4Unidrive M200 / M201 Quick Start Guide

Issue Number: 1

6 Running the motor

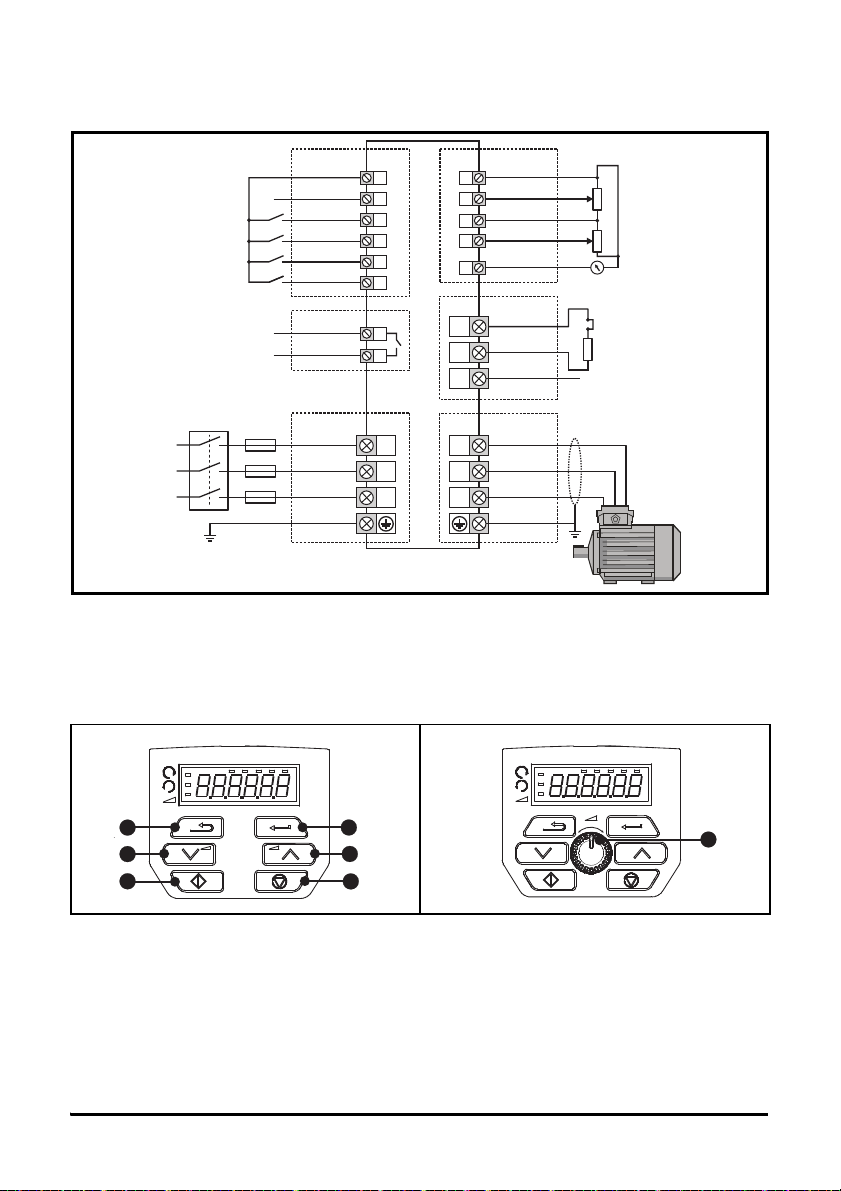

This section takes a new user through all the essential steps to running a motor for the first time. Section 4

provides the minimum connections required to connect and run a motor. The most commonly used

parameters are shown on the terminal cover of the drive.

0478-0038-01

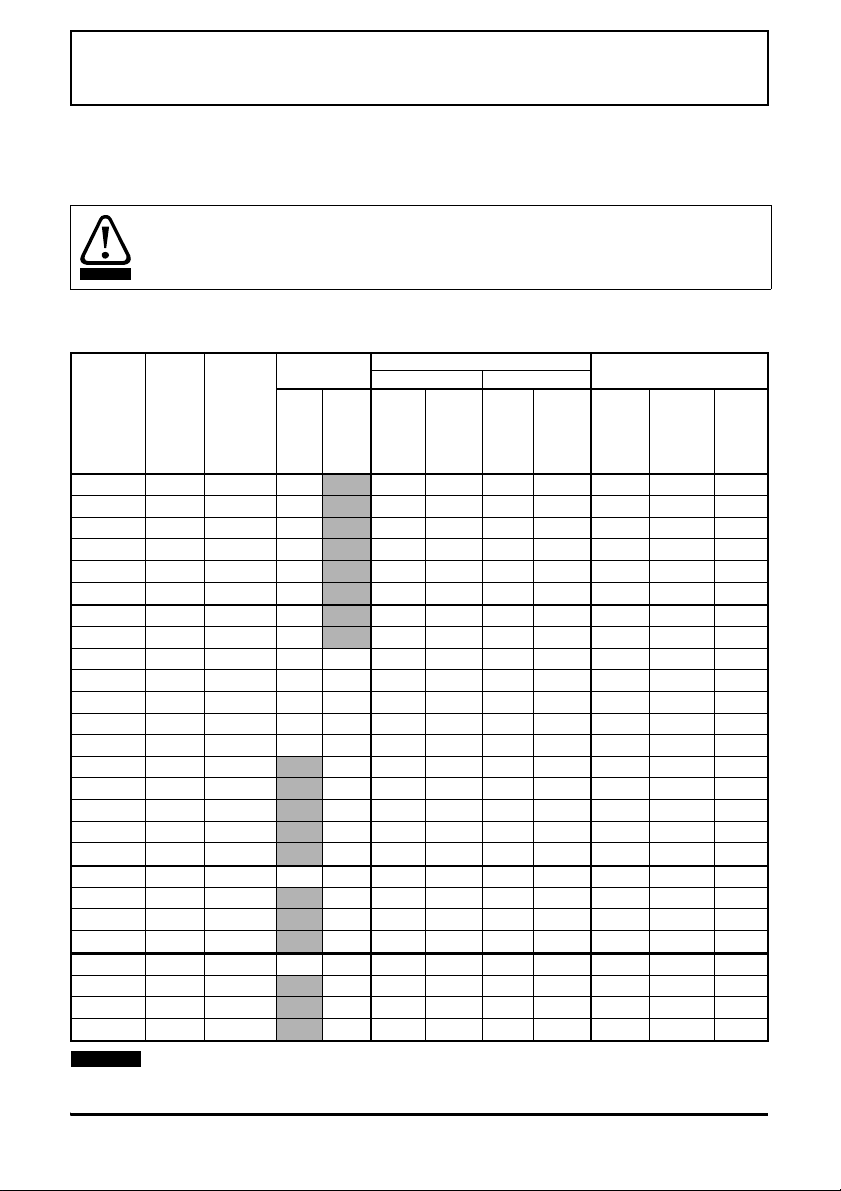

Action Detail

Before power up

Ensure:

• The drive enable signal is not given, terminal 11 is open

• The run signal is not given, terminal 12/13 is open

• The motor is connected to the drive

• The motor connection is correct for the drive Δor Y

• The correct supply voltage is connected to the drive

Power up the drive Ensure:

• The drive displays: Inh

Enter minimum and

maximum speeds

Enter:

• Minimum speed Pr 00.001 (Hz)

• Maximum speed Pr 00.002 (Hz)

Enter accel and

decel rates

Enter:

• Acceleration rate Pr 00.003 (s/100 Hz)

• Deceleration rate Pr 00.004 (s/100 Hz)

Enter motor

nameplate details

Enter:

• Motor rated current in Pr 00.006 (A)

• Motor rated speed in Pr 00.007 (rpm)

• Motor rated voltage in Pr 00.008 (V)

• Motor rated power factor in Pr 00.009

• If the motor is not a standard 50/60 Hz motor, set Pr 00.039

accordingly

Ready to autotune

Autotune

The drive is able to perform either a stationary or a rotating autotune.

The motor must be at a standstill before an autotune is enabled.

To perform an autotune:

•SetPr00.038 = 1 for a stationary autotune or set Pr 00.038 = 2

for a rotating autotune

• Close the drive enable signal (terminal 11). The drive will display

’Rdy’.

• Close the run signal (terminal 12 or 13). The lower display will

flash ’tune’ while the drive is performing the autotune.

• Wait for the drive to display ‘Inh’ and for the motor to come to a

standstill.

• Remove the drive enable and run signal from the drive.

Autotune complete

When the autotune has been completed,

Pr

00.038

will be set to 0

Save parameters

Save parameters

Select ‘SAVE’ in Pr mm.000 (alternatively enter a value of 1000) and

press the Stop / Reset button to save parameters.

Ready to run

Run The drive is now ready to run the motor.

Increasing and

decreasing speed

Turning the speed potentiometer will increase and decrease the

speed of the motor.

Stopping

To stop the motor under ramp control, open either the run forward or

run reverse terminal. If the enable terminal is opened while the motor

is running, the motor will coast to a stop.

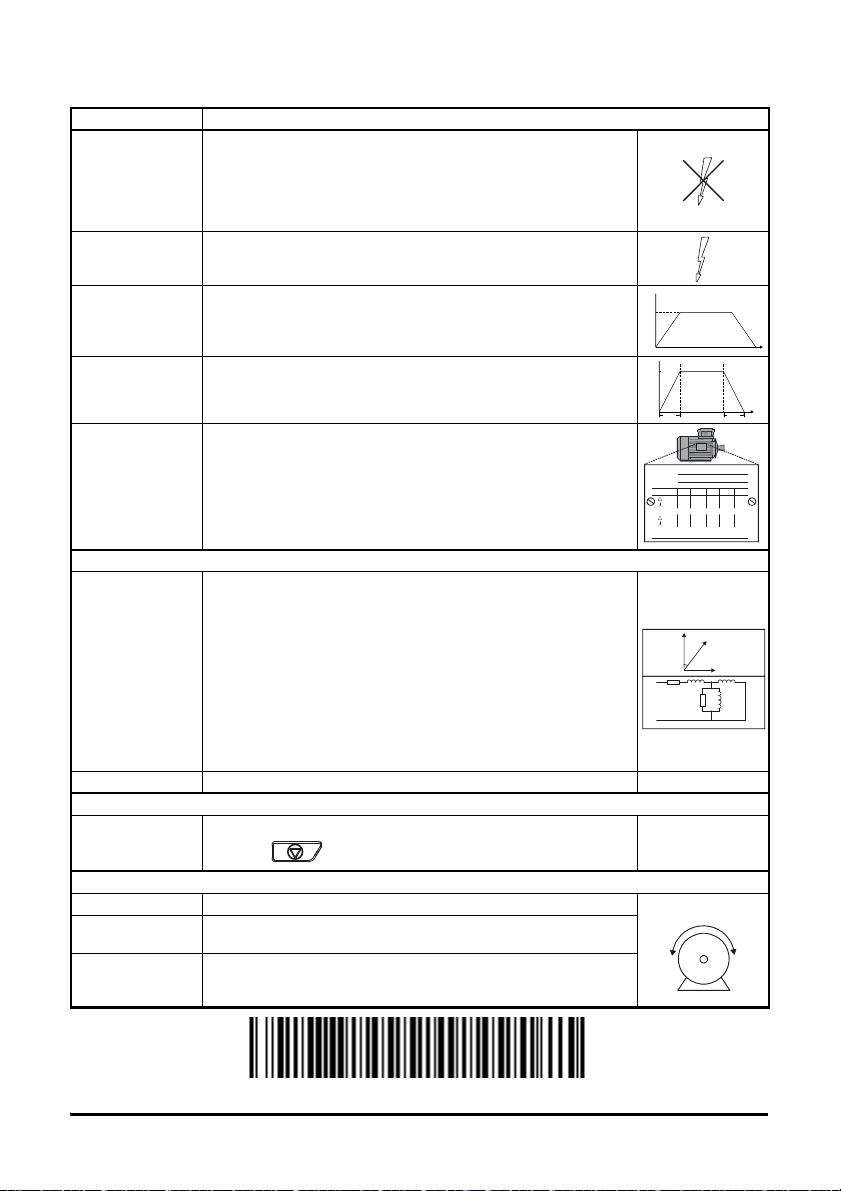

Mot X XXXXXXXXX

No XXXXXXXXXX kg

IP55 I.cl F C 40 s S1

°

VHzmin

-1

kW cos

φ

A

230

400

50 1445 2.20 0.80 8.50

4.90

CN = 14.5Nm

240

415

50 1445 2.20 0.76 8.50

4.90

CN = 14.4Nm

CTP- VEN 1PHASE 1=0,4 6A P=110W R.F 32MN

I.E.C 34 1(87)