

2.6 General Information .................................................................................................................................................................................... 12

3INSTALLATION INSTRUCTIONS ............................................................................................................................................................... 14

3.1 General warnings ...................................................................................................................................................................................... 14

3.2 Installation standards ................................................................................................................................................................................ 15

3.3 Packaging .................................................................................................................................................................................................. 16

3.4 Installation .................................................................................................................................................................................................. 16

3.5 Flue connection ......................................................................................................................................................................................... 17

3.5.1 Exhaust through external wall........................................................................................................................................................ 18

3.5.2 Exhaust through roof by means of traditional flue ........................................................................................................................ 19

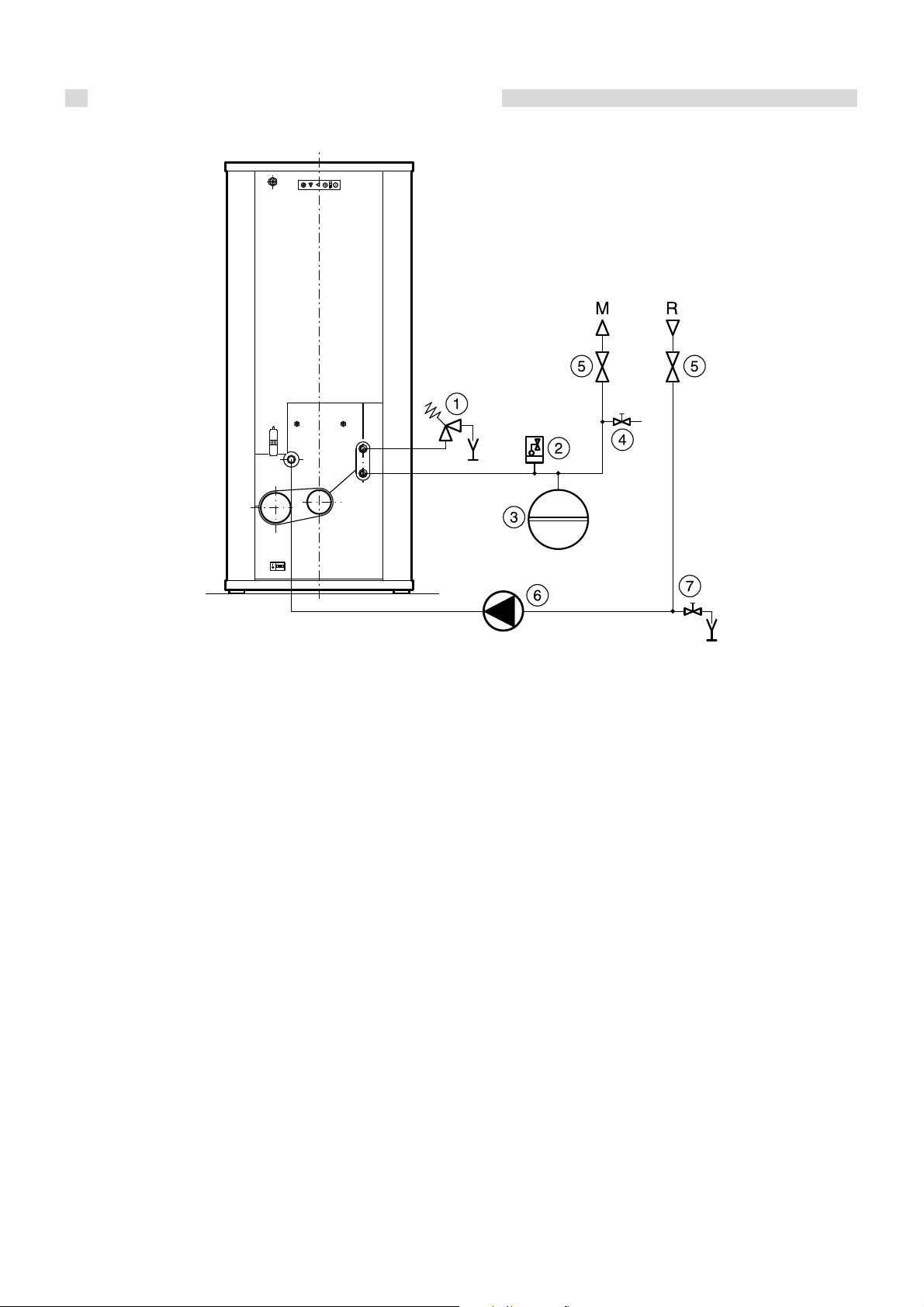

3.6 Connecting heat stove to system ............................................................................................................................................................ 20

3.7 Filling the system....................................................................................................................................................................................... 20

4ELECTRICAL CONNECTIONS .................................................................................................................................................................... 21

5HEAT STOVE START-UP .............................................................................................................................................................................. 24

5.1 Commissioning .......................................................................................................................................................................................... 24

5.2 Initial lighting checks ................................................................................................................................................................................. 24

6INSPECTION AND MAINTENANCE ........................................................................................................................................................... 25

6.1 Troubleshooting ......................................................................................................................................................................................... 28

7PROGRAMMING SETTING ........................................................................................................................................................................... 29

7.1 Using the product ...................................................................................................................................................................................... 29

7.2 Remote control .......................................................................................................................................................................................... 30

7.3 Function of buttons ................................................................................................................................................................................... 32

7.4 Menu ........................................................................................................................................................................................................... 33

7.4.1 User menu ........................................................................................................................................................................................ 33

7.4.2 Menu 01 - set clock ........................................................................................................................................................................ 35

7.4.3 Menu 02 - set chrono ..................................................................................................................................................................... 35

7.4.4 Menu 03 - choose language........................................................................................................................................................... 39

7.4.5 Menu 04 - standby mode ............................................................................................................................................................... 39

7.4.6 Menu 05 - buzzer mode ................................................................................................................................................................. 39

7.4.7 Menu 06 - initial load ....................................................................................................................................................................... 39

7.4.8 Menu 07 - heat stove status .......................................................................................................................................................... 40

7.5 User operating mode ................................................................................................................................................................................ 41

7.5.1 Lighting STILE 27 ............................................................................................................................................................................. 41

7.5.2 Start-up............................................................................................................................................................................................ 41

7.5.3 Failed ignition ................................................................................................................................................................................... 41

7.5.4 Heat stove working......................................................................................................................................................................... 42

7.5.5 Changing room temperature setting .............................................................................................................................................. 42

7.5.6 Using external thermostat / chronothermostat............................................................................................................................. 42

7.5.7 Changing water temperature setting ............................................................................................................................................. 43

7.5.8 The room temperature reaches the set temperature (SET temperature) .................................................................................. 43

7.5.9 The water temperature reaches the set temperature (SET water temperature) ....................................................................... 44

7.5.10 Restarting after extinction having reached set room and/or water temperature ..................................................................... 44

7.5.11 Cleaning the brazier ..................................................................................................................................................................... 45

7.5.12 Heat stove extinction .................................................................................................................................................................... 45

7.5.13 Heat stove off ................................................................................................................................................................................ 46

7.5.14 Heat stove re-ignition ................................................................................................................................................................... 46

7.6 What happens if......................................................................................................................................................................................... 47

7.6.1 The pellet does not light .................................................................................................................................................................. 47

7.6.2 Electric power is missing ................................................................................................................................................................ 47

7.7 Alarms ........................................................................................................................................................................................................ 48

7.7.1 Flue gas temperature probe alarm ................................................................................................................................................ 48

7.7.2 Flue gas overtemperature alarm ................................................................................................................................................... 48